How to Make a Band Saw Video

Choosing an electric saw, the question may arise, but which band saw to choose? How to choose a band saw blade?

But do not be afraid, everything is not as complicated as it might seem at first glance. In our article, we will help you figure it out.

Criteria for choosing an electric saw

The first thing to do is to decide for what purpose you are buying a saw. As a rule, it is needed for craftsmen working with wood. But, there are also metal band saws. This is also worth paying attention to.

When buying an electric saw, pay special attention to following points:

- band saw material;

- quality and safety of operation;

- warranty service life of an electric tool;

- saw dimensions;

- an indicator of the noise level during operation;

- speed mode;

- the quality of the teeth of the band saw;

- price.

There are other selection criteria, but you will need them when choosing a specific sawing device.

Give an example, The German manufacturer Proxxon offers a wide range of models of band saws, allowing you to cut workpieces from thick wood, metal, plastic, ceramics and even glass.

Home band saw

Band Saw is a must-have tool in every workshop. Also, band saw blades are used on sawmills, band saws and cutting saws.

The quality and reliability of the tape web provide an excellent opportunity for its multiple use and allow it to be used in all areas of construction.

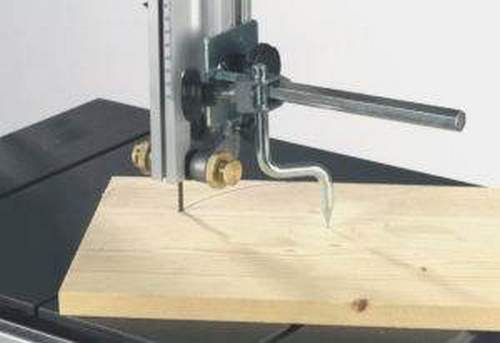

Band-saw Is a cutting tool used for band saws. By design, the band saw has the form of a flexible steel tape tightly looped, with a series of teeth along one edge.

The tape is mounted on two pulleys that rotate the electric motor of the band saw.

Using a band saw, you can make both straight and curly cuts. That is why the field of its use is very diverse and is not limited only to construction work and furniture production.

Types of Band Saws

Band saws can be divided into the following kinds:

- toothed;

- toothless;

- electrospark principle of action.

Serrated Band Saws, unlike hacksaw blades, they are released in a closed loop. They are used for cutting and cutting a variety of materials, including foam concrete, metal structures, wood and other materials.

Video: How to Make a Band Saw Video

Toothless Band Saws and electric spark saws actions work similarly to circular saws. The only difference is the purpose of the teeth.

When choosing a metal band saw, you need to pay attention to the design features of the band saw.

The main purpose of the band saw for metal. This is the implementation of angular, straight and curly cuts. If you need to make a cut at an angle, you will need to purchase special rotary jaws on this machine.

Characteristics and properties of the band saw

The main properties and characteristics of the saw are:

- cut height and width;

- type of cutting blade;

- electric motor power;

- the total mass of the machine and the diameter of the pulleys.

It is generally accepted that belt saw models with a pulley:

- up to 300mm. light;

- from 420 to 500 mm. medium;

- with a pulley diameter above 500 mm. heavy.

Lightweight band saws are equipped with an electric motor up to 2 kW, medium and heavy electric motor up to 4 kW.

Types of Cutting Blade

For cutting with a saw, special demands are made on the band saw.

Carbon steel sheets were widely used. According to their heat treatment, tape web can be divided into the following types:

- with the same hardness indicator over the entire width;

- with flexible blade and hard teeth;

- hardened fabrics over the entire width.

Cloths with the same hardness indicator across the entire width work perfectly on medium diameter pulleys. The hardness of the paintings according to Rockwell is 47 units.

Saws with a flexible blade and hard teeth have a specific structure. Only the upper half of the tooth will be hardened, leaving the saw blade flexible. The hardness of the body of the saw according to Rockwell is 31 units, the hardness of the teeth is 64 units.

Saws with a hardened blade over the entire width are the most popular. Their Rockwell blade hardness is 52 units, and the tooth hardness is 67 units.

Sharpening band saws on wood

When sawing wood or metal, the teeth of the band saw may lose their initial sharpness. That is why it is necessary to sharpen a tape electric saw.

Sharpening the saw blade is as follows:

- initial sharpening;

- cleaning;

- wiring;

- final sharpening.

To restore the cutting qualities of the teeth of the saw blade, use special grinding machines.

As a result initial sharpening you will eliminate all cracks in the axils of the teeth, and also restore the profile teeth in compliance with a certain symmetry to the rest.

When cleaning all metal filings remaining after sharpening are removed.

When wiring change angles.

At final sharpening correct the allowed symmetric distortions of the angles and give sharpness to the working edges of the teeth.

Sharpening saws with your own hands will require certain skills from you. Therefore, if you are not sure of the quality of your work, leave this matter to specialists.