How to hold an angle grinder when cutting

General tips for working with an angle grinder

In order to understand how to properly work an angle grinder, you should familiarize yourself with the assortment of attachments, among which. brushes and circles. The former are intended for polishing and cleaning surfaces. In this case, you can polish the welds and clean the metal from rust. Different circles can be used for different tasks depending on the composition. Some can cut ceramics, while others are suitable for metal. You can familiarize yourself with this information by looking at the instructions on the disc or packaging.

How To Use An Angle Grinder. Ace Hardware

Basic rules for cutting

When cutting a workpiece, it is important to make sure that you follow the basic rules. the cutting line should pass by the person, but not rest against him. If the disc becomes seized, the jet propulsion of the equipment will bypass the operator. It is important to provide protection with a shroud. It should be located between the employee and the circle.

There is no need to apply excessive pressure on the tool. The unit will be able to cope with tasks using its own weight. Whereas overloads will cause the circle to skew. The inclusion of an angle grinder when the disc is in the profile of the workpiece is excluded. You should start cutting the profile from the place where the cross-section is the smallest.

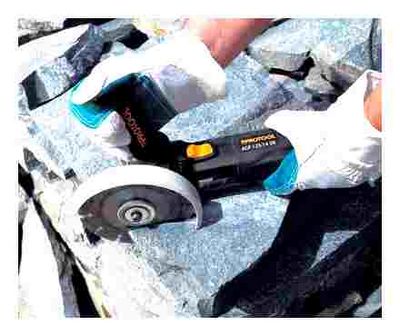

It is important to remember that when cutting tiles, concrete and stone, a lot of dust will be generated. Respiratory organs should be protected from it. Some manufacturers produce hoods with a nozzle for a vacuum cleaner. You can also suppress dust with water, directing a jet into the cut. If you need to work on opening the wall, you must be prepared for the fact that reinforcement, pipe or cable can get under the circle. This will certainly cause kickback. Stay clear of the cutter line to avoid injury.

Rules and guidelines

After fastening the wheel, the tool should be started and checked in idle mode. Within 30 seconds, the equipment is run at maximum speed. If you have not noticed any extraneous sounds and vibrations, and the protective casing does not touch the disc, then you can start work.

Quite often, novice home craftsmen ask themselves how to work an angle grinder correctly. Before starting manipulations, the operator should prepare himself, for this you need to wear:

- special clothing;

- safety glasses or mask;

- respirator;

- thick gloves.

The operator needs to remove all jewelry, such as watches and bracelets, because they can be wound around a circle. Do not start work if you are tired or drunk. Eliminated the use of saw blades for wood when working with an angle grinder.

Operational Safety Angle Grinder

Before starting the workflow, you must prepare the tool. For this, a circle is selected and installed. The motor has a certain power, it provides for the need to select a circle of certain sizes. The smaller the circle, the higher the speed of rotation it can support. If the wheel is used incorrectly, it will cause wear on the equipment and deformation of the nozzles.

If you are thinking about the question of how to properly operate an angle grinder to avoid injury, then you should know that discs that are larger than those for which the unit is designed should not be installed on the tool. The attachments must not be deformed. If cracks or potholes appear on the circle, then you should get rid of them. You should not use those circles that have deviations from the original shape.

What is an angle grinder for?

Having looked at modern angle grinders, you will notice that they are able to cope with many tasks, including:

- polishing;

- grinding;

- cutting glass, tiles, stone, plywood, concrete, brick and metal.

A specific abrasive tool should be used for each type of work and material.

How to cut an angle grinder

In the early stages of its operation, many owners of the described equipment are interested in the question of how to properly operate a small angle grinder. It is worth noting that the method of cutting the workpiece in this case is no different from that when a professional-grade tool is used in the work. Workplaces need to be cleaned, mark the workpiece, only then can you start work.

The equipment must be held with both hands. If the wheel becomes jammed, the tool must not be pulled out of the hands. You should always be prepared for kickbacks, which can cause severe displacement. In general, kickback is one of the most dangerous moments in the operation of an angle grinder. In this case, a sharp sudden kickback of the tool occurs when the disk is jammed in the workpiece.

What should I definitely mention when talking about how to work properly with an angle grinder? Where do sparks fly in the process of carrying out certain manipulations. here is what the master needs to watch out for. They should not come into contact with face, legs and clothing. It is important to make sure that the power cord is out of the drive’s reach. If you need to move to another object, then the equipment should be turned off first and dragged the cord. If there is a power outage, the device must also be de-energized. It is very important to understand the question of how to work the angle grinder correctly. for yourself or away from yourself. The answer to this question is the following statement: the movement of the tool and the direction of rotation of the disc must match. However, the sparks will cover the markup. It is for this reason that the operating rules are often ignored, but in vain. In order to prevent the wheel from jamming, the disc should be brought into contact with the workpiece at full spindle speed.

Which angle grinder to choose

If you are faced with the question of how to properly operate an angle grinder, then you should know that not only attachments are different, but also angle grinders. They are presented in different classes, including:

- industrial;

- professional;

- domestic.

The latter option is suitable for use for a limited time every day. A professional angle grinder can work for several hours every day. Industrial equipment is a device that works almost tirelessly. The instruments are also different in appearance. Thus, the body can be supplemented with one or two handles as well as vibration-absorbing handles.

Correct start, stop and breaks

Before turning on the device, it is worth carefully examining and carefully checking the disc. Do not use tips with chips, delamination, cracks or any other damage.

Before connecting to the network, the cutting (grinding) wheel must be installed on the angle grinder with a pattern upwards, then tighten it with a special nut. The size, as well as the permissible revolutions, are indicated in the technical documentation for the tool.

The mismatch of characteristics leads at least to a defect in work, premature wear of the disc, in the worst case. to injuries.

When inspecting the tool, you need to check that:

- there is no damage or cracks on the case;

- serviceability of the cable (cord), protective tubes and plug;

- the handle is well screwed;

- the circle is fenced, and the casing is securely fixed.

After that, the idle operation of the tool is checked. To do this, you need to connect the plug to the outlet, turn on the power button and the latch. Observe for a minute the work of the angle grinder. Make sure that it works without extraneous sounds, excessive vibration, and the disc does not touch the protective casing. When disconnected, it will become clear whether the power button and latch are malfunctioning or working. If everything is ok, you can get to work.

To take a break from work, you need to turn off the power with the button, wait until the disc has come to a complete stop, put the angle grinder and unplug it.

Interruptions in work are usually associated with overheating of the disc or angle grinder, replacement of attachments, the need to move the workpiece or the worker himself. In any case, you must first turn off the button, and then disconnect from the network. It is important to monitor the instrument and avoid overheating.

Cut from yourself

This is a very good way, but it is important to observe one condition. cut from yourself, with sparks under your feet. In this case, when biting the disc, the angle grinder throws out, therefore it is not capable of causing harm to health. In this case, the drawn cutting line is clearly visible, and besides, there is very little chance of doing something wrong. The disadvantage of this method is that sparks fly to trousers and under your feet.

How to cut an angle grinder correctly: by yourself or by yourself

Angle grinders are in many farms and garages, but most owners do not know how to properly hold and use an angle grinder. Therefore, they make mistakes that can lead to marriage at work, which is even worse. to serious injuries. Remember that an angle grinder is a very dangerous tool. Therefore, before using it, you need to learn a few safety rules.

Safety when working with an angle grinder

Grinding and cutting power tools are hazardous activities. Therefore, when working with an angle grinder, you must take into account the possibility of direct or indirect action of factors hazardous to health:

- cold or heat;

- poor illumination of the workplace;

- strong noise, vibration from a typewriter;

- great physical activity;

- rotating parts of equipment;

- falling objects (processed materials);

- flying off sparks and solid particles of parts;

- work at height, depth or in a confined, hard-to-reach place;

- danger of electrical injury.

Securing workpieces

All small and medium-sized parts must be securely fixed in a vice or using clamps. When fastening, a safe place must be provided for the possible fall of the cut parts.

Sometimes it becomes necessary to machine an angle grinder on large parts or structures that cannot be clamped in a vice. It can be:

- metal sheets;

- profiles;

- pipes;

- structures, machines, mechanisms.

In such cases, you need to make sure that the surface to be treated is securely fixed (stands or lies stably), after processing it will not lose stability, and the cut off part will not fall on the worker or others. At the slightest doubt, support with stops, jacks, or sling and securely fasten the slings to the surrounding metal or reinforced concrete structures.

Workplace safety

Regardless of where the workplace is located. in the garage, in the country or in a free area, it must be well lit, meet basic safety requirements.

Requirements for the equipment of the workplace:

- A workbench, table, rack, wardrobe or bedside table must be installed for storage, as well as placement of devices, tools for productive safe work.

- All immovable equipment is securely placed (attached) on the floor.

- The surfaces of the workbench and rack must be at least as large as the workpieces and tools used.

- The surface of workbenches is made of sheet steel, aluminum, and other non-combustible materials.

- The vise must securely grip the workpiece. On the surfaces of the jaws of the vise, there should be a cross notch with a depth of 0.5. 1 mm for every 2. 3 mm.

- The vise is fastened so that the workpieces are at the level of the worker’s elbow.

- On a closed vise, the gap between the jaws should not be more than 0.1 mm. Handle and jaws. no potholes or burrs.

- The movable part of the vise should not fall out when fully unscrewed and move smoothly, without jerking.

- The floor around the workbench, as well as the entire work area, must be dry and level.

- Power tool sockets are located above the level of the workbench work surface.

When working at a height (more than 1.5 m), it is necessary to use scaffolding (scaffolds) with a handrail of 1 m, sheathed from below with a continuous sheathing to a height of 150 mm or higher.

It is not recommended to use coasters, barrels, boxes that accidentally come to hand. Scaffolding (scaffolding) must not be overloaded. In any case, when working with an angle grinder, you need to have a flat, solid surface under your feet.

Individual protection means

The name PPE, or personal protective equipment, is understood as means for personal use, which are used to protect against pollution, prevent or reduce the effects of harmful and dangerous factors. For most workers, this is workwear appropriate for the profession. It usually includes pants, a jacket, a hat, closed shoes. Since the angle grinder is a hazardous tool, the clothing is supplemented with other protective equipment:

- glasses or visor;

- ear muffs or earplugs (ear plugs);

- vibration-insulating gloves;

- respirator, especially when cutting stone, tiles, concrete or slate.

The goggles will protect you from sparks, small debris or a grinding disc. The use of headphones or ear plugs helps to eliminate noise, thus avoiding difficulties with hearing after work. The gloves will protect you from abrasion and vibration. A respirator against a large amount of dust generated.

Cut on yourself

There are many supporters of this method. It is only important not to forget that when you pull the angle grinder towards you, the sparks must necessarily fly in the other direction. This minimizes the risk of biting the disc. Although he always stays. Therefore, when moving the tool towards yourself, it is imperative to leave the cutting line of the cut.

Push

The “Pull” cutting technique involves rotating the blade clockwise. This method is considered safer, since in the case of biting the circle, the tool is jerked in the opposite direction from the worker. The disadvantages of the method include the fact that a sheaf of sparks, as well as dust, fly to the worker.

Important! When working with metal, the sparks are intense enough to ignite clothing. Therefore, the use of fire protection is required.

Workplace features

The operator’s working area must meet a number of requirements for arrangement and lighting.

- For work, a workbench or table made of non-combustible material is installed, in which the equipment is stored.

- The working surface of the workbench should not be less than the workpiece.

- A vise is used to fasten products.

- The floor surface around the workbench is leveled. It must not slip or have potholes.

Important! Boxes, barrels and other items are not used for work; unsuitable items.

Features of cutting different materials

The angle grinder is applicable for processing various materials. Based on the type of product, select suitable nozzles.

Important! The angle grinder is not suitable for cutting soft, resilient or stringy materials.

Rules for working with an angle grinder for cutting different types of materials

One of the main tools that every home has is an angle grinder. It is multifunctional. The angle grinder allows you to cut durable materials, process sharp edges of metal, glass, wood. It is important for novice craftsmen to learn how to work an angle grinder correctly.

angle grinder. multifunctional tool for cutting and grinding materials

Ceramic tile

For ceramic tiles, use a diamond disc.

- The tiles are laid on the table and fixed.

- The first is to make an incision with a depth of 1.5 millimeters at low speed.

- At the end, the tile is transferred to the edge of the table and broken along the mowing line of the cut.

Glass

Glass is prone to chips and cracks and should be cut with extreme caution.

- A diamond-coated disc is installed in an angle grinder.

- Marking is applied to glass.

- Moisten the incision area with water.

- The incision is made to a depth of no more than 1.5 millimeters.

- A crack is made according to the cut.

- The edge of the chip is sanded.

When cutting glass, chips and cracks often occur, work is carried out with extreme caution

Angle Grinder: 4 Mistakes to Avoid

Metal

an angle grinder is a suitable tool for cutting rebar, round timber, pipes, corners and other metal products.

- The disc is selected based on the type of product.

- The work is carried out with short interruptions. It is not recommended to cut continuously for more than 5-7 minutes.

- The workpieces are securely fixed.

- To cut a thick profile, additional disk cooling is used. The cut is carried out straight.

- Do not apply strong pressure to the angle grinder. Excessive force leads to breakage and clamping of the disc.

- Grinding heads are used to process the edges.

Working an angle grinder correctly. how not to expose yourself to danger?

An angle grinder is a useful device that should be in the arsenal of any craftsman. It allows you to perform a whole range of complex and important work, but it should be used with caution so as not to get injured. We will tell you about the rules for using an angle grinder in this article.

- 1 Personal protection rules when working with dangerous tools

- 2 How to use the detachable tool on an angle grinder?

- 3 General advice on the use of an angle grinder. how not to endanger yourself?

- 4 Backfire. what it is and how to avoid?

Correct work of the angle grinder, without endangering yourself, can only be extremely collected and attentive. The device should not even be taken in hand, being unhealthy, tired and drunk. Inattention can be costly when using a sander. In some cases, negligence leads to very serious injuries, and sometimes to the death of a negligent master.

The main condition for correct work with the tool is the use of glasses and a protective cover. The operation of an angle grinder necessarily leads to the scattering of sparks, metal fragments, scale and abrasive particles. If you don’t protect your face and eyes, there is a high chance of injury. It is best to use a mask or goggles. Fragments and sparks from an angle grinder fly along complex trajectories, therefore they can fly under the glasses if in some part they do not fit tightly enough to the body. The mask is best used with a safety net, as during work there is a possibility of separation from the circle of debris that fly at high speed and can penetrate unreinforced protective equipment.

All new angle grinders are now supplied with a guard, which is required for use.

The first barrier between the grinder operator and the rotating wheel is the guard. In practice, the wheels often break during operation, which usually occurs due to the wheel jamming in the cut. The casing is fixed to the instrument in such a way that it protects the person from sparks and possible fragments in the event of their appearance. The cover must be fixed to the machine as securely and firmly as possible in order to completely exclude the possibility of its spontaneous rotation. Of course, working with the cover is more difficult and less convenient than without it, but by removing this protective screen, you expose yourself to unnecessary danger.

To work with an angle grinder, you need not only a shroud and a face shield, but also hand protection. gloves or gloves. Your hands will be very close to the spinning circle, so they should be protected from sparks and all kinds of debris. We recommend using thick leather gloves or gloves to protect your hands, cotton products are not able to reliably protect you.

When processing concrete and stone materials, it is also necessary to use a special respirator. it will protect the respiratory tract from dust. All your clothing should be wide and well tucked in, any loose piece of clothing can be caught in a high-speed circle and cause injury.

The angle grinder allows you to perform different types of work, process different materials and for each of them you should use a specially designed abrasive tool. By using the wrong circle, you increase the likelihood of it splitting and endanger yourself. Never place larger discs on the unit than those specified for this model.

Small angle grinders differ from large ones in a higher rotational speed of the disc. Circles of large diameters can simply not withstand too high rotation speeds and collapse. This applies to both new circles, and used and because of this reduced in size. Another reason for avoiding large circles is that to use such a disc you have to remove the cover that protects the operator, and this is completely unacceptable. over, large circles create a greater load on the tool assemblies. it wears out faster and may soon fail.

You can put the disc on the angle grinder if it is suitable for the device used and is not damaged in any way. Cracks, potholes, chips and other irregularities or flatness significantly increase the likelihood of kickback and wheel clearance during operation.

Diamond discs for an angle grinder should be chosen at least in terms of price and quality.

For safety reasons, it is completely forbidden to install saw wheels for wood on the angle grinder. Very often, such actions lead to tragic consequences, therefore, do not repeat other people’s mistakes if your life is dear to you. You should not cut wood with an angle grinder for several reasons. Firstly, wood is a heterogeneous material, in which there are knots, and sometimes foreign bodies, for example, nails, because of which the circle can break at high speeds. Secondly, such work is simply impractical. due to high revolutions, the discs for wood will quickly become dull.

To use the angle grinder safely, it is necessary, after installing the disc, to check the operation of the device at idle speed at maximum speed for 60 seconds. When checking, the circle should rotate freely, with minimal vibration, without touching the protective casing.

It is equally important to secure the workpieces with high quality before work. Its own weight can rarely guarantee the complete immobility of an object, therefore it is best to secure materials in a vice or clamps on heavy structures. Do not try to handle objects in your hand. By doing this, you violate two safety requirements at once, which read:

- 1.The angle grinder must be held with both hands.

- 2. The workpiece to be processed must be rigidly fixed.

Holding the workpiece with your hand increases the likelihood of the workpiece shifting and wheel jamming. You should completely avoid bending the workpiece in the cut area, especially if it can narrow the cut. This will almost inevitably cause the disc to jam and kick back.

Despite the dangers of an angle grinder, it can be used safely if you follow safety precautions and make no mistakes. To do this, you need to hold the tool with only two hands. If you hold the device securely, even a kickback will not lead to strong displacement and falling out of your hands. It is also necessary to ensure that the position of the whole body is as stable as possible, without the risk of losing balance.

Operate the device so that the power cord is always kept away from the rotating circle. If the cord is near, you can cut it, or it can be pulled into the wheel, which creates the risk of a short circuit or an abrupt stop of rotation with displacement of the tool.

The machine must not be released until the disc movement has completely stopped. If this requirement is not met, the rotating disc may catch on objects or surfaces. It is possible to move from one work area to another place only with the device turned off, otherwise the circle can capture your clothes. In the event of a power outage, the angle grinder must be unplugged from the socket, otherwise it may turn on uncontrollably when the power supply is restored.

Keep in mind that discs can become very hot during operation and should not be touched until they have cooled completely. Make sure that all unauthorized persons are at a safe distance from the place of operation of the tool, because abrasive particles can harm not only you, but also those around.

To start working with an angle grinder. to make contact of the rotating disc with the material or workpiece, it is possible only when the spindle reaches full revolutions, otherwise the disc may jam. Machine manufacturers advise cutting in such a way that the tool always moves in the same direction in which the installed disc rotates. So you will protect yourself from a sudden exit of the circle from the slot made.

Think seven times. cut one!

Many users do not follow this recommendation, since when the tool is held in this way, a jet of sparks from under the circle hides the markings applied to the workpiece. If you drive the machine in the opposite direction, you can easily control the cutting accuracy, but because of this, a safety violation does not cease to be. And when choosing between convenience and safety, it is better to give preference to the second.

It is imperative to ensure the correct position of the tool throughout the entire use. the cutting line should not rest against the operator, it should pass by, away from you. In case of jamming, jamming of the circle, the jet movement of the apparatus will continue to the side of the person. No need to press hard on the tool when cutting, give the angle grinder the ability to cut by yourself. A heavy load on the machine can lead to skewing and even jamming of the wheel. Your task is to direct and adjust the tool, you only need to press on it occasionally and not very hard. Never turn on the tool if the circle is in the kerf, cutting metal and other materials in this case is likely to end with a kickback.

It is imperative to observe safety regulations during grinding work. It is not necessary to use very thin discs for grinding, as well as cut-off wheels that are not intended for such work. they can break. Grinding should be done with the edge of the disc at an angle of 15-40 degrees to the surface. The tool should be moved forward and backward with moderate pressure. After installing a new, unused disk, it is better to first work with it in one direction. forward. If guided backwards, it can cut into the work surface. Once the disc has been rounded, it can be operated in both directions.

Use cutting discs for cutting tiles, stone and concrete substrates. When working with these materials, a lot of dust hazardous to health is generated. It is best to organize automatic dust extraction using a construction vacuum cleaner connected to a protective casing. Otherwise, be sure to use a respirator. To reduce the amount of dust, it is necessary to ventilate the room during work, and also suppress the dust with a stream of water, which is directed to the cut. You will need an assistant for this.

The angle grinder can be used for various jobs, including chipping. When cutting walls, in which there may be reinforcement, as well as elements of engineering communications, you must be especially careful and careful. A short circuit or kickback may occur if the disc comes in contact with such elements. Therefore, before carrying out work in unfamiliar places, be sure to examine the presence of communications within the walls.

There should be no flammable materials and flammable liquids inside or near the work area. Keep work pieces and any objects away from the angle grinder that could be damaged by sparks or abrasive debris. If such things cannot be removed, it is best to cover them with a wet rag. In damp rooms for use, the angle grinder should be connected via an RCD. This is the only way to guarantee the prevention of electric shock.

Never entrust unauthorized persons to work with an angle grinder if you are not sure of their qualifications and ability to comply with safety precautions.

Kickback is a sharp, sudden kickback of the angle grinder due to a jammed rotating wheel. It poses the greatest danger to the operator, as it is usually accompanied by the destruction of the disc. When the disk is jammed, the reactive displacement of the tool is carried out in the opposite direction to the rotation of the disk. Most often, the kickback occurs due to erroneous actions of the operator or direct violation of safety measures.

Our recommendations will help to avoid such problems as kickback or, if it occurs, to avoid serious consequences. Always use standard handles to hold the tool and do not hold it with only one hand. Stand firmly on the ground so that you do not lose control of the tool if the tool is thrown. Always stay away from where the tool will move on kickback. When moving the angle grinder away from you, it may bounce directly at you.

Special care must be taken when processing edges and corners. Kickback often occurs at the end of the cut, when the last bridge is cut, connecting the two parts of the same object. In such a situation, in order to avoid problems, it is recommended not to bring the cut to the very end, it is better to remove the circle from the opening and cut the jumper on the back side. If the device is jammed, it should be turned off and carefully removed from the cut made.

Despite all the difficulties and dangers, you are quite able to work independently with an angle grinder. Just follow our guidelines, they will help you cut and sand without problems.