How to grind a wall without a punch

Slitting with a puncher

Wall chipping with a perforator

A hammer drill is a tool that should be in the arsenal of any home craftsman or hired electrician.

Usually small professional type rotary hammers with SDS chuck are used.

It is undesirable to use large rotary hammers and jackhammers, as this can lead to an unnecessarily deep penetration of the wall, exceeding the permissible depth of the groove.

Also, these rock drills are usually heavy and too heavy to work.

The hammer drill should be three-mode, allowing the inclusion of a pure chiseling mode. Dual mode hammer drills, which only allow drilling and hammer drilling, are of little use. Cheap perforators of the “home” class are also poorly suited for these purposes.

They, as a rule, do not tolerate long-term chiseling very well, and after two or three hours of such work, the gearbox, the cartridge assembly and other mechanisms may fail.

It will not be difficult to chisel through the wall without dust with your own hands using a puncher. Usually the hammering is not too dusty. Much more large pieces are formed than dust. However, there will still be dust. To prevent it from scattering around the room, use a construction vacuum cleaner.

In extreme cases, you can do with an ordinary vacuum cleaner. For work, you need a second person who will hold the vacuum cleaner close to the grooving zone. He usually sweeps up the garbage and puts it in a bag. Some rotary hammers have a built-in vacuum cleaner. for example, Makita 2432. Here you can do with the forces of one person.

Slitting discs with a vacuum cleaner

Different chisels are used for work. blades of different widths, peaks, special groove chisels.

The most convenient for slitting is the grooving blade.

It is slightly curved, has the shape of a shovel with curved edges.

Of course, the impact force of such a blade will be transmitted worse than along a straight chisel, but in this case it is possible to perform gantry continuously, without removing the blade from the groove every 3-4 cm.

It must be hardened to the required hardness not only in the area of the tip, but also in the area of the shank. The shank should be slightly hardened so as not to rivet and at the same time not to injure the hammer drill gearbox during impacts. It’s better to overpay for a shovel than to throw out the hammer later.

How to grind a wall without dust: a neat repair

Very often, when carrying out repairs, they are faced with how to grind a wall without dust.

The fact is that often people live in an apartment being renovated.

And dust has a bad effect on health, and on well-being, and in general on mood. no one wants to live in mud.

Hang Pictures On Old Walls Without A Drill!

After minor repairs lasting a couple of hours, it is often necessary to do the cleaning, which lasts half a day. Therefore, the question is more than relevant.

Slitting with an angle grinder

Wall chipping angle grinder

angle grinder or angle grinder. a power tool designed for cutting metal or stone materials with abrasive discs.

Clean chasing an angle grinder is generally not used.

Usually at the groove, extreme cuts are made with an angle grinder, and the middle is selected using a perforator.

This technology allows you to make the strobe more accurate, constant depth. Productivity is also growing.

How to grind a wall for dust-free wiring with an angle grinder? After all, the main drawback when working with an angle grinder is simply a huge amount of dust. The entire volume of the cut material turns to dust. There are two ways to solve the problem: using a wet cut and using a vacuum cleaner.

Wet cuts with an angle grinder are rarely used because of the difficulties in implementation. No one wants to see jets of water running down the walls of the apartment during the renovation, which can flood the neighbors. However, if other methods cannot be applied, a wet cut can be applied using special tools.

Under no circumstances should you spray water by hand near a working disc:

- firstly, there is a danger of damage by the disc to another worker

- secondly, if water gets on the angle grinder itself, if you work carelessly, you can ruin the tool and get an electric shock

Shtrobing an angle grinder with a vacuum cleaner connection is carried out using special devices. They cost from 1.5 to 10,000 rubles. Good devices allow not only to suck out dust and prevent it from scattering, but also to cut to a strictly defined depth, adjust it and increase productivity, convenience and safety.

When using such devices, it is easier to ensure a smooth cut by fixing the rail along the groove at the required distance and pressing the device with one edge against it.

Slitting with special tools

For laying strobes in large volumes, a specialized tool is used. wall chasers.

Perfect accuracy and depth of the groove is achieved, all work is done in one pass.

A special construction vacuum cleaner is connected to the wall chaser, which sucks out almost all the dust.

The main disadvantage of wall chasers is the orientation to one type of material. Most often, they are designed for laying strobes in aerated concrete, wall chasers for concrete and brick walls are more expensive and have low productivity.

Also, at the same time, there is a great chance of damage to the reinforcement. if in the case of an angle grinder and a hammer drill, the reinforcement hit will be immediately noticeable, then with a chasing cutter it is easy to overlook and cut.

It is undesirable to use any other tools for laying the strobe, except for an angle grinder, a chasing cutter and a perforator. For example, when chipping in plaster to a shallow depth, it is tempting to use a router.

However, if by chance a small corner of a brick protrudes from the wall, which is covered with plaster, the cutter or tool will break. It’s the same with other instruments. For manual chasing in small volumes, use a bolt with a rubber protective gasket and a mallet.

You can look at dust-free chasing with a household vacuum cleaner at

Have you noticed a mistake? Select it and press CtrlEnter to tell us.

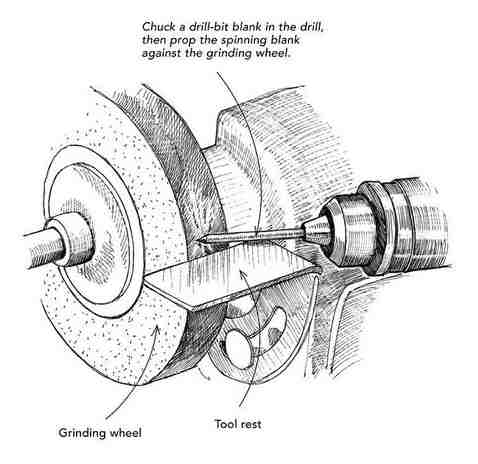

Rotary hammer with attachment

It is used for chipping in masonry and concrete walls. Not suitable for high strength concrete substrates.

- Affordable tool price;

- Small amount of dust;

- No special skills required to operate the tool.

- Uneven edges of the groove, requiring additional leveling work;

- Noisiness.

Slitting methods

There are four main methods for grooving. Their main difference lies in the use of the tool and the resulting application technologies.

- Hammer and chisel. The disadvantage of this method is the inconvenience of working with “old-fashioned” tools. Even with good dexterity, it takes a long time and with curved highways. A huge plus is the cost. definitely cheap.

- Impact drill (hammer drill). Minus. strobe with uneven edges. Pros. speed of the process and relative cleanliness during work.

- Angle Grinder. Cons. a large amount of dust, which is difficult to collect even with a construction vacuum cleaner. Plus. even grooves in a short period of time.

- Wall chaser. The downside is the high cost of the tool. It is too expensive for one-time use. Pros. fast, not so noisy, smooth edges of the strobe, no dust.

Hammer and chisel are ideal partners

This work is performed in separate stages. First, you need to mark the edges of the strobe with a chisel for one or two widths of its spire. Then, putting the point across the groove, it is necessary to knock out a small piece of the wall in depth. Then you can act in two ways. first remove the entire top layer of the intended recess and only then knock out the depth of the groove, or “dig” deeper to the end after each centimeters of the removed top layer.

Important! Using a hammer and a chisel to make a strobe in concrete is almost impossible.

Chipping wooden walls

When conducting electrical wiring in a wooden house, incl. bath, chipping of walls is prohibited by fire safety rules. At its core, physically it would be simply cutting (gouging) a groove, which would be an impractical process. For such cases, there is external wiring, hidden by special cable channels, disguised as a tree.

To what depth is it forbidden to groove in load-bearing walls

Sometimes it is necessary to perform chasing along the load-bearing wall. In this case, the groove depth should not exceed 20-30 mm. If you make the groove deeper, then there is a risk of damage to the reinforcement located in the wall. This is not only a violation of the rules, but can also lead to a collapse.

Chipping wooden walls

Fire safety regulations prohibit chasing walls in wooden buildings, this also applies to baths. In the event of a short circuit, there is a risk of ignition of the walls from the electrical wiring laid in them. In this case, special cable channels are used.

Monolithic walls

Slitting in a monolithic base can be dangerous for the entire structure of a building. This is due to the fact that all walls of such a building are load-bearing and create a single structure. Their frame made of reinforcement is connected to each other. Any violation of it can lead to disastrous consequences.

Such work is performed only in case of emergency, with the receipt of appropriate permits and with the involvement of specialized organizations.

The organization must have a license to carry out chipping in monolithic walls, a professional and serviceable tool, qualified workers.

Almost everyone who has decided to start repairing their apartment, summer cottage or house is faced with the need to cut walls.

This part of the repair work is carried out in the event that during the repair it became necessary to carry out new electrical wiring or replace the old one, lay pipes and other communications.

How to grind walls for electrics without dust

- How to grind walls for electrics without dust

- How to connect to an outlet

- How to chisel under the wiring

Slitting walls is a laborious process that requires a power tool. It is much easier to lay wires using cable ducts or in skirting boards. In this case, sockets and switches must be mounted at lowered hand level. This will not only not damage the design of the room, but also make its operation more convenient.

What tool to use for chipping walls?

Most of the dust is generated when working with a wall chaser, since this tool is equipped with two diamond wheels and makes two cuts at once. It can be used to make strips of the required depth in both brick and concrete. Less slurry will form during operation of the angle grinder.

The most dust-free way of chipping is to make holes and cuts with a hammer drill, while turning on a construction vacuum cleaner. However, it should be noted that this method is more laborious and causes vibration of walls and floors. If it is possible to use an angle grinder equipped with a vacuum cleaner, the ingress of small particles of concrete, plaster or brick into the air will be minimal.

How to chisel a wall without dust?

Before starting work, you need to mark the wall with a pencil by drawing a line of wiring. Further, on these lines, cuts are made using an angle grinder. If it is equipped with a vacuum cleaner, you can continue to work with it, deepening and expanding the strobe. If the tool is ordinary, after making cuts along the mowing line of the marking, turn on the construction vacuum cleaner and start knocking out recesses using a puncher.

Deep grooves should not be made on load-bearing walls, as they can weaken the structural frame of the building. Therefore, for cuts for wiring, a depth of 1-1.5 cm is sufficient.Vertical slots should be removed from the corners of the room by at least 10 cm.If you want to lay the cable near the gas pipelines, they retreat from them by 35-40 cm.

The easiest way is to work with a puncher on plastered walls: the potholes are smoother and smoother. It is more difficult with concrete and brick, since this is a more durable material and you will need to rework the slots with an angle grinder or a wall chaser.

To reduce the amount of dust, use a construction vacuum cleaner. Therefore, it is advisable to work with a partner who will hold the suction bell in close proximity to the working tool (angle grinder or rotary hammer). This method will reduce the amount of dust as much as possible, but it will still be. Therefore, before starting work, it is recommended to cover furniture, window sills, floor with polyethylene or old newspapers.