How to install a grinder on a rack. Materials and tools to make nozzles for a grinder

How to make a rack for a grinder at home

Bulgarian in the household is an indispensable thing. Quickly spins, polish, cut off the desired workpiece with even edges. However, her character is quite obscure, the speed is high. It is quite difficult to hold in your hands. If it starts to vibrate, then talking about the accuracy of work is no longer necessary. A tripod or a stand for a grinder will help to cope with a powerful tool.

Grinding Disc Storage Rack

Of course, you can buy a rack in the nearest construction store, but often, taking into account the power of the available grinder, you have to partially modify. High.Quality models are expensive, and Chinese analogues with stamping of sheet material are unreliable, unstable, quickly flying apart from strong vibration of the machine. You can make a rack with your own hands, the benefit that drawings, diagrams, master classes, photos today have plenty. The home.Made can be made by conscience, then cut the blanks with even edges if necessary. In particular, the load on the hands, thanks to reliable clamps, fasteners, will be significantly reduced.

Necessary tools and materials

The reliability of the planned home.Made rack depends on such a criterion as the stability of the base. The design of the manufactured rack must satisfy the needs of factors such as the strength and stiffness of the base. Do not forget that when working, the angular grinding machine has a sufficient level of vibrations that should not affect the design of the rack.

Below will be considered a phased process of manufacturing a rack for a grinder, so first you should stock up on the following type of materials:

- Steel profile: 25252.5 mm.

- Steel profile: 40202.5 mm.

- Steel sheet 4-5 mm thick.

- Ballic bearings in the amount of 2 pcs.

- Diameter bar, which is equal to the inner diameter of the bearings used.

- Rod with a diameter of 10 mm.

- Metal tire 204 mm.

- Nuts and bolts.

In addition, you will need to make sure that a number of the following tools are available: Ushm, Drill, Rozhniki and Welding apparatus keys. If there is no welding machine, then the task will become somewhat more complicated, but at the same time it will be necessary to perform all the connections using bolted fasteners.

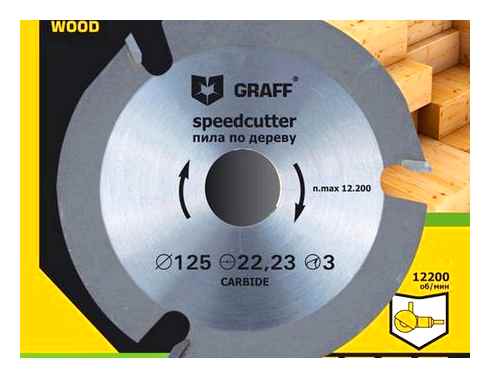

The grinder can be used with a circle diameter from 125 mm. Must this tool must be professional purpose. The manufacture of the considered simple design should be carried out directly for the existing tool.

Homemade bed for Ushm

Initially, it is required to prepare the appropriate drawings, on the basis of which the device will be made.

Drawing of the manufacture of beds for the cutting machine of the frame type

The drawing above is an example, therefore, in each case, you should adapt your schemes to the grinder available at the disposal. The process of making a home.Made bed for a rack for a grinder looks as follows:

- First, workpieces are prepared in accordance with the preliminary drawing.

- A sheet of steel is prepared, which will play the role of a load.Bearing platform.

- Continuing the manufacture of a bed for a grinder with your own hands, it is required to cut the role of a pendulum lever, to weld the axis. Using this axis and two bearings, one part of the mount to the countertop will be fixed.

- To fix the body of the existing tool, it is necessary to make a kind of bracket-hood, from a piece of a steel tire curved in a P-shaped shape. Drill two holes in it, at the level of holes for an additional handle on a grinder. With this, we will reliably fix the heapon by the gearbox to the mobile part of the rack.

- The device is made for additional fixing the tool. For this, a metal frame is made, which additionally fixes the grinder body, the gearbox above. It can be made as you wish. The main thing is that she has reliable stops and clamps.

- After the tool is mounted, you can fix the frame to the pendulum stance. Previously, you should put the bearings on the shaft on both sides, and then weld one of the parts (internal or external) of this hinge to the countertop, and the second to the frame in which the Bulgarian is fixed. As a result, the mobile part of the machine should turn through the bearings relative to the bed.

- A protective casing is made, which can be made from the remaining segments of the metal. The casing is an obligatory attribute of the device in question, since it is able to protect not only from sparks during sawing, but also from the possible consequences of the disk rupture.

- You can also make a counterweight from the spring. The degree of tension of the spring must correspond to the weight of the used lotion. Previously, in order to fix the spring, the corresponding stops should be welded to the bed and pendulum.

- After everything is ready, you can carry out a trial launch of the device. At a trial start, all flaws are investigated, which should be eliminated without fail before starting work.

- At the final stage, it is advisable to attach a ruler to the bed, as well as stops for blanks.

As a result, a bed is obtained on which the grinder needs to be installed, and to start work on sawing blanks and materials. The above method of manufacturing a rack for a grinder is approximate, therefore, in each case, it is necessary to navigate the existing material and tool. For example, instead of bearings, you can use door awnings, and the design of the frame for a grinder can be made from reinforcement.

TOP 6 drawings with explanations for the manufacture of a home.Made cutting machine for metal

It is not difficult to create a typical circular saw if you fix the grinder under the desktop with a slot. You need to think over the guide system for high accuracy of the movement of workpieces.

Look at the picture number 1, what does a typical cutting machine look like. Here the Bulgarian is fixed on a movable hinge, which complicates the structure somewhat. This scheme has several advantages:

- Simple and reliable fastening of the workpiece;

- A significant weight of the upper part will help to use lower efforts when cutting blanks;

- If necessary, a manual electric tool is dismantled to perform working operations in normal mode.

Read also: What is an ultrasound bath

Such a power frame is collected from standard steel corners, pipes with a square section. Welded joints are obtained more durable. But it is also acceptable to create a prefabricated design using screws and nuts.

Such a project can be used as an example for the manufacture of a high.Quality cutting machine for metal. Equipping with wheels facilitates the movement of heavy product.

Look at the picture example of a wood processing machine. This technique is suitable for cutting large blanks. It is necessary to choose a grinder of sufficient power so that it is enough to work with large diameter disks. On the reverse shoulder of the lever (instead of an electric motor, as in a drawing), a load is fixed. The weight and place of fastening is selected in accordance with the personal requirements and features of a specific design.

This machine can be redone for fixing in the lower part of the Ushm. If the longitudinal sawing of wood is supposed, such an engineering solution will be optimal.

Picture number 6. The design of the factory end saw on wood

Look at the picture number 6. It can be used to make a set of drawings with your own hands. It is recommended to pay attention to the spring, which raises the working unit to the original state. A turning table with measuring devices will help create a machine with increased admission requirements.

In the manufacture of this part of the machine, thick metal is used. This solution increases the cost and weight, but extends the service life, increases reliability, improves fastening of hinged elements and processing accuracy.

Photo racks for a grinder with your own hands

Sharpening of the chainships with your own hands: sharpening the circuit and recommendations for building a sharpening device (125 photos and videos)

DIY drill.Sharpening device. Home.Made devices for sharpening the edges of the drill (85 photos and videos)

Do.It.Yourself revolutions regulator: detailed instructions How to make, schemes, drawings and examples (95 photos video)

DIY MTZ repair: disassembly, repair, restoration, adjustment and assembly of Minsk tractors (105 photos)

Do.It.Yourself branches with your own hands: projects, instructions how to make and tips from what to make a home.Made chopper (135 photos)

DIY circular saw: how to make manual and semi.Automatic circular (80 photos)

Read here. How stickers are printed?

Photo racks for a grinder with your own hands

Sharpening of the chainships with your own hands: sharpening the circuit and recommendations for building a sharpening device (125 photos and videos)

DIY drill.Sharpening device. Home.Made devices for sharpening the edges of the drill (85 photos and videos)

Do.It.Yourself revolutions regulator: detailed instructions How to make, schemes, drawings and examples (95 photos video)

DIY MTZ repair: disassembly, repair, restoration, adjustment and assembly of Minsk tractors (105 photos)

Do.It.Yourself branches with your own hands: projects, instructions how to make and tips from what to make a home.Made chopper (135 photos)

DIY circular saw: how to make manual and semi.Automatic circular (80 photos)

Read here. Hand cutter with your own hands: Detailed instructions How to make a milling machine (video and 100 photos)

Assembly of a pendulum machine

The design of the pendulum machine consists of three main nodes:

- Stannaya is the simplest element of the machine for a grinder. The node is made from a steel slab with a thickness of at least 10 mm with the stands from below. You can cook the frame from the profile pipe, and on top of the leaf metal 3 mm thick. A bracket with a hinge of the pendulum mechanism is fixed to the bed.

- Pendulum. The main working mechanism of the machine. The design in the form of the letter “T” is welded from the profile pipe. By one end, the clamp for a grinder is fixed, and the other side of the pendulum is attached to the articulated mechanism.

- Clutch for a grinder is made of metal brackets. The structure is firmly fixed to the pendulum through the console.

To make a machine, you will need a drawing or at least a simple scheme. One option is presented in the photo. The dimensions of the machine will have to calculate your dimensions available to the existing grinder.

For the correct calculation of the size of the machine nodes, the dimensions of the grinder are first measured, and then the distance between the holes on the gearbox body. When designing a pendulum, it is important to minimize the distance between the cutting disk of the grinder and the articulated mechanism. This will give the rigidity of the machine, which will allow you to perform a more even cut.

After developing the drawing, they begin to manufacture all the machine nodes:

- According to the size of the metal scheme, blanks are cut for all nodes. First, the bed is made. It must be taken into account that during the cut, the disk of the grinder will fade into the slot of the plate. If you cook a rectangular frame from the profile for the bed, and sew a steel sheet on top, then a niche forms from below. Space will be enough to enter the cutting disk. In the manufacture of a bed in the form of a stove made of steel 10 mm thick from the bottom, you need to weld the stands.

- Next, proceed to the manufacture of a pendulum. A axis for the hinged joint bearings is welded to the end of the workpiece from the profile pipe. On the other side of the pendulum, you need to make a clamp for a grinder. To do this, from the steel strip bend the bracket in the form of the letter “P”. It should enter the gearbox of the grinder. In the lateral shelves of the bracket, holes are drilled for a bolt connection.

- The second part of the clamp is bent from a steel rod. You should get a clamp in the form of the letter “P”, inside which the Bulgarian housing is included. At both ends of the clamp, the thread is cut. The clamping bar is cut off from a steel strip 5 mm thick. The holes at such a distance are drilled along the edges of the bar that they include the threaded tips of the clamp.

- Both P-shaped mounts, that is, clamp and bracket, are fixed on the console. The part is a rectangular steel plate, which, together with clamps for a grinder, is further fixed to the second end of the pendulum.

DIY Drill and Grinder Rack. Tool Storage

- The next stage is the assembly of the hinge. Two bearings are planted on the shaft welded to the pendulum. Nests for them can be made from a piece of pipe of the corresponding diameter. Cut off the rings are planted on the clips of the bearings. Now this node must be fixed to the bed.

- The nests will only have to be welded to the stove without taking out the bearings. The node is placed with an indent 5-6 cm from the edge of the bed. During welding, the bearings are covered with a wet cloth or watered with water to avoid overheating.

- The lever of the pendulum with the hinge is ready. Now the time has come to its second end to fix the console with clamps. The grinder itself on the pendulum can be fixed so that the rotation of the disk is carried out “from itself” or “to yourself”. Here, every master chooses at his discretion.

- So that the pendulum with a grinder does not arbitrarily fall, provide a return spring. She should act in stretching and be very elastic. The spring is fixed with loops welded to the bed and pendulum.

- The machine is almost ready. It remains in the stove to make a slot for the entrance of the disk. There is even nothing to measure here. A grinder clamped in a pendulum is turned on and cut a slap with a cutting disk. Initially, the slot will turn out to be thin. To expand it, a thick disk is put on a grinder, after which they repeat the procedure.

4-1/2″ Angle Grinder Rack

During the performance of the slot on the bed, the machine test occurred. Only the last node is missing. A latch for blanks. There are many options here. You can just fix small tesa to the stove.

As an option, from a piece of a profile pipe, an emphasis is welded to the bed, and opposite it they fix a nut with a screw. It turns out a good screw clamp.

If you fix the metal ruler on top of the stubborn bar, it will be convenient to cut the workpiece on the desired size.

Shock absorbers’ machine

A reliable machine for a small grinder will be obtained from old car shock absorbers. The principle of its action is similar to the pendulum, but the design of the nodes differs, which allows you to adjust the departure of the cutting power tool along the guide.

Review of possible options for making racks for a grinder

Stand for Ushm, as mentioned above, is a simple mechanism, but such a statement applies only to the simplest designs. Having examined the whole variety of factory.Made and self.Proceeding devices, three main types of devices can be distinguished:

- The simplest pendulum type;

- A pendulum mechanism with a rotary node for cutting a grinder at different angles;

- Stannia for a corner grinding machine with the so.Called length.

The most common and easy to manufacture a home.Made machine for a grinder is built on the basis of a pendulum console. With the help of such equipment, you can easily saw different pipes of both round and profile section, as well as rods, reinforcement and metal parts, the thickness of which does not exceed the thickness of the working part of the disk, and the cut length can be adjusted by moving the workpiece along the village. Features of the device for Ushm:

- Simplicity in the manufacture and work;

- High reliability, since only one mobile knot is used here;

- Such equipment will not be able to saw at an angle;

- It is difficult to cut leaf material: small accuracy and injury hazard.

The device of a bed with a rotary mechanism for Ushm allows you to carry out all the above cutting operations, but the function of sawing a grinder at different angles is added. There is also a pendulum node, and, besides it, the pendulum support itself can turn, or the emphasis is rotated, which holds the workpiece. Features of the device:

- Expanded capabilities of Ushm metal;

- Relative simplicity of design;

- It is more difficult to get an accurate perpendicular and corner cut due to the rotary mechanism and the need to calibrate the angle.

Testing a grinder with a stand

Now you can, moving the lever behind the influenza, it is easy to change the position of the grinder relative to the desktop, after which, thanks to the Ushm spring, it returns to the starting position.Submit the voltage to the tool and check it in the case. Using a corner directly mounted on the table, we cut long lashes (pipes, corners, channel, etc. D.).

If the length of the length is necessary to saw at an angle of 45 degrees, we use as a guide the second corner.

Folding them along the cutting line, and applying the angler to the inner corner, we are convinced that it is exactly 90 degrees.

Ushm stand. Advantages and disadvantages

An angular grinding machine (Ushm or Ushma), which is unofficial, “Bulgarian” is one of the most common universal tools designed for abrasive processing of various products made of metal, wood, stone. She is “Bulgarian” because she first appeared in the USSR from Bulgaria, where it was produced at a factory in the city of Lovech. To carry out various accurate work by a grinder, many craftsmen do a stand for the Ushm with their own hands.

Block: 1/6 | Summer characters: 471Source: https: // spacnavigator.Ru/instrumenty/bolgarka/sdelat-stjku-dlya.Oshm.HTML

It will be needed for a cutting machine

Install them on a rectangular plate. The distance between them is a little more than the thickness of the width of the profile.

So that the stand has more weight and is stable, we install all this on a rectangle from chipboard. Of course, instead of all this, you could immediately take a thick steel plate.

We fasten the steel base to the wooden one in several places, after making holes in the steel plate.

To attach the handle, it is necessary to drill a through hole in all three segments. See photo:

So that the Bulgarian itself can rise up to the starting position, you need to enter a return spring into the system. Similar can be found in the brake system of the car.

Drill two holes and hang the spring. If the lifting force is insufficient. Enter another spring.

Angle Grinder rack/holder v2

Now how to hang a grinder, you need to make a hole in the handle from the profile. Previously try on the grinder to the installation site.

At any time, the tool can be removed and used as usual.Such a stand will definitely come in handy. It will facilitate your work when we say, you will need to make a lot of vertical cuts.A useful thing, a minimum of costs and time. The effect is obvious.Also, for refinement, it will not be superfluous to make a downward limiter. Thank you for your attention!

Features of the use of Ushm as a saw

It will not be superfluous for your safety that not all types of disks can be used directly for a grinder. First of all, this applies to saws for sawing wood, which have significantly lower speed indicators than are used in almost all grinder.

The exception is special wood discs designed for standard turns of corner grinders.

It’s good if your tool has a speed adjustment. And if not, then before using your UShM as a trim on wood, make a simple The regulator of its revolutions Based on the KR1182PM1 chip, or close to it according to this scheme.

Use a simple rheostat for this is not worth. Together with a decrease in speed, it will also proportionally reduce the power and torque of the tool. And for the grinder itself, use in such operating modes is harmful.

We strongly recommend that you provide your rack button of emergency shutdown tool, because access to the shutdown button after installing the grinder in the rack may be difficult. And even securely fixed in the adaptation of Ushm. The tool is quite traumatic.

You can put such a button in an incision of the wires of its power, but it is better to tear it off the supply of the electric massagistral, because removed from the bell rack becomes an ordinary mobile tool with all its advantages.

Advantages of a pendulum saw

- Bulgarian;

- Electrician;

- Drill or desktop drilling machine;

- Epoxy adhesive;

- Welding machine;

- Wrench, pliers;

- Roulette, pencil.

Production of a rack with a turning table

The stand with a turning table is most difficult to manufacture, but in the end it turns out a multifunctional machine. On it you can reliably fix the part of any form at the right angle to make a perfectly even cut. To understand how to make a rack, let’s look at what components it consists of:

- The bed is welded from a steel corner with a cross section of 50 mm, channel or profile pipe. The design serves the support frame of the rack. In the future, the bed is put on a workbench, table or any solid stand with a flat surface.

- The universal rotary mechanism of the round shape is fixed to the bed with bolts. A flywheel with a screw mechanism and a countless limb allows you to adjust the position of the table. If the rotary mechanism could not be got, it is made from the car hub.

- The countertop is cut out of sheet steel with a thickness of at least 10 mm. The stove is attached to the rotary mechanism.

- Tits are fixed on the countertop to fix the blanks. It is advisable to use the console to balance the overturning moment from the grinder.

- Star from the profile pipe is welded to the bed. In the future, a hinge mechanism with a holder for a grinder will be fixed to it.

- As a return mechanism, two elastic springs are used, acting in stretching. They return the grinder to its original position, preventing the detachment of the detachment of spontaneously resting on the countertop.

- The control lever is attached to the rack through the hinge mechanism. A grinder is fixed to it with a bracket.

- A feature of the rotary table is the line of transport. The measuring tool is attached in the corner of the countertop. It allows you to count linear and angular movements.

All sharp corners of the structure must be rounded. Especially. This applies to the countertop. When turning it, while working, there is a threat of injury to sharp corners.

Summarize

What needs to make a rack for a grinder with your own hands.

- 2 meters of a profile pipe, provided that you have not found the base for your rack anywhere, an ordinary metal frame in size 400×300.

- A spring for creating a counterweight can be bought in a store or take from an expander.

- A couple of bolts and a few tubes to make some kind of a bearing, if you do not want to suffer with a rotation knot.

- Metal sheet 400x300x3 for a reliable base.

And in conclusion, several videos of examples of how to make a bed for a grinder for an hour with step.By.Step instructions and a detailed description of the size. Since the video is intelligibly told with explanations of the sizes of details, you can do without a drawing.

Simply, quickly from improvised means and that trash that is in almost every garage. Residues of a profile pipe, a metal frame and several bolts. Yes, you can’t do without welding in manufacture.

But this is not a hindrance, you can cut the workpieces and ask the welder for the wrong price to cook everything. In any case, it will cost much cheaper than an expensive stand from the store, and in quality no worse.

Safety precautions

As when handling any electrical tool, you should follow the rules of electrical safety. You can not work in rooms with high humidity. When installing a machine on the street, it is advisable to build at least a temporary canopy of precipitation over the workplace.

Like any cutting tool, Ushm, even fixed in the machine, requires strict observance of safety precautions. The work without a protective casing around the disk is completely unacceptable. And also necessarily the use of protective glasses or transparent shield.

Many neglect gloves. And completely in vain. Sparks flying out of saw stone only seem small and non-hazardous. Crumbs of abrasive and processed material fly like bullets and can penetrate deep under the skin.

You can find out about how to make a metal rack for a grinder with your own hands.

Block: 4/4 | Summer characters: 2285Source: https: // Stroy-podskazka.Ru/instrumenty/bolgarka/izgotovlenie-stjki/

DIY stand for a grinder

Good day to all! So I decided to make myself a homemade rack for a grinder.

Homemade has a universal design, it can be installed anywhere, separately from the base.

A home.Made stand works fine, due to the node on the bearings, there are no backlash at all!

Author of the Homemade: Andrey Yangbaev.