How to find out the chain pitch on a chainsaw

Interchangeability of domestic and foreign motorcycle chains

Owners of such motorcycles as “Jupiter” and “Voskhod”, who live in “civilization”, on the contrary, sometimes do not find the necessary motorcycle chain, for this very reason they sometimes put themselves a DID chain on their domestic “steel horses”.

As all motorcyclists are well aware, when marking motorcycle chains, manufacturers follow certain established rules, which makes it possible to select the correct chain when replacing an old one, depending on parameters such as chain pitch and roller width. Take the 525th chain, for example. Here 5xx is the chain pitch and x25 is the roller width. Of course, the Russian Federation has its own standards. Naturally, the dimensions of the chains are the same, however, their marking was carried out in accordance not with international rules (520, 525, 530, etc.), but according to the TU 3-1060-78 standard and some other standards. there are a large number of them. It is for this reason that sometimes difficulties arise, which chain is used where.

In reality, everything is very simple to understand. Here are the dimensions of several chains that are usually used in motorcycle equipment that plow the vastness of our country, which may have been released several decades ago:

- mopeds such as “Karpaty”, “Verkhovyna” and “Delta” use a chain PR 12.7. 18.2 / 1, which has 112 links (including the key);

- motorcycles “Voskhod”, “Minsk” use the chain PR 12.7. 18.2 with 112 links (including the key);

- motorcycle ZID “Sova-175” uses PR 12.7. 18.2 with 122 links (including key);

- the motor scooter “Ant”, as well as the old “Java” and “Cheseta” use PR 12.7. 18.2 with 128 links;

- motorcycles IZH (“Jupiter”, “Planet”) use a more serious chain PR 15.875. 23/1 with 104 links.

Now let’s take a look at each circuit separately:

- PR 12.7. 18.2: chain pitch. 12.7 millimeters (analogue. 428th chain);

- PR 15.875. 23/1: chain pitch. 15.875 millimeters (analogue. 520th chain);

- PR 12.7. 18.2 / 1: chain pitch. 12.7 millimeters (due to the fact that it has a too narrow roller width, it has no foreign analogue).

That’s all! I hope the information described in this article will help motorcyclists.

How to measure and choose the step, size, chain length for a chainsaw, what exactly you need to know about them?

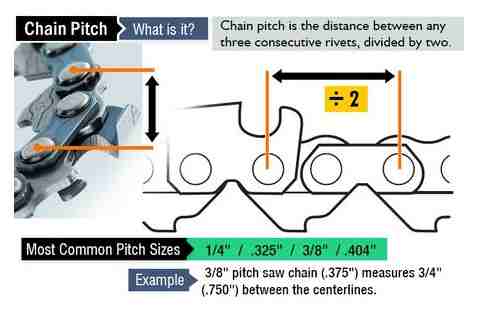

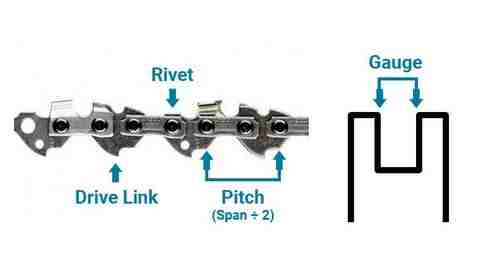

The step in the chainsaw chain is the distance between the 3rd rivets located nearby (this is the distance between the 2 cutting teeth), measured in the center between the rivet axes, the step affects the quality of the cut.

Here is a schematic image, we find the center of the rivets and, for example, measure the distance between them with a ruler, although this is all superfluous, chainsaw chains are marked and there is this information (step) measured in inches.

For chainsaws with a capacity of up to three horsepower (2500 W), it is better to take chains with a pitch of 0.325 inches (it is also the most common for a non-professional tool).

The power of the chainsaw is indicated in the product passport.

There is a pattern, the more the power of the chainsaw, the higher the step, and of course it is necessary to take into account (when choosing) what exactly we are sawing (branches, twigs, thick logs, etc.).

As for the length of the chain, it all depends on the parameters of the saw itself, the size of the stars, the power of the chainsaw, etc.

The manufacturer in the instruction manual indicates which chain length is preferred for a particular model.

When choosing a chain, you must take into account the type of links, they are different.

How to know the pitch of a motorcycle chain

The drive chain in any motor vehicle is a very important element and the further operation of your vehicle will depend on what condition it is in.

Chain 0.375 or 3/8.

Why did we write two numbers? It’s simple, if 3 divided by 8 we get 0.375. And the parameter in the form of a fraction 3/8 is very often used for marking. The reason is ordinary, so as not to confuse the numbers 0.325 and 0.375, so we are not surprised if the chain at 0.375 is difficult to find, it is better to look for the 3/8 marker right away. The chain marked 0.375 is less popular with the 0.325 brand and is used on 4 hp chainsaws. from. Such a chain is used already on felling relatively thin trees and for cutting wood of medium thickness. For its group of non-professional and professional types of saws, this is the most optimal size.

SashaMoto.ru

Reviews of moto and bicycle equipment, useful articles about repair and operation

© 2018 The rights to materials belong to their legal owners.

Choice by depth of cut

Owners of professional chainsaws should also pay attention to the plunge depth when choosing chains. As a rule, the sharpening of the cutting edge in this case is carried out in a domestic environment using special devices. The features of this parameter are the following:

- The depth of cut can be adjusted by shifting the stop position of each link.

- The chain parameter can vary from 0.025 to 0.03 inches.

Only if you know the type of profile, you can correctly select the height of the limiter. The considered parameter is taken into account in most cases by professionals who can themselves change their parameters.

How to Know What Chain Pitch on a Chainsaw

Chain marking for chainsaws

In some situations, the owners of chainsaws may experience some confusion in their awareness of all the chain markings for these tools. This will ultimately lead to bad purchases. The choice of chainsaws is often determined by only a few basic aspects, one of which is the chain pitch. This indicator helps to highlight the future capabilities of the tool, including its cutting speed, and according to the norms, it should correspond to the level of motor power. How are chains marked? Let’s try to figure it out!

How to find out the chain pitch on a chainsaw

Choice by type of sawing

The chainsaw can be used for several types of work. The classical classification is as follows:

- Rip sawing is a job that involves removing material along the grain of a tree. In this case, the cutting angle is maintained in the range from 5 to 15 °.

- Cross cut. the chain in this case moves across the grain. To ensure the required cutting efficiency, the sharpening angle is maintained in the range from 25 to 35 °.

The selection criterion under consideration can be called the main one, since it is not recommended to use a crosscut saw chain for longitudinal sawing: an incorrect sharpening angle can cause increased wear.

Accounting for the material from which the teeth are made

In the manufacture of a tooth, a wide variety of materials can be used, which must be taken into account. In most cases, high quality chrome plated steel is used. It has the following properties:

- Fairly high hardness.

- Corrosion protection.

- High machinability when sharpening.

Work can also be carried out with high density wood, as well as frozen material. For such cases, a carbide chain is highly suitable and can withstand significant impact. The disadvantage of such a proposal is the rather high cost, as well as the need for a special tool for sharpening.

features of choice by chain pitch, type of links

Even with careful operation of the chainsaw, from time to time you have to face the need to replace the chain. On sale there is just a huge number of options for the execution of such a product, the operating period and the main properties of the chainsaw at the time of operation depend on the correct choice. Experts point out that it is best to install the chain, which is recommended by the manufacturer of the chainsaw. Let’s consider all the features of the choice in more detail.

Tensioning the chain

You can put a chain on a chainsaw in two ways: fast and frontal. For the first method, it is necessary to loosen the wing nut, then tighten the tensioning screw in a clockwise direction. Then you need to fix the wing nut again.

For front tensioning, unscrew the nuts and lift the tire. Tighten the chain with the special bolt on the right, then lift the bar again and clamp.

Choosing the right chain for your chainsaw guarantees a long operation of the whole mechanism. To do this, it is also necessary to regularly lubricate its links and carefully replace the element.

When a chain replacement is needed?

Like any other product, the chain must be replaced with a new one as it wears out. In order to delay the wear of the chain, we recommend regularly changing the chains in operation: first use one, the next time. the second.

Thus, you postpone the wear time of one material and change both the tire and the sprocket at the same time. This principle will help you maximize the life of the saw elements.

We have listed the main parameters by which the circuits differ from each other. For a more detailed study of the elements of chains with a photo of chains for chainsaws on the Internet.

Chain marking for chainsaws

In some situations, owners of chainsaws may have some confusion in understanding all the chain markings for these tools. As a result, this leads to unsuccessful purchases. The choice of chainsaws is often determined by just a few basic criteria, one of which is the chain pitch. This indicator helps to highlight the future capabilities of the tool, including its cutting speed, and also, according to the norms, should correspond to the level of engine power. How are chains marked? Let’s figure it out!

Chainsaw chain pitch. Table

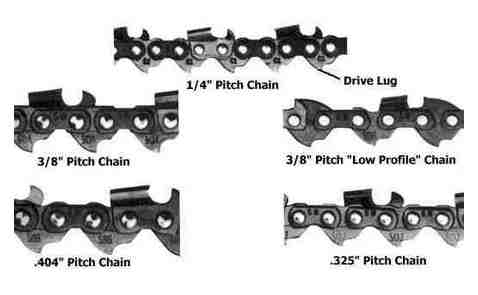

Taking into account the step size, at the moment the chains are divided into several subtypes:

| No. | Distance between rivets | Chain pitch (width in inches) |

| one | 6.35mm | 1/4 |

| 2 | 8.25mm | 0.325 |

| 3 | 9.3mm | 3/8 (0.375) |

| four | 10.26mm | 0.404 |

| five | 19.05mm | 3/4 |

As you can see from the table, the chain pitch is designated as an ordinary number (3/4) and decimal. “0.375”. This division is due to the similarity of the decimal values - “0.325” and “0.375”, since the difference of one digit created confusion when choosing a saw. Therefore, at one time it was decided to establish two different designations: decimal and ordinary fractions.

The pitch is stamped in the area of the special cut depth stop on each tooth.

The pluses of chains with a large pitch include:

- high level of productivity due to wide cut;

- the ability to perform complex work (felling large trees).

But it should be borne in mind that a wide cut requires the use of a more powerful engine, which in turn significantly increases resistance.

The advantages of small pitch chains are:

- low vibration;

- smooth movements when cutting;

- cleanliness of cut.

Benefits are achieved due to the large number of teeth and the small distance between them.

All known classification of circuits is based on the features of their marking, depending on the step, which is designed for specific needs and is produced for a specific power of electrical equipment. For a better understanding of each type of step, they should be considered separately.

Step and its dimensions

A step is an intermediate distance between three rivets, which are located side by side. To correctly calculate the chain pitch, measure the distance between the axes of three rivets placed close to each other. In the form of a formula, it looks like this:

Best file size to use for sharpening 3/8 pitch chain

L = S / 2

Where, L is the step length, which in chainsaws characterizes the degree of distance between two teeth in relation to each other;

S. the value of the gap between the two extreme rivets of three.

The step size can also be equal to the length of the distance between two adjacent shanks.

Regularity: the greater the distance between the cutting teeth, the deeper they will enter the material being cut

By increasing the chain pitch, it becomes possible to increase the performance of the chainsaw. However, in such a case, the amount of force applied to rotate the drive sprocket changes. And the higher the chain pitch, the greater the power of the motors should be and the more physical forces are expended to pull it when cutting materials.

Main parameters of chains

Applying the marking of the chain assumes the presence of the following parameters:

- Step:

- “0.325” is the most common and minimum step size that is used in semi-professional and household chainsaws with low powers. The standard value of power for such a step ranges from “0.325” to “3hp”, but not higher than “3.5hp”. When working with this type of chain, the sawing is smoother, more comfortable, without “gusts” of the processed products.

- “0.375” (“3/8”). applied to chainsaws with a capacity of “4hp”. This chain is used when sawing wood of medium and small thickness.

The accuracy and quality of the created cut depends on the value of the step. In cases where it is not important to achieve high quality when working with a chainsaw, the accuracy of the cut is sometimes of particular importance. To do this, it is imperative to take into account the dependence of the step for the release of wood according to pre-applied markings.

- The thickness of the leading links (tails). When the chainsaw is working, its chain accounts for most of all the loads. Considering this, another main characteristic of the saw is the thickness of the link elements, which enters the grooves of the bar. This parameter also determines the overall thickness of the fastening links, which is measured with a standard caliper. Standard thicknesses include:

- “1.1 mm” (“0.043”) and “1.3 mm” (“0.05”) are used in the production of entry-level chains, which are designed to carry out small amounts of work. Often, with such values of the link thickness, the chain pitch length can be “0.325”, which implies the presence of low loads and a gentle mode of operation. Therefore, they are used in household and semi-professional devices;

- “1.5 mm” (“0.058”) is the most common thickness on the market for chainsaws and accessories. This value is able to ensure safe operation with a step size of “3/8”. The 1.5mm chain is not suitable for professional cutting;

- “1.6 mm” (0.063) and “2.0 mm” (0.08). designed for the most difficult work. The metal in the manufacture of such chains is steel of special grades, and the characteristics of increased strength are laid in the design.

The greater the thickness of the link and the wider the groove of the tire, the higher quality the chainsaw is considered, since it is able to withstand heavy loads.

What size chain does my chainsaw take?

- Depth of cut is a distinctive feature of the produced chains and is characterized by the height of the profile of the cutting teeth. It is measured by the gap between the stops and the cutting top edge. Both high-profile (0.762 mm) and low-profile (0.635 mm) types of chain products can be presented on the market.

The higher the profile height, the higher the entry into the material (depth) and the cutting speed

High-profile chains are installed on chainsaws with increased engine power. Information about the height of the profile, as a rule, is written in the characteristic for the instrument.

The profile affects the occurrence of vibrations, which subsequently cause wear of the drive or problems when holding the tool in the hands. over, the higher the cutting parts, the stronger the vibration will be.

Household types of chainsaws are equipped with a low profile. In semi-professional devices, different variants of the types of chains can be combined. However, in most cases, they adhere to the principle:

In a chain with a large pitch, a low profile is set, and with a pitch of “0.325”. a high

Such variations increase the cutting speed not due to the step, but due to the change in the depth or height of the profile. Although in professional tools, the emphasis is on increasing the step, explaining this by the fact that the chainsaw becomes more controllable.

- Cutting Teeth Geometry. Profile can be of two main types:

- chipper (popularly “sickle”). has a crescent shape and has a high performance. It is easier to sharpen during operation and does not require strict sharpening angles. Disadvantage: risk of high loads and deterioration of cutting performance;

- chisel (popularly “seven”). has a straight working surface in the form of the number “7”. They are used in chains with a pitch of “0.404” or “3/8” on professional saws. The main disadvantage of chisel links is the difficulty of sharpening the cutting elements and sensitivity to dirt.

- The number of cutting teeth is defined as the ratio of the number of teeth to the number of rails in the tire. Chainsaws of good production should combine two guide links in the cutting part of the tool.

- The type of link sharpening. directly depends on the type of future work. Classic types of chainsaws are used mostly for cross-cutting trees and are rarely used for longitudinal sawing. Taking into account the resistance of the tree in both cases, the chains can use a different angle of the links. On construction counters, you can now find chains with the following types of cutting links:

- longitudinal type of chain. involves cutting the tree along its fibers. The cutting angle reaches 5-15 degrees.

- transverse type. the cut is carried out across. The cutting angle in the chains is 25-35 degrees.

- Chain length. depends on the parameters and technical characteristics of the chainsaw itself: power, dimensions, etc. With standard or normalized chain tension, its length is most often indicated in the passport.

- The order of the links. the sequence of the links can be different:

- standard. there are two driving links for each cutting link in the chain;

- with a half-pass. every third link in the chain in terms of placement is replaced by the so-called connecting link;

- with a pass. at the locations of every second link for cutting, a connecting.

Why skip links in a chain? In the chains themselves, the most valuable is the quality of the cutting links, since they are manufactured using special technologies and are more expensive than connecting links. If it is impossible to shorten the chain, the only option to reduce the cost of the chain is to skip the cutting elements. In operation, chains with skipped links show reduced performance and wear quickly.