How to make a saw wiring correctly. How to sharpen a wood saw

What to do if the arc flew out of the last braces. Oral cavity

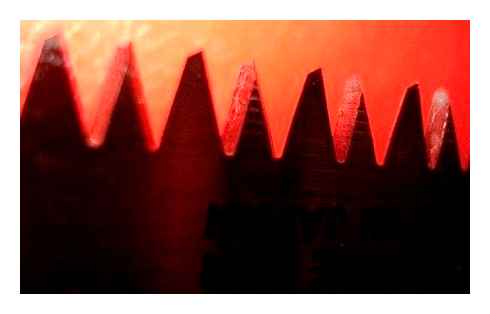

The main cutting element of any manual saw is a number of teeth cut on the canvas and are cutters in the form of wedges. The wood, in the manufacture of all kinds of products from it, is sawn along, across and at an angle θ to its fibers, in this regard, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished and, in each case, the appropriate type of saw is used, which differs from other forms teeth.

During transverse sawing, transverse saws are used, the cutting edges of the teeth of which, when moving in wood, is interrupted by its fibers as a knife and form a cut. The longitudinal sawing differs from the transverse in that the direction of movement of the saw parallel to wood fibers. The front edges of the teeth of the longitudinal drank string the wood, like knives in the shirts, and, deepening, form a cut. When sawing wood at an angle θ to its fibers, universal (mixed) saws with teeth, which are an intermediate shape of the teeth of transverse and longitudinal saws are used.

Sharpening of the saw

Sharpening of teeth drank. In its kind art, requiring fidelity of hands, good eye, attention. It is not difficult to learn this matter, it is necessary to have a desire and clearly adhere to the following rules:

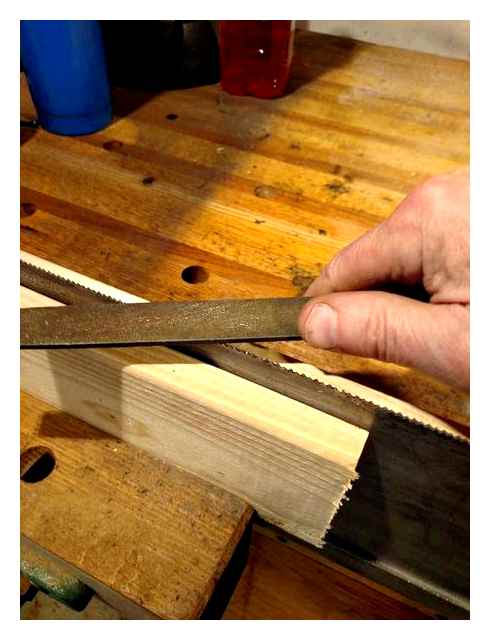

- The saw canvas must be rigidly fixed in a special device made of wood, which is also steadily installed on a well.Lit desktop. Sharpening of teeth drank on stools or knees does not give a satisfactory result.

- You should use a personal file, followed by stripping the sharpened faces of the teeth with velvet (with a small notch) or a file. It is desirable that the file is new, sharp and with a mounted handle. If at the right time it was not the same, then you can use a used, but necessarily cleaned with a steel brush and grated with wood coal, so that the file does not clog and does not stupor. When sharpening the tooth, the file should cling to its metal and remove its layer depending on the strength of pressure. And if it slides down the tooth without removing the metal, then the teeth of the saw are rolled or the file is Istrut. In this case, it is necessary to repeat the sharpening with a new file. If in this case it slides along the tooth, then it remains to take another saw.

- The handle of the file is clamped with the right hand, and its end holds the end with his left hand and the file is directed to the teeth of the saw. About the work of the file, depending on the type of saw, is described below.

- The pressure of the file on the teeth should be smooth and uniform and only one way from itself. When the file is returned to the starting position, he should not touch the teeth.

- We must try to grind the metal from the faces of the teeth of the minimum of the same thickness, the lead of the file is the same number of times with the same pressure, which allows you to maintain the values of the angles, the step and height of the teeth after sharpening.

- On the faces of the tooth from the side of the file of the file, burrs are formed, which reduce the sharpness of the tooth, and if you do not remove it, then during the operation of the saw they are painted, and the teeth are significantly blunt. To remove the burrs, the edges of the teeth are wetted with a file with a velvet notch and the burrs from the side faces with a wet donkey are removed.

- After sharpening the teeth, it is necessary to check their sharpness. Look at the tip of the needles and the edge of the razor blade: they, sharpened, do not shine in the light. And if they lick them, then rounded surfaces appear on the tip of the needles and on the edge of the blade, which reflecting the light, sparkle well. On this principle, a check of the quality of sharpening of teeth saws was built. For this, the saw is placed in front of the eyes and examine its teeth along the canvas. If their cutting edges and peaks do not shine, then the teeth of the saw are saturatedly stumbled, and if some of the teeth with brilliance (often it happens), then they need to be undermined by a file with a velvet notch, remove the burrs and again check the reflection of the light with their edges and peaks.

The teeth of the transverse saws are pulled, using a trihedral file with a fine notch with an angle at a top of 60 °.

To sharpen the teeth, the saw is clamped in a special device, which allows you to install its canvas at an angle of 45-50 ° to the plane of the desktop. The file is carried out parallel to the desktop at an angle of 60-75 ° to the saw canvas and thus, in the first tooth, the left line is A1A2V2V2.

Sharpen the teeth of the saw in several tricks. First, they pass the files along the left edges of the odd teeth located in the far row, setting up hands on the same movement. Then they pass a file on the right faces of the same odd teeth, completing the sharpening of the main cutting edges with very sharp peaks. After the sharpening of the odd teeth is completed, the saw canvas in the solid device turn over and thus sharpen even teeth, which ended up in the far row. When sharpening the teeth of transverse saws, it is necessary to carefully monitor that the sharp main cutting edges with the dual-sided angle φ = 60-75 °, a short cutting edge and a sharp peak are obtained in each tooth.

So maybe someone is a divorce and sharpening of a saw (hacksaw on wood)

My method of divorce and sharpening hacksaw

For the ability to make a hacksaw divorce, it is better to use special devices to perform work. The essence of the saw divorce is to bend the teeth from the center of the canvas to the sides. The simplest device for this is wiring. It is made from a segment of a metal plate, the slots are made across. The width of the slot corresponds to the transverse section of the tooth, and the depth must be in the framework of 1/3 partially to the height of the tooth. You can make wiring yourself, sprinkling in a metal plate the necessary depression with a hacksaw on metal. If the width of the canvas of the hacksaw is not enough for all this, then the double canvas is used.

At work to establish the correct difference between the cutting parts, the saw canvas is clamped in locksmith or carpentry vice. At the same time, plywood gaskets are used. It is necessary to install the saw canvas so that only the teeth protrudes above the edge of the lips. Wiring with its cut is put on the cutting part. The desired deviation is made. Teeth bend through one alternately.

Signs of a correctly diluted saw

The correctness of the divorce can be judged by the contents of the saw, filled with a mixture, 2/3 of which are sawdust and 1/3. Air. In practice, this is manifested in the fact that the saw with proper intelligence evacuates from the saw more than 4/5 of the volume of wood trifles.

With a very large wiring in the cut, the volume of air increases and the removal of waste deteriorates. With a small torn of the teeth, the board is covered with a layer of tightly compressed hot sawdust.

With too large divorce, sawing will be with jerks, with a small one will become a wave.Like. We consider it worth reminding again that only the upper part of the tooth is divorced so that sawing occurs only by a sharp corner at the very top of the tooth. Before the divorce, the saw is sharpened with the minimum of the cutting of the metal, literally limited to stripping burrs.

Recommendations for the preparation of a divorce machine for work

Indicator

Before a divorce, it is necessary to remove the burrs formed after sharpening with a wooden bar, otherwise the indicator will give incorrect indications. If your indicator is measured in inches, it is better to immediately replace it with an indicator that measures in millimeters, since one division of the indicator in inches corresponds to approximately two and half of the indicator in millimeters. Thus, when the sharpener makes two.Inch divisions, this corresponds to the five divisions in millimeters, which is a lot, and vice versa, the admission of two divisions in millimeters corresponds to only half of the division in inches. Wiring, when the indicator is defined in millimeters, becomes more accurate. Saw a saw evenly, without jerks. The indicator head should walk softly, without jamming and without stuck. In order for the tooth edge to rest on the plane of the indicator end, it must have a diameter of 7. 10 mm. Every day or at least once a week you must check the zero indicator. To do this, a glass (it is easier to make) or a metal plate with a thickness of at least 2 mm, 100. 150 mm long (so that it becomes at the reference points) and a width of 40. 50 mm. The plate is placed in place of the saw, fixed with spring.Loaded stops or stubborn plate, which should press the body of the saw to the fixed plate, and zero is set.

Since the glass is almost perfectly even, zero is exhibited very accurately, the main thing is not to be transmitted here, otherwise the glass will simply split.

Metal cold cutting saw blade sharpening machine

Rice. One. Types of the end of the pusher

Many are trying to do this on the body of a strip saw. But the body is very thin and is easily bending at 0.1. 0.2 mm, which is practically not visible to the eye, and the indicator error with such a zero can reach 10 or more divisions, which is unacceptable, especially if the real divorce comes out For permissible limits. With a real small divorce (less than 0.45 mm), the saw will begin to clamp in the propyle, it loses stability with the formation of a wave. With too much real divorce (more than 0.75 mm) the teeth will be too deep over the wood, and with a sharp change in density on the drains, the saw will begin to earn faster, since with a slight blunt it will be taken aside. Setting up the vertical angle of the indicator is carried out using the same plate. After the clamping of the plate, the end of the indicator should be densely, without a gap, fit to the plate (rice. One).

Wire Saw. Multiple Use Essential Tool

Motionless and movable plates

The plane of the plates should be rectangular, without bends, production and dirt. The end of the motionless plate to which the tooth is pressed should be straight, without production. Before each wiring, the plate must be cleaned, otherwise the dirt sticking to it will definitely knock the wiring and make it uneven.

Support points

The support points wear out as they work, recesses appear in them, into which the back of the tape saw can fall from time to time, and the teeth will be diluted at different heights. The saw will be sawed with jerks. Worn supports must be replaced.

Loaded stops Make sure that during the pressure on the tooth for a divorce the body of the tape saw is not squeezed from the motionless plate, that is, the springs of the stops of stops have enough strength to keep it. If the body still leaves, try to tighten the spring with special screws. You also need to monitor the wear of the ends of these stops. They must press the body with the whole plane. If you miss this, you will get a “swing”.

Try to make the sharpener make admission when divorcing no more than two or three divisions. Then the saw will saw for a long time and efficiently. But, as practice shows, it is usually the admission of five to ten divisions.

In this case, even the best strip saw can be detained after the first log.

Inexpensive indicators are sold separately to check the wiring. If you want the sharpener to be more responsible for wiring, buy this device and at least sometimes use it.

It is very important to establish the initial position of the saw in the divorce device (rice. 2). Many put the lower level on the tooth hollows. It is not right. Tooth divorce turns out to be an arc from the root. This is a very large lever, therefore, with a small blunt, and on the bitch, most likely, the saw will immediately earn it. The lower border must be installed depending on the type of saw, given that the smaller it is, the more stable the saw in the cut. But at the same time, we must always remember: the more the hot tooth in the saw’s body is fixed, the more should be. Otherwise, during a divorce, you will simply break the teeth. Constant Hardness. 3 mm. FLEX BACK. Hard Edge, Hard Back with a weak tooth fixation. 3.5 mm. FLEX BACK. Hard Edge, Hard Back with medium and strong tooth fixation. 4 mm.But even with the correct installation of height with a crumpled supporting plane of a fixed plate, you will still get a radius (rice. 2a) and appropriate saw quality. It is necessary that the planes of the motionless plate are even, then the end of the tooth will bend into broken and thereby acquire maximum resistance to loads (rice. 2b).

Tooth pusher

The emphasis of the pusher should account for approximately 2 mm below the top of the tooth, then the divorce will be carried out normally.

Attention. The teeth should be diluted not with one strong press, but two or three not very strong. Then you will always correctly dilute the teeth and no one will break.

If you went too far, bending it back, you need to take it so that it does not break, not behind the cutting edge, but a little lower, behind the back.

Even a good sharpener, for the above reasons described above, never knows whether he has been divided the ribbon saw correctly. It is necessary that the sharpener is mandatory, after a divorce was carried out in one direction, again quickly looked at the divorce of 7. 15 teeth. If the divorce corresponds to the values that should be, then everything is in order and you can work further. If he sees other numbers, it is urgent to put the machine in order, otherwise the enchanted circle will turn out. Saw poorly saws, waves, experiences strong stresses, quickly returns to the sharpener, it grows the volume of work. Instead of three to five ribbon saws per day, he needs to do 10. 15. Saws saw a little and quickly break. As a result, because of one incorrect operation at a loss, everything: the owner loses money on the saws, the sharpener does not cope with the volume of work, the rabble cannot work normally.

Four options for a choice

There are four options for wiring the saws.

One. Manual classic. The body of the saw when a tooth is clamped is clamped with two spring.Loaded pins. Divorce is made on one side of the strip saw. Then the saw is removed from the machine, turned out, installed again on the machine and the divorce is made on the other side.

Manual improved (by type of press). Divorce is carried out in the same way as in the first version, only the body of the strip saw here is securely fixed by the stubborn plate under the dent, which is guaranteed to bend when the pusher is pressed on the tooth (the effect of the “swing” is completely excluded).

Divorce of two teeth immediately on both sides.

One. All options are based on classic.

The layout of parts of the machine for different manufacturers may vary slightly, but the principle of operation is the same for everyone. The main disadvantage of the classic version, even with high.Quality manufacture of the machine, which is extremely rare, is that the body of a strip saw when a tooth is divorced is clamped with spring.Loaded pins. Bloons almost always for various reasons, when a tooth is divorced, cannot reliably hold the body of the saw, and instead of a tooth divorce, you get the so.Called “swing” effect with an unpredictable divorce.

Divorce machines of this option are made by almost all manufacturers of sawmills. Below are the main elements of such machines (rice. 2).

The absence of any part or poor-quality production leads to a complication or fundamental impossibility of obtaining a good result.

How to Choose Hand Saws | Ask This Old House

One. Massive supporting plate on which all the details are attached.

A fixed support plate on which the indicator (7) is attached and sometimes guides for a mobile plate (10).

The plate must be blessed. It is even better if the plate has an all.Social stamped insert in the plate. If the plate is non.Combustible, then in the place of bending of the tooth, crushing is very quickly formed, that is, the tip of the tooth will bend not broken, but along the radius. Therefore, a hard lever of the bent part of the tooth with the entire tooth does not form. Now, with a relatively high supply or with a sharp change in density on the bitch, the tooth will no longer be able to cut the wood normally. He will bend (spring) on the radius, hook in another place and thereby lead the saw from a flat drink.

The plate should be attached to the supporting plate so that its vertical planes are perpendicular to the base of the bearing plate.

The mounting of the indicator should be such that it is possible to adjust it in horizontal and vertical planes. This is necessary in order to set the end of the indicator tip (8) strictly parallel to the vertical plane of the motionless plate and, accordingly, the plane of the saw, otherwise, depending on the place of touching the tooth, different values will be obtained.

It is necessary that the plane of the end of the indicator ends is necessarily torn, otherwise, depending on the place of touching the tooth, different values will be obtained.

The indicator tip must be hardened, otherwise the pothole forms very quickly and the divorce values begin to jump.

The holes for the guides should be strictly perpendicular to the vertical plane of the motionless plate, be at the same distance from the level of the stove and provide a minimum gap with the guides, otherwise when the movable plate moves in different directions, the body of the tape saw will not be well clamped and the effect of the “swinge will turn out well “”.

Mobile plate. The tooth pusher (11) and two spring.Loaded stops (9) are installed on it, which, when the lever presses, should clamp the body of the saw.

The plate should be made with accurate observance of parallelities and perpendicular to its planes. All holes in the plate must be very accurately drilled in compliance with the parallelism with planes, without lateral deviations, otherwise it will be impossible to provide an accurate clamp of the planes of a motionless and moving plates, stops to the body of a tape saw and the pusher end to the tooth.

The holes for the guide movements should have a minimum gap and be at the same distance from the lower edge of the plate. After installing the guides in them, the gap between the supporting plate and the lower facet of the plate should be 1.5-2.5 mm.

The hole for connecting the mobile plate with the pushing mechanism should be complicated with the axis of the mechanism, so that when they are connected, the general movement is already gently, without jerks, hooks and bullying.

The holes for stops should have a minimum gap and be at the same distance from the upper plane of the plate.

The hole of the pusher should be at such a distance from the upper plane, so that after installing the pusher during the divorce, the distance from its lower part to the upper plane of the fixed plate is 0.5-1 mm.

It is necessary that the thread of the opening of the pusher is cut very accurately, otherwise when the length of the pusher is changed, its end pushing point (plane, etc. D.) will change height.

Springs of stops should be tough enough so that the body of the strip saw is not squeezed during a tooth divorce, and have such a length so that stops during a divorce can almost completely go into the grooves of a movable plate.

The pusher of the tooth is made of hot or non.Core steel. This will greatly change its wear resistance (accuracy of pressure on the tooth). The end of the pusher can be (rice. 3):

- In the form of a cone. The tooth pushing is made by the top (point) of the cone, which is quickly flattened, which does not allow exactly the divorce;

- In the form of a truncated cone made of hardened steel. A form convenient for work, although it is extremely rare. The hardened end has not a point, but a circle with a diameter of 1.5-2.5 mm and is capable of, relatively long without changing its geometric dimensions, to carry out the divorce of the teeth;

- In the form of a beveled plane. It is impossible to make the angle of the plane to the required divorce, so the tooth divorce is always carried out by touching not by the entire plane, but only its parts in the form of a straight line, the height of which, depending on the necessary deviation of the tooth, changes, which does not allow accurate divorce;

- In the form of a carbular plate. The problems are the same as in the previous paragraph, only wear resistance is higher;

- In the form of a truncated cone with a hooked ball at the end. The best option. The pusher always rests on the teeth in the same place, and with the right roller, the ball is almost not erased for a long time. The ball must rotate freely. If it is jammed, then they will quickly erase on the one hand, and all the advantages of this shape of the end will disappear.

Sharpening recommendations

The right choice of the type of sharpening circle is important. It must correspond to the steel brand from which a strip saw is made. Corundine circles are used for instrumental steel structures. If you need to improve the cutting properties of bimetallic models, you should use elborus or diamond circles.

Depending on the technical capabilities, it is possible to perform full.Profile processing or each cutting part separately. In the first case, you will need an elbox circle, the end of which has the same shape as the saw. For the second option, each tooth is processed.

Previously, you will need a machine. It should have the functions of regulating the speed of the disk and a change in its location relative to the tool. After fixing the canvas in a special bed, such actions should be performed according to the following instructions.

- The emery goes down. At this time, the front edge with the cutting edge is processing.

- Cutting in Padin. This is done without separation from the canvas. This stage allows you to remove microcracks and unevenness. An important point is a decrease in surface tension, which is the main cause of deformation of the canvas.

- The circle moves up. The back of the tooth and its cutting edge are tinted.

According to the same technique, all other teeth are updated. It is important that the values of the angles of the entrance and exit are everywhere the same. Otherwise, with the differences of geometry in one of the parts, operational qualities deteriorate.

With prolonged contact of the circle with the metal, the temperature on the surface of the latter may increase sharply. To eliminate this effect, special coolants come directly from the machine. The feed is carried out constantly to avoid the formation of the intensity zone. In this part, the mechanical strength will be worsened.

In order to avoid the appearance of Zazubrin before processing wood, you need to check the presence of metal components in it. Particular attention is also paid to fixation and uniform handling for sawing.

In the video, you can familiarize yourself with the recommendations for amateur sharpening:

In a cycle of articles on tape sawing, we already talked about the problem of proper adjustment of the saw process, gave detailed recommendations for the purchase of machines for sawing logs, ribbon-leading machines for the production of epaulets or tape-fed machines for a furniture enterprise. We also talked in detail about the new method of sharpening tape saws. In this article, we will consider the second part of the preparation of the strip saw for work. The process of wiring its teeth.

Wiring the teeth of the strip saw, despite the apparent simplicity, turns out to be the most severe process, since after the end of the divorce, accuracy cannot be checked in the appearance of the saw, and the quality of the surface of the lumber mainly depends on how accurately it is made.

Read also: Hydraulic DGS jack is intended

Having visited so many sawmills, I can confidently say that more than 90% of the wave during sawing arise precisely due to poor-quality wiring. Uneven (jumping) dentist, divorce of teeth is not broken, but along the radius or below 4 mm from the top of the tooth, a divorce with a unequal value on both sides of the strip saw or simply the incorrectly selected divorce leads to the instability of the saw in the puncture. Another 5% are sawing with dull or initially poorly sharpened saws, and the remaining 5% are obtained with improper settings of sawmills.

Insidious waves

First you need to refute an almost universal misconception that it is easy to cut a tree with a tape saw. This is not iron. In fact, everything is just the opposite. At those speeds of the saw on the pulleys, such a large supply during the cut and significant unevenness of the density of the wood itself along the entire length of the log (knot), the saw can maintain a straightforward movement only with very high.Quality preparation.

Often our clients, when we show them how to properly breed a strip saw, they say, is there a difference for sawing from how accurately the divorce of the drain of the saw is made. With the admission of the indicator into one division, that is, ± 0.01 mm, or 10 indicator divisions, that is, ± 0.1 mm, because even the difference is not visible by eye, which means that for the saw it does not matter. Only after we showed them in a microscope the size of dulling the cutting edge, in which the saw begins to lose stability in the propyle, that is, earned (rice. 1), they began to understand that there is no difference for the eye, and for high.Quality sawing the difference is very big. It was repeatedly verified by us on different sawmills. Regardless of the time of operation or sawed volume of the pilot, the strip saw was removed from the sawmill at the first appearance of the wave. About the same results were obtained everywhere. The minimum dulling of even part of the cutting edges of the teeth of the saw only by 0.05-0.07 mm, which is equivalent to a decrease in the divorce by five to seven indicator divisions, already leads even on medium-sized excess forms. Those who worked on tape machines, sawing metal, know very well that round rental, especially steel 3, can be sawed with a saw, in which the cutting edges are simply demolished.

It’s not about the sharpener

A good divorce machine is a purely technical problem. The apparent simple appearance of the machine misleads many manufacturers. They think that it can be very easily done. When you look at those machines that the sharpeners are trying to breed their ribbon saws in the field, it seems that almost all of their manufacturers absolutely do not understand how, in fact, the machine should work and strive to make its design to the maximum, and, accordingly, for better sale, And reduce the price. And the problem, which is that it is not possible to properly breed such divorces is explained by the fact that we must look for a good sharpener. But the point here, as with the grinding machines, is not in a good or bad sharpener, but in the fact that such divorce cannot be well diluted with a saw in principle. The entire mechanism dangles, some of the main parts of the machine are simply absent, the parallelism and perpendicularity of the ends of the stops and planes of the plates are not observed, the body of the saw cannot be squeezed well. Thus, instead of a tooth divorce, you get the effect of “swing”. The pusher presses on the tooth, but instead of the deviation of the tooth, the body of the tape saw begins to bend (this bending will be only 0.3-0.7 mm, rarely more, completely invisible to the eye), and the body will bend differently, and it will bend differently, and So, all teeth will bend with the same indicator of the same values on an absolutely unpredictable value.

Useful tips / a little about the divorce of teeth on tape saws ! Tips “experienced”.

To date, the market is full of machines for a divorce of various modifications, but 95% of them are created in order to earn money to the company to the manufacturer (seller), but not to the buyer, but also to force the buyer to buy tape saws as often as possible.

The answer is simple, the machines that these enterprises offer weak nodes of fixation of the saw, backlash, poor welding of the main nodes.

You put the saw in the divorce machine, press the handle forward so that the needle’s needle bent the saw tooth for the due value (looks on the indicator that is included), and the machine instead of bend the tooth forward for due value, the lower saw bends back, and itself The tooth is as it should be ahead, but, thereby, the effect of the swing occurs, which leads to deformation of the saw, and such a tool will not be suitable for work after a long time.

Since the saw has each tooth, and after the divorce it is sprinkled in different ways, about 20-25 minutes of time should go to one saw in order to hang out the deviation angle of each tooth as much as possible.

On most machines, the indicator can show the correct deviation of the tooth, and the reality will not be like that

Since the machine is simply not able to give out accuracy. This is easy to check, leaning against the teeth. A manual indicator for measuring the divorce of the teeth of the saw (production of Germany), which will show the level of teeth deviations as accurately as possible, the result will be depressing.

There are also machines on the market that bred two teeth at the same time. Service organizations and private individuals who need a “crazy speed” are very fond of buying this.

Since the levers that breed the tooth are only set to one divorce (deviations), and do not have the ability to squeeze the tooth, as required. Accordingly, each tooth will be divorced in different ways.

How to get out of such a situation so that the divorce is accurate, and the preparation of drank and the subsequent sawing does not bring a headache?

To date, on the market, machines with a clear fixation of the body of the saw in the form of the press have appeared, that is, in one press you fix the saw, the fixation is tough, so much that you cannot move it if you wish, and dilute the tooth with the second press, and squeeze it like it It requires it, the press excludes the swing regime (the example is given above), and in the end you get a well.Divorced saw.

Soft deciduous rocks: (sharpening angle of 12-16 degrees, minimum tooth height 4.8 mm, teeth divorce 0.54-0.66mm)

Soft coniferous rocks, medium resitness: (sharpening angle of 12-15 degrees, minimum tooth height 4.8 mm, teeth divorce 0.52-0.66mm)

Soft coniferous rocks, high resinousness: (sharpening angle of 12-16 degrees, minimum tooth height 4.8 mm, teeth divorce 0.52-0.60mm)

Hard-faced rocks: (sharpening angle 8-12 degrees, minimum tooth height 4.5mm, teeth divorce 0.41-0.46mm)

Soft deciduous rocks, ice cream: (sharpening angle 8-12 degrees, minimum tooth height 4.5mm, teeth divorce 0.46-0.56mm)

Handsaw | Woodsaw | How to sharpening correctly | Woodworking tools

Soft coniferous rocks, medium tar, ice cream: (sharpening angle 8-12 degrees, minimum tooth height 4.5mm, teeth divorce 0.41-0.46mm)

Soft coniferous rocks, high resinness, ice cream: (sharpening angle of 10-12 degrees, minimum tooth height 4.8 mm, teeth divorce 0.41-0.51mm)

Hard-faced rocks, ice cream: (sharpening angle of 8-12 degrees, minimum tooth height 4.5mm, teeth divorce 0.41-0.46mm)

Since when sawing a certain type of breeds, the saw should have a different angle of sharpening and a different deviation of the divorce of teeth. Only then will the saw be sawing perfectly, without a wave and with high quality.

On average, the saw serves 25-30 m3, after which there is a gap, or even the complete unusable saw for further work.

There are two types of saws for sharpening saws on the market, simple machines with an abrasive circle and full.Profile machines with a diamond circle.

The machine with an abrasive circle sharpens the saw only on the front and rear faces, while to well sharpen the saw with such a machine, you need highly qualified personnel capable of performing routine work. Since such a machine should be adjusted not only before the sharpening of the saw, but often and even during sharpening, a saw with such a sharpening machine will serve you 20 m3 after which it will become unusable.

The full.Profile machine, sharpening the saw not only on the front and rear faces, but throughout its profile, the coolant is also used during sharpening, so that the saw is not cauterized, the machine in addition to sharpening the saw also performs properties such as grinding, when grinding sharpening with a machine with an abrasive circle, microcracks are very strongly developed, due to which the saw rupture is subsequently rupture. A full-profile machine, polishes the saw so that microcracks disappear, thereby the service life of the saw can reach up to ~ 60 m3 instead of 20-30, and it also removes the voltage from the saw, which is very important, each tooth will have the same profile, which will increase the resistance of the saw In the boot.

The saw should work no more than 1-1.5 hours, after which it is removed, it is turned inside out, and weigh the nail for 24 hours, to relieve tension, you do not need to grind the saw after each shift, the more often sharpen the saw, the cutting properties of the saw preserve at least more1-2 shifts.

The divorce must be watched constantly if the operator feels that the sawmill goes tight during the saw, remove the saw and first of all check the Division of the saw. It is he who is the foundation.

Information on the site under no circumstances is a public offer.When using materials from this site. A link to it is required!

Homemade sharpening machine

How to sharpen a wood saw. And even so that the sharpening of the teeth of the hacksaw is the same. Homemade grinding machine for saw- this is the way out. Most likely someone will say you can sharpen the saw with a file. But at the same time I’m wasting time. And besides, the quality of sharpening the hacksaw will suffer. It is necessary to properly sharpen the saw or hacksaw. How to sharpen a hacksaw now is not a question. I made my first home.Made sharpener for drank in just one day. However, I did not spend expensive materials. But the quality did not suffer from this. Watch below the photo.

Type of the machine

The base for the machine is the frame, which I cooked from square pipes with a cross section of 30 x30.By the way, I cut all metal on my home.Made machine from a grinder. On this site there is an article on a stationary cutting machine from a grinder. As a table, I used a sheet of iron with a thickness of about 2 mm. Because nothing else was found. But this thickness is enough. See photo in drawings 1.2.4.

Frame of the machine

I installed a power supply for connecting a motor into the base building. And installed the legs on the frame. Because when working, the machine moves without legs. In the machine, I used an all-in-one printer engine. In my surprise, the motor turned out to be quite powerful. You can watch my homemade home.Made sharpening machine on the Zhelezkin channel. Since the motor had a diameter of 3.17 mm, my nozzle from China came up. But, unfortunately, the nozzle has a beating. In drawings 3.4 you see a motor with a nozzle. I have already installed the motor on the frame. See the drawing below, and in drawings 3.4 you see what the mounts look like.

Details of the machine for sharpening saw