How To Insert The Line Into The Trimmer Head

Thick line

It is stored at the top of the trimmer body.

Spare coil storage space

It is very simple to install such a fishing line into the reel. according to the internal scheme inside the reel. We insert the center of the line with a metal mount in the upper part of the reel, and draw the ends of the line along the grooves and lead out.

Trimming the line into the trimmer.

I want to devote today’s article to the sore subject of summer residents and gardeners of the entire post-Soviet space “How to fill the line in the trimmer.” Many trimmer manufacturers do NOT answer this question in their instruction manuals. Therefore, it is also difficult for simple gardeners to figure out how to do it correctly.

I want to start with a brief description of the technical characteristics of the trimmers.

So, trimmers are electric and gasoline. The cutting element in trimmers can be a fishing line and a knife. The line is ordinary, four. Pentahedral and intertwined (in the form of a pigtail). Knives come in 2, 3 and 4 bladed knives. Knives also come in plastic and metal.

The line feed system from the trimmer is manual, semi-automatic and automatic.

The development engineers who create new models of trimmers accurately calculate the diameter (thickness) of the line and the number of knife blades, according to the power of the trimmers. Otherwise, the motor is overloaded, resulting in damage. And these are additional and significant costs.

Trimmers on the market today:

With one nozzle. only a line.

With two nozzles. a fishing line and a three-four-blade knife.

With one attachment. only three to four blades.

Our Kulibins long ago learned to improve any mechanisms. So, for example, some gardeners make successful, in their opinion, replacement of fishing line with a metal cable, or fishing line. But at the same time, they DO NOT think about the safety of their own and their loved ones, because the cable with the power of the working trimmer can easily break out and not only injure the mower and others, but leave him crippled for life. Using a fishing line can and gives a better effect, I have never personally tried it than a trimmer line, but such work has a number of inconveniences: when it comes into contact with hard objects, it loosens or can simply be pulled out of the reel without limit.

So, what is called closer to the topic. Here is an example of how to thread the line into the trimmer (Trimmer BOSCH Art 30). Everything is very simple. Started.

After you have chosen the line for refueling, you need to cut off the required amount of line, because all the line in skeins will NOT be wound into a reel.

Cut off and start reeling.

Removing the coil and protective cover from the coil.

They took it off. Fastening one end of the line into the gap and carefully and evenly wind the line.

The amount of line should be such that the protective cover of the reel closes and the line on the reel unwinds a little.

We put the other end of the line into the hole on the protective casing.

Next, take the coil and the coil cover. We squirt the end of the line from the reel into the metal hole on the protective cover of the reel. We tighten the line a little.

We put it all on the trimmer. Turn the coil clockwise until it clicks.

I fixed it. Now connect the trimmer to the mains. We put the trimmer in the starting position for work. We turn on the trimmer. Excess line length will be cut into the trimming blade.

Spool in trimmers

That’s all we start working.

In addition to the standard lawn line, my trimmer has a thick line for cutting rough weeds. It is shaped like a pigtail, i.e. Three lines are tightly intertwined. This line has its own spool. Material you can see

A little advice. Try to keep the line out of contact with hard objects when cutting. With this contact, the line will be cut. And since in this trimmer the line is not fed automatically, then you have to stop work every time, remove the spool and release the line again.

Heavy-duty line in a reel

This reel is attached to the trimmer in the same way as a reel with an ordinary line.

How to properly thread the line into the trimmer spool: tips and

How to thread line into the trimmer spool: tips,

In order to mow the lawn and give it a well-groomed look, it is not necessary from time to time to work on the site. With any volume of work, such a device as a trimmer will cope as quickly as possible. This type of technique can cut grass of any length and density, it all depends on the chosen model. In order for the unit to fully work and perform its main function, you need to refuel the line, otherwise the trimmer will NOT be able to complete the task.

Line selection

First of all, you will need to choose the correct line. You should NOT do it “at random”, as it all depends on the model of the unit. Pay attention to indicators such as the diameter of the thread, as well as its cross section. You can find information in diameter in the instructions for the trimmer. The second indicator (section) depends on what kind of work you are going to do. If this is a soft young grass, round will do, if it is tough, choose a square or 5-sided section.

How to properly fill the line in the trimmer: instructions

If you set the line incorrectly, the unit may break down and you will have to fork out to repair it. Therefore, before starting the procedure, be sure to read the detailed step-by-step instructions. It is easy to learn how to do this and in a few minutes you can go mowing the grass.

How to tuck the line into the trimmer:

- First you need to remove the attachment that is located on the gearbox. This is easy to do: the connection is the hole located on the side of the bottom washer and the recess. You can find notches on the axis. Be sure to insert a screwdriver to prevent the shaft from turning. When removing the nozzle, you need to twist to the right, not to the left. Let’s disassemble the coil. drown the clips located on it into the body, then gently squeeze the edges.

- How to handle the line automatically? You need to handle it as carefully as possible, otherwise the spring will fly out of it (the same applies to the fishing line with a semi-automatic mode). Hold the parts with your fingers and take your time.

- Spool with a through hole on the body. you need to pull the line through both holes (outer and inner). Then turn the dial and RELEASE the thread.

- If the reel functions only with the first cutting element, the procedure is quite simple and quick. You will find a small hole in the inside of the spool, it is through it that you fix the thread. You need to insert the end of the thread into the hole, then start winding. This should be done in the opposite direction in tone to the movement of the coil. Take a closer look. perhaps your reel model has an arrow, it indicates the direction in which you need to wind.

- The end of the thread is fixed with a groove located in the inner part of the bobbin. Leave a long piece of line outside.

- If your model has a groove, hold the end of the thread with your hand, then install the top of the spool and thread the end of the thread into the hole.

- Place the spool in the trimmer and get to work!

How much line will you need?

For normal functioning of the trimmer, 3-4 meters of material is enough. The length of the thread depends on the dimensions of the spool. The larger it is, the longer the line.

If your trimmer has a coil not with one, but with 2 cutting elements, unwind the required amount of fishing line and thread the thread through the hole, the fishing line should be divided into 2 equal parts in length. Then start winding 2 pieces at the same time. When almost all of the line is wound, leave short ends and clamp them in the grooves. This method is suitable for a single groove spool.

If the device has not one, but two grooves, you need to insert the fishing line in the second way. Fold the cut thread in half, at the end you will have a loop. You need to insert this end into the groove, it is located between the two grooves. Each groove has one end. Assemble the coil in the same way as in the previous case.

How to properly thread the line into the trimmer spool:

If the above instructions did not help you, check out theses. You will clearly see how to thread the line step by step.

Types of trimmer line

As a rule, line separation is based on different sample diameters, which can vary from 1.2 to 4 mm. The most commonly used material is a material with a thickness of 2 mm, but in no case should we forget that the choice should depend primarily on the trimmer model.

There is one main rule here: the more power the apparatus has, the thicker the line should be.

This element can also differ in the type of its section. So, it can be round (suitable for cutting plain grass) or square (for mowing soft green cover), sharp edges (tall grass) or be equipped with notches ideal for thin grass.

Do not forget that with the help of a fishing line it is allowed to mow only grass, and for other, coarser vegetation, it is imperative to use knives.

Next, you should consider in more detail the process of how to insert the line into the trimmer correctly. Indeed, it is with this procedure that many consumers often have difficulties.

How do I fit the line into the trimmer? Operating tips

The trimmer is an excellent modern device designed for mowing unnecessary grass, and its main advantage is that this technique can be used in places where an ordinary lawn mower will simply not be able to reach due to its massiveness. It is necessary to understand in more detail what trimmers are, and how to choose the best option for a particular suburban area.

How to tuck the line into the trimmer?

Any machine for mowing vegetation is necessarily equipped with a spool, which, in turn, may differ in different models by the filament feed system (automatic, semi-automatic and manual). It is from this parameter that it is worth starting from before deciding how to fill the line into the trimmer.

In order to tuck the line into the trimmer, you need to take at least 5 meters of material, which is then folded in half. The center of the cutting element should be inserted into a specially designated place, and then the cutting attachment should be wound on the spool showing the direction using visual cues. At the end of all the work, the lid, of course, will need to be tightened.

What is a trimmer?

This equipment is based on the following elements:

- Motor, the main function of which is to rotate the cutting head at the end of the rod;

- Directly the head, consisting of a coil on which either a fishing line or a knife can be wound;

- Knives or line rotating at high speed, which are the main cutting part of the device, how to load the line into the trimmer, it will go a little further.

An electric device is inferior in its power to a gasoline one, so it is ideal for working on a standard plot of land, which is adjacent to a house with source of electrical energy. The main positive aspects of this technique are the absence of noise during operation, light weight, ease of use and, of course, environmental friendliness.

As for gasoline trimmers, such equipment, of course, is more mobile, so it can be safely transported from place to place and get rid of annoying vegetation in any area. It is not necessary to use electricity here at all, which has a positive effect on the functionality of such an apparatus. the cutting attachments can be changed, working with weeds of various types.

One of the most common attachments is the fishing line, so you should dwell on this element in more detail.

Line adjustment

One of the main rules when replacing and adjusting equipment is any manipulations with the mechanism Should be carried out exclusively with the engine off and the device plug disconnected from the mains.

Perhaps these tips will tell you how to tuck the line into the trimmer as correctly as possible and, accordingly, give your site a neat and aesthetic appearance. All that is required is to correctly select the cutting material required by the type and, of course, to determine the category of the most used trimmer.

How to tuck the line into the trimmer?

Any machine for mowing vegetation is necessarily equipped with a spool, which, in turn, may differ in different models by the filament feed system (automatic, semi-automatic and manual). It is from this parameter that it is worth starting from before deciding how to fill the line into the trimmer.

In order to tuck the line into the trimmer, you need to take at least 5 meters of material, which is then folded in half. The center of the cutting element should be inserted into a specially designated place, and then the cutting attachment should be wound on the spool showing the direction using visual cues. At the end of all the work, the lid, of course, will need to be tightened.

What is a trimmer?

This equipment is based on the following elements:

- Motor, the main function of which is to rotate the cutting head at the end of the rod;

- Directly the head, consisting of a coil on which either a fishing line or a knife can be wound;

- Knives or line rotating at high speed, which are the main cutting part of the device, how to load the line into the trimmer, it will go a little further.

An electric device is inferior in its power to a gasoline one, so it is ideal for working on a standard plot of land, which is adjacent to a house with source of electrical energy. The main positive aspects of this technique are the absence of noise during operation, light weight, ease of use and, of course, environmental friendliness.

As for gasoline trimmers, such equipment, of course, is more mobile, so it can be safely transported from place to place and get rid of annoying vegetation in any area. It is not necessary to use electricity here at all, which has a positive effect on the functionality of such an apparatus. the cutting attachments can be changed, working with weeds of various types.

One of the most common attachments is the fishing line, so you should dwell on this element in more detail.

How do I fit the line into the trimmer? Operating tips

The trimmer is an excellent modern device designed for mowing unnecessary grass, and its main advantage is that this technique can be used in places where an ordinary lawn mower will simply not be able to reach due to its massiveness. It is necessary to understand in more detail what trimmers are, and how to choose the best option for a particular suburban area.

Types of trimmer line

As a rule, line separation is based on different sample diameters, which can vary from 1.2 to 4 mm. The most commonly used material is a material with a thickness of 2 mm, but in no case should we forget that the choice should depend primarily on the trimmer model.

There is one main rule here: the more power the apparatus has, the thicker the line should be.

This element can also differ in the type of its section. So, it can be round (suitable for cutting plain grass) or square (for mowing soft green cover), sharp edges (tall grass) or be equipped with notches ideal for thin grass.

Do not forget that with the help of a fishing line it is allowed to mow only grass, and for other, coarser vegetation, it is imperative to use knives.

Next, you should consider in more detail the process of how to insert the line into the trimmer correctly. Indeed, it is with this procedure that many consumers often have difficulties.

Line adjustment

One of the main rules when replacing and adjusting equipment is any manipulations with the mechanism Should be carried out exclusively with the engine off and the device plug disconnected from the mains.

Perhaps these tips will tell you how to tuck the line into the trimmer as correctly as possible and, accordingly, give your site a neat and aesthetic appearance. All that is required is to correctly select the cutting material required by the type and, of course, to determine the category of the most used trimmer.

Single Barbed Trimmer Spool

Reel for single-barb lawn mowers

Many owners and experts note the ease of use and ease of refueling the bobbin with one mustache. Depending on the manufacturer, the length of the threaded line can vary from 2 to 5 meters. The end of the line is inserted into the head into a special technological groove or hole, and the winding is carried out in the direction opposite to the working rotation of the bobbin. Most reels have arrow marks on the outside of the body that indicate the direction of the trimmer reel movement.

After winding, you need to leave a free end of 15-30 cm to enhance the centrifugal force, which is decisive when removing the trimmer line in automatic and semi-automatic spools. Passing the left end through the working hole of the coil and assembling the head.

Trimmer head with two tendrils

Double flute head

After removing the spool from the spool body, we determine the number of strands for winding the fishing line (1 or 2). In principle, there is no difference between bobbins with one and two grooves, but with careless threading into the paired groove, there will be operational problems. Due to the likelihood of interlacing the adjacent line of the tool, a situation may arise when, after wear of the working antennae, it is impossible to remove new ones.

Regardless of the number of streams, a fishing line with a length of 1.5 to 3 meters is taken for refueling. Winding must be done in the opposite direction of rotation of the head, since winding in the direction of travel will lead to the fact that the line will not be removed from the reel. After the fishing line is tucked into the trimmer coil, the free ends (15-30 cm) are threaded into special holes. Next, we assemble the head in the reverse order of disassembly and check the operability. Do NOT worry if the ends of the two antennae are very different in size, because when you start the trimmer, the knife installed on the protection will cut off excess.

Preparing to wind the line

Before the winding process, it is necessary to remove the spool with line from the body. Depending on the manufacturer, power and type (electric or gasoline), there are three design types of trimmers:

-

Compact Electric Trimmers.

Straight bar trimmer

This model provides the ability to install a knife. Removing the coil in such models is done by means of two keys recessed into the coil body. To mount the trimmer knife, it is necessary to align the hole of the reel and the rod, and then insert the device in the form of a steel pin (screwdriver, iron bar). After fixing the coil, the body can be easily unscrewed by hand clockwise.

How to wind line on a trimmer reel: key points

A gasoline or electric trimmer is an indispensable tool in the arsenal of a modern summer resident or owner of his own home.

Thanks to these garden devices, even a large garden plot can be mowed with ease. After purchasing this tool and performing several mows, many people think about how to properly wind the line on the trimmer reel. For an inexperienced user, the first operation to replace it will seem problematic and time-consuming, since the developers often do not fully reflect the instructions for replacing the fishing line in the operating manual.

Winding the line to the trimmer

Measured and accurate dismantling of the spool from the spit coil makes it possible to go directly to winding the line. The design features of the head, the number and location of the fixing holes dictate the sequence of actions when performing this operation, and also determine the methods used. Today there are several types of reels, depending on the number of line antennae and the methods of threading it:

- Trimmer head with one working Mustache;

- Bobbin with two tendril fishing lines;

- Auto winding reel.

Trimmer head with automatic line threading

Types of trimmer heads

Some models on the market are fitted with a reel with an automatic winding mechanism. It is enough for the owner to properly thread and fix the ends in the head, and the winding operation will be performed by the tool itself when it is turned on. It is almost impossible to wind the line incorrectly into a trimmer with such a head, since the coil independently determines the position of the antennae. The advantages of the automatic trimmer head include the ease of threading the line, and the disadvantages are frequent breakdowns of the mechanism due to the complexity of the design and the high cost.

How to remove and disassemble a coil

Before starting the process of changing the cord, it becomes necessary for trimmer users to remove and disassemble the coil. Let’s see how to do it.

The trimmer mowing head consists of several parts: a cover, a spring (not on all models), a spool with a cord and a cover.

In trimmers, 2 options for mounting the mowing head are most often used.

Changing the line to a disc or knife

When ennobling a personal plot, park areas and other places where it is required to mow various kinds of plants, it is often necessary to change the cutting tool to trimmers. This is dictated by the fact that the standard pipe installed in the mowing head can only handle grasses. But when a bush or young growth of trees appears on the path of the worker, the fishing line cannot cope with such a task, and it needs to be changed to a more efficient cutting tool.

Trimmer manufacturers have foreseen such situations, and supplemented their products with a mass of attachments in the form of knives with several “petals” or in the form of discs, similar to circular saws.

If you replace the fishing line with a knife with several “petals”, then with such a tool you can mow both Tall grass and plants with thick and dry stems. And by changing the fishing line to a disk, the lawn mowers user becomes able to cut shrubs or small trees.

Knives and discs are installed according to the following algorithm.

- The first step is to remove, lock the shaft, the mowing head (turns clockwise) or the boot nut, if the unit has NOT been used yet.

- Place the dust or cutting knife so that it fits over the small protrusion (bushing).

For a better understanding of the tool changing process, see this.

What can be used instead of fishing line

Many users of trimmers ask themselves the question: what can be used to replace the default cord used in this kind of machines? Begin unsafe experiments by installing metal or copper wires, metal ropes or strings, and ordinary fishing line in the mowing head.

If you install a metal cable instead of a fishing line, the trimmer turns into a dangerous device Not only for the user, but also for those around. This fact is explained by the fact that during the operation of the unit, the steel cable will gradually be triggered, its ends will unravel, and small pieces of wire will scatter in different directions at high speed.

And if you accidentally hook your or someone else’s leg while working with a steel cable (wire), then a strong and deep tissue incision, and in some cases amputation of your toes, is guaranteed. The manufacturer does NOT use nylon for THESE purposes in vain, since it is light and strong enough, and when it comes off it does not fly far away and cannot cause injury.

Of course, you can use fishing line in the trimmer instead of the standard one, but this will add extra trouble to you, since it wears out quickly, tears, mows slowly and is NOT suitable for cutting tough grass. In addition, when carrying out work, a lot of time is lost to replace the broken tool more than once.

In practice, the installation of a conventional line is justified if the user is going to mow the grass near the fence, especially if he is from the netting. In this case, in order to protect the standard, and sometimes expensive, line from wear and tear, it is changed to a fishing line, which is not a complaint. Usually, in order to change the line to the line, it must be selected The greatest thickness. 2-3 mm.

Line winding algorithm

Depending on which trimmer model is used, the type, thickness and length of the line are selected. The diameter of the cord can be from 1.2 to 4 mm. It is not difficult to guess that the thicker you fill the cord, the harder and thicker grass it is able to cut.

There are 3 ways to find out which line diameter you can use on your mower.

- View information on the thickness of the cord in the instructions for the device.

- Look at the bobbin itself. It can contain information about the possible diameters of the line.

- Insert the line into the outlet. If it easily passes into it, then a cord of this diameter can be used.

The line is wound on a reel in the mowing head. Therefore, you first need to open it (this was discussed above). There are 2 ways to wind the cord.

Option

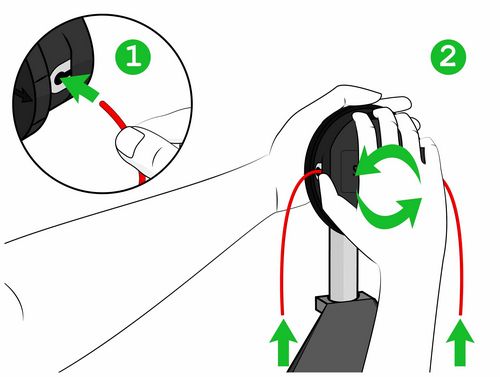

In this embodiment, the head is screwed onto the gearbox shaft. To remove it, you need to fix this shaft. To do this, in such trimmers, for example, in the Huter and Champion devices, a hole is provided through which you can insert either a thin screwdriver or a metal rod.

So, to remove the bobbin, follow 2 easy steps.

- Insert a screwdriver into the hole and lock the shaft.

- Grasp the head body and start turning it clockwise. Torque in this direction follows because the thread cut on the shaft is left.

Cord breaks

If the line breaks frequently, this may be due to the following reasons:

- Stones, small branches and other solid obstacles come across in the grass;

- Users are mowing the grass right next to the fence, and if it is mesh, it cuts off even faster “antennae”;

- Poor cord quality (it is recommended to purchase a quality one)

- The outlet holes in the mowing head are worn out, which causes the line to be erased on the sharp edges of the bushings and break off (a complete replacement of the part will be required).

How to change the line to the trimmer

The trimmer is the most common machine used for cutting grass and small bushes. This device is distinguished by its simplicity in service, simple operation during operation, and due to its low weight, even women can handle it. It is no secret that the correct selection of cutting tools is required for high-quality performance of work on mowing grass. As the latter, special cutting attachments (discs, knives) or trimmer heads with a fishing line inside are used in trimmers. Nozzles and line are expendable tools, but if the knives can be sharpened, then when the line is used up, it must be replaced. In this article, we will tell you in as much detail as possible how to properly replace the fishing line.

Second way

Some reels have a second method of securing the cord: you can charge 2 pieces of yarn instead of one folded in half. The line is replaced according to the following algorithm.

- Before you change or load a new thread into the spool, determine how many meters it will take using the method described above.

- One end of the cord Fold into a hook.

- Find the hole at the bottom of the bobbin for fixing the line, and insert the end of the thread bent in a loop into it.

- It is required to wind the cord according to the direction of the arrow to the required level, and not exceeding the coil diameter.

- Do the same for the second bobbin compartment.

- The assembly of the head does not differ in any way from the method that was given when it was considered threading the bobbin with a piece of line folded in half.

For Shtil lawn mowers, there is a very simple and quick way to change the line without disassembling the mowing head, which you can get acquainted with by looking at this.

The ends of the cord protruding from the holes in the casing can be cut to the desired length when the part is installed in the trimmer. This can be done in two ways:

- Turned on the trimmer (when rotating, the ends of the line will be cut into a knife, fixed for THESE purposes on the protective casing)

- Cutting off the excess ends with scissors so that they DO NOT touch the casing body.

The second method is used if a large diameter cord had to be supplied, and the edging knife cannot shorten it.

If a charge was made to whine into the mowing head, but the length of the protruding ends of the cord is insufficient, then they must be lengthened before starting the machine. this applies to the head with manual adjustment. However, there are cases when using a semi-automatic mowing head, when, due to the insufficient length of the protruding ends of the cord, they do NOT automatically lengthen. In this case, it is necessary to turn off the unit (on electrical apparatus, it is imperative to unplug the plug from the socket), manually press the button located at the bottom of the part, and pull out a little line. After this procedure, the cord can again be extended due to centrifugal force, if you set the maximum spindle speed.

Line problems

Users of trimmers, both gasoline and electric, sometimes have problems with the cord. “Advanced” Owners of mowers easily cope with difficulties in automotive products, understanding why this happens, and for beginners, these are problems that have no rational explanation. But in fact, everything is solved quite simply. The most common problems that happen with the line are as follows.

How to properly wind the line on the trimmer spool

Many, having worked out the factory line on the recently purchased trimmers, are trying to wind a new one, but they cannot, because they do not know how to properly wind the line on the spool (bobbin) of the trimmer. It seems that there is an instruction, but it still does not work. Let’s try in this article to deal with this issue.

So, in order to wind the line, you first need to remove the coil from the trimmer. this will be more convenient. The removal method will depend on the type of trimmer.

Removing the coil from the trimmer

On small electric trimmers with a bottom-mounted motor (when it is in the ground while working), the reels usually have two keys on the sides. Click on them and disconnect one half of the coil body from the second, which remains on the trimmer. Together with the first half, the inner part is also taken out, on which the fishing line is directly wound. When disassembling, be careful: there is a spring inside that can fly out and get lost.

On electric and gasoline trimmers with a curved bar (there is still no way to put a knife on such trimmers), you need to grab the coil body itself with one hand, and with the other hand you need to start rotating the lamb on it counterclockwise. It is he who attaches the coil to the Trimmer Bar. Having unscrewed the lamb, carefully remove the entire coil, trying NOT to lose the spring inside.

On electric and gasoline trimmers with a straight bar and a gearbox at its end (on such trimmers, in addition to fishing line, you can also install a knife), we look for a hole under the coil, insert, for example, a screwdriver into it, quietly rotate the coil until the screwdriver does NOT crawl even deeper and the coil will lock. Now steep the whole coil clockwise (since the thread is left-hand) and remove it from the trimmer. Then we disassemble the coil. It can be assembled using snaps or a twisted lamb. If the coil is on latches, then press on the sides on the base of the latches so that they bend and release one half of the coil body from the other. We just unscrew the lamb. There may also be a third type of connection between the two halves of such a coil: with it, you need to grab the lower part with one hand, and the upper part with the other, and start turning them in opposite directions. When disassembling such a coil, you also need to make sure that the spring inside is not lost.

than 200 types of trimmers in one place at the lowest prices. Click and watch

Now, having removed and disassembled the coil, we proceed, in fact, to winding.

Winding process

If your coil is designed to work with only one tendril, then it’s simple. You need to unwind 2-4 m of fishing line (depending on the size of the reel), find a hole on the inside of the reel for the fixing line, insert one end of the line there and start winding the line in the direction opposite to the direction of rotation of the reel on the trimmer. On the inside of the reel, they usually indicate with an arrow in which direction to wind the line. I wound the fishing line, we leave a small piece of it unwound to put it out. We fix this piece in a specially groove located on the inner part of the reel and designed so that at the time of collecting the reel, the line does NOT unwind. If there is such a groove, then you will have to hold the fishing line with your finger to prevent it from unwinding during the further collection of the coil. Next, we take the outer part of the coil and threading the outer piece of fishing line into the existing hole, collect and put the coil back on the trimmer.

If the coil is designed to work with two tendrils, then do the following. On the inside of the reel, we look at how many grooves there are for winding the fishing line. There may be one or two of them. If there is only one groove, then both tendrils are wound along this one groove. If there are two grooves, then each antenna is wound along its own groove. Reels with one groove should have a through hole through which the fishing line is threaded. We rewind 2-4 m of fishing line, threading it through this hole so that the fishing line sticks out equally on each side. And we simultaneously wind both tendrils of the fishing line in one direction, opposite to the direction of rotation of the coil to the trim tabs and coinciding with the direction indicated by the arrow on the inside of the coil. We leave a little of the fishing line unwound, the resulting ends We fix in the Special grooves, and if they are not there, we hold them with our fingers. Threading both ends into the existing holes on the outer casing of the coil. We collect the coil and fasten it to the trimmers.

If there are two grooves, fold a piece of fishing line 2-4 m long in half. Insert the loop obtained at the place of the fold into the groove between the two grooves, and simultaneously wind both ends of the fishing line along its own groove. Further actions are similar to the previous option.

There are also spools in which the fishing line is threaded through a through hole on the inside. After that, the ends of the line, and not winding, are threaded completely through the holes on the outer body of the reel, assemble the reel and begin to rotate the button, which is usually pressed, in order to release the line during operation as it wears out. Turning the button. the line itself is wound inside. In this case, twisting it in the “wrong” direction will NOT work, since it can only rotate in one direction. If you get used to it, you can wind fishing line on such a reel without even disassembling it. you just need to combine the through hole of the inner drum with the holes on the outer body of the reel, and then thread the fishing line through them.

That’s all on this issue. Happy winding!