How to increase the power of a trimmer for Sturm grass. At high speeds

Trimmers for Sturm grass (Sturm)

Trammers for Sturm grass are known for their endurance, solid traction parameters, an impressive margin of torque. A powerful engine and an enhanced cutting system make it easy for each model of this brand to cope with the hardest weeds without the risk of overheating and breakdown of the main working elements. This makes the Sadovo technique of Sturm the best option for operation on large in the territory and strongly overgrown areas.

The German brand first entered the world market more than 20 years ago. Since the emergence of the enterprise, its management has headed for the development of his own innovative technologies with their subsequent implementation in the manufactured technique.

Nowadays, the German brand actively supports its brand, releasing a large number of welding machines, climatic equipment, as well as locksmithing, turning, measuring and other types of economic tools. Among the gardeners of special attention are deserved by Sturm motorcycles. Among their main advantages are high power, increased endurance and extremely low fuel consumption. All this, together with democratic prices, makes trimmers for the grass of the German brand popular, both among beginners and among experienced gardeners.

Sturm BT8952D Benzotrimmer. tools

This household trimmer for Sturm grass is popular among gardeners who own small and medium sections. Due to the high power, an enlarged motor resource, the model successfully cuts not only a soft young shoot, but also shows itself well when removing large weeds, not dried bushes.

The basic equipment of this Sturm mower includes durable gasoline ICE with one cylinder and forged piston, as well as a whole metal gearbox, a direct non.vegetable bar and a hard drive shaft.

The main factory parameters Motokos is:

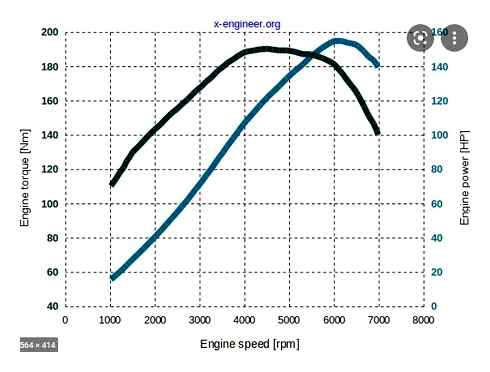

- The power of the factory engine is 2 liters. With. at 6500 rpm;

- fuel tank. 1.1 l;

- coverage when mowing with a cord/knife. 41.5/25.5 cm;

- permissible diameter of the cord. 2.5 mm;

- Weight. 6.6 kg.

Almost all internal spare parts of the models are made of metal, which increases the reliability and durability of its main working mechanisms.

Balancing the lawn mower

The lawn mower is a convenient tool for the mowing of the lawn or high grass, if it is correctly balanced. It will not be about the balancing of the cutting fishing line or knives. You need to balance the working handle, as well as the position of gasoline braids for grass on the belt. Many gardeners do not use a belt when working with a gasoline scythe, so their hands and back are getting tired. For convenient work, it is necessary to use a supporting belt. Such belts are supplied with professional gasoline braids. For Chinese gasoline cobs, a supporting belt must be purchased additionally.

The lawn mower must be correctly fixed on the belt. In order for the garden tool not to rise up when working, and it was convenient to mow grass, the belt is fixed behind the handle. If you fix the belt too close to the filled fuel tank, then the gasoline braid for the grass will delve into the ground, and the cutting elements will touch the soil. No cutting element is designed for contact with the ground. In the wrong position of the lawn mower, the cutting elements quickly dull. To extend the service life of cutting elements, gardeners raise the lawn mower. With such work, the back is quickly getting tired.

A gasoline braid for grass should freely hang on a belt. For proper balancing, fix the belt so as to balance the filled fuel tank and the working body of the lawn mower. It is also important to find this position of a gasoline braid for grass, when working in which, you will not close the exhaust hole of the engine, otherwise the engine will overheat during long.term operation.

Balancing pens

For easy work with a benzocosa, you need to find the correct position of the handles. For the convenience of configuration, it is advisable to find a model with separate adjustment of the handles. In such models, the handle is attached to four screws. Up the upper screws, you can adjust the angle of rotation of the handles. Having removed the lower screws, you can adjust the hilt under your growth.

Some models of the benzos are equipped with paired handles, which do not adjust the angle of rotation. In order to prevent your feet from resting with such braids when working with such braids, they must be lowered on a working shaft. You have to bend or raise the lawn mowed to the lowered handles, so when prolonged work, the back or hand gets tired.

How to set up a lawn mower carburetor to work better, and fuel eats less

Get one most read article by mail once a day. Join us in and

Nowadays, the word “carburetor” is familiar mainly only to those who have yet found cars with the corresponding engines in their memory. At the same time, carburetor power units are universally used in a variety of agricultural machinery for giving. Just get into an important detail with a screwdriver, few will dare to imagine it with a sort of “sacred cow”, which is better not even to approach. And in vain.

In fact, a carburetor is a fairly simple device. The same can be said about its configuration. There is nothing out of place in this matter, especially when it comes to garden technology. Equipment adjustment options, in fact, only two: setting idle revolutions and setting up a mixture of gasoline and air. Both calibrations are carried out by carrying out manipulations with one of two bolts. Most often, the setting of the supplied mixture is made using a thick yellow screw, and the idle calibration is sold using a thin white screw.

Before performing any manipulations with a carburetor of any garden tool, the engine first needs to be turned on for several minutes and warm up. In this case, the damper regulator must be put into a position corresponding to the work regime. Immediately after warming up the mechanism, the screw that is responsible for the quality of the air-banding mixture is twisted so that the idle speed of the tool begins to fail. The motor may stall.

Next, the screw is unscrewed from the reach of the half-turn in the opposite direction. We give full gas, if the tool engine did not stall and did not begin to zoopet, then everything was done correctly. If nothing has changed, then the mixture screw is unscrewed by another quarter turnover, behind this is again the check and so on until the victorious end. We can check the result of prolonged gas without fail. the lack of cotton, zabulak, and extraneous noise will confirm success.

The next thing that can be done to set up a trimmer for grass is to set a suitable idle parameter. The principle of adjustment here is exactly the same, only now we work with a thin white screw. On a heated engine, we tighten it to a state of zabovki of the unit when pressed on the gas, after which we begin to gradually release. First to the turnover, then half, then a quarter. until the tool starts working normally and without obvious interruptions.

The correct calibration of the revolution screw will reduce the amount of fuel consumed, and the competently set the mixture screw. increase the capacity of the tool. By the way, the details about the setting are contained in the technical leadership, which was supposed to be included with the acquired garden tool.

Winter is no longer around the corner, and therefore it should be read about what a real cleaning mechanization is: how to make a snowball player from a trimmer for grass.

At idle

At single speeds, the common reasons for stopping a trimmer for grass are as follows:

- reducing the speed of the gearbox when heating it, which is a consequence of the use of inappropriate fuel mixture;

- clogging of the throttle;

- air entering the system;

- not enough fuel for the operation of the lawn mower.

If a carburetor is a problem place, then the technique will stop at the “cold” and with a “hot” launch.

Immediately after you started

The unit can stall immediately after the launch, if the carburetor is cesspool or was incorrectly configured. this causes Uneven fuel supply

The result is that the device begins to vibrate clearly. To eliminate problems, the carburetor is reconfigured, acting according to the instructions for the mechanism.

The engine also stops when Clotting of the valve

, supplying fuel. In such cases, it is enough just to clean it. If the lawn mower at first earned, but then immediately stalled, then possible fuel to the carburetor unit enters some difficulty. The weakening of the valve helps to solve the issue, which provides free circulation of the mixture in the system.

The stop may also be called Air suction

In the presence of mechanical damage to the hose (holes, cracks) that fuel fuel fuel. In this case, the drive should be added to the drive to quickly drive air bubbles from the system.

In no case should you store gasoline in plastic containers from under water. When mixing the fuel mixture, a static charge accumulates, you can “catch” the spark.

Therefore, at gas stations it is not allowed to refuel gasoline into plastic canists, only in metal. Before pouring gasoline in a metal canister, it is better to put it on the ground, so statics are removed from the case.

But there are situations when simple manipulations with a motorcycle do not help. The engine still does not start. In this case, we are in progress, we check the power and ignition system, guided by the rule “the motor does not work if there is nothing to burn or set it on fire”.

Benzotrimmer loves cleanliness. It is necessary to monitor the purity of the air filter and fuel. It is better to defend gasoline bought at a gas station for 2 days and pass through the simplest filter. a piece of bike matter.

We check the electrical equipment as follows:

We unscrew the candle, examine the gap between the electrodes. We set the right gap between the electrodes can be a “grandfather” way. We take a blade from a razor, scraps in half and insert a home.made probe between the electrodes. If the blades enter tightly, then the gap is perfect.

We put on a candle cap of a high.voltage wire and lean the candle against the metal surface of the engine. Twist several times by the starter. If the spark beats well at one point, then the gap is adjusted correctly. If not, the spark is weak or “wanders”, then it is necessary to re.adjust the gap between the electrodes.

FIFA 23 | SK Sturm Graz vs Lazio. Friendly | Gameplay

How to adjust the carburetor of the lawn mower with your own hands

Adjustment

- Run the motor. When it is launched on the XX, knives should not rotate, but if the opposite occurs, then we reduce the speed of the idle.

- We adjust the screw l. He is responsible for the mixture at low speeds. First, scroll to the stop clockwise, then unscrewed 90 degrees against the sentry. If you find failures, we repeat this action, weakening it for 1/8 part, that is, 45 degrees.

- Adjust the La screw, more frequent name. t. With an increase in speed XX, more air is added to the mixture. Power is lost. But if there is not enough air, fuel is burned worse. We unscrew the screw so that it works perfectly at low speeds, while the knives should not rotate. In the process of setting, you need to feel momentum, it should work stably on XX.

- Adjust the screw h, which sets up the mixture at high speeds. To identify their maximum quantity, we use a tachometer. Upon reaching the largest number of engine speed, we unscrew the screw to the left by 180 degrees, the adjustment on this ended.

Sometimes only the correct setup and the use of the device reveals its entire potential. No need to neglect it and conduct as necessary.

The main problems and malfunctions of the carburetor.

Mesh filter. There are only two problems with this element more often:

In order to find out the cause of the breakdown, the fuel filter lid is unscrewed to extract the mesh filter. If dirt just accumulated on it, then flushing in gasoline or purging will help.

With visible damage on the mesh filter, you must definitely put a new. There may also be damage to the fuel supply pipe (during the repair they practice checking this element).

The starting device of the carburetor in most cases does not function due to blockages. Should be used for flushing acetone or the same gasoline.

Purging parts of a carburetor with click of compressed air. permissible and convenient repair practice.

The hull of throttles, the ligaments of the parts of the carburetor, the intake or graduation pipeline. all of the listed parts are subject to depressurization. You can probably check in a primitive way. spread the problem area with soap foam.

The device of the carburetor of the lawn mower

The basis of the carburetor of the lawn mower is an aluminum corps. It has a diffuser (hole with internal contours). Air is pumped through this hole. The speed of oxygen (air) is dependent on the cross.sectional (passage opening) of the diffuser.

The diffuser is equipped with fuel channels. Fuel is drawn from them using air flow.

Repair of an electric trimmer for grass

The electric trimmer for the grass replaced the usual spit. Today, most urban residents do not even know how to use a “rare” tool correctly. A modern person does not need this, because he has an electric counterpart. But if an ordinary braid had to just sharpen from time to time, then things are more complicated with the power tool. Equipment requires a certain care, and if a malfunction occurs, the repair can lead to big expenses. However, it does not always make sense to carry the failed tool in the workshop: often you can cope with the breakdown on your own.

To understand what exactly can break in an electric cost, first you should figure out how it is arranged.

Ethletric trimmer for grass usually consists of the following elements:

The current is supplied to the power unit through the connector on the case, to which the cable is connected. Inside the rod is hollow. it plays the role of a protective shell for a flexible shaft, transmitting torque from the motor to the coil of the trimmer for the grass. The handle located on the case has a button, when pressed on which the device turns on.

The described design is considered a classic. However, there are options for executing the tool in which the motor is located in the lower part near the coil, as well as the battery versions.

Repair of an electric trimmer for grass with your own hands: Frequent causes of breakdowns

One of the scenarios in which the tool is out of order is the mowing of a very neglected area. In this case, the equipment is affected by increased loads and often fails of the power unit. A breakdown of bearings or coils is also possible.

And when work is carried out in rainy weather, electrical equipment can simply close. Also, do not forget about a certain resource of individual assemblies of the tool, which are not designed for constant use. The device requires timely inspection with the replacement of worn parts.

Repair in some cases can be carried out independently, without the involvement of third.party specialists, the cost of which is often considerable.

Repair of the launch button

If the tool does not respond to attempts to turn it on, two options for a malfunction are possible. a cable break inside the handle or the failure of the inclusion button.

Important! Make sure that the device is disconnected from the network if it is a stationary type. In the case of the battery version of the instrument, the power terminals should be first disconnected, and only then proceed to repair.

In order to understand what exactly the breakdown is, you need to disassemble the handle.

Having gained access to the inside, you should, armed with a multimeter, measure the resistance of the button. If it is absent after pressing, the button must be replaced.

You also need to check the contacts of the connection of the power cable with the contact group. Often the need for such a measurement disappears, t. to. The cliff can be found with the naked eye. In this case, it must be eliminated by soldering.

In the absence of a multimeter, the same work can be done using an indicator screwdriver. To do this, after disassembling the body of the power cable handle, it is connected to the network and the phase is checked by a screwdriver before and after the button. If zero comes to the button, the fork in the outlet can be turned and measured again.

Attention! You should be very careful when checking the presence of a phase in this way. There is a possibility of gaining electric shock!

Checking the electric motor

If the button and cable that feeds the tool will be serviceable, you should go to the diagnosis of a power unit. To do this, disassemble the case in which it is located. It is usually necessary to simply unscrew several bolts or screws and remove the lid.

First of all, you need to check the condition of the collector brushes. The wear of this node can lead to unstable operation or to a complete stop of the engine. If the brushes are in satisfactory condition, you should check the winding of the motor for a short circuit.

BATTLE OF THE CRAZY ULTRAS at LAZIO vs STURM GRAZ ��

For this operation, it is necessary to completely remove the engine, and then check all the collector plates in the mode in the mode. The device should not show significant deviations in measurements.

The second check is the “ringing” of the rotor winding to the “mass”. To do this, you need to connect one of the multimeter contact to any collector plate, and the second to the “mass” of the rotor. In this case, the resistance measurement mode should be more than 1 MOM. If there is no short circuit, the device will show a very large meaning.

If, according to the results of these checks, all the parameters turned out to be normal, you need to measure the resistance of the stator winding. Indications should be similar, as in the case of the rotor. If not, then the malfunction lies in the stature.

If there is an interval circuit in the engine, it will not be diagnosed in this way. However, this problem can be identified by observing the trimmer for grass in action. An indirect sign of such a malfunction will be a decrease in the power of the work and overheating of the equipment.

When, as a result of diagnosis, it became clear that the engine was “burned out”, it would be easier to notice it on a new. In the vast majority of cases, repairs, consisting of rewinding, will cost as much as a new power unit.

If the engine is installed on the engine, then it will turn off the power when overheating. If the problem is the malfunction of the relay itself, this can be identified using the same multimeter or tester. With a cold engine in good condition, the relay should pass the current.

Mechanical malfunctions

Such problems include a breakthrough of the flexible shaft. It is easy to recognize it. the motor works, and the coil with a fishing line does not rotate.

The reason for the breakdown is the unfair care of the tool, which consists in the timely lubrication of the inside of the bar. In the absence of the desired amount of lubrication, the shaft will be subjected to excessive friction and the cliff will become a logical result.

This breakdown is corrected by replacing the shaft, which can be removed by disconnecting the upper part of the trimmer for the grass from the bar. If the second part of the shaft is not extracted, disconnection and lower.

When installing a new shaft, it should first be lubricated.

Such a malfunction can occur only with a classic layout of parts. In devices where the power unit is located in the lower part, there is no flexible shaft. However, with such a layout, the role of the gear ratio is played by a bearing located on the engine shaft closer to the place of transmission of the moment. In this situation, the bearing must simply be replaced with a new.

The reasons that the trimmer for the grass does not develop momentum

External signs

The reasons are that the lawn mower is not gaining momentum, vary. Some are not even related to the breakdown of the device, for example:

- Getting on the filter of dirt or dust.

- Pouring low.quality fuel mixture.

- Using poor gasoline or overdue oil.

- Pollution of the engine components, which does not allow the instrument to gain momentum.

In the case of pollution on the carburetor, he sees a lot of soot. It is the reason that the trimmer for the grass does not gain momentum.

Internal problems that the gasoline trimmer for grass does not develop momentum

Technical malfunctions are manifested in both old and new devices. Do not be surprised. even a new trimmer engine for grass may not develop revolutions. Check the ignition system and supply of the mixture for serviceability:

- Когда коса для травы заводится и тормозит или даже не заводится, то проблема может быть в свече. A dark carrion appears on it. a sign of poor.quality gasoline and poor carburetor work.

- A flooded fuel hose is another problem due to which STIHL is not gaining momentum.

- With prolonged work without cleaning parts, a muffler can clog. Check the system for the presence of dark particles and clean the pipe, then the motor will start and start working as a new.

If the problem is in the motor itself and you do not know what else to do, be sure to take it to any master. You are unlikely to do something inside the motor, all the more right. And you will always have time to harm the device.

Serving parts of a benzotrimmer to prevent a problem

In order not to in vain to disassemble the motokos, it is worth diagnosing each zone separately. the problem can be in both one and several parts. Where to look and what to check.

Carburetor

One of the main nodes of the correct work of the trimmer for grass. So that the part functions as necessary, adhere to the conditions:

- Each month to remove and clean the part;

- Configure idle, according to the manufacturer’s instructions;

- If you yourself cannot set up. take the master.

One of the popular reasons for the breakdown of the motor. the carburetor cable is not pulled. To eliminate the problem, you need to disassemble the carburetor first, clean it, and only then tighten the cable. Just do not overdo it so that it does not pull like a string.

It is worth checking additionally: an intake needle, a membrane, a setting lever, a damper and other components of a carburetor. They may also have problems that interfere with the correct work of motorcycles.

Spark plug

Even if you don’t know what a normally working candle should look like, just remove it, dry it and clean it with sandpaper. Return the part to the place.

You can also check the distance on the main part. Maximum. 1 mm gap between parts of the fabric.

If the candle is too black, then there is no point in cleaning it. just buy a new one and install it on the motor. Then the whole system will work with new forces.

Filtering system

The blocking of an air filter can sometimes affect work even more than problems with the candle. To check if it is a problem. run the engine with the filter removed. If you started, rinse the filtration sponge in gasoline or other moisture. And you can buy a new one. this will only benefit your trimmer.

The clogged filters do not let the fuel mixture into the motor, so it stalls or does not start. The lack of gasoline can be fixed with banal cleaning: both a filter under the lid and the filter of the fuel hose (located inside the plastic tank for fuel).

Motor malfunctions

Internal combustion engine. the basis of the operation of the gasoline apparatus. What may be wrong with him if the motor does not gain power:

- The fuel mixture is incorrectly prepared, or its expiration date has long been released;

- The piston rings broke;

- Cylinder or piston in scratches and cracks;

- The device is used without breaks.

With the repair of the motor should be careful. This is because if you incorrect all the details, then you can stay like without a trimmer for grass, and also with injuries. Trust the case to a specialist!