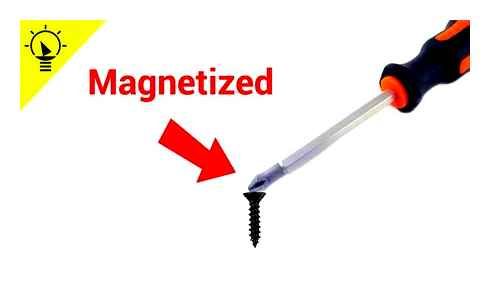

How to magnetize a screwdriver at home

How to magnetize a screwdriver: easy ways at home

Most likely, for any “real man” will not be a discovery that when working with self-tapping screws and other small things shows one of their amazing properties. This property sometimes is almost miraculous. they manage to hold on when it is not necessary, and at the right moment, on the contrary, they fall down.

It’s okay if they just fall down, but they tend to get lost somewhere. One, two, three. When the tenth one disappears from view, the working spirit disappears somewhere, as if the neighbor’s cow came and licked it with her tongue. And screwdrivers with magnetized tips help avoid that. over, it is not necessary to rush to the store in search of this particular model, you can magnetize any screwdriver that you have in the household.

You can magnetize a screwdriver in two ways:

Why do you need a magnetized screwdriver?

Such a screwdriver will be the perfect helper for the home handyman.

Screwdrivers often need extra help when tightening screws. After all, the master is holding a screw with one hand and a screwdriver with the other. And sometimes you need to keep the part being held in position.

But if the screwdriver holds the screw itself, the handyman can easily get the job done without too much trouble. And this is just one of the reasons why home handymen need a screwdriver with a magnetic tip.

This tool can also serve other needs. For example:

- screws that are removed from hard to reach areas can be attached to the screwdriver shaft so they do not get lost;

- If any metal object has fallen and your hands are busy, including the screwdriver, it can still be quickly picked up;

- there is no need to hold a screw if you have to hammer it in too tight for a free hand.

In order to repair, installation and other work was carried out quickly and efficiently, nothing should interfere, especially if it is a small screw that tends to fall off the screwdriver. For convenience, you can buy a special analogue with a magnetic tip.

But do not throw your regular screwdrivers in the trash, because they can be made from them, too. To do this, most craftsmen use magnetizers, but there are also other ways to make such a miracle screwdriver. And for this you do not need to go to the service, everything can be done easier and faster. Read on to find out how to magnetize a screwdriver at home.

Screwdriver magnetizers

A screwdriver with a magnetic tip is certainly a good thing, but in some situations it can on the contrary hinder or even harm. For example, when working with electronics, a magnet can cause serious and irreparable harm to some parts.

And constantly juggling screwdrivers is quite silly and inconvenient. Therefore, most craftsmen who often have to wield a screwdriver, use a special device, a magnetizer. It can be used to quickly magnetize and demagnetize a tool without much manipulation.

Previously, such a service could produce in the workshops, but now, with the advent of this device is no longer a question, how to magnetize a screwdriver at home.

Magnetizers are simple in design and use, which can change the corresponding parameter of metal objects. A huge plus of the device is that it does not require additional connection to the network, recharging. And the small size allows you to always have such a useful thing with you. And if we consider the construction itself, the magnetizer consists of:

Each of these slots is responsible for a particular function, magnetizing, demagnetizing. Usually, the slots are signed, but even otherwise, you can very quickly check the parameters of each compartment.

The principle of operation is incredibly simple: put the object in the right hole, wait a little. These devices have a difference in the size of the tool itself, the size of the cut. The second parameter depends on how big the object is to be magnetized.

For the price they are not much different, the usual, although you can find more expensive models. Whether they are worth the money is up to everyone.

Magnetizing process

To magnetize a screwdriver, you need to quickly run a magnet over it in one direction. You should rotate the tool slightly each time you perform this procedure. This will help the iron atoms line up in the same direction, causing an attraction effect.

For each screwdriver, about 20 seconds of magnet exposure is sufficient. There’s no point in doing it longer, since all the atoms will have already lined up in the trimmer’s fishing line in that time. The magnetic force will not increase by rubbing the screwdriver a hundred times.

Check your screwdriver afterwards. You can easily tell if it has become magnetic. You need to hold the tool up to the screws and see if its tip helps pick them up.

Screwdriver magnetizers

A screwdriver with a magnetic tip is certainly a good thing, but it can also be confusing or even detrimental in some situations. For example, when working with electronics, a magnet can cause serious and irreparable damage to some parts.

And constantly juggling screwdrivers is pretty stupid and inconvenient. Therefore, most craftsmen who have to often wield a screwdriver, use a special device, a magnetizer. With it, you can quickly magnetize and demagnetize the tool without much manipulation.

Previously, such a service could produce in workshops, but now, with the advent of this device is no longer a question of how to magnetize a screwdriver at home.

Magnetizers are easy to design and use, which can change the corresponding parameter of metal objects. A huge plus of the device is that it does not require additional connection to the network, recharging. And the small size allows you to always have such a useful thing with you. And if we consider the design itself, the magnetizer consists of:

Each of these holes is responsible for a particular function, magnetizing, demagnetizing. Usually the slots are signed, but even otherwise, you can very quickly check the parameters of each compartment.

The principle of operation is incredibly simple: put the object in the desired hole, wait a little. These devices have differences between them in the size of the tool itself, the size of the cut. The second parameter depends on how big object you want to magnetize.

They are not much different in price, the usual, although you can find more expensive models. Whether they are worth the money is up to everyone.

How to magnetize any tool

This is an old magnetic gripper that has long been demagnetized and can barely hold even a small screw. In this tutorial I will show how very simply you can remagnetize an old magnet without reversing its polarity. By the way in the same way you can magnetize almost any metal tools. It is a hundred times more convenient to work with the same screwdriver when it is magnetic and there is no need to hold a screw with the other hand.

Materials: Any copper wire with electrical insulation tape

Tools: Screwdriver with a cylindrical shank Magnetic COMPASS A DC power source, batteries or rechargeable batteries.

Wrap the insulated wire around where the magnet is. If you do not have insulated wire, then enameled wire will also work. I wound almost the full length of the grip shank just in case, although obviously the magnet itself is shorter than it. You can see how simple it is, I do everything by eye, I don’t count the turns of wire, and I decided to wind three pieces.

I want to strengthen the magnet, so I have to demagnetize it to zero and then build up in reverse polarity. To find out the polarity of the magnet we can use the regular COMPASS, I positioned the COMPASS so that it was not in the north-south axis, then I brought the magnet closer to the compass, and it attracted the south pole of the magnet in the compass.

After that, you have to figure out which wire of the coil is the plus and which is the minus. To do this I removed the coil from the shank of the grip, and put it on a screwdriver of a slightly smaller diameter, so that the coil was easy to remove and put on, it should be a little rewound with duct tape. By the way this is how you can magnetize the screwdriver itself. To avoid messing with the wires, I made one wire long and the other short. Well, after I put the coil on the screwdriver, the only thing left was to bring it to the compass, and connect the wires to the battery in such a polarity that the screwdriver would attract the south pole of the magnet.

Then I took the coil off the screwdriver and put it back on the shank of the magnetic clamp, so that the shorter wire was closer to the front end of the clamp, as it was on the screwdriver, on the previous shag. I used two old flashlight batteries to power the coil, and held the wires from the coil with my hand for a couple of minutes. This time was quite enough, 3 volts was also quite enough to magnetize the grip quite well.

Checking the magnetic grip: it holds better than new!

You will hardly need magnets for the rivet gun, but you can buy consumables, rivets 5 mm, as well as rivets of any other size, you can on our website.

useful self-tools:

- Laser level with your own hands

- PVC ring spanner

- PVC gardening shovel

- How to Make a Metal Ruler

- Angle clamp with your own hands

- Makeshift knife with a wooden handle

important cautions

Here are a few points that the craftsman should definitely pay attention to:

- A sufficiently strong neodymium magnet (including the magnets in hard drives) can severely damage the skin. Therefore, it must be used with extreme caution;

- do not connect uninsulated wire to the battery. Instead of creating a magnetic field, the current will pass through the bare wire and strike anyone who dares to touch it;

- individual items of electronics can be seriously damaged by magnets. A magnetic screwdriver is usually too weak to cause problems with machinery. But still use it in this case will have to be at your own risk.

Important Cautions

Here are a few things the handyman should definitely pay attention to:

- strong enough neodymium magnet (including magnets in the composition of hard drives) can severely damage the skin. Therefore, it is necessary to use it with extreme caution;

- Do not connect the wire without insulation to the battery. Instead of creating a magnetic field, the current will pass through the bare wire and hit anyone who risks touching it;

- Individual items of electronics can be seriously damaged by magnets. A magnetic screwdriver is usually too weak to cause problems with machinery. But still you have to use it in this case at your own risk.

A device for removing magnets from clothing

The easiest way to remove clips is to use a magnet and magnetic devices. You can buy this system, that is, a magnet in a store, or use another, more powerful. Pay attention that more often such a clip opens when using a magnet with an area of more than 2 cubic centimeters. If the magnet is low-powered and has a small magnetic field, the clip most likely won’t open.

- Accordingly, the magnet must be large and powerful. Unfortunately not everyone has it in the household, so you can use other, more affordable methods. One of them is the use of a locksmith’s tool, that is, pliers, pliers, and other sharp objects. Please note that these methods are only suitable if there is no paint inside the clip.

- If you are sure that there is no paint inside the clip, you can open it with a sharp object. Otherwise, if you do not know, not sure, we recommend freezing the clothes in the freezer beforehand. That is, leave it for about 2 hours to let the paint inside the capsule freeze. That way, even if you break the clip, the contents will not leak out, because of its aggregate state, you can remove the clips from your clothes without obstacles.

- In the network you can find a lot of advice on how to open such clips, what to do with them. One of the easiest variants is to put a part of a clip with its flat side on a hard surface and to cover the other part with some metal object and to hit it strongly with a hammer. As a result of this blow, the mechanism inside will simply fly apart. The balls will shift, thus the rod can be easily removed. This is the principle on which the magnet works. The balls are pulled to one side and the spring with the rod to the other. That’s how the two parts of the clip can be detached.

Why do you need a magnetized screwdriver

This screwdriver is the ideal helper for the home handyman.

[idea]When screwing the screws, quite often you need extra help. After all, with one hand the craftsman holds the screw, with the other the screwdriver. And sometimes you need to keep the part to be fixed in the right position.[/idea]

But if the screwdriver will hold the screw itself, the craftsman can easily manage the job without too much trouble. This is just one of the reasons why home craftsmen need a screwdriver with a magnetic tip.

This tool can also serve other needs. For example:

- screws that are removed from hard-to-reach places can be pinned to the screwdriver shaft so they don’t get lost;

- if any metal object has fallen and your hands are busy, including the screwdriver, it can still be picked up quickly;

- there is no need to hold on to a screw if it must be driven into an area that is too tight for a free hand.

How to make a magnetic screwdriver at home

The magnetic screwdriver. a useful thing in the household, but it is not used so often. Therefore, and “magnetizer” for her, in fact, risks becoming just an unjustified item in the expense item.

It follows that there is a need to find a suitable way to explain how to make such a tool at home using improvised means. That is, without using a magnet in principle. And there are several ways to do this at once.

Improvised coil

If you have no magnet on hand and you need to magnetize a screwdriver here and now, you can make a suitable device yourself.

All you need is to wrap any metal object with a layer of ordinary paper and a varnished copper wire.

To get it right the first time, the wire length should be decent. enough for 200-400 turns (depending on the size of the object). Thus, you will get a coil, to which you can apply a voltage.

[alert]Voltage can be obtained, for example, from a battery, charger, etc.[/alert]

Home power grid

In this version, too, you need a homemade coil. The only difference is that the voltage is applied from a household socket. A very important detail. the presence of a fuse, which will help to avoid a short circuit. Extreme caution must be exercised, as there is a risk that the fuse could burn out when connected.

Hammer

Surprisingly, you can even magnetize a screwdriver with an ordinary hammer. You can do it by hitting the screwdriver shaft a lot and often. Focus is that there are enough iron atoms in the steel that the shaft is made of. And the hammer blows help align them in the same direction and thereby make the magnetic field.

This may take some time, but this method can be useful if you really have nothing but a hammer at hand at the right moment. It is not difficult to demagnetize the tool in the same way. by hitting the shaft a few times. This will disperse the iron atoms again, disrupting the magnetic field.

Battery

This method is used more often than others, so it will be described in detail.

- A 6-9V battery;

- sticky tape;

- electrical wire about a meter long (core dimensions up to 1.3 mm);

- tool for stripping the insulation.

- Remove the insulation on the ends of the wire about 2.5 centimeters. The diameter of the wire must be at least 0,6 mm, because a wire that is too thin risks overheating. And too thick won’t do any good.

- Due to the wire with thin insulation, magnetizing will be more effective. The best result is achieved by using enameled coil wire. To clean it, you can use an emery cloth with 220 grit.

- Tightly wrap the wire 10-20 times around the screwdriver shaft. If the tool is short, you can wrap it in a couple of layers. But don’t change the direction of the winding. For example, it will move right, left, and then right again. If necessary, the wire can be secured with duct tape.

- Beforehand, rubber gloves should be worn as a protective measure. They will protect against electric sparks and possible electrocution.

- Attach the ends of the wire to the contacts of the battery, which is the source of direct current here. The incoming electricity will create the necessary magnetic field.

[alert]Important! It is not recommended to use batteries of higher power, if the wizard does not have enough experience in the correct handling of this device. The fact is that any battery that is more powerful than nine volts should be attached to the wire for just a second or two. And this is enough for magnetization.[/alert]

- The tool shaft wrapped in the wire will become magnetized. However, you should be careful, because both the contacts of the power supply and the wire will heat up fairly quickly in the process. You can remove the battery after no more than a minute.

Now you can try to pick up the screwdriver. If it didn’t work and immediately after disconnection the magnetic properties disappeared, you can try magnetizing again. But this time make more turns on the shaft.

Any of the above methods is important to carry out in a safe manner. Otherwise there is a risk of serious damage to your own health. If the handyman does not have the necessary experience or knowledge, it makes sense to ask a specialist for advice.

It is easy to demagnetize a screwdriver. A few strokes on the shaft are enough if it is urgent. If not, after a while it will lose its magnetic properties by itself.

The demagnetizer

The fungus with magnets is closed with a plastic lid. It can be sized to the diameter or machined.

To use the device, you need to clamp it in a drilling machine or drill. It is important that the demagnetizer rotates. The tool that needs to be demagnetized is placed flat on the side of the plastic cover. It is held for a couple of seconds, after that it is slowly withdrawn towards itself parallel to the plug plane. As the tool yields to the alternating magnetic field from the opposing magnets, it is demagnetized and no longer attracts metal.

It is possible to cut the plate from tin plate additionally for the device. By leaning it up to the cap of the mushroom, you can short out the magnetic field, which will save you from cleaning the fixture from shavings.

Magnetizer

The principle of using a magnetizer is very simple. With both holders, it is attached to the tool that needs to be magnetized. To magnetize them, leave them clamped together for a few minutes or hours, depending on the weight.

Both are homemade devices that are cheap to make and are often useful. They are fail-safe and effective, so in many ways better than factory-made counterparts.Original article in English

Wire tap and fault location

If you hold the stylus of a screwdriver with your finger clamped on the top indicator to a wire at one end of the cable, and then take a wire of the same color at the other end, the indicator should light up. If the screwdriver does not respond, the wire is broken.To find the fault underneath the insulation, you should connect one end of the damaged wire to a phase. Then the top contact on the screwdriver is pressed with a finger, and it is smoothly led with the feeler gauge along the wire from the connected edge. The indicator will light up all the time, and will stop over the gap. If the insulation is removed at this point it will be possible to repair the cable.

Check the integrity of fuses, diodes, light bulbs

One contact on the bulb, fuse or diode should be touched by hand and the other by the stylus of the screwdriver. After that its contact on the handle is pressed. If the diode lights up, the unit is intact.