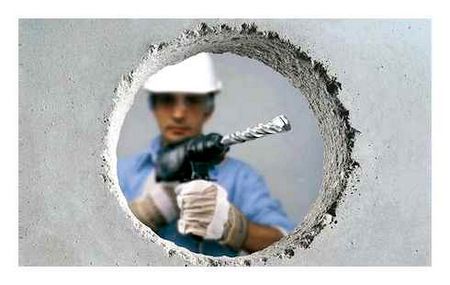

How to drill a hole in concrete without a hammer

How to drill a concrete wall with an ordinary drill

For drilling concrete designed perorator, but in its absence in many cases with the work will cope with a hand-held electric drill. Achieve success is possible if you choose the right drill bit or drill bit. To understand how to drill a concrete wall with an ordinary drill, it is necessary to know a clear algorithm of action, take into account a number of important nuances of drilling.

Additional tools for drilling in concrete

Start drilling concrete is reasonable if the electric drill is equipped with a hammer function. Using a drill with a hammerless tool makes no sense. The drill will simply overheat, which will end with the motor burning out. A non percussion tool can be used to drill a large hole with a diamond drill bit if the motor’s power allows.

For simple percussion drilling of small holes, an additional tool will be needed:

- Concrete drill set with different diameters. They can be distinguished by special hard-alloy tips. The item is a small plate with the edges sharpened at an angle of 60 o. The helical part and the cylindrical shank are made of normal tool steel.

- Drill bit. The drill bit is shaped like a rod with a sharpened tip. The piercer helps break up the concrete by hitting it with a hammer.

Concrete drills have one weakness. It breaks out when it makes contact with the reinforcing bar. If the drill bit has stopped sinking into the concrete, and a characteristic whistle appears, the hole is pounded with the punch. In the presence of reinforcements, the drilling point is moved to the side.

When you need to cut a large hole for a socket with a drill, use a core bit instead of a drill. When selecting the nozzle, look at the shank. Its shape must be suitable for clamping in the chuck. The drill can be fitted with a hexagonal or SDS bit shank.

Drilling in concrete is carried out by three types of bits:

- Bits made of tungsten carbide materials have a serrated cutting edge. Bits can only be used for percussive drilling. If the drill has no hammer function, the tips overheat and fall off the cup. Fear of contact between the core bit and the rebar. To save the cutters, try drilling into the wall with a drill bit before drilling. Additional action will help find out if there is any rebar in the area.

- Drilling a concrete wall with a hammerless drill is done with a diamond drill bit. Nozzles are not afraid of contact with reinforcement. Air-cooled drill bits are available for residential use. They can be identified by the presence of holes in the cutting edge. Do not use wet-cutting bits with a drill. Diamond coating comes in hard, soft or medium hardness, as indicated by the marking of the nozzle with the letters “T”, “M”, “C”. With a drill, “CS: GO” drill bits are usually used. The design of the bit includes slots for air cooling. The dusting of the cutting edge is made of diamond chips of medium hardness.

For a drill bit sold in carbide materials, where instead of tips there is a sputtering of carbide-tungsten crumbs. The bit can be used to accurately drill through a tiled wall. It is reasonable to use the crowns if the power of the drill exceeds 1 kW.

Drilling the wall with a drill

The impact drilling process requires great effort. Takes more time than with the torch because of the lower power of the tool. The drill must occasionally be given time to rest. The entire procedure of making a hole with an impact drill consists of the following steps:

- On the wall, the place of the future hole is marked. The punch is placed on the mark and the hammer is struck sharply 2-3 times.

- After impact, a small crater is formed in the concrete. Insert the drill bit with a solder inside the cavity, switch on the hammer mode on the drill, start drilling. When the hand feels the motor overheat, the tool is given time to rest.

- The drill can stop penetrating for two reasons: hard fractions of concrete or reinforcement. Stop drilling. A drill bit is inserted inside the funnel and a hammer is used to hit it sharply. When the hard fractions collapse, continue drilling. When hitting the rebar, it is better to displace the hole to the side. If this option is not suitable, the bars are dealt with a diamond drill bit or metal drill bit.

The action continues until the desired depth of the hole.

The nuances of correct concrete drilling

To drill the concrete successfully, take into account a number of important nuances:

- Drilling a hole with a diameter of more than 12 mm and a depth of 100 mm is better to perform a hybrid electric tool drill-power tool.

- For plastic dowels, the depth of the hole is 7 mm longer than the length of the fastener. The stock will be clogged with concrete dust when inserting the dowel.

- Start work at medium drill speed without impact mode. Increase speed when drill gets to 4mm deep. Simultaneously activate the hammer function. Such a measure is necessary to prevent the drill from shifting on the wall due to strong vibrations.

- Drilling is accompanied by a lot of dust. If you use a vacuum cleaner, flying particles of concrete are immediately sucked up and do not clog the room.

- While clamping the drill bit into the chuck, check that the drill shank is fully inserted.

- Run low-powered drill for 15 minutes at most. A rest time of 10 minutes is sufficient. Dip the drill in water before starting work. A little trick helps to reduce wear on the cutting tips.

- When making a through hole at high RPM, a piece of concrete can break off from the back side of the wall. Reducing the rotational speed helps to avoid damage.

If the drill bit is stuck in the concrete, do not try to extract it by hammering, loosening with pliers. The shank from such actions will break off, and the screw part will remain inside the wall. It will only be possible to remove the stuck element if you drill holes around it with a drill bit of small diameter.

Drilling in concrete can be considered successful if the end goal is reached and the tool is not broken.

- Even with a concrete wall, many home masters wonder how to hang a picture without drilling. There are several ways of doing this. If the partition has a finish in the form of wallpaper, you can stick a sewing needle there, on which the picture is hinged.

- To make it easy to work and to avoid putting too much strain on the hand, the operator should practice holding the drill. The tool is taken in one hand on the principle of gripping a gun. The second hand rests on the handle, if there is one. Fingers should be placed near the chuck.

Attention! Quite often, when making holes in the concrete drill is chosen, but it is important to remember that this tool is not intended for such work. This is because the bearings, gearbox and motor are highly stressed. Therefore, use the equipment with care so that it does not break down under high loads.

Safety precautions

Drilling in concrete is dusty, difficult and extremely demanding work. Above all there is a risk of injury. Drilling into walls can also damage their strength and integrity, and when drilling, you can bump into lines of communication and damage them or even receive an electric shock.

Personal protective equipment must be worn during work: respirator, goggles, ear mitts, canvas gloves and special clothing. Works at height over 1,5 m from ground level are works at height, so it is necessary to provide the worker with safe support in the form of scaffolding. It is strictly forbidden to drill into walls from a ladder or step-ladder.

Peorator must be in good condition. The insulation of the power cable must not be damaged. During drilling, the cable must be positioned so that it cannot be damaged in any way. Concealed wiring and junction boxes embedded in walls are also a great danger. Before you start drilling, therefore, you should carefully check the surface for live conductors with an electromagnetic radiation detector.

A little bit about the construction of the drill and the installation of the drill

Scheme of drilling a concrete wall. The classic drill consists of power cable, push button, capacitor wire, reverse, brushes and springs, armature, stator, gearbox and chuck, bearings, wrench and fixing screws. A correctly inserted drill bit increases the drilling quality and can make it safer.

The first thing to check when starting work with the drill is whether there is any contamination on the drill itself. A rag is a great helper for cleaning the drill bits. If the drill bit is loose, there is a risk that it will fly out and injure the craftsman. Accordingly, it is necessary to plunge the drill bit into the chuck as much as possible (up to the stop)!).

Under no circumstances try to “lengthen” the drill bit by not fully dipping it into the chuck!

It is important to make sure that the drill bit in the tool is fixed strictly along its axis. If this rule is not observed, the drilling in the concrete will be performed poorly, the shape of the hole may be unpredictable, and the cause of all these misunderstandings will be the elementary effect of drill bit run-out.

How to make a hole in concrete

Concrete is characterized by high strength properties, which causes difficulties in the process of making holes in the base. It is therefore necessary to choose the right tool and auxiliary equipment. Then you can avoid a lot of dust, destruction of walls, and the work takes less time and effort.

It is impossible to knock out a hole in a solid base without destroying the entire wall. The only correct approach is to drill concrete. For this purpose, manufacturers make several variants of removable tooling. The choice is determined according to the parameters of the necessary hole and the power of the used power tool.

Drill bit or drill bit

Such a tackle is presented in the form of a rod. There is a shank on one side. This is the part that is installed in the socket of the power tool. The main part has a spiral-shaped notch and a groove for dust extraction. T-shaped working tip. this is a cutting plate made of hard alloys. Its characteristics determine the durability of the tool and the quality of its work.

To understand which drill to drill concrete or drill, you need to understand the difference between the gear. It consists in the following:

- The shank may be executed as a hexagonal cylinder or with longitudinal grooves. Drills are suitable for the drill chuck, and drills (second) under the peorator and marked as SDS.

- The durability of the tool material. The drilling movement is reciprocating, which means that the concrete is subjected to an impact force. Therefore, the drill has a higher hardness and wear resistance index than the drill.

- The drill bit has a special groove in the main part of the rod to divert mineral chips from the hole.

To drill a hole in concrete, manufacturers supply three types of tools to marketplaces. They can be designed for rotary, reciprocating, or combined. Accordingly the safety margin of the latter parts will be higher than that of the former.

The tungsten carbide in the drill bit tip can be pobedite (tungsten-cobalt alloy) or diamond.

In a drill only the first option is possible, because diamond is a brittle material. Depending on the parameters of the desired opening, one of three nozzles is used:

Drills are selected according to the type of shank and diameter. The size should be slightly smaller than that of the given hole, so during the formation of the hole the walls of the hole are slightly destroyed as the nozzle moves deeper into the wall.

It is also important to understand that you can drill a hole in the concrete with a drill only of small parameters. This is explained by the fact that the mechanism of the power tool is designed only for rotary motion. Peorator additionally performs the function of a baffle, so choose a drill for it.

The peculiarity of concrete walls is the presence of iron reinforcement. If it is hit by a diamond or carbide tipped bit, the bit will fail quickly. Therefore, in this case, it is necessary to change the drill bit to one that is designed to work with metal.

bit

Under the sockets with switches, laying ventilation with the pipes need holes of larger diameter than under the fixing elements. To do this, they use nozzles, which are called drill bits. tool also has a drill bit, but there is additionally a hollow cylinder with diameter from 30 mm between the shank and the tip. Its outer edge is the cutting element of the tool.

Face of the bit for concrete is equipped with special hard teeth. Their performance depends on the quality of work, the speed of forming the hole and the durability of the nozzle. Based on this, there are three types of tools:

- Pobeditovye use for percussive drilling holes with a diameter of 20 to 100 mm. Material fails when exposed to temperature fluctuations, so it is allowed to work only in dry conditions. in case of contact with reinforcement, chipping of tooth is possible.

- Tungsten carbide has a reinforced coating. This bit is designed to make a hole in a concrete wall without a torch. It handles brick and tile neatly, so it is used for work on tiled substrates. often such bits are sold in sets with interchangeable bowls of different diameters. There is only one disadvantage. the metal causes the tool to break down.

- Diamond tip is used for work with a hammerless or percussion drill. The dry drilling method and the periodic wetting method are acceptable. The end of the cup is divided into segments with slots in the longitudinal direction that have diamond dust or chips on them. It is not afraid of metal, practically does not form chips and has a high working life. The latter is relevant for the formation of multiple holes.

Use of the teeth

Often you need to get a hole in the wall of a large diameter for the socket. How to drill a load-bearing wall in this case? Then the teeth are used, which have metal tips on the circumference. Crowns can be found in a variety of sizes, but the most in demand remain 68-centimeter, which are designed just for sockets. Working with these parts, it is necessary to turn off the impact mode.

Holder for Drill with My Hands

Circular saw from a drill The entire machine (without the electric drill) consists of a base, on the worktable, four racks they do not have two holders: the drive (electric drill) not the free end of the shaft of the saw blade. For the base we used a furniture (veneered) particle board with dimensions of 300×250 mm not thick. For the table (worktop) selected a rigid duralumin plate with a thickness of 4 mm not []

Diamond drilling

This is another easy way to drill a concrete wall. However, it is used only by professionals with special equipment (high-powered electric motor and the like).

How to drill a frame wall? That’s no problem, because diamond drilling makes it possible to drill holes of large diameters and depths, and without irritating dust. In parallel, water is applied directly to the drill bit, so that it cools. As a result, the resulting holes have a neat appearance, and the appearance of cracks is completely excluded.

How to drill a tile so as not to crack? See here. What is a drill rig for drilling holes? Read about in this article.

Drilling concrete walls with this method is usually performed by professionals of specialized firms. In the vast majority of cases of installation of hidden electrical wiring can not do without such a dirty and noisy procedure as piercing. So it makes no sense to stock up on a diamond drill rig for do-it-yourself work.

Screwdriver

The screwdriver is one of the most popular tools in repair and construction work. With its help, you can screw and unscrew screws, drill wood, metal, chipboard, plywood, plywood, plywood, lightweight concrete.

Yes, making a hole in the wall is quite realistic using other tools, but there are a number of factors that contribute to this.

One of the main considerations is the material of the wall. The worst thing is if it is made of a solid material. brick, concrete or stone. Although in the first case, you can still try to do something, but in the last two cases, you can hardly do without a torch, drill or electric screwdriver.

How to drill a concrete wall with an ordinary drill or a torch: tips

How to drill a concrete wall with an ordinary drill?. This is the question many craftsmen have asked when they have had to hang shelves, cornices, etc.

Cordless Drill Bit. No Hammer Action!

Concrete is a tough material and therefore amenable to drilling extremely poorly. Even how to drill a wall in a panel house, the task can seem unsolvable.

Although, if you know certain secrets, this process can be greatly simplified.

Choosing the tool

So, the first question a home handyman should ask himself is not how to drill a concrete wall with rebar, but with what. The main helper in this case will be a peorator, because it is designed for stone and concrete. At the same time, even a powerful drill can not cope with a wall width of more than 12 cm. Although when it comes to foam concrete, the drill is preferable, because the tool will simply break it.

On the quality of the drill also depends on whether you can drill a hole in a concrete wall.

One of the best options is to use drills that are specifically designed for an impact drill. Their working part is a plate made of hard metal. With the help of these drills, the question of how to drill a thin concrete wall can be considered solved.

There are also ring drills, which have a diamond coating. They are very strong, involving them in special drilling machines, so they cost quite a lot. Therefore, to solve the problem of how to drill a hole in a concrete wall at home, it is impractical at least.

Using core bits

It is often necessary to get a large-diameter hole in the wall for the socket. How to drill a load-bearing wall in this case? Then use the drill bits, which have metal tips on the circumference. Crowns can be found in a variety of sizes, but the most popular remain 68-centimeters, which are designed just for sockets. Working with these parts, it is necessary to turn off the impact mode.

Such bits are also available for drills. But they have a different kind of spraying. from cathode-tungsten alloy. They are easy to use, because to drill a hole in the wall with a drill made of concrete and simultaneously make a hole in the tile is quite possible. Only suitable for such bits with a powerful drill.

Drills are another tool to drill through a concrete wall. Their diameters are varied. Experienced craftsmen advise to make a selection based on the diameter of dowels.

Drilling Concrete with a Peorator

So, how to drill a hole in a concrete slab using a peorator? The procedure is not complicated:

- The drill is switched to percussion mode, after which drilling begins; the tool must be held strictly at a right angle;

- after some time the drill bit is wet with water, this will help avoid overheating;

- After you have succeeded in drilling a reinforced concrete wall, the drill, without turning off the machine itself, must be taken out;

- To free the dust from the hole, the drill bit is inserted several times.

It is not possible to drill through the wall? The drill bit hits something hard? So you have to try to make the hole somewhere else.

We do it with a drill

How to drill a concrete wall without a perforator? The question of using an ordinary drill when working with concrete remains unsolved. So whether or not you can drill through a concrete wall, everyone decides for himself. The tool can break, after all. And the procedure will take longer.

Drill a hole in the concrete with a drill, you can use a special tool. a puncher. Operating with it is simple: put the sharp end to the place where the hole will be located, hit it several times with a hammer, and then you can start drilling.

It’s important not to overheat the tools.

As soon as the drill comes across an insurmountable obstacle, you need to activate the drill again until the desired goal is reached. This is how to drill through a concrete wall correctly with a drill. Although it takes more time and a lot of force, in the absence of a drill, it can also be used.

Diamond drilling

This is another easy way to drill through a concrete wall. However, it is only used by professionals with special equipment (high-powered electric motor and the like).

How to drill a stud wall? This is not a problem, because diamond drilling allows you to get a hole of large diameter and depth, and without irritating eye dust. In parallel, water is fed directly to the drill bit, so it cools. As a result, the resulting holes have a neat appearance, and the appearance of cracks is completely excluded.

How to drill a tile so that it does not crack? Look here. What is a drilling guide? Read in this article.

Drilling concrete walls with this method is made, as a rule, professionals of specialized firms. So it does not make sense to stock up on a diamond drilling unit for independent work.

Read also:. for installation of locks in metal doors. Oven repair at home. Repair of interior doors. Repair of plastic windows with their own hands. Shower cabin with their own hands from tiles in the photo and tips on making. Repair of locks on doors: how to do it yourself?

How to save money on a peorator and drill a concrete wall with an ordinary drill?

Many people live in houses with concrete walls, and as they need to make a hole there, they meet with brutal difficulties.

READ How to Make a Polishing Machine with Your Own Hands

Do not despair and get upset if you can not hang a shelf, lighting or cabinets, read our tips everything will work out.

There are a few options, by which it is natural without the help of others to drill a concrete wall.

In his time performing the designated works, it is necessary to adhere to the developed technologies and safety rules, then you can easily not only make a hole without the help of others without attracting expensive experts, but avoid injury.