How to line the Stihl trimmer

Coil with two working tendrils

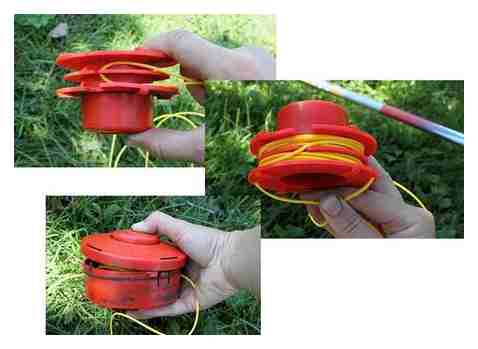

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

Working with the stihl fse-60 trimmer head

- one groove. both antennae are wound together in one groove;

- two grooves. each antenna is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the rod side. inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the spool is closed and attached to the trimmer bar.

The difference between the line winding in two-groove spools is that initially a 2-5 m long line segment is folded in half (to determine the middle bend), and the bend loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The video below will clearly show how to thread the line into the trimmer spool and wind it correctly. this operation is not difficult and with some patience it will certainly be crowned with success:

Coil with one working tendril

The simplest option and uncomplicated sequence of actions:

- The dimensions of the reel and the length of the original factory winding determine the recommended length of the line for winding. 2. 5 m.

- One end of the line is inserted into the fixing technological hole located inside the spool.

- The fishing line is wound on the drum in the opposite direction of the spool rotation on the trimmer product. as a rule, on the inner side of the reel, an arrow indicates in which direction the winding is carried out.

- A small section of the line is left free to lead it out. it is fixed in a specialized groove on the inside of the bobbin, designed to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole in the outer part of the reel.

- The bobbin halves are assembled and put on the trimmer bar.

Single-barbed trimmer spool

Single-barb lawn mowers reel

Many owners and specialists note the ease of use and ease of refueling the bobbin with one mustache. Depending on the manufacturer, the length of the threaded line can vary from 2 to 5 meters. The end of the line is inserted into the head into a special technological groove or hole, and the winding is carried out in the direction opposite to the working rotation of the bobbin. Most reels have arrow marks on the outside of the body that indicate the direction of travel of the trimmer reel.

After winding, you need to leave a free end of 15-30 cm to increase the centrifugal force, which is decisive when removing the trimmer line in automatic and semi-automatic spools. We pass the left end through the working hole of the coil and assemble the head.

How to thread the line into the trimmer spool video

The warranty production of the factory trimmer refueling will inevitably require line replacement. Having a very rough idea of how to thread the line into the trimmer reel on their own, beginners are reluctant to take up this business. However, with some skills, mastering this simple science does not present any difficulties, and the similar instruction presented below will make this process as easy as possible.

We carry out the winding of the fishing line

Slowly completed disassembly of the spool-spool without losing its spare parts allows you to proceed to the main task. winding the fishing line into the reel. Technological features of the spool design and the number of working antennae determine the sequence of actions.

Method 2. two segments

Two coiled line lengths

fundamentally no different from the method The only difference is two wound pieces of fishing line, instead of one.

The end of each segment is folded

The end of each segment is folded.

Two special fixing sockets

There are two special fixing sockets on the coil (see picture above).

We start winding the line

They hook it with a hook formed earlier on the fishing line, and begin to wind the fishing line.

Winding is carried out in a special order

The winding must be carried out in the following order: first the lower line, i.e. the one that is closer to the fixing holes at the bottom of the coil, and only then the top one, i.e. the one that will overlap the bottom section.

The bottom line is reeling

The tips are cut into the holes in the trimmer spool body. They are pulled up until they click, which means that the line has come out of the latches.

The tips are threaded into the holes in the trimmer spool body

The coil is fastened into the body. The line in the spool has been replaced.

The line in the spool has been replaced

Automatic line winding on a spool

There is a type of reel in which the automatic mechanism winds on its own. from the user it is enough only to correctly fill the line. The fishing line is passed through a hole on the inner part of the body, its antennae without winding are passed through the hole on the outer body, the reel is assembled, and when the winding button is rotated, the fishing line inside is wound independently. In such a spool, it is impossible to make the winding wrong: the mechanism itself will determine the correct direction, since it can only turn in one direction.

A trimmer is a necessary and useful tool for a summer cottage and a private house. Many people own and actively use it, but not everyone knows how to replace the line in the trimmer, especially at first.

In this manual, we’ll walk through the entire replacement process step by step. Looking ahead, there are two ways to line the trimmer spool. There is no fundamental difference. the difference lies in the fact that in the first case one line will be refueled, folded in half, and in the second there will be two such lines.

Briefly about the line

Taking into account the models of the tool, the thickness of the line is 1.2-4 mm. There are such configurations of it:

- round. the most durable;

- curly. for soft grass;

- twisted or serrated. for thin grass;

- professional, not suitable for all instrument models.

When changing the cutting thread, choose the one that suits your trimmer type. Preference should be given to specialized. Before tucking the line into the trimmer spool, it is best to soak it in water for half an hour. Then it will become more elastic and stronger.

How to tuck the line into the trimmer so that working with it does not get tired

Many summer residents use a trimmer to combat weeds. a scythe with an electric or gasoline engine. It is convenient when working in hard-to-reach places for a lawn mower: near fences, flower beds, houses, in a garden on narrow aisles, and can cut small branches. The main element of this miracle technique is an ordinary fishing line, wound on a reel. The device is simple, but the cutting part wears out quickly and needs to be replaced. And the question of how to fill the line in the trimmer worries many owners of summer cottages.

How to quickly remove the coil from the tool

Before the thread is wound on a bobbin, it must be removed. over, the removal methods depend on the characteristics of the instrument. On trimmers with a motor near the ground, the reel has two side buttons, when pressed, part of the body is separated together with a device for winding the thread.

On tools with a bent rod, the lamb on the device is moved counterclockwise; having disconnected it, they remove both the bobbin and the spring inside it. On trimmers with a straight bar, fix it with a screwdriver, rotate it clockwise and remove it. Then the device is disassembled either using latches or by moving its parts in different directions. Take out the spring from the coil.

Threading the line into the trimmer

The main question is how to properly wind the line on the trimmer reel, securely fixing it there?

In the case of a device with one antenna, up to four meters of fishing line are unwound, inserted into the hole inside it, fixing the fishing line, one end of it and moved in the direction indicated by the arrow. The end of the thread is fixed in a groove inside the bobbin so that it does not unwind during assembly. If there is no groove, then this free end is fixed with a finger. Then the coil is assembled.

How to thread a trimmer coil if it has two antennae? In this case, they check how many grooves there are on it. one or two. In the first case, both antennae are directed into a common groove, if there are two of them, then each of them into its own. 2-4 meters of thread is passed through the hole in such a way that the free ends of the thread are of the same length, and twist the bobbin in the direction of the arrow-pointer. The ends of the thread are inserted into the grooves or held with a finger, the device is assembled and attached to the trimmer.

In a spool with two grooves, the same piece of thread is folded in the form of a loop, sent to the groove between them and the ends are wound at the same time. Then repeat the previous assembly. With semi-automatic winding, the bobbins operate as follows. The fishing line is passed through the hole inside, its ends are fixed in the holes on the body, collect it and press the button. This allows the thread to be easily wound in the correct direction.

It is important to remember that the cutting surface must be protected from hard objects so that it does not wear out. Otherwise, it will be necessary to constantly stop and, having removed the reel, replace the used line. Keep your job fun and enjoyable!