How To Make A Plow On A Tiller

Plow device

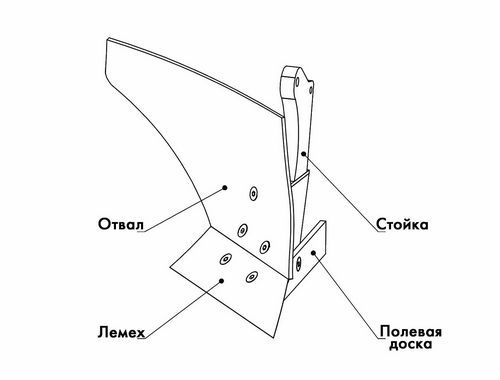

Depending on the model of the device, its design differs. The main structural elements of the unit:

- Frame. The body and the adjusting wheel are attached to it. Two lanyards are installed on the frame, which change the position of the body in a horizontal and vertical position.

- Housing. This is the main working element of the plow. On it are fixed: a ploughshare (knife), a blade and a field board. The body is height adjustable by moving the rack. The ploughshare is responsible for cutting the soil layer, and the blade is responsible for turning the soil. The field board is a service element for setting up.

- Support wheel. Depending on the set height of the support wheel, the plowing depth also depends.

In addition to the main working and service bodies, plows are equipped with other parts. It depends on the type of device and its purpose.

Adjusting the plow to the tiller

To work on different types of soil, the unit must be configured differently. But the main adjustment takes place according to several criteria:

- Setting the plowing depth;

- Adjustment of the angle of attack;

- First furrow cutting.

Plowing depth. Here is the setting of the plowing depth depends on the further process of growing crops. If you adjust the depth insufficient, the roots of harmful plants will remain under the soil, and if the depth is too deep, then the fertile soil will mix and the plants will NOT receive the necessary nutrients.

Attack angle. The adjustment takes place using a field board. The performance of the unit depends on the angle of attack: if the angle of attack is greater than necessary, the device will get stuck in the ground, and the tiller will skid; and if the angle of attack is insufficient, the plow will not remove the required layer of soil.

First furrow. After making all the adjustments, the first furrow must be plowed. At this stage, it becomes clear whether the plow is set up correctly. With the next mouse, the car is lowered by one wheel into the Track, and further adjustment takes place into the furrow.

How to choose a plow for a tiller

When choosing a plow, pay attention to the technical characteristics of your tiller. For processing small areas, a single-body share unit is suitable, and if you are the owner of a heavy diesel tiller, then you can connect a Double-body device, which will speed up the land cultivation process twice as compared to a single-body unit.

Plowing depth adjustment

The plowing depth is set according to two parameters:

- Type of cultivated land;

- Design features.

Before starting the setup, you need to find the most level area. If it is possible to make adjustments on asphalt, then move the machine to it. When the machine is plowing the soil, it moves with the right wheel along the track, and the left wheel is on uncultivated ground. To recreate this position of the machine, you need to install stands under the left wheel of the tiller, the height of which should be the depth of plowing.

The plowing depth is adjusted using the adjusting wheel. The deeper the support wheel is lowered, the shallower the plowing depth will be and vice versa. The height of the support wheel must be equal to the height of the Raised side.

Sharpening the share

The main working element of the plow is a ploughshare (knife). The share carries the main load during plowing, because it is this element that cuts through the soil layer. Over time, the share dulls, which leads to a decrease in plowing performance. The unit must be equipped with a removable share.

If the cutting edge is damaged, the device stops easily sinking into the ground, and the tiller starts axle box. If the plowing process has deteriorated, then it’s time to make repairs. Correctly sharpening the ploughshare is possible only on special equipment that will heat the steel in order to make it plastic. After the steel is more plastic, it is straightened, cooled and sharpened. At home, you can use a tool sharpening machine. The share must be sharpened at a slight angle, from the side on which it crashes into the ground.

Frequent problems and solutions

Remember that plows are structurally different from each other. The general adjustment process is similar, but the elements for which the adjustment takes place may differ. Before starting the connection and setup, read the instructions that came with the device.

The same goes for the tiller. Specify, based on the instructions, whether it is necessary to change the wheels to lugs, and what diameter they should be. It is recommended to install weights on light and middle class tillers so that the unit sinks under the weight of the machine. If the plow is set up correctly, but the machine is still skidding, then the unit is too large for your tiller capacity. This problem can be solved by installing weighting materials.

When choosing a device, focus on the power of the tiller. The heavier the machine, the larger the diameter of the plow. Heavy diesel tillers are equipped with double-body devices, which increase the productivity of the processing of the site.

The design of the plow is simple and straightforward. the main thing is to be attentive to the unit itself and think sensibly when connecting it. Remember that the unit should be looked after in the same way as the tiller. Clean your implement after plowing, try NOT to plow Stony soils and service your helper in a timely manner.

Single-frame plow mounted SCOUT PL-130 HYD with scoring disc

The single-body plow SCOUT PL-130 HYD is equipped with a scoring disc for more efficient work on sod soil. The unit is connected to mini-tractors and tillers with a single-point attachment mechanism. The working part is made of durable steel.

The angle of attack of the ploughshare is regulated with lanyards. The limiter wheel adjusts the plowing depth. The scoring disc is designed for cutting the roots of plants during plowing, which increases productivity and quality of plowing.

For plowing heavy soils and virgin lands, you need to install on the equipment weights of 80 kg in front and 60 kg in the rear.

Preparing the tiller for plowing

Land cultivation is a technological process that requires special preparation of motor vehicles and a plow. First, you need to move the car to the field to be processed. If you are using a lightweight tiller, then it can be transported in the back of a car. Before starting plowing, you need to carry out daily maintenance of the machine and check its performance.

For the period of plowing, lugs are installed on the light and middle class tillers instead of wheels. They improve traction and increase the total weight of the vehicle. Before installing the lugs, you need to transport the car to a flat area, substitute a stop under the rear hitch and remove the wheels. If you can replace the hubs on the Tilleri with longer ones in order to increase the Track, then replace them. After that, the lugs are installed. Pay attention that the tread pattern on the lugs is directed in one direction. Narrowing of the pattern indicates the direction of travel.

After carrying out maintenance and replacing the wheels with lugs, you can start connecting and adjusting the plow.

First furrow and blade angle

The last adjustment is the first furrow cut. After a trial plowing, it becomes clear whether the device is configured correctly. If the equipment does NOT slip and the unit sinks easily, then the plow is adjusted.

After cutting the furrow, the machine is lowered into the tracks with the right wheel. Then check the plowing depth and adjust the machine. Now you can start full plowing.

Average

This technique is rear-wheel drive. Motor power. 5-12 horsepower. The device is capable of treating a plot of half a hectare. tiller weighs from 50 to 70 kilograms, his. Most tillers in this category can mount plows and other equipment.

This technique has 2 gears, is equipped with a headlight. Compared with the heavy tiller, the average is more maneuverable, but the depth of plowing the ground with it exceeds 12 cm.And this is unacceptable for planting Some plants

Heavy

With this equipment, you can plow huge areas, significantly exceeding an area of half a hectare. Engine power. 12-30 horsepower. A plow, trailer, hiller, potato digger and other equipment can be attached to a heavy tiller. It is easier to work with such a technique and many times faster than with light and medium ones. It adjusts the steering wheel, wheels.

The disadvantages include the heavy weight of the model, lack of access to non-standard surface areas. In addition, such a technique has to be turned with effort. As for the types of plow to the tiller, they are reversible with two bodies, which plow the soil using a blade, or rotary, plowing the soil thanks to rotating discs.

How to setup? Tiller launch

Every time before starting the engine, the oil level and the amount of fuel are checked. a lack of both can damage the engine. The diesel engine is fueled with seasonal diesel fuel (for warm or cold seasons). Before starting, check the operation of the clutch, steering wheel. Movements in systems occur with a certain effort.

To start the engine, you need to release the tubes from the air with an electric starter, which will subsequently be filled with diesel fuel. During manual start, it is necessary to give access to fuel, to produce gas and some katana with a starter. The decompressor returns to its original state, and the engine starts.

For two-stroke engines, gasoline is used (the proportions of dilution with oil are indicated in the instructions). To start the tiller, open the gas tank, direct the handle to “start”, several times the feat with the starter does not turn on the ignition. And only then turn on the ignition to start the engine. Further, the handle should be at the “Work”.

Installation of wheels

Before the start of the summer season, you will need a tiller setting for plowing. Before plowing, rubber wheels must be replaced with metal lug wheels. This must be done so that the unit does NOT slip during excavation work. The choice of wheels should be taken seriously, otherwise it will turn out to plow the soil compacted after winter.

Firstly, their diameter should be at least 55 cm, and secondly, the width of the wheel is selected within 20 cm, otherwise, with too narrow wheels, the tiller will lose stability and it will swing in different directions. If the diameter is too small, the gearbox will catch on the soil and may become unusable, and it is known to be the “heart” of the tiller.

For the wheels, a monolithic rim is suitable so that the Earth does not get hammered into the lugs. They work with the wheels, put the tiller on special stands. The height of the hill directly depends on the depth of future plowing: for working with ordinary soil. 20 cm, with frozen soil. 25 cm.

Installing the plow

Thanks to the hitch (attachment), the plow is mounted to the tiller. This work is best done with an assistant, as it will require some effort and skill. First, the hitch is mounted on the tiller, then connected to the plow mount with a steel pin. The connection does not have to be installed tightly, you need a slight horizontal movement, otherwise, when processing the soil, the tiller will “skid” to the sides due to uneven soil.

After basic installation, the plow needs to be adjusted. You will have to tinker with the adjustment. the quality of plowing depends on it. The plows are tilted with the help of the mountings so that its “heel” is directed horizontally to the ground. The adjusted tiller is placed on the ground and the steering wheel is checked. it should be in the area of the plowman’s belt.

It remains to check whether the unit is ready for earthwork. It is necessary to make several test furrows from the depth measurement, to check the quality of the soil dump. Pay attention to the lane between the furrows. It should not be too wide (no more than 10 cm) or crossed by the plow.

Lungs

This mini-technique is often called a motor cultivator. Power It does not exceed 4 and a half horsepower, therefore it is cheaper than medium and large units. The advantages include the light weight of the monoblock and the availability of processing inconvenient areas due to the small grip of the cutter.

The downside is the rapid overheating of the low-power motor, which means that it will take a short time to work with such equipment. In addition, the depth of the excavated soil is less than in a heavy tiller. In addition, there are no mounts for additional equipment in light vehicles.

How to properly plow with a plow on a tiller?

tiller is a universal unit for agricultural work in a personal or summer cottage. It can be used to plow the land, plant and harvest. The purchase of such equipment will greatly facilitate agricultural work.

With the help of tillers, you can perform various types of agricultural work. Depending on the size of the area to be processed and the demand for equipment in different fields of activity, equipment is acquired in light, medium and heavy classes.

Plowing a plot

With the help of a tiller, a small area can be processed in half an hour (if plowed correctly), while manual digging will take a week. The technique can be used to prepare a small field or vegetable garden for planting.

The equipment is delivered to the area where the soil needs to be plowed. To work with a plow, the equipment must be heavy or medium class. a tiller weighing less than 70 kilograms will NOT pull the plow.

Knowing the boundaries of the field, the furrows should be made in the length of the section. this will reduce the number of tiller turns. During operation, the equipment always slightly “pulls” to the right, therefore, for a clear plowing of the first furrow, the limiting twine should be pulled. He will mark the border of the site.

the tiller is controlled from the side of an unplowed field, so the steering wheel is turned slightly to the left. The first furrow is always a trial one: it is made at low speed, then the plowing depth is checked. if it is less than 15-25 cm, then the unit will have to be adjusted.

Having reached the border of the site, the tiller is turned around, the right wheel is set in the furrow (this position “skews” the unit according to the horizon). It turns out that only in the first row the plow takes a vertical position, and then the share, together with the tiller, slightly tilts, so the plow should be slightly shifted in the opposite direction.

To do this, loosen the nut, adjust the position of the plow and tighten the nut again. A correctly aligned plow will ensure smooth, high-quality plowing.

Do not push the plow while driving. The engine must be monitored. It must not overheat. If this happens, the equipment is given time to “rest”, otherwise it will fail.

When plowed, the earth is enriched with oxygen. At this time, fertilizers can be applied to the soil. It is useful to loosen the ground in the fall, then in the spring, after the snow melts, the soil is well saturated with moisture. If you have to dig the same area from year to year with the help of a tiller, the direction of the furrows should be changed from vertical to horizontal. so the soil will acquire a more uniform structure.

For the features of working with a tiller plow, see below.

How to make a plow for a tiller

Lemekh

For the manufacture of this working part, a steel sheet with a thickness of 3-5 mm is suitable. First, a removable share is made. a circular saw blade is suitable for this. After the share is cut according to the template, its cutting part is processed on an anvil, and then sharpened.

How to make a plow on a tiller yourself

The plow is widely used in farming and horticulture. They can easily and conveniently prepare the soil for sowing. The special design is adapted for loosening the soil and can turn entire layers.

To automate this process, the plow is made part of a tiller. This makes work faster and more productive. Loosening occurs due to the immersion of the working element in the soil. This is a metal blade that is pre-sharpened.

Dump

To make a dump, you will need a metal pipe 50 cm in diameter. A template is cut out of thick cardboard, and the blade itself is made from it using a gas cutter. Then the blank of the blade should be processed on an anvil and a grinder.

How to assemble a plow for a tiller with your own hands

Before assembling, you can make sure that the proportions of all parts are correct. Using the drawings of a homemade plow, a layout is made of cardboard and assembled. If everything is done correctly, it’s time to start assembling the prepared plow elements.

You will need a steel plate with a thickness of 2-3 mm and an area of 50X50 cm. Further actions:

- Align it well and indent the edges by 4 cm.

- The ploughshare is applied to the letter at an angle of 25 degrees and is point-welded on both sides.

- The guard of the stand is joined to the share in a vertical position. Its edge Protrudes by 5-8 mm.

- The guard is installed 1 cm above the cutting edge of the share. This is necessary for its free movement while loosening the soil.

- Further, the share is connected to the blade. No gaps should be left between them. the structure must be solid.

- Blade and blade top Must be 6-8 degrees.

If the ploughshare and the blade cannot be exactly docked, then the blade must be given the necessary bend. The easiest way to do this is with a hammer. If everything is the same, then the blade is connected by welding from the back with a share and a side shield.

Further, the shield Weld to the base and the spacer bar. Also attach the ploughshare mount to the base plate. thrust angles.

All these operations are done by spot welding. Inspect the structure and check the correct assembly. If everything is in place according to the template, you can cook thoroughly.

Detach the loose parts of the steel sheet from the general structure. After the metal has cooled, it will clean up the uneven edges of the parts and quarrels. Sandpaper the surface of the blade.

Tiller plow shapes and designs

Plows vary in shape and design. They are divided into the following types:

- Single-hull;

- Negotiable;

- Rotary.

The first option is the simplest. It is he who is recommended to choose for self-production, especially with insufficient experience in this matter.

The reversible plow for the tiller is equipped with a curved blade, which allows not only loosening, but also immediately turning the soil over. It is convenient to use on firm ground. Making such a plow yourself is not easy, you need professional skills.

The rotor design is even more complex. On one here several plowshares are placed. In the process, she turns over a whole layer of earth.

Setting up a homemade plow for a tiller

First you need to tighten the nuts on the mount, but leave them a little free for adjustment. Then fix the structure with a tiller earring. for this, two metal rods are used.

Now you need to configure the unit:

- install the tiller on a level place on a hill or stand, at a height of about 20 cm, and balance.

- The required tilt of the plow is set with special bolts. His “heel” should be parallel to the ground.

- Installing the tiller on the ground, adjusting the height of the handles to the level of the plowman’s belt.

- The final stage is to check the correctness of the assembly in practice. Plowing of 2-3 furrows is carried out with the measurement of the depth and distance between them. it does not have to exceed 10 cm.

For better grip, metal lug wheels should be installed on the tiller instead of the usual rubber ones. So the technique will be less axlebox on loose soil.

How to make a disc plow for a tiller?

The disc plow-hiller is a very useful device that allows you to prepare even furrows for planting potatoes and other tuberous crops. Before you start making such a plow, Examine the drawings. You can use them to control the build progress and avoid mistakes. The procedure for making a disc plow for a tiller is as follows:

- The support angle acts as a plow base. To make it, use an equilateral corner, the shelves of which in the cold state Should be reduced at an angle of 70 °;

- Weld the sock to the corner. After that, weld the heel through the stop bar;

- Fasten the cheeks to the support corner with hinges. The distance between the corner and the cheeks should be such that when the cheeks are opened, their end sides are NOT pressed against each other;

- Weld the rotary mechanism to the stop angle so that the supporting part of the mechanism is perpendicular to the angle.

Finally, adjust the plow cheeks. To do this, fix each of them with pressures and adjust so that in the end they are bent in the opposite direction from each other.

Installing the plow on the tiller

In the design of any plow, regardless of its size and shape, there is a hitch by means of which the device is attached to the tiller. The hitch can be stationary or universal. The most optimal option is considered to be an element of the second type, since it gives more opportunities for adjusting the plow.

Regardless of the type of coupling, the assembly of the structure on the tiller is always carried out in the same order. To trailer the plow to the tiller, proceed in the following sequence:

- First, install the tiller on the stands. you can use bricks or logs for this;

- Attach the plow hitch to the tiller’s hitch so that the holes on both elements coincide with each other;

- Secure the hitch to the towbar with the bolts.

Many beginners believe that the more secure the plow is attached to the tiller, the more efficient the attachment will be. However, practice shows that too rigid a connection will only worsen the quality of plowing. The fact is that during the operation of the plow, forces act on it, leaving perpendicular to the plane of the blade. This creates resistance that pushes the plow away from the tiller. To eliminate this, when installing the plow, you need to leave a horizontal backlash of about 5 degrees.

How to adjust the plow to the tiller?

The quality of plowing depends on how correctly you set the plow to the tiller. Adjustment of the attachment is done in 3 steps, during which you must:

- Adjust the plowing depth;

- Adjust the slope of the board:

- Adjust blade angle.

Plowing depth is the plowing depth when plowing the soil. As a rule, this value should correspond to the height of the bayonet of the shovel. If the immersion depth is not enough, then as a result, most of the roots of the weeds will remain underground. If the immersion height is too high, it will mix the fertile soil layer with the soil below it. This will leave the planted plants without nutrients.

The plowing depth is adjusted by means of three bolts connecting the lock and plow shank. By lowering the plow or lifting it up, you can adjust the depth of its immersion in the ground.

The slope of the plow board is often referred to as the “angle of attack”. This parameter implies the level of inclination of the soil cultivation plane in relation to the ground surface. The tilt of the field board is adjusted using a screw handle. This requires:

- Place the tiller with a plow on several stands;

- Turn the handles so that the field board is on the ground;

- Twist the handle in the opposite direction until the board hangs above the ground at a height of 2-3 cm.

If the “attack level” is too high, the plow will cling to the ground, which will cause the tiller to constantly slip. If this parameter is too small, the plow will not remove the required soil layer.

After completing the previous 2 steps, you can begin to adjust the blade angle. The procedure is as follows:

- First, place the tiller with a plow on the edge of the garden and go through the first furrow. This is necessary in order to determine the depth of plowing the soil;

- While driving, try to keep a perfectly flat trajectory so that the following furrows are also level. To obtain even furrows, you can use a thread stretched between the beginning and end of the row;

- Next, position the tiller so that its wheel fits in the furrow and the plow is perpendicular to the ground. For best results, use a set square.

After completing all the above steps, you will set the tiller‘s plow as correctly as possible, which will help achieve the best result when plowing the garden.

Tiller Reversible Plow. Manufacturing Procedure

As in the first case, in order to make a rotary plow, you need to study the design diagram. Otherwise, even the slightest inaccuracy will lead to low efficiency of the finished attachment. To make a Zykov plow, proceed in this order:

- For making the share, use sheet steel about 5 mm thick. Cut a workpiece out of it, heat with a gas burner and bend it as shown in the figure. The ploughshare must be removable. The cutting part of the part is bounced against the anvil and sharpened on a specially designed machine;

- Next, make a blade. It can be made from a pipe with a wall thickness of 5 mm and a diameter of 50 cm. Using a template Cut out a blade blank with a gas burner, then grind the product with an angle grinder;

- After that, from sheet steel, 3 mm thick, make a plow body and Assemble the structure, Using a quarrel;

- File welds and sandpaper.

As a result of work, you get a universal plow for a tiller, with which you can work Not only dry, but also wet soil.

Rotary plow on a tiller. manufacturing features

The skid wheel rotary plow is the most sophisticated type of attachment used today for plowing. When working on it, you need to be extremely careful, since the slightest mistake will lead to poor quality of soil processing. The manufacturing procedure is as follows:

- The cutter acts as a working body, which can be made from a steel pipe and metal plates. The plates need to be welded to the pipe in such a way that when they rotate they grind the soil and throw it aside;

- Next, make a frame for the plow gearbox. It can have any shape, the main thing is that moisture and debris do not get inside the gearbox;

- The gearbox cannot be made. you need to purchase it. After that, the mechanism must be connected to the tiller’s gearbox;

- Since the rotary plow is a rather large structure, separate wheels will be required for its use. They can be taken from an old moped or motorcycle.

A finished plow for a tiller will serve well for more than one year. The main thing is to change the oil for lubricating the gearbox on time.

How to make a plow for a tiller with your own hands?

Before you start making a plow with your own hands, you will need to carefully study the drawings. They should tell you how to fix the structural parts together. The further procedure is as follows:

- First, make a ploughshare. To do this, take steel with a thickness of at least 5 mm, and give it the desired shape. Beat the cutting part of the steel workpiece onto the anvil, then sharpen it. This is done in the same way as in the case of sharpening a manual braid;

- Next, you need to make a homemade blade. For this, a steel pipe with a diameter of 50 cm is suitable, and a wall thickness of no more than 5 mm. Cut out the blank for the future blade with a cutter. To give the product the desired shape, beat it off on an anvil and grind it on a grinder;

- Next, you need to assemble the parts of the plow into one structure. Take a sheet of steel, the dimensions of which should be 50 × 50 cm and the thickness should be 3 mm. Make a 4-centimeter indent along the edges of the sheet and align it so that the result is a zero angle;

- Then, using wedges, attach a ploughshare to the letter and make double-sided spot welding, observing an angle of 25 °;

- Connect the ploughshare and the blade together as tightly as possible. An angle of 8 ° should form between the top of the blade and the share blade;

- Then weld the side shield, the share and the rear of the blade together. details about the manufacture of a plow will tell.

Then take accurate measurements of all angles again. Only after making sure that the connections are correct, you can finally weld the plow parts. Once the structure has completely cooled, clean out any existing welds.

Types of plows for tilers

The plows used for plowing are divided into several types. These include:

- Single-body designs. these products are the easiest to use. They are lightweight and consist of fewer parts;

- Reversible or reversible plows. the upper part of such structures is equipped with a curved blade designed to turn the soil directly during plowing. Reversible plow Most effective on heavy soil;

- Rotary plows. this type of attachment has the most complex design. On sale you can find a two-body plow, consisting of two, and a three-body plow, consisting of three Plowshares;

- Disc plows. structures of this type are used primarily for plowing wet land. The depth of soil processing with such plows is slightly less than in the spring of previous types of equipment.

Each of the listed types of plows has found application in plowing one or another type of soil. Nevertheless, the most versatile is considered to be a two-sided reversible plow. it shows high efficiency in processing any type of soil.

Plow to a tiller with your own hands from an equestrian. how to do it yourself?

Unlike other types of attachments, the horse plow can be made almost entirely of wood. The only metal part is a ploughshare, since a wooden element will quickly deteriorate due to regular soil processing. The plow manufacturing algorithm is as follows:

- First, take 2 wooden beams, about 10 cm thick. they will serve to make handles. It is necessary to put on rubber pads on the upper part of the handles;

- Connect the handles to each other at a right angle so that when plowing you could firmly grip them with both hands

- Connect the lower parts of the parts with self-tapping screws;

- Take another beam, 20 cm thick. It should be bent so that its upper and lower ends are parallel to each other;

- Fasten a ploughshare to the lower end;

- At the top end, install a hitch, which can also be made from small wooden blocks;

- In the middle, fasten the double part of the handles.

Despite the simplicity of the design, the horse plow shows a fairly high efficiency. True, using it for plowing wet soil is quite dangerous, since wooden elements can simply break from the weight of the earth.

Regardless of the method you choose for making a plow, each of the self-made structures can be used to work with the Mole, MTZ, Salyut tillers, as well as the Neva MB-1 and MB-2.

Tiller plow: adjustment parameters and step by step instructions

In the article, we will cover topics such as preparing a tiller for work, correct

installation of a mounted plow on it. Also how to properly adjust it, and in

conclusion tips for plowing the land.

the tiller is an excellent assistant for the gardener, when preparing the land for

further work. One attachment can replace many tools for plowing, loosening and other work.

Preparation for use

The first stage when using a tiller is its preparation, which consists in the following steps:

- Removing it on a flat surface.

- Preparing the hook for soil and variable axes.

- Removing wheels and replacing them with soil hooks.

After preparation, you should proceed with the installation of the mounted plow.

How adjustment is done

The exact adjustment of the plow for the tiller is built according to three parameters:

- Width;

- Depth of entry;

- Tilt angle.

For self-adjustment of the plow, the width is set along its edges. For the best

crushing and light cuts in the ground, its edge should be fastened at the same height with the hook for the ground, focusing on the inner side.

Read here what is better to use a tiller or cultivator in the country.

The depth is built after the tiller is placed on the stands. Set up firmly, without shifting towards the plow.

The height of the stands should be adjusted depending on how deep you plan to plow the soil. If this is plowing before the winter season, then the depth

choose approximately 25 cm.In spring, the depth is up to 20 cm.

After setting and choosing the depth, adjust the plow mount. The option is considered ideal when it is adjacent to the soil.

If this is the first experience in plowing the earth with a tiller, then use a tension rope for a guide, since the first row should be straight in order to push off further from it.

You can also use the wheel for support, it is located to the left of the plow, and walks on uncultivated ground, thereby preventing too deep penetration and regulates the depth.

After installation, the tiller is adjusted with special bolts so that the rear of the plow is parallel to the soil.

The last step in the adjustment is to remove the tiller from the stand, set the steering wheel to the height of your lower back. This is done to reduce the stress on the arms when

long work.

Installing the plow attachment

There is nothing difficult to install. To do this, you will need:

- Secure the plow to the hitching device and do not overtighten the nuts. This is done so that in the future it would be possible to adjust the parameters of the plow;

- The hitch should be fixed together with the plow to the Shackle with two fastening pins.

This completes the installation and you should proceed to the next stage. adjustment.

Adjustment is a very important step, as the quality of plowing depends on it and

the amount of effort expended. If the adjustment is incorrect, the tiller will NOT be able to

will cope with their work efficiently and it will take a lot of time for simple

tasks.

Recommendations for high-quality plowing of the land

- Change the plowing direction every time to prevent soil displacement.

- To simplify the work Turn the wheel of the tiller to the left, then you will be walking on unplowed soil.

- With petrified soil, work the ground twice: first time

shallow grip depth, the second time. you need.

For the tiller to work properly, it is important to set up and adjust the plow correctly. These tips will help you with this. Also adhere to all recommendations for plowing the land.

From this you can visually familiarize yourself with the plow adjustment on the tiller:

Preparation for use

The first stage when using a tiller is its preparation, which consists in the following steps:

- Removing it on a flat surface.

- Preparing the hook for soil and variable axes.

- Removing wheels and replacing them with soil hooks.

After preparation, you should proceed with the installation of the mounted plow.

How adjustment is done

The exact adjustment of the plow for the tiller is built according to three parameters:

- Width;

- Depth of entry;

- Tilt angle.

For self-adjustment of the plow, the width is set along its edges. For the best

crushing and light cuts in the ground, its edge should be fastened at the same height with the hook for the ground, focusing on the inner side.

Read here what is better to use a tiller or cultivator in the country.

The depth is built after the tiller is placed on the stands. Set up firmly, without shifting towards the plow.

The height of the stands should be adjusted depending on how deep you plan to plow the soil. If this is plowing before the winter season, then the depth

choose approximately 25 cm.In spring, the depth is up to 20 cm.

After setting and choosing the depth, adjust the plow mount. The option is considered ideal when it is adjacent to the soil.

If this is the first experience in plowing the earth with a tiller, then use a tension rope for a guide, since the first row should be straight in order to push off further from it.

You can also use the wheel for support, it is located to the left of the plow, and walks on uncultivated ground, thereby preventing too deep penetration and regulates the depth.

After installation, the tiller is adjusted with special bolts so that the rear of the plow is parallel to the soil.

The last step in the adjustment is to remove the tiller from the stand, set the steering wheel to the height of your lower back. This is done to reduce the stress on the arms when

long work.

Tiller plow: adjustment parameters and step by step instructions

In the article, we will cover topics such as preparing a tiller for work, correct

installation of a mounted plow on it. Also how to properly adjust it, and in

conclusion tips for plowing the land.

the tiller is an excellent assistant for the gardener, when preparing the land for

further work. One attachment can replace many tools for plowing, loosening and other work.

Installing the plow attachment

There is nothing difficult to install. To do this, you will need:

- Secure the plow to the hitching device and do not overtighten the nuts. This is done so that in the future it would be possible to adjust the parameters of the plow;

- The hitch should be fixed together with the plow to the Shackle with two fastening pins.

This completes the installation and you should proceed to the next stage. adjustment.

Adjustment is a very important step, as the quality of plowing depends on it and

the amount of effort expended. If the adjustment is incorrect, the tiller will NOT be able to

will cope with their work efficiently and it will take a lot of time for simple

tasks.

Recommendations for high-quality plowing of the land

- Change the plowing direction every time to prevent soil displacement.

- To simplify the work Turn the wheel of the tiller to the left, then you will be walking on unplowed soil.

- With petrified soil, work the ground twice: first time

shallow grip depth, the second time. you need.

For the tiller to work properly, it is important to set up and adjust the plow correctly. These tips will help you with this. Also adhere to all recommendations for plowing the land.

From this you can visually familiarize yourself with the plow adjustment on the tiller: