How to make a miter saw from a circular saw

Installing the carriage

For a more convenient arrangement of workpieces on the bed and their facing, it is necessary that our carriage has a vertical stroke. This condition will provide us with a window hinge.

We fasten it with self-tapping screws to the edge of the carriage and to the base so that the movable part can rise and fall to a right angle position. In this case, the carriage will act as a stopper, and will not allow the cutting disc to drop below a predetermined level.

The advantage of homemade trimming

Today, a miter saw is no surprise. A lot of modifications, from branded to cheap Chinese ones, with longitudinal and angular cuts are present on the market. However, their cost sometimes goes off scale, and the accuracy does not always correspond to the declared one. Is it possible to do without buying a specialized tool, you ask. The installation we offer proves that the rip saw can also be made at home. Its assembly costs are minimal. In addition, the drill on the basis of which our crosscutting is made can also be used for its intended purpose.

We fix the base stand

We mark the position of the base stand on the bed, shifting it to the left from the middle, and cut galvanized under it with a chisel.

We take a piece of plywood 18×14, and screw it vertically onto 3 self-tapping screws, having previously glued the connection to the bed.

For more stability, you can put down several stops in the form of corners from the same plywood. We put them on glue on both sides of our rack.

How to make a miter saw from a circular saw

Crosscutting is a device for cross-cutting a product along the length, and not only wood materials, but also any other that can be cut by circular saws (for example, plastic). There is a sufficient number of hand-held circular saws on the market (the so-called parquet flooring), with the help of which you can:

- fit molded products to the size;

- remove excess material by cutting out blanks;

- or even make long longitudinal cuts.

But these machines are very expensive. And besides, as a rule, the need for them is never long-term, unless you are professionally engaged in carpentry. In this case, it makes sense to build a homemade miter saw using an existing hand-held circular saw. But what is the right way to make a homemade miter saw from a circular one? We will talk about this on the pages of this article.

Preparation of the base

The base of the circular facing is a rectangular sheet of thick plywood or chipboard, not deformed. In the future, a shelf for the movement of the circular saw will be rigidly attached to the base.

How To Make A Mini Chop Saw Machine || Circular Saw Hacks

In the base sheet (in the table), you need to make a slot for free passage of the saw blade. The blade must completely cut the workpiece positioned on the table surface, so the saw teeth must go deeper than the table surface, but the blade must rotate freely. It is even recommended to form a table from two sheets of chipboard or plywood, attached to each other flat: then in the top sheet it will be necessary to make a through transverse slot for free movement of the saw blade.

Step by step guide

Let’s analyze the sequence of actions when converting a circular into a miter saw. The peculiarity of the “parquet” is its characteristic course. You need to move it along the surface of the material being cut, but not vertically. Therefore, the machine will represent their basis, which, firstly, will allow positioning and fixing the workpiece, and secondly, it has a base with stops along which the circular saw will move in the device (parquet flooring).

Getting started

Fixing the drill

From the back of the carriage, we attach the drill holder to the self-tapping screws. It can be made from a small piece of plywood by making a sufficient hole for the chuck.

We press the drill with a cuff made of a galvanized plate, pulling it onto the screws to the handle.

Varieties of miter saws

There are several types of miter saws (popularly also called “miter saws”). Let’s get acquainted with these varieties.

Saw from various scrap metal

This is a rather weighty instrument on a metal table. In order to work with him, you need to make some effort. But in the end, trimming occurs gradually, without jolts, easily.

The bed is made of guides, corner, bed racks. The plane for work is a sheet of metal: we drill a hole in it, clean the ends with a file. We weld the pendulum stand from a channel placed on a metal sheet, its height is approximately 0.8 m. The stand for the electric motor is made in the form of a plate placed on hinges.

DIY Miter Saw DIY Guide

A do-it-yourself miter saw is often not inferior to a factory one. You can see the manufacturing with drawings of such a unit below. The device of such saws is similar to circular saws. Their advantages are limited weight and dimensions. In view of this, they are used not only in garages, but also on construction sites. The tool is needed for one purpose. cutting the ends of the boards at different angles. Due to the fact that the part is fixed during operation, the cut comes out even.

People who deal with woodworking prefer a home-made unit. Saws made with your own hands, according to your drawings, can be used for a long time. The unit is a circular saw, the device of which makes it possible to better cut at an angle most materials, including metals. By making the trimming with your own hands, you can save finances.

Circular facing

When it is difficult to acquire such a tool due to lack of finance, you can make it yourself.

The welder is used to cut holes in a sheet of steel, and its ends are processed with a file.

A particularly powerful electric motor is not required to use the tool, 0.9 kW is enough. It is mounted on the base with an additional spring performing a stabilizing task. To rotate the unit, it is necessary to attach a handle, as a result, it will be possible to achieve a gradual movement of the saw. The characteristics are as follows:

This will allow you to easily handle wood up to 0.07 m thick with your own hand-made tool. Take care of the adjustable stands and supports. For pendulum risers, take a channel mounted on a metal base. As a result, our tools will become stronger and heavier, but thanks to it, trimming work will be done with ease. You can take a three-phase electric motor (2.3 kW) and a plate swinging on hinges.

Slide the belt over the motor pulley. The pendulum can be fixed on the base of the frame material. For convenient work with wood, the saw diameter must be 0.42 m, and the rotation speed must be from 2800 rpm. Cut a slot under the disc.

As you can see, it is possible not only to purchase a high-quality tool, but also to make it yourself. Here’s what we got:

With a broach

This device is considered the most versatile, since the saw can be displaced not only around the axis, but also along the cut along a straight mowing line.

Combined

When using a combined saw, the cutting angle can be changed in 2 directions. The device, like the previous version, contains an additional hinge. In order to change the cutting angle, it must be adjusted and retracted to the side opposite to the place where the drive is mounted.

Manufacturing details

We apply markings on the chipboard at different angles of facing and screw the hardware according to the marks.

The slewing mechanism is placed on the rotary axis of the car wheel (kingpin), it is supported by a bearing with a diameter of 0.15 m or more. Installing a rotating semicircle with cuts.

We attach ears to the outer side of the bearing to hold them on the base with M6 screws. We put a lock with a lamb on the side.

We carry out the broach from non-working shock absorbers. Oil is poured from them, ventilation holes are drilled, which must be protected from small particles. So that there is no jerk at the start of the start, a smooth start must be installed on the saw, which will slightly reduce the speed. We install a working bed with a slot for the saw.

The last stage of the activity is the installation of a protective mechanism for the disc. And screw the guide rail to the bottom.

You can make a tool from a circular in the same way.

Benefits

When a tool (and even more so a machine) is made independently, then its design, as a rule, takes into account as much as possible those needs and tasks that are supposed to be solved with its help:

- so that molded parts do not have burrs and creases during cutting, it is necessary that the circular saw has an adjustable speed of movement relative to the plane being cut (so that the burrs are removed by the cutting edges of the saw teeth);

- suppose you need to make not the usual transverse trimming of molded products, but at a certain angle. In this case, it is necessary that the workpiece be fixed in order to avoid backlash during the cut;

It is extremely difficult to find a cross-cut saw on sale that has the function of not only rotating the desktop, but also the option of clamping the workpiece. And if you can find such a tool, then it will not cost cheap.

- and, of course, the price. The miter saw can be literally assembled from scrap materials, moreover, from parts that cannot be used anywhere else. Economy is not a decisive advantage?

All these features are inherent in the self-made designs of cross-cutting machines, which makes their production on their own justified and profitable.

Step by step guide

Let’s analyze the sequence of actions when converting a circular into a miter saw. The peculiarity of the “parquet” is its characteristic course. You need to move it along the surface of the material being cut, but not vertically. Therefore, the machine will represent their basis, which, firstly, will allow positioning and fixing the workpiece, and secondly, it has a base with stops along which the circular saw will move in the device (parquet flooring).

With a broach

This device is considered the most versatile, since the saw can be displaced not only around the axis, but also along the cut along a straight mowing line.

Miter saw from circular saw

Miter saw. the same circular saw based on a conventional circular saw. It allows you to cut with great accuracy at the required angle almost all materials. from plastic to metal. There is such a tool from the manufacturer, that is, ready-made, not cheap, and assembling it yourself is not so difficult. Therefore, if you have an urgent need for a miter saw, and your hands are growing from the right place, further information will be very useful.

Safety engineering

When preparing blanks from a chipboard or thick plywood, it is inevitable to use the same circular saw, which will later become an integral part of the miter machine being formed. All the potential danger of doing work on the manufacture of the machine with your own hands is associated with this particular tool.

It is advisable to carry out work on a professional workbench, but if for some reason this is not possible, then you should carefully monitor that the teeth of the saw blade do not accidentally touch any surface, and of course, in no case touch any part your body. The cutting tool is a subject of increased danger to the user.

How to choose a saw

Of course, when you have experience of work, and you do not want to invest large funds in the purchase, you can make such a machine with your own hands. When purchasing a saw for it, take into account:

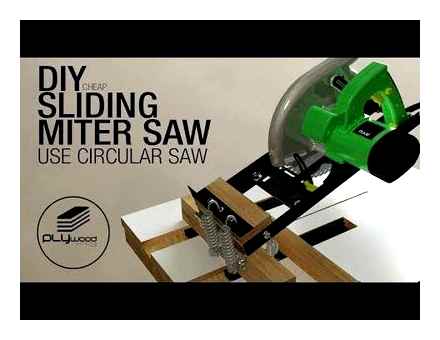

DIY Cheap Sliding Miter Saw use circular saw. simple sliding miter saw

- Buy a device with protection, which is obliged to close the disk not only in peace, but also during work.

- Select the weight and dimensions of the device taking into account your own goals. It will be more difficult to interact with volumetric, you will get tired after half an hour of activity.

- Consider the convenience of the saw so that you can work comfortably with it.

- Consider the diameter of the disc (no more than 0.2 m mark). Investigate the dimensions of the cut. when cutting the volumetric parts it is necessary to select a larger size.

- Ensure that the rotary unit and bed are of good quality.