How to lubricate removable perforator cartridges. Conclusion

How to lubricate a drill drill

Greetings on my site! This article will talk about the lubrication of the perforator. The operation of this tool requires not only a simple careful attitude. Be sure to periodically lubricate the gearbox and cartridge.

At the same time, the gearbox, of course, is already coming from the factory. But over time, the lubricant leaks somewhere, somewhere dries. In addition, it is intended only to reduce friction, and not to eliminate it. Therefore, one way or another, and the details still rub against each other, which is why fine metal dust is gradually formed, which remains in grease.

As a result of such mixing of metal and lubricating material, the properties of the latter are gradually lost and the wear of the parts is accelerated.

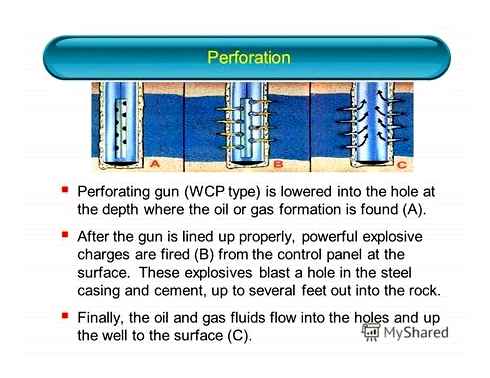

The cartridge from the plant goes dry. Here, in fact, not the cartridge itself is smeared completely, but only its place, which is in contact with the drill, since it is in it that severe friction occurs, without reducing which the cartridge itself and the tail of the drill itself can be damaged.

So, below, consider how and how to lubricate these elements. The SDS perforator will be considered with a horizontal location of the engine, since it is they who in the vast majority of cases are used by home craftsmen, and the article is mainly written for them.

Features of the selection of lubricant for the gearbox, drill, cartridge

Lubrication is a substance designed to reduce the friction force between the details interacting with each other. Of course, friction is partially left, and when operating the tool, in contact of structural elements continue to wear out. But in the presence of lubrication, the process is significantly slowed down compared to friction “on dry”.

Lubricants are synthetic, mineral and semi.Synthetic. The second variety is made from oil. She quickly loses its operational characteristics, it is more often required to change.

The main parameter of lubricant is the degree of its viscosity. Manufacturers of perforators in the operating instructions for them recommend using a lubricant with a certain value of this characteristic to care for their tools.

Each brand of lubricants has its own technical characteristics that should be taken into account when choosing. To lubricate the gear gears, cartridge, and the barrel of the nozzle, only varieties of compositions suitable for processing these parts are used.

To lubricate the passage of the perforator, it is recommended to use gearbox oil. It is poured through a special hole in the case in the amount required according to the instructions. In this case, it covers the interacting details, filling out the crankcase. Punch oil should be a liquid consistency.

Also, the transmission mechanism is lubricated with special plastic compounds. But it must be borne in mind that not all equipment can work normally when using substances with such a consistency. If the gearboxes (partially or completely) are plastic, then it is possible to use silicone lubricant, for example: 220-R Silicone DBC or HVS-100 Silicone #3 from Huskey.

To reduce friction between the tail parts of the nozzles and cartridges, it is necessary to use compounds of a thick consistency, which indicate that they are intended directly for drilling. If there are no such, then you can use a graphite analogue. But he takes heat worse than a special composition. Thick varieties of silicone lubricants are also used for cartridges.

Recommended lubricants

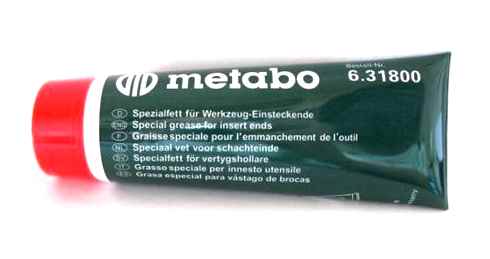

Lubrication can be used as proprietary (from manufacturers of perforators, for example, Hitachi, Metabo, AEG, Bosch, Bosch, Interskol, Bison), and from companies involved in the release of lubricants (XADO, Ravenol, Shell and others). The most popular companies with a demanded product range are presented in the table below.

| Company manufacturer | Suitable assortment | The appointment of lubricants |

| Bosch | 3605430008, 1615430012 | Perforator oils |

| 1615430005 | Reducer oil | |

| 1615430010, 1615430009 | For the tails of nozzles | |

| 1615437512, 1615430014, 1615437511, 1615430015, 1615437509, 1615430019, 1615430016 | Perforator lubricants in various packaging | |

| Makita | 181573-3 | For drill |

| 042024-0A | SDS tool gearboxes | |

| 183477-5, 042005-4A | SDS devices | |

| P-08361 | SDS MAX tools gearboxes | |

| LubCon | Thermoplex Aln 250 EP | Gear lubricant |

| Thermoplex Aln 1002 | for perforators | |

| Turmogrease NM 4602/0 | Universal composition | |

| Nanothek | MetalPlak Electra | Treatment of the tail parts of nozzles |

| Metabo | 631800000 | Lubrication of drills |

| Bison | Zubble expert 60 | Processing of the shanks of the nozzles |

| Zubble expert 125 | ||

| Zubrov ZSB | ||

| Interskol | B9000327 and B9001698 | Small smearing |

| Prorab | 0125 | Plastic composition designed to process the tail parts of nozzles |

| Kress | 98035301 | Small smearing |

| Different manufacturers | Litol-24, Litol-24 lux | for lubricating the gear ratio and equipment |

When using a tool, the quality of which is confirmed by a special certificate, only the lubricant of the products indicated by the manufacturer should be used. The use of other materials will lead to a loss of the possibility of warranty repairs and maintenance of a perforator.

Some may have a question: whether the lid is suitable for lubrication of the perforator? It is associated with the fact that this lubricant in terms of its characteristics is inferior to specially designed compositions from well.Known firms. Litol can be used, only it will need to be changed more often. The best grease option is the composition specified by the manufacturer. There will be no problems when using it, in t.H. With warranty service.

Why should you make a lubricant

Perforator is a mechanism inside of which there are many mobile details experiencing heavy loads. To figure out why the perforator needs lubrication, we will figure out the appointment of lubricating substances. Lubricants are entered into the design of the unit for the following purposes:

- Reduce friction. With a decrease in friction, the service life of parts increases, so it is necessary to lubricate almost all movable nodes and mechanisms, except for the inside of the electric motor (rotor or anchor rotating inside the stator)

- Increase heat and increase heat. During the friction of the parts, they are heated, to fight with which lubricants are intended

- Protecting the mechanism from the penetration of dust and moisture from the outside, as well as the detention of metal dust and particles that are formed during friction

The presence of lubricant not only reduces the friction of the parts, but also increases the efficiency of the mechanisms. It is on the frequency of preventive work that it depends on how much the perforator can last.

It is interesting!The cartridge and the tail of the nozzles need lubrication, which is done to reduce friction, as well as to reduce heating. Indeed, in the process of working, the nozzle of the cartridge with the tail part is in contact, which quickly heat up.

Features of graphite lubricant for a perforator

Plastic graphite lubricants are increasingly used in perforators. They are created on the basis of graphite. One of the forms of carbon with the addition of calcium oil and soap thickener. They meet all the requirements for anti.Adhesives for the punch reducer, but also have disadvantages:

- Due to low temperature, melting calcium thickener;

- For nodes with high accuracy of manufacture, they are not in the best way. Graphite molecules disrupt the geometry in places of contact with metal at a microscopic level, which leads to accelerated wear of parts at high speeds.

What details in the perforator need lubrication

There are main details that need mandatory preventive maintenance.

Sights of nozzles

Sights of working tools of the tool smell whenever you have to install them. Carefully wiped before that. With intensive use of the tool, you need to watch and control the degree of lubrication of the landing site of the nozzle. There is no need to apply too much oily composition. Why this cannot be done? The lubricant will flow out, sprinkle from a rotating cartridge, as a result will be on working surfaces that are difficult to clean. The drill will rotate slower.

Gearbox

After the engine, the main in the perforator is the gearbox is considered. It works in conditions of constantly changing speed of rotation, severe friction, increased heating, penetrating small contaminants and dust. After prolonged operation, a lubricant is necessarily applied to the inner surfaces of the gearbox. This will allow protect the shafts and bearings.

Cartridge

This part has no protective coating. Before starting to work on landing surfaces, they are introduced under the replacement tool 1-2 g of cooling lubricants. Otherwise, due to shock loads and large friction, the cartridge will break. The layer of the composition will not let small particles and dust penetrate into the internal device.

Than to lubricate the punch

Different types of lubricants are used to lubricate the gearbox and a cartridge with drill.

Lubrication for the gearbox

A special lubricant is used here, which should be called. Gearbox. It can be like under the brands under which the Perfs themselves are produced. Makita, Bosch, Aeg, etc.D. But it can also be released by a company that is engaged in this type of product, for example, Ravenol, Shell, XADO, etc.

Some use simple lilet or salutol for these purposes. But compared to special lubricating products, they dry faster, and they do not eliminate friction as it should.

Lubrication for drills

Everything is exactly the same here. Special lubricants for this purpose are called. For drills. And are also usually produced by the same firms that do punch.

For lack of special lubrication, you can use graphite. But it does not so well remove the heat from the shank, but this is important, since sometimes with prolonged work the shank happens and is flattened, which is why it is difficult to extract later.

How often you need to lubricate the tool

The tails of the nozzles should be smeared with each installation, having previously wiped dust or other pollutant. If the work is carried out intensively, then you need to visually control the degree of lubrication of the seat of the nozzle used.

The perforator works for different users with different intensity: some use it every day, while others only occasionally. Therefore, there is no unequivocal answer about the regularity of introducing or replacing lubricants. To decide on the need to replace lubrication in the general case, you need to FOCUS on the following:

- The intensity of the use of the tool;

- Recommendations set forth on this issue in the instructions for the perforator;

- Warranty service period.

What manufacturers produce grease for perforators

The use of branded lubricants for a perforator is the best option, as this prevents the tool breakdown. Several world.Famous brands are represented on the market: Bosch, Makita. Their assortment allows you to choose the right tool without any difficulties. And also on sale you can find more budget options: Intercker, Diold, Ermak.

The assortment of this manufacturer is quite wide. High quality Bosch lubricants:

| Appointment | Range |

| Perforator oils | 3605430008, 1615430012 |

| Reducer oil | 1615430005 |

| Cauldron of nozzles | 1615430010, 1615430009 |

| Perforator lubricants | 1615437512, 1615430014, 1615437511, 1615430015, 1615437509, 1615430019, 1615430016 |

Ermak

Domestic manufacturer, in the assortment of which different models of punch and lubricants are presented to them. Products are of good quality and moderate price.

Makita

Japanese manufacturer who provides a wide selection of lubricants for perforators.

The presented assortment for processing the following parts and tools:

Knowing how to lubricate the gearbox and drill punch Ermak 646042, as well as any other tool model, you can independently replace the old layer with a new. This will help control the load on the details of the tool and significantly extend its operation of it.

Clime cartridge for a perforator: device, replacement, repair

Any tool is subject to wear, and the punch in this regard is no exception. One of the common breakdowns of a perforator is a malfunction of a clamp cartridge.

The nozzles in it can be poorly held, sometimes it is impossible to extract them. Most often this happens with improper care of the tool.

Although the cartridge device is quite complicated, its repair or replacement is quite capable of the home master.

How is the perforator cartridge

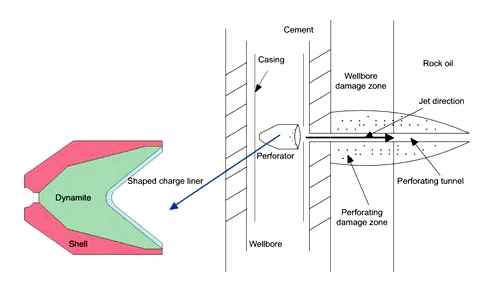

A modern punch cartridge has a SDS design. This abbreviation hides the words STECK, DREH, SITZ.

Translated from German, this means “inserted, turned, fixed”. It is in this sequence that the nozzles are installed in the perforator.

At the same time, the type of nozzle does not matter. Drill, peak or adapter for the drill. The most common types of cartridges:

Both options provide a rapidly removable mode of replacement of nozzles.

SDS-Plus

This design is equipped with light perforators designed to drill holes with a diameter of up to 20 mm in concrete or brick. Four grooves are located on the tail of the nozzle.

Play (4) direct the movement of the nozzle during installation, they are in contact with the wedges (5) of the cartridge. This is how the rotation of the working tool is ensured.

Grands (2) serve to fix the shank, they include stopping balls, not allowing the Boers to jump out.

SDS-MAX

SDS-Max is used on heavy perforators. Such tools have a powerful engine with a lot of impact force. They make holes up to 50 mm. To reduce the loss of torque, the number of grooves in it is increased. The rest of the design is similar to SDS-Plus.

Other cartridges

In addition to SDS, there are less common clamping structures. They are designed to fix the tool with a smooth shank.

Key cartridge for a perforator, it is also a gear-cage, is similar to a standard clip for a drill. The nozzle in it is fixed with three fists that move by the influence of a special key. Although the nozzle holds reliably, the use of this design is limited, since the change of tool takes quite a lot of time.

Quickly.Packed structures are more convenient in work, save time spent on replacing nozzles.

In a two.Different cartridge, to squeeze or free the working tool, you need to hold the back and rotate the front, that is, both hands are involved.

One.Month design allows you to act with one hand, but requires fixing the working shaft. Such an option should be laid in the design of the perforator.

Despite the convenience of fast.Packed cartridges, the championship is preserved behind the design of SDS.

Dismantling of the SDS cartridge

To assess the condition of the perforator cartridge, this node must be disassembled. Start disassembly with the removal of the anterior rubber dust. It is not attached with anything, just put it with a screwdriver.

Replacing your cartridge! 101

Next, remove the locking ring and washer. So the spring is released.

When removing the spring, you must be careful: under it there are locking balls, they easily slip out and may get lost. After removing the spring, you can remove the rear boiler.

The cylinder is fixed with four inserts, simultaneously passing through the walls of the punch trunk. The inserts enter the walls flush, there is nothing to grab them for.

After conducting an inspection, they make a conclusion: it is required to replace the entire cartridge or only some details. Assembly is carried out in the reverse order.

Typical clamping malfunctions

Most often, the following details are faulty for the perforator.

- The boot is rushed or has cracks, which is why building dust penetrating inside the cartridge pollutes the lubricant and prevents rotation.

- Stop ring. Its weakening frees the spring, the balls fall out of the grooves, the drills do not hold.

- The guide cylinder. Wear of the inner grooves does not allow to reliably fix the drills.

- Spring. Her wear or break reduces shock absorption.

- Balloons. Reducing their diameter due to wear does not allow the restraint.

Balls, a spring and a locking ring can be replaced with suitable details from other mechanisms or try to make it yourself. Antrasses and the guide cylinder are not repaired, they will have to be changed to proprietary serviceable specimens.

All necessary details are sold in specialized stores.

As you can understand, repair of a perforator cartridge is not such a complex process. After the warranty period is completed in the event of a breakdown, the perforator can be repaired by your own, without contacting the service center.

How to lubricate the punch gearbox and how to do it right

The assortment of the presented compositions for the drills is quite wide. And not always a beginner can determine which lubricant is better suited for a perforator.

- Makita 196804-7. Japanese remedy intended purely for processing the shank and the inside of the cartridge. Provides uninterrupted operation of the tool even with daily walls of walls for 6 hours. Contract.

- Arsenal AR-401 (100 g) Patriot. An American product intended for drills, the speed of rotation of which is 1-4 thousand. In min. Characterized by economical consumption, but when heated, the consistency becomes fluid.

- Zubrov ZSB-125. Lubrication of Russian production. It has a semi.Synthetic basis. Does not lose its operational qualities even at low and high temperatures.

- Elitech 2006.000100. Semi.Synthetic Russian lubricant, which is suitable for all types of shanks and working equipment. There is no strong spraying when overheating.

Ermak

Domestic manufacturer, in the assortment of which different models of punch and lubricants are presented to them. Products are of good quality and moderate price.

Grease for drill punch

When buying a tool for drilling tools, it is included. It is characterized by a thick consistency. And also in the instructions for use it is indicated how to use grease for drills of the perforator, and the frequency of applying it to the working surfaces is indicated.

But subsequently you can purchase a tool and another manufacturer. The main thing is that it is suitable for this model, and it was indicated that the composition is intended specifically for the processing of drills.

Types of cartridges for a perforator

Different perforators can be used Types of cartridges. Everyone has their own differences.

Tozhcato-Vennian

It is also called Key cartridge. This variety allows you to install a nozzle in which the shape of the shank is cylindrical. The mount is carried out using a special slot key. They are shifted by fists that reliably clamp the working organ. The plus of a gear-cage cartridge is a reliable fixation of devices with a cylindrical and hexagonal tail. But in order to fix or remove the drill in these cartridges, you need to spend a lot of time.

Quickly joke

Quickly and fast.And.Packed are mainly used in the design of screwdrivers. There are one.Button and two.Lump. Are fixed in the same way as key, only without using the key, everything is done manually. A more reliable mount is provided by two.Luminous cartridges. But since the clamp is performed with hands, the fixation is inferior in terms of reliability by the clip.

The disadvantage of the fast.Fastenced fastener is that with long operation, it unreliably fixes the drill of large diameter. As a result, during the drilling, the instrument turns, which negatively affects on the quality and speed of work.

How to fill and manually prime refillable ink cartridges.

This variety is considered the best option for perforators, although it appeared not so long ago. Many call SDS-patrons Quickly removableand. They are suitable for drilling concrete, drilling wood and metal. But their clamping equipment can be of different types, therefore you need to know their features.

Equipped with several types of clamping devices:

- Plus. The tail of the cartridge of the tool designed for use at home.

- Top and Quick. Very rarely used. Buy nozzles for installation on such types of cartridges is not easy. Few firms are engaged in their production. Therefore, when buying, you should look at the modification of the latch.

- Max. These details are used only in specialized perforators models.

Cartridge for the perforator securely fasten the drill. Fixation is carried out using 2 guide wedges and 2 stop balls. The advantages of SDS cartridges are that working with a clamping device is simple and safe. It perfectly combines torque and shock force. 90% of all manufactured perforators are equipped with these simple devices.

Cartridges for perforators their types and distinctive parameters

SDS type cartridges are popular, and they are suitable for both concrete drilling and for drilling metal or wood. However, clamping equipment of the SDS type can be of different types, and therefore it is necessary to find out their features to distinguish, for example, when there is a need to buy a cartridge for a perforator. So, there are such types of cartridges for perforators belonging to the SDS class or quickly ascense:

- SDS-Plus is a running type of fixers used on household and professional devices. Then mostly light and medium severity units that serve for use in everyday life and in repair and construction work. How the barrel of the nozzle is arranged, which serves to accommodate in such a cartridge, described above. In addition, it should be noted that such shanks have a length of 4 cm and a thickness of 10 mm. Manufacturers produce brows with shanks for this type of latch with a diameter of 4 to 32 mm

- SDS-MAX is an analogue of the previous type, only an employee for more serious high-power tools over 1.2 kW. The distinctive feature of such cartridges is that the nozzles for them have the following dimensions: length 9 cm, thickness 18 mm, and the diameter of the working area reaches 60 mm. If you need to drill a hole of more than 6 cm, then crowns are used. Devices of this type practically have an identical form of grooves, like SDS-Plus, only with a slight difference-the presence of not two slots, but three. This means that there is one open groove on the shank of the installed drill, and on the opposite side there are two. Boers and other types of nozzles of SDS Max serve to work with perforators that have the force of a blow up to 20-30 joules. Perforators with the SDS-Max cartridge serve exclusively for working with appropriate types of nozzles

- SDS-Top is a type of cartridges that are no longer used, but they can be found with the owners of an outdated tool. They were originally intended for middle.Class perforators, that is, for semi.Professional models. The thickness of the shanks of the drills for such clamping devices is 14 mm, and the length is 70 mm. In addition, manufacturers produced drills that allow you to drill holes from 16 mm. Today, you can find drills and other devices for such perforators only in single copies

- SDS-Quick is another classification of cartridges for perforators that have not received wide popularity. Their distinctive feature is that they have a cylindrical design of the shank, and instead of grooves, there are slots or protrusions. These types of fixers were designed specifically for Bosch Models UNEO. Nozzles to such perforators can be used even on drifts and screwdrivers with canging clamps

- SDS-HEX is also an experimental modification of cartridges that were designed specifically to fix the peak and chisel in powerful units. However, in addition, the special design of the shanks shows that they are quite reliable when working with drills

- Spline-a variety of cartridges that have some similarity to the SDS-MAX type equipment. Designed in China, and are produced exclusively for North America countries. Have a slotted structure, and shock movement occurs at the expense of the compaction on the tail of the nozzle

All varieties of cartridges to perforators are equipped with dustproof covers. All the types of clamping devices presented above serve to perform shock actions, which is important when processing concrete. Looking in advance, it is worth noting that a zang cartridges are also made for perforators, which are used for the purpose when the tool is used more for drilling wood or metal.

Lubrication for gearboxes

Lubrication of the punch gearbox just bought is not required. I have already placed the calculated amount of oil on the sir, so it is often missed by its presence. Nevertheless, during work, it decomposes, polluts and ceases to fulfill its role.

After some time, it is recommended to replace the oil. With the one that is intended for difficult working conditions and strong heating. Friction occurs inside the gearbox during rotation, characterized by frequent and sharp extrusion of fluid from friction vapor. Therefore, specialized oils are used that can:

- Protect metals from oxidation;

- Capture and divert pollution;

- Stick to surfaces to protect them;

- Be water.Pushing;

- Do not be afraid of strong heating,

- And also self.Heal.

Reducer of the barrel punch how to lubricate

Reducer on a perforator is the second main in size node, on the serviceability of which the instrument efficiency depends. Modern professional models of barrel punch are equipped with special containers that are designed to make lubrication. Special liquid oils are poured into these containers (crankcase), which in the process envelop the transmitted mechanism.

To fill the oil in the construction of the case, there is a special hole (usually in the upper part of the tool), the location of which is indicated by the manufacturer. The principle of replacing oil for lubricating the gearbox in such devices is much easier, and it is based on the following actions:

- The cap is dismantled, which depends on the manufacturer

- The remains of the old lubricant are removed

- Carter purging or washing with gasoline is performed

- New oil is refueling in the amount recommended by the manufacturer

- The cover is installed in place, and you can continue the operation of the tool

Pour exclusively recommended oil into such perforators. Another advantage of such perforators is that they do not demand to wait until the warranty term ends to disassemble the housing and make a lubricant. However, there is a lack of devices that are manifested in the following factors:

- High cost

- The need to regularly monitor the amount of lubrication and perform its add.Ups and replacement

- The inability to simultaneously lubricate the sliding bearings, since for access to them you will need to disassemble the case

Dismantling of the SDS cartridge

To assess the condition of the perforator cartridge, this node must be disassembled. Start disassembly with the removal of the anterior rubber dust. It is not attached with anything, just put it with a screwdriver.

Next, remove the locking ring and washer. So the spring is released.

When removing the spring, you must be careful: under it there are locking balls, they easily slip out and may get lost. After removing the spring, you can remove the rear boiler.

How to Load a Grease Gun Cartridge Video

The cylinder is fixed with four inserts, simultaneously passing through the walls of the punch trunk. The inserts enter the walls flush, there is nothing to grab them for. It is most convenient to use the inserts to use inserts small magnet or magnetized screwdriver. The released cartridge is taken out, slightly twisting from side to side. After conducting an inspection, they make a conclusion: it is required to replace the entire cartridge or only some details. Assembly is carried out in the reverse order.

How to insert a peak into a perforator?

How to insert Bour in the SDS cartridge It must be cleaned of dust. After that, you need to apply specialized lubrication to the locks of equipment and with effort insert In the cartridge punch. It is necessary to press the click. Pull the drill over yourself, if it is not taken out, the installation was successful.

For lubrication drills you can use the lubrication of brands such as Bosch, Makita or Litol. After dismantling drill It must be borne in mind that only a gearbox is subject to lubrication. Before, how to lubricate It is worth removing the old grease if possible, as it may contain processing products from six.

Lubricant for Makita perforator

Japanese corporation, which has been engaged in the production of various construction tools since 1915. The very first owner of the company was Masaburo Makita, in whose honor the company still bears its name. To date, the corporation is one of the leading manufacturers of power tools (350 types) and accessories (4500 varieties) to them.

How to disassemble and lubricate the punch Makita video

Assortment of products (lubricants):

- “042005-4A”. For SDS perforators (packaging 16 kg);

- “042024-0A”. For the SDS punch reducer (packaging 2.5 kg);

- “P.08361”. For reducers of SDS Max perforators (packaging 30 grams);

- “183477-5”. For SDS perforators (packaging 30 grams);

- “181573-3”. Lubrication for drills (packaging 100 ml).

Bosch punch grease

- The founder of the German concern was Robert Bosch, an engineer and businessman, who in 1886 opened a small company for the sale and manufacture of electrical equipment. And despite the fact that initially the staff consisted of only one mechanic and one electrical engineering, the company was able to reach unprecedented heights.

- Today is a leading supplier of various categories of construction and consumer goods, including power tools. The subsidiaries of the enterprise are located around the world, including the Russian Federation. And, perhaps, in every city of Russia there is an official Bosch service center, and since 2007 a plant was opened for the production of equipment in the city of Engels.

- Many technologies, which are considered innovative today, have been successfully tested for many years in this company. Bosch tools are a reliable and ergonomic technique with the most advanced achievements. The policy of the corporation is not to sell as many tools as possible, but that each purchased apparatus serves as long as possible. That is why specially designed branded tools for maintaining power tools, including perforators, began to produce.

- “1615430009”, “1615430010”. Lubricants for inserted tips of the tools (packaging 30 ml);

- “1615430012”. Oil for perforators (packaging 1 l);

- “1615430014”. Lubrication in tubes for perforators (packaging 45 ml);

- “1615430015”. Lubrication in tubes for perforators (packaging 225 ml);

- “1615430016”. Grease for perforators (packaging 1 kg);

- “1615430019”. Grease for perforators (packaging 1 l);

- “1615437509”, “1615437511”, “1615437512”. Grease for perforators, complete with a sealing frame (packaging 50 ml);

- “3605430008”. Hydraulic oil (packaging 1 l).

Lubricant for labCon perforator

- German company founded in 1980 in the city of Frankfurt. Produces various types of synthetic lubricants for power tools. Products are supplied around the world, including Russia. The company positions its products as environmentally friendly compositions. For their development, only components are used that meet the highest requirements.

- Lubrices are distinguished by special thermal stability, they do not oxidize and perfectly prevent friction even with maximum load. These are waterproof compositions that guarantee the durability of the majority of power tools.

Assortment of products for power tools:

- “LubCon Thermoplex Aln 250 EP”. Grease for gearboxes;

- “Lubcon Thermoplex Aln 1002”. Grease for perforators;

- “LubCon Turmogrease NM 4602/0”. A universal composition for lubrication.

Lubrication for punch nanoeche

The Russian company is engaged in the production of synthetic, semi.Synthetic, mineral, semi.Liquid and plastic lubricants. For the first time in the Russian market, products under this brand appeared in 2004 and since then Nanonet has been increasing the range of its products annually. Lubrication and oil meet the high requirements of our time.

Lubricant for Metabo perforator

- The company first began its activities in 1924, Albrecht Schitzler and Julius Klos are considered its founder. The initial plans of the creators of the company were to release tools that would meet the increasing needs of modernity in a technological plan. Initially, the tool was manual, and only in the 30s of the 20th century they began to make electrical apparatus.

- The company is trying to make products that would have been durable. And for these purposes they create a whole line of electric tool care products, including lubricants for perforators. Most often these are plastic products, designed for shanks of drills.

Lubrication for the punch of the bison

The company is a Russian manufacturer of various materials and tools that have proven themselves to both domestic and foreign markets. The goods have an affordable price and good quality, the assortment range is constantly replenished with new categories of products. All products are tested in the laboratories of the company and only after their successful completion do they enter the design bureau. The finished product is mandatory undergoing quality control, and then, goes on sale.

- “Zubble.Expert 60”. Grease for drill (packaging 60 g);

- “Zubble Expert 125”. Grease for drill (packaging 125 g);

- “ZSB ZSB”. Lubrication for drills (packaging 125 g).

Enches

Russian enterprise, today is one of the leading domestic manufacturers of power tools. The company has extensive experience in the development and production of various products and has its own design and test office. The factories are located in Russia and Spain, and the products themselves are supplied to many European countries.