How to drill a wall without a punch

Diamond drilling

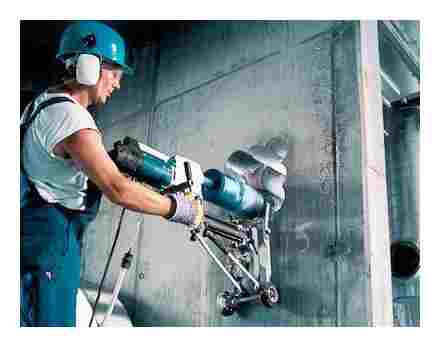

This is the most effective way by which you can easily and quickly make a hole of the required diameter in a concrete wall.

To perform these works, you will need special equipment, consisting of the following elements:

- electric motor;

- a stand that is securely fixed to the base;

- drill bit.

It is not necessary to cool the drill during operation, as water is supplied to it, which not only cools the tool, but also prevents the formation of dust.

If specialists work, then together with the specified equipment they use a vacuum cleaner with which they remove dust and water.

Features of the

Concrete structures are highly durable, so it is quite difficult to drill them yourself.

This is due to the fact that crushed stone is used to create concrete products and when you get on it while drilling, the process becomes very difficult.

The need to drill a concrete wall occurs quite often, it is necessary for the installation of shelves, cabinets, an air conditioner, gluing wallpaper, fixing a lamp, when attaching insulation or during plastering walls for attaching beacons.

There are several ways to solve this problem:

- using a hammer drill or a powerful impact drill;

- an ordinary electric drill or screwdriver;

- diamond drilling.

It should be remembered that for walls made of relatively soft materials, it is impossible to use victory drills, since the holes will turn out to be uneven, and the wall will collapse. It is also impossible to work with metal with such a tool.

To create large-diameter holes or cut a doorway, diamond-coated core drills are used. To use such a tool, it is necessary to use special installations, they allow you to make holes with a diameter of up to 250 mm.

Since the cost of such equipment is high, it is easier to hire specialists or you can rent it.

During the performance of these works, it is necessary to adhere to the developed technologies and safety rules, then you can not only make a hole yourself without the involvement of expensive specialists, but also avoid injuries.

A little about the device of the drill and the installation of the drill

A classic drill consists of a power cable, a button, a capacitor wire, a reverse, brushes and springs, an armature, a stator, a gearbox and a chuck, bearings, a key and fastening screws. Correctly inserted drill improves the quality of drilling, and is able to secure it.

The first thing to check when starting to work with the drill is whether there is any dirt on the drill itself. When cleaning drills, a rag will be an excellent assistant. If the drill is loose, there is a risk that it will fly out and injure the master. Accordingly, it is necessary to immerse the drill as much as possible into the chuck (all the way!).

Do not under any circumstances try to “lengthen” the drill by incomplete immersion in the chuck.!

It is important to ensure that the drill in the tool is fixed strictly along the axis. If this rule is not followed, drilling in concrete will be of poor quality, the shape of the hole may be unpredictable, and the cause of all these misunderstandings will be the elementary beating effect of the drill.

Power selection for drills

The optimal power for working on concrete, in order to drill a hole, is considered to be a power of at least 600 W and 2500 rpm, but this figure must be adjusted depending on the manufacturer’s recommendations so as not to spoil the drill. As already mentioned, concrete “crumbles” when we drill, and this does not require too much speed.

With an ordinary drill or screwdriver

If you do not have the tools described above, then this work can be done using a conventional electric drill or a powerful screwdriver.

To complete drilling, you will need more time than using a hammer drill, but you can do everything yourself.

In this case, in addition to the drill and drill, you will also need a punch. First, a small indentation is made in the place of drilling using a punch and a hammer.

After that, a working tool is inserted into it and begins to drill. If the drill stops, break hard areas again with a punch and continue working.

Step-by-step instruction

How to make a hole in a concrete wall or slab on the ceiling without a punch or other similar tools?

First you need to prepare everything.

Despite the presence of a special drill, work on a concrete wall is carried out taking into account the recommendations of specialists.

The wrong approach can lead to tool breakage and partial destruction of the wall. Before starting work, prepare the following set of tools and materials:

- drill of sufficient power;

- drill with victorious (carbide) surfacing;

- punch. a metal pin of the required diameter;

- hammer or sledgehammer;

- a vacuum cleaner.

The process of drilling concrete with a conventional drill is not fast, so the DIYer should be patient. Concrete dust eats into the flooring, and it is recommended to cover the surface with newspapers to maintain cleanliness. Collect spilled particles from time to time with a vacuum cleaner. The sequence of work is as follows:

- An appropriate drill is installed on the tool. A drilling point is marked on the wall.

- Mark the drilling point by operating at minimum speed with light pressure. A small hole is made in the surface so that the drill does not slip with increased action.

- They go deeper into the wall by 8-10 mm. Hold the tool at a right angle during drilling. If tilted, there is a risk of damage to the surface, handpiece or hands.

- Take out the drill and punch through the concrete with a steel bar.

- They go deeper into the wall by another 10-15 mm and again finish off the concrete with a punch. After each stage of work, the drill is cleaned of concrete particles.

IMPORTANT. Each drilling step should last no more than 30 seconds. The total duration of continuous drilling with a low-power tool is no more than 10-12 minutes. The instrument motor must be cooled after each session, otherwise it will overheat and fail.

Drilling concrete with a diamond core bit can be viewed at

In the video, the author tells how to drill concrete without hitting:

What Lubricant For Rotary Hammer

Rotary hammer lubricant: which one to use A professional home craftsman should take care of the tools that he uses in the activities of his company. For this reason, the duration of the equipment operation directly depends. The power tool needs good quality lubrication. This will protect the nodes not mechanisms from wear. Work here will be much more effective. Therefore, the lubrication of the rotary hammer is extremely important. It must be selected [.]

How to drill a load-bearing wall in a panel house with a perforator

In most panel houses, the walls are made of concrete, to make a hole with a hammer drill, you need to use a drill bit.

In addition to them, you can use special crowns. They have soldering around the circumference. When using them, you need to turn off the percussion function of the punch.

Experts use diamond drilling, this requires powerful equipment and skills.

How To Punch Harder Using a Wall

Expert advice: how to drill a concrete wall with a conventional drill

Almost every home craftsman can face the problem of how to drill a wall of concrete with an ordinary drill. The lack of the necessary tools to do this work and the lack of experience often lead to disastrous results: the drill breaks, and the hole in the wall does not work. To easily cope with the task at hand, the home craftsman should use the recommendations of the specialists presented in the article.

Is it possible to do without a drill and punch

Make a hole without a drill and hammer drill, but not in a concrete wall. This will require a bolt or punch.

Hang Pictures On Old Walls Without A Drill!

The working end of the tool is applied to the place where the hole will be. On the opposite side of it, you need to hit hard, rotating the tool after each turn.

Useful video

How to drill a concrete wall without a hammer drill

How to drill a concrete wall with a conventional drill and hammer drill?

How to drill a concrete wall with an ordinary drill? such a question was asked by some masters when it was necessary to hang shelves, cornices, nothing else.

Concrete is a tough material, so it is very difficult to drill. Even how to drill a wall in a panel house, the task seems insoluble.

Although, if you know certain secrets, this common hearing process will greatly simplify for you.

Dismantling the Bosch Rotary Hammer With Removing the Switch

Instructions for disassembling the Bosch rotary hammer The principle of the Bosch 2-26 rotary hammer does not differ from the recognizable brands of rotary hammers. The rotating rotor transmits the torque to the intermediate shaft of the mechanical unit of the rock drill, immediately transferring the translational motion through the rolling bearing to the hammer mechanism of the rock drill, not an impact impulse. A rotational moment with a translational shock impulse is transmitted to the working tool. […]

Safety precautions for making holes in concrete

The structural frame of a building made of reinforced concrete is a durable non-uniform material. Inside it is metal reinforcement, gravel or crushed stone of various fractions. Therefore, drilling a hole without observing safety standards means exposing yourself and those around you to the risk of injury. Experts recommend compliance with the following requirements when drilling / drilling reinforced concrete structures:

- use of protective equipment. workwear in combination with goggles / mask, petal respirator, helmet;

- installation of fences: during through drilling, when the worker does not see the opposite side of the wall, there is a risk of pieces collapsing on passers-by or his colleagues;

- the use of reliable scaffolds: without them, work at a height of more than one and a half meters is prohibited, since the stability of the operator is not ensured, when using ladders, it is necessary to strengthen them with stops.

To drill a hole in concrete, it is necessary to change the speed of the drill, hammer drill, special diamond machine smoothly, use only a two-handed tool. The presence of plaster dramatically increases the risk of destruction of internal communications. Therefore, before you drill a hole in the supporting structure of the building, you must make sure that they are absent.

Drilling with a hammer drill in percussion mode is allowed only when a drill or drill is used as a working body. If a crown is immersed in the concrete, a non-impact rotation is applied. The tool is able to drill a hole, cut high-quality internal reinforcement, stones.

Unlike a conventional drill, which destroys crushed stone inclusions by impact, it is not able to drill through the reinforcement. To drill a solid wall, you need to study the location of the seams. It is in them that the internal wiring of the power cable, gas, sewer pipes is often hidden.

Power tool selection

To create small-diameter holes in small quantities, an impact drill, a perforator with a power of 350 watts is enough. Professionals engaged in the distribution of communications in panel houses, brick cottages on a concrete foundation, use professional punchers or diamond machines.

Large diameter hole cannot be obtained using a standard three-jaw chuck with a key, collet chuck.

Making a 1/2″ hole in wall without a drill

When passing through reinforcement, granite crushed stone, the clamping force will not be enough, the tool is guaranteed to start scrolling in the chuck, wearing out the shank, cams.

Therefore, for large holes, an SDS chuck with a diameter of 10-18 mm is required. Slotting when creating holes with a crown is completely excluded, the perforator must have this function.

HOW TO DRILL A HOLE IN CONCRETE?

Holes in concrete are necessary for conducting, installing communications. The works are distinguished by an abundance of dust, noise, high labor costs, and require high-quality power tools. To drill a hole in this material, it should be borne in mind that each hole in the structural frame of the building reduces its strength, is fraught with damage to the engineering systems located inside (mainly electrical wiring, ventilation ducts), and is traumatic.

Concrete wall drilling pattern.

Through holes with poor tool quality cause shedding of adjacent wall sections at the exit of the drill / bit from their back side. Additional finishing is required, the terms of work are increasing.

DIY technology for making holes in concrete

In the process of construction, finishing of buildings, there is a need to manufacture blind or through holes of different diameters. Blind holes are created for fasteners, their diameter is limited to 2-16 mm. In this case, compliance with the declared diameter is an important factor. Otherwise, plastic dowels for self-tapping screws and nails in the broken holes will loosen over time, reducing the fixing strength of wall cabinets, curtains, pipelines, decorative elements.

For drilling blind holes of large diameter or through penetration of reinforced concrete walls, crowns are used to enter communications. They represent a cylinder, one side of which is attached with a shank to the chuck of a drill, perforator, the second has pobeditovy or diamond crowns welded to it. A victory drill is installed in the middle of the structure to give direction.

Drilling with a drill or drill leads to the destruction of the entire volume of concrete at the point of contact of the tool with the structural material. If there is reinforcement inside the reinforced concrete structure, it is impossible to pass it with a drill, the hole is moved to the side.

Drilling holes in concrete with a crown differs from the previous method:

- concrete collapses only along the perimeter of the hole;

- a concrete cylinder remains inside the crown.

Therefore, after reaching the required depth of the blind hole, the inner concrete cylinder remains connected to the wall by the rear end. To remove it from the hole, destructive methods are used: a chisel with a hammer or a perforator. During through drilling, concrete cylinders are removed from the tool by light blows of a mallet on the body

Drilling holes in concrete is done with the following tools:

- spiral impact drill. more often used for blind holes, the diameter of the carbide tip inserts is always larger than the spiral body of the tool, the shank is round, not intended for working in concrete with a perforator with SDS chucks;

- spiral drill. instead of a pobedit, a zirconium or tungsten tip is used (spraying), a shank with grooves is suitable only for SDS cartridges (Max, modifications), dust-free, low-noise drilling is ensured;

- diamond core bit. a large diameter tool exclusively for high speed rotary drilling.

In the marking of the impact drill, the caliber is indicated, not the diameter. This is the distance between the protruding edges of the solder / insert. Holes are drilled with this tool in the following modes:

- 800-1200 turns for diameters within 4 mm;

- 300-500 turns for diameters 5-13 mm.

Even the presence of a red marking on the tip of this instrument does not guarantee that the tip material will match the metal declared by the manufacturer. Cheap substandard at the first use folds into an incomprehensible configuration, becomes unsuitable for work.

Zirconium, tungsten burs are suitable for the following operating modes:

- 60-100 revolutions with a diameter of 42-76 mm;

- 150-400 turns for diameters 4-60 mm.

The length of the drill can reach 1 m, a small amount of dust when working with this tool allows you not to take furniture out of the room. The concrete to be destroyed “flows” from the hole in a trickle along spiral channels, is collected on a lined film, paper.

Professionals make blind holes for large-diameter socket boxes in a few seconds. A home craftsman who does not have regular practice of working with such a tool most often runs the risk of damaging the crown at the slightest distortion. Working modes when using crowns are 2,000-3,000 revolutions for any diameter. The advantage of the crown is the high-quality cutting of reinforcement of any diameter, granite, basalt crushed stone inside the concrete at high cutting speeds.

The following modifications belong to the category of a professional, highly specialized tool:

- segmented tubular drill. it is difficult to work, it is used by specialists in areas with a high probability of the presence of thick reinforcement;

- a crown drill with a centralizer. a carbide modification, inside which a drill is located in the center, which facilitates the setting of the direction, reduces the sensitivity to pressure, distortions of the working body; these options are not suitable for cutting reinforcement.

The latest modifications of the crowns are operated at 600-1200 revolutions, when in contact with the reinforcement, the teeth crumble instantly. Therefore, before drilling, the walls are carefully examined with a special tool for the presence of an armored belt.

Features of drilling concrete structures

When using a conventional crown, water is fed into the hole, which reduces the temperature of the working body. Some companies produce professional dry drilling bits. The hole is obtained with the correct geometry, there is no tearing out of pieces of the wall from the back side. An example is Maxima crowns Ø3.2-20.2 cm, 15-25 cm long, with and without perforation.

When drilling holes of large diameter (0.5-1.5 m), diamond machines and installations are used. The hole is created by plunge sawing with a core tool. The frame is fixed on a horizontal, vertical, inclined surface, the package includes a compressor for supplying coolant.

A smooth hole is obtained by moving the working body with the top drive along the guides (analogue of a manual tile cutter). The quality of the holes is higher than with manual drilling. The drill is not used in this professional equipment, even as a guide body.