How to disassemble perforator interskol p 30 900er

Interskol P-30 / 900ER

Advantages:

price, power. drills faster than anyone else in his hands. straight beast.

Disadvantages:

broke down after 4 years, but it is impossible to replace the cartridge. the bolts are closed with a metal ring.

the suitcase is uncomfortable, small (the wire from the handle of the puncher has to be bent), the handles of the suitcase broke, I had to farm

Comment:

lowered sockets and switches, kneaded concrete, drilled a lot.

enough power to drill holes quickly. warming up? well, yes, but at the same time the work goes faster. if you do housework, then this is one of the best solutions. for 8 hours a day. choose with vertical impact mechanism.

sorry that he died in 4 years

Advantages:

Power

Disadvantages:

Not yet discovered

Comment:

Drilling speed is excellent.

Advantages:

The price, of course, is beyond competition in this segment.

Disadvantages:

The revs are too small (general impression), the steel tape of the front grip attachment quickly breaks down. Tight suitcase.

Comment:

The quality of workmanship has dropped over the past 5 years. The first, after repairs, still threshes, the second (purchased 3 years after the 1st) has been lying for half a year. In the second, the reverse contact plate burned out, but this is a trifle. It does not develop turns from the very beginning (replacement of the trigger did not help). The overall impression of the new rotary hammer is an order of magnitude lower than the old one of the same model. It’s a pity, I counted on the same quality.

Disadvantages:

Not!

Advantages:

comfortable

Disadvantages:

small case, there is nothing additional in the package

Comment:

generally good, it’s a pity the sweets are not included in the kit

Advantages:

excellent apparatus.

Disadvantages:

not

Comment:

not a bad machine.

Advantages:

Powerful, inexpensive, maintainable. Tenacious enough.

Disadvantages:

You can run into a defective copy. A couple of years ago, there were up to half of the marriage. The marriage mainly concerned the cartridge, chisels flew out during swotting.

Comment:

I already have four of these perforators, plus I bought it as a gift to friends. Once I bought it in a hurry and surprisingly liked the puncher. Since then, it has been my main working tool. Its main advantage is that it is universal. Power allows both the mixer to twist and the strobe to do. And relatively compact. True, the case is bad, but I use cases from other punchers of which I had a lot.

This is the perfect hammer drill for your home or garden. If it is not fun to exploit it, then it will last for a long time. It will be enough for him to make a complete renovation in the apartment, with a cable channel and socket boxes. True, for these purposes, it is wiser to take a more powerful puncher, there are a lot of Chinese punches with a force of 4.5-6.0 J, and they are extremely tenacious for the most part.

The problems with this model are most often the following.

1. Marriage. It occurs, and therefore, you need to check immediately upon purchase, so that nothing crunches during operation and generally without alarming sounds.

2. Patron. Boers can fly out when swotting. over, when the model just went on sale, there were no such problems. And a couple of years ago, half of all copies came with defective cartridges. At the same time, good expensive Bosch drills held up much better, but cheap Chinese chisels flew out in a moment. Was treated by replacing the cartridge under warranty or on its own (ball, bracket, spring).

3. There may be problems with the mode switch, it is necessary to periodically clean it (2 minutes of time), as well as with various mechanical components. But this is after quite intensive use, mainly during gating.

There have never been any problems with the electrical part, everything is reliable. Even considering the dust.

If you chase for a long time, then the puncher heats up and you need to give time to cool down.

In general, a solid unit for home and even professional work, if you do not demand from it beyond its capabilities.

I prefer this model mainly because of the versatility that comes with good power and good punching force. As an instrument on duty, it is almost perfect.

Disassembling the stator

To disassemble the stator pos. 74, it is necessary to pull out the protective diaphragm pos. 72 from the housing pos. 77, which covers the stator from the ingress of dirt, dust.

Unscrew the two screws, pos. 73, and pull out the stator, pos. 74. To facilitate the process of pulling out, it is enough to knock on the end of the stator cover with a wooden hammer or block.

Terminal strips, pos. 75, can be removed from the stator. This is done in order to check the quality of the contacts from the stator to the brush holder.

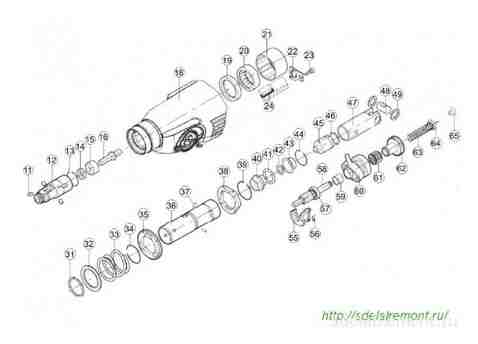

Dismantling catchers, strikers

Dismantling the safety catcher pos. 40 consists in separating from it the shock absorber pos. 41, the striker catcher pos. 42, the safety catcher cover pos. 43 and the retaining ring pos. 44.

In the piston poz.47 inserted striker poz.45, which must be removed.

From the striker poz.45 is removed the o-ring poz.46.

From the ears of the piston, pos. 47, it is necessary to separate the pin, pos. 48, and remove the two rings, pos. 49.

Disassembling the rotor

The rotor is disassembled in the case when it is necessary to replace the collector, bearings, rewind the windings.

It is possible to separate the rotor from the hammer assembly by releasing two screws, pos. 68 and removing the shield, pos. 67.

From the rotor, pos. 69, it is necessary to remove the bearings pos. 66, 70, the damping sleeve pos. 71. Bearings can be easily removed with a puller.

Design features of the keyless chuck type SDS-plus

Let’s start with the differences in the design of the keyless chuck attachment.

The principle of disassembling keyless chucks is almost the same for all rotary hammers.

Interskol rock drills use a keyless chuck type SDS-plus. To work with the Interskol perforator, it is necessary to use a tool with an SDS-plus shank.

Dismantling of the percussion mechanism of the Interskol P710ER perforator

The design of the percussion mechanism and the disassembly procedure for the Interskol 710ER perforator is somewhat different from the perforators of other models.

Major differences in the design of the countershaft, hammer barrel and mode switch.

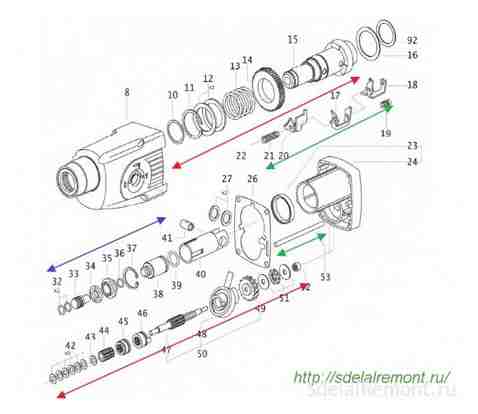

Diagram of the percussion mechanism and the intermediate shaft of the Interskol P710ER perforator

The perforator Interskol 710ER is a rotary-percussion machine. Consists of an electric drive and an actuator. A collector motor is used as an electric drive. The actuator is a combination of a compression-vacuum type percussion mechanism and a rotary mechanism. The reciprocating motion is transmitted by a rolling bearing.

The diagram shows the procedure for disassembling the barrel pos. 15 (indicated by a red arrow), the composition of strikers and strikers (indicated by a blue arrow). The green arrow indicates the details of the mode switch.

The intermediate shaft consists of a shaft pos. 47 and parts mounted on it. Easily disassembled, according to the attached diagram, does not require special knowledge.

Disassembling the stator

To disassemble the stator pos. 74, it is necessary to pull out the protective diaphragm pos. 72 from the housing pos. 77, which covers the stator from dirt, dust.

Unscrew the two screws, pos. 73, and pull out the stator, pos. 74. To facilitate the process of pulling out, it is enough to knock on the end of the stator cover with a wooden hammer or block.

Terminal strips, pos. 75, can be removed from the stator. This is done in order to check the quality of the contacts from the stator to the brush holder.

Disassembly of control circuits and dismantling of carbon brushes

The basis for controlling the Interskol perforator is a switch pos.87 and a reverse lock pos.90. Using the combined button, the perforator can be set to the speed of the electric motor.

To get the brushes pos. 83, it is necessary to remove the brush holder pos. 81. It can be removed by turning it counterclockwise by 90º. Having released the brush holder, it is easy to get the carbon brushes.

The scheme of Interskol P710ER and P600ER perforators has its own characteristics:

- there is no combined brush holder;

- different type of switch used.

All! Perforator Interskol disassembled. Read the repair instructions and how to assemble and lubricate the hammer drill.

Dismantling perforators Interskol models P18, P22, P26, P28, P30, P600, P710

The principle of operation is the same for all rotary hammers.

The rotational moment from the rotor is transmitted to the barrel shaft and the working tool attached to it. At the same time, with the help of an oscillating bearing, popularly called “drunk bearing”, the torque is converted into a reciprocating motion, which transmits a shock impulse to the working tool.

All Interskol perforators are assembled according to one general scheme and consist of the same blocks.

Conventionally, Interskol perforators consist of three blocks:

- Impact unit reducer block.

- Stator block.

- Power supply and control unit.

Repair of Interskol perforators should begin with a study of the tool diagram, preparation of tools and a workplace.

The indicated blocks of the listed models have their own design features.

For ease of consideration, we will divide the presented perforators into groups.

- In the first group we will include perforators Interskol P-18, P-22, P-24, P-26, P-30.

- In the second group, we will consider the disassembly of Interskol P-600 and P710 perforators.

Dismantling catchers, strikers

Dismantling the safety catcher pos. 40 consists in separating the shock absorber pos. 41, the striker catcher pos. 42, the safety catcher cover pos. 43 and the retaining ring pos. 44.

In the piston poz.47 inserted striker poz.45, which must be removed.

From the striker, pos. 45, the O-ring, pos. 46, is removed.

Перфоратор Интерскол П-30-900 эр. Нет удара. Диагностика

From the ears of the piston, pos. 47, it is necessary to separate the pin, pos. 48, and remove the two rings, pos. 49.

Dismantling the block of the percussion mechanism of the perforator Interskol P26 / 800ER

Most of the differences are in the design of the striking mechanism.

The striking mechanism consists of several units:

- percussion barrel;

- intermediate shaft;

- strikers and drummers;

- a piston sleeve;

- friction bearing.

The percussion mechanism in Interskol perforators works on the same principle. Differences in design features.

Dismantling of the percussion mechanism of the Interskol P710ER perforator

The design of the percussion mechanism and the disassembly procedure for the Interskol 710ER perforator is somewhat different from the perforators of other models.

Major differences in the design of the countershaft, hammer barrel and mode switch.

Diagram of the percussion mechanism and the intermediate shaft of the Interskol P710ER perforator

Perforator Interskol 710ER is a rotary percussion machine. Consists of an electric drive and an actuator. A collector motor is used as an electric drive. The actuator is a combination of a compression-vacuum type percussion mechanism and a rotary mechanism. The reciprocating motion is transmitted by a rolling bearing.

The diagram shows the procedure for disassembling the barrel pos. 15 (indicated by a red arrow), the composition of strikers and strikers (indicated by a blue arrow). The green arrow indicates the details of the mode switch.

The intermediate shaft consists of a shaft pos. 47 and parts mounted on it. Easily disassembled, according to the attached diagram, does not require special knowledge.

Disassembling the instrument receiver

The tool receiver, pos. 12, is disassembled after removing the keyless chuck parts from it.

At the first stage, four rollers, pos. 11, are carefully removed. Further, the receiver is removed from the body, pos. 18, in which the needle bearing, pos. 20, is inserted.

The needle bearing is attached to the barrel poz. 36.

Remove the tool receiver from the barrel.

From the tool receiver it is necessary to remove the industrial mass pos. 16, the bushing pos. 15, the collar pos. 14 and the rubber O-ring pos. 13.

Disassembly procedure for Interskol perforators

Recently, Interskol perforators have been especially popular. They are reliable and easy to repair. They are easy to get spare parts on.

Interskol perforators have a wide range of models. The tools are conventionally divided into two segments: rotary hammers equipped with an SDS-plus chuck, and rotary hammers with an SDS-max chuck.

Repair of the Interskol perforator can be carried out both in service centers and independently. To repair Interskol perforators with your own hands, you need to have the skills of a locksmith and knowledge in electrical engineering in the volume of secondary school.

And always remember to comply with safety rules.

Each tool has a corresponding identification plate. For example: puncher Interskol P-18 / 450Er. It stands for:

- the letter P indicates that the tool belongs to the family of punchers;

- the number 18 indicates that a drill up to 18 mm in diameter can be used with this rock drill;

- the number 450 indicates the power of the hammer drill in watts.

The line of Interskol perforators with SDS-plus cartridges is represented by 13 models: P-18 / 450ER, P-20 / 550ER, P-22 / 620ER, P-24 / 700ER, P-24 / 700ER-2, P-26 / 750EV, P-26 / 800ER, P-26 / 800ER-2, P-28 / 800EV, P-30 / 900ER, P-30 / 900ER-2, P32 / 1000E, P-32 / 1000EV-2.

Interskol perforators with SDS-max cartridges are represented by the following models: Interskol P-35 / 1100E, P-35 / 1100EV-2, P-40 / 110EV-2, P-45 / 1100E, P-50 / 1200E.

There are other models of Interskol perforators on the market: Interskol P-600 ER and Interskol P-710 ER. These models were produced at the beginning of the development of Interskol production.

Among domestic users, the most common models are Interskol P26 / 800ER, P30 / 900ER, P710 / ER perforators.

Disassembling the stator

To disassemble the stator pos. 74, it is necessary to pull out the protective diaphragm pos. 72 from the housing pos. 77, which covers the stator from the ingress of dirt, dust.

Unscrew the two screws, pos. 73, and pull out the stator, pos. 74. To facilitate the process of pulling out, it is enough to knock on the end of the stator cover with a wooden hammer or block.

Terminal strips, pos. 75, can be removed from the stator. This is done in order to check the quality of the contacts from the stator to the brush holder.