How to Make a Drill Sander

How to do something yourself, with your own hands. home master site

EXCELLENT TOOL FOR MASTERS AND HANDICRAFTS AND EVERYTHING FOR GARDEN, HOUSE AND COTTAGE LITERALLY A GIFT HAS REVIEWS.

In the age of information technology, computers become obsolete so that the user has to periodically upgrade his “typewriter” in order to keep pace with the times

As a result, unnecessary spare parts remain.

But it only seems to be unnecessary.

In the economy, as you know, everything will come in handy.

EVERYTHING NECESSARY FOR THIS ARTICLE IS HERE >>>

See how an old 3.5-inch hard drive, usually installed in block computers, turns into a grinder by simple steps!

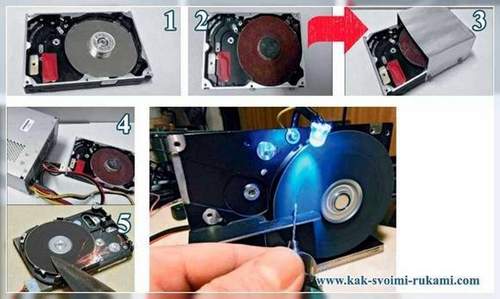

First you need to disassemble the hard drive.

To do this, remove the lid and carefully remove the servo arm and the rocker itself.

If simpler, everything is to the left of the magnetic disks.

STEP 2. Sandpaper

From sandpaper we cut a circle with a diameter of 9 cm with a hole in the center for the size of the spindle. Then evenly glue several strips of double-sided piping tape to the resulting circumference and set the grinding disk on the pancake.

STEP 3. Security

To prevent the grinding disc from dropping out, we recommend making a protective shield, which can be made from a conventional aluminum can.

STEP 4. Connection

After assembling the hard drive, it remains only to connect it. For this, you can use a conventional computer power supply with a cable connected to the hard drive. As a result, we get an inexpensive and miniature grinding machine with the ability to sharpen knives and scissors.

Video: How to Make a Drill Sander

How to make a grinding machine from a hard drive with your own hands: photo

© Author V. Lipatov. Photo by the author.

DRILL GRINDING

In the manufacture of wooden or metal objects often have to grind the surface. In order not to spend money on buying an expensive tool, he made a simple nozzle for a drill.

For a nozzle it is necessary to use an emery cloth on a fabric basis. Since the slits are wide, you need to insert the end of the paper by bending it to the depth of the groove.

I found an old air drill in the garage (photo 1). There was a knot in it resembling an electric motor anchor (photo 2 p. 1) Disconnected it from the tool, removed everything superfluous, cut the front part, the bearing and the casing, grinded it (2). The nozzle turned out, it remains to fix sandpaper on it and install it into the drill chuck (photo 3).

Such a nozzle is suitable for grinding not only flat surfaces, but also the walls inside round objects.

Depending on the surface to be treated, the emery cloth in the nozzle can be fixed in two ways: insert a separate piece into each slot (photo 4 p. 1) or cut a strip of diameter with a margin, wrap the tool with it and fix it in one of the channels (2)

If there is no old air drill at hand, such a nozzle can be made from the rotor of the electric motor (photo 5). All unnecessary (bearings, impeller) must be removed from the shaft. Since all windings are filled with glue, it is necessary to melt it on a fire and choose a wire from the grooves.

Do-it-yourself grinding nozzle for a drill

© Author: Gennady Pobozhiy, Krasnoznamensk. Author photo