How to make a screwdriver from a 220v network

Convenient screwdriver from the network: features of use

The cordless cordless screwdriver is a great companion in your home. Almost everyone who he has never let down can agree with this. Those who stopped working halfway have a completely different opinion. This tool will help you always and everywhere, but exactly until the time the battery is discharged. over, the quantity in it is limited. In moments of idleness, the battery can also deteriorate. Batteries usually last no more than three years. When this time expires, it has to be changed or sent to the museum of obsolete things. The situation is possible if you convert the screwdriver into a network one. There are enough ways to do this.

The power supply unit of the device provides the function of changing alternating current with a voltage of 220 V. Standard screwdrivers consume a constant current, with a nominal value in the range of 9-18V. In this regard, connection to the network is carried out subject to the use of an electronic transformer. For these purposes, products of the Toshibra and Feron brands are most suitable.

Mains transformers of these brands are of high quality and reliable in operation. In addition, they are quite compact, lightweight, and do not complicate the work with the tool. Their load characteristics are close to those required for a standard screwdriver. In their design there are 2 input and output wires, which allows you to supply power to halogen lamps and other types of electricity consumers with a voltage of 12V. However, to use the converted device, you need to adhere to some rules.

Here they are:

- Let the appliance rest for 5 minutes every 20;

- Fix the cable at the elbow with your hand so that it does not interfere with the work;

- Clean the power supply from dust;

- Do not use too many extension cords;

- Do not use the device without grounding;

- It is forbidden to use a converted device for work at height.

Before each start of work with the converted device, make sure that it is working properly.

How to convert a battery device to a screwdriver from a 220 volt network

Today the screwdriver belongs to the devices that we very often use in everyday life. It is also irreplaceable in production. This device is suitable for a variety of electrical and construction work. With its help, furniture and other items are assembled, the design of which requires threaded connections.

The cordless screwdriver is compact and portable. But not everyone is happy with these advantages, because the device quickly runs out of battery, and you have to interrupt work halfway. Therefore, many owners of this tool are interested in the question of how you can convert a screwdriver with a battery to a network.

The reason for this decision is also the fact that when the device is not used for a long time, the battery is discharged on its own, which leads to a breakdown of the screwdriver due to the destruction of some elements. It is impossible to repair a failed battery, and it is not always possible to purchase a new one. Often, component parts can only be purchased from the official representatives of the manufacturer. Accordingly, the cost of a new battery will be almost equal to the cost of a new screwdriver. Therefore, some craftsmen come to the decision to turn the screwdriver into a network.

Materials and tools required for this:

- Charger from this screwdriver;

- His native battery;

- Soft stranded electrical cable;

- Soldering iron and solder;

- Insulating tape;

- Acid.

First, you need to solder the loose ends of the cable to the terminals of the charger. You need to know that copper wires of a cable with brass contacts can only be soldered after they have been treated with acid. Experts recommend using special solder, but sometimes the simplest methods are used in the form of acid treatment.

Converting a screwdriver to a network using laptop charging

In the event of a battery failure, a household screwdriver can be switched to mains power by making some changes to its design. This does not require a lot of expenditure of finance, time and effort. The positive nuances of this transformation are obvious: you do not need to constantly charge the battery, and at the same time, the forced downtime will go away. After all, the shortest duration for charging the device is more than 3 hours.

However, when deciding to perform such a transformation with your screwdriver, you should understand that from now on you will need an alternating current to work with it. You will no longer be able to use it away from communications.

If you need to connect the screwdriver to the network, you can use the charger from an old laptop. It has similar characteristics to a screwdriver, and it can be easily found in every home or workshop. But, nevertheless, check what output voltage is shown for your charging. In this case, chargers for 12-19V are suitable.

Scheme of your actions:

- We take out unusable batteries from a failed battery pack.

- We take charge from the laptop.

- Cut off the connector and strip the wires from insulation.

- We solder the bare wires or wrap them with electrical tape.

- We make an outlet for the wire in the case.

- Assembling the structure.

This manipulation will allow you to use the screwdriver at any moment, and without stopping for charging.

Why do you need to remodel a mains-powered screwdriver

In order for you to be able to use a screwdriver even in the most inaccessible places without unnecessary wires, at any time, the mobile screwdriver is converted to a network.

To carry out such a procedure is not so difficult as it seems at first glance. With the appropriate skills and all the necessary components, this process will take a little time.

Methods for converting a cordless screwdriver into a network vary in complexity. One of them. powering the charging from a laptop practically does not require knowledge and skills. To mount a computer power supply, you need to know how to handle a soldering iron, and to repurpose a Chinese adapter, you need to know how to handle a measuring device. In addition, there are several other methods for converting a cordless screwdriver directly into a network.

Namely:

- Using a power supply device from a personal computer instead of a battery;

- Giving new life to the car battery;

- Using, as source, a power supply from halogen lamps;

- By connecting the Chinese 24V power supply board.

For brainy craftsmen, it is not difficult to perform such manipulations. If you are not confident in your abilities, then it is better not to risk it and seek the help of a knowledgeable specialist.

How to convert a cordless screwdriver to a network: 5 options for solving the issue

How to make a screwdriver from the network

When the batteries stop working due to the fact that they have simply outlived their life, many begin to wonder how they can fix the situation and remake their old cordless screwdriver into the network with their own hands. After all, it is no longer possible to repair a battery with a destroyed element, and the cost of a new one is almost equal to the purchase of a new screwdriver. But zealous and skillful owners came up with a way out. to power the screwdriver from the mains. Some were even able to invent a device that works simultaneously from the mains and from the battery. But it’s better not to do it.

Alteration of the electronic transformer

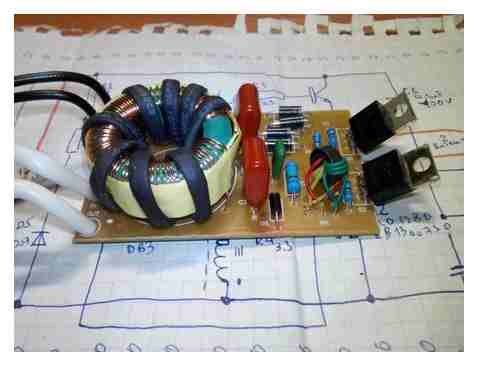

A good and fairly compact power supply can be made from the so-called electronic transformer (ET), designed to power low-voltage halogen lamps.

But in order to use the transformer in conjunction with a screwdriver, it (the unit) must be modified. Let’s take a look at the classical scheme of the simplest ET.

This is the simplest pulsed step-down power supply, assembled in a push-pull circuit. The output voltage is removed from the secondary winding of the output transformer. The circuit shown in the figure is, of course, not the only one. There are devices that are simpler, there are more complicated ones. Available with output voltage stabilization, soft start system and short circuit protection. But what interests us is an invariable part of any electronic transformer. So what’s the difficulty?

The problem is that the output voltage of such power supplies is variable with a frequency of tens of kilohertz, and even modulated with a frequency of 50 Hz. It is suitable for powering incandescent lamps, but not suitable for a screwdriver. Hence, it needs to be straightened and smoothed. To do this, we use the diode VD1 and two smoothing capacitors. C1 and C2, connecting them according to the diagram below.

The H1 lamp serves as a load lamp when the screwdriver is turned off. It is necessary to start the converter. without load, it simply will not start. A high-voltage electrolytic capacitor can be taken from a power supply unit for a computer or any other device, say, from a TV with a switching power supply. It is located in the housing of the electronic transformer. The diode and the capacitor are placed in the body of the instrument, and the lamp is installed so that it also illuminates the workplace. it killed, as they say, two birds with one stone. Such a lamp will be much more convenient than the standard illumination, which is turned on only with the instrument. Aim blindly in the dark, then start the screwdriver and look where you hit.

The KD2960 diode is a high-speed rectifier diode designed for a current of 20 A and withstanding a reverse voltage of 1200 V. Its foreign counterpart is 20ETS12. Replacing this diode with an ordinary rectifier will not work. it has too low a speed, and at a frequency of tens of kilohertz it will warm up more than it will straighten.

But there is a replacement. A Schottky diode is quite suitable, withstanding a current of 15-20 A and a reverse voltage of at least 25 V. You can find such diodes in PC power supplies. There they serve the same purpose. The diode, of course, needs to be put on the heat sink.

Miniature light bulb. It can be found in Soviet New Year’s garlands, or use two 6.3 V, connected in series. We assemble the rectifier, place it in the tool case, bring out the wires through the hole made, solder one part of the connector. The second is soldered to the wires from the transformer. and the revision is completed. Since the voltage at the output of the electronic transformer is variable, the polarity of connecting the wires from the ET to the rectifier can be disregarded.

As mentioned above, there are transformers that provide a smooth start for halogen lamps. Are they right for us? Quite. As soon as we connect the ET to the network, it will start and within 1–3 seconds it will enter the operating mode. this will be clearly noticeable by the smooth flashing of the H1 lamp. After that, the tool can be used without problems.

Conversion instructions

Let’s consider in more detail, step by step, how you can convert a cordless screwdriver to a network.

What power does the power supply need and how much does the screwdriver consume from the power supply?

It is not difficult to calculate the required power of the power supply unit. you need to multiply the current consumed by the electric motor of the tool by the voltage. For example, the tool is powered by a 12 volt battery. The current that the electric motor needs to operate is 10 amperes. We get 120 watts. But this is the minimum value.

To ensure normal operation under loads, for example, when driving a screw into a hard wood, the power supply unit should be selected with a margin of 30-40%. Otherwise, the screwdriver will not be able to work normally under load or the power supply will fail.

The current strength, depending on the model, can be 7-10 A for household screwdrivers and 30-40 A for professional models. Battery voltage may be 12V, 14V, 18V depending on the specific model.

The required parameters of voltage, power and capacity of the battery are usually indicated on the label of the instrument itself or in the technical documentation for it.

If the operating voltage of the instrument is 12 V, the number of power supply options increases, for example, you can connect it to a computer power supply. It is quite possible to buy an old one with a power of 300 W for a small price. In addition, the output power is sufficient with a margin. The advantages of this option include: ease of alteration, as well as the fact that a power supply unit from a computer with a capacity of 300 W or more is relatively easy to find.

The block parameters are indicated on the sticker on the wall. For example, it says that a voltage of 220 v comes to the input, a current of 25 A is supplied to the 12 v output. We get a power of 300 W.

If desired, as a power source for 12 V from the network, you can use:

- LED driver;

- electronic transformer for supplying low voltage halogen lamps;

- car battery charger.

If the instrument is powered by a different voltage, say 14 V or 18 V, there are few options for choosing the power supply. For a tool operating from a voltage of 14 V and having a maximum current of up to 25A, there is a universal power supply unit AIDA BSH 14 PRO on sale. There is also a power supply unit for 18 V, rated for current up to 20 A, AIDA BSH-18 PRO.

You can do it yourself with a power supply unit for the required voltage. But this requires some knowledge of electronics. You can see the diagram of such a power supply unit. There are power supply circuits that can be mounted instead of batteries.

When connecting power from the charger to the screwdriver, you must use a wire with a cross section of more than 2.5 mm². Otherwise, the wire will become very hot, which can lead to melting of the insulation and a short circuit.

Also, the level of voltage losses depends on the length of the wire. The longer the wire, the correspondingly greater the loss. If you choose the wrong length of the wire, it may turn out that the screwdriver “does not pull”, they cannot screw the screw into hard wood, etc.

The quality of the wire connection also affects the voltage loss. Twisted wires will have a high contact resistance, which will significantly affect voltage losses.

Old inverter welding

You can power the screwdriver using the old inverter welding, but this will require skills in the theory of electrical engineering. Indeed, in this case, it is imperative to add the secondary coil of the transformer, which will make it possible to obtain at the output a completely suitable current to power the electric motor of the device. Therefore, before connecting the screwdriver to the welding machine, it is necessary to measure the current and voltage at the output, which must correspond to the values of the device.

Do-it-yourself conversion of a cordless screwdriver into a network

The third option is to convert the cordless screwdriver for mains operation. You will need knowledge of electronics and circuitry, so this is not for everyone. In addition, you will need to know the operating parameters of your battery.

If the battery is broken, then you can ask people on the DIY forums to measure the parameters of the current and voltage of the battery. This will help you make the mains power supply. Basically, if you have a good knowledge of electronics, you can simply disassemble the battery. In its design, there will be chemical batteries connected in a certain way. Knowing their type, from the name of the battery, as well as the connection diagram, you can quickly estimate the parameters of the battery. And then assemble the rectifier with the required operating parameters. Or even replace the cells in a failed battery. And then you don’t have to assemble the rectifier.

We wanted to know how to make a screwdriver directly from charging?

Congratulations! Now that you have learned how to convert a screwdriver into a network, you can put this knowledge into practice.

It doesn’t matter if your screwdriver is loaded or not. No need to think about how long the battery will last

Good luck with the rework!

Connecting wires directly

Connecting the wires directly to the screwdriver is done as follows:

To connect the wires directly, you first need to disassemble the screwdriver, that is, unscrew the bolts holding the two halves of the case.

Consider the connections, find the plus and minus, remember the polarity of the connection. For convenience, it was decided to remove the lower wide part of the handle.

Next, you need to connect the wires, this can be done with a soldering iron or good old electrical tape.

And the final touch is to wrap the wires at the exit of the handle for additional fixation and insulation.

Preparation and the first stage of changing the power supply of the screwdriver

The first step is to solder the metal conductors of the wire to the charging terminals. The soft cable has copper conductors. Terminals are usually brass.

To solder such materials together, pre-treat them with acid. The craftsman uses special solder for this process, but practice shows that ordinary rosin will also work.

How to Magnetize a Screwdriver. The Easy Way

The process is quite simple, although many owners still manage to make it easier for themselves. They use crocodiles to connect the contacts. We still recommend using a soldering iron for greater reliability of the device.

How to make a screwdriver from the network

All modern screwdrivers are divided into professional and home (household). It is not strange that most buyers prefer the second type, because they cost an order of magnitude cheaper.

The problem is that when used in regular standard mode, the battery of the device often fails. Replacing a fixture isn’t all that cheap.

Not every owner will be able to repair, especially if the device has broken down not for the first time, it is almost impossible to do this.

There remains one, but one hundred percent option. convert the power supply of the instrument from the battery to a 220V outlet. You just need to figure out how to make a screwdriver from the network.

What you need to rework a screwdriver

The whole process is quite simple, if you have at hand a good instruction, a set of necessary materials and tools.

Namely, you will need:

- Native device battery.

- Serviceable charger.

- Stranded wire. Desirable soft.

- Soldering iron and rosin.

To get the most out of your tool, you need good drills. You can buy them inexpensively online. For example, on the Aliexpress website.

How to make a screwdriver powered from the network. We use an old battery

The other end of the wire, as you already understood, connects to the screwdriver itself. For convenience, we will use an old battery. Here you cannot do without a soldering iron, since the “crocodiles” will constantly fly inside the case.

Pre-disassemble the battery and remove the insides. Materials are toxic, so be sure to use skin and respiratory protection.

Next, clean the inside of the case. To do this, rinse it with a weak mixture of alkali and water, then rinse it with clean water. Let the plastic dry and you can solder the ends of the wire. Remember to consider the polarity of the device.

Before soldering, pass the cable through the pre-drilled hole in the bottom of the battery case, that is, in the handle. It is desirable to fix the wire inside. Use duct tape. It will perfectly secure the cord inside the screwdriver.

How to restore the center of gravity of a converted screwdriver

The parts of the tool were calculated in such a way that the device was as convenient as possible in work. You have changed the weight of the fixture, so the center of gravity has shifted. This will bring some discomfort when using a screwdriver.

To prevent this from happening, add weights to the empty battery by inserting a weighting material into its body that matches the weight of the internals of the device. The fixture can now be connected and tested.

Self-made power supply. in fact, a simple process, but requiring special attention.

Conversion of a screwdriver to mains power

A screwdriver is a tool designed for driving screws and drilling small holes. There are mains, powered from a 220V network and rechargeable, with two replaceable batteries.

If the battery in such devices fails, then there are three options:

- replacing the battery is expensive, in a budget class device the price of a set approaches the cost of a new device;

- repair is not always possible, and in some cases its cost is comparable to the cost of new batteries;

- conversion of a cordless screwdriver to a network.

This article describes how to power a screwdriver from a 220v network, or how to make a network out of a cordless screwdriver.

Screwdriver device

This mechanism consists of the following parts:

- DC electric motor. It has the shape of a cylinder; instead of the field winding, there are permanent magnets in the housing. This simplifies the design and provides sufficient torque at low revs. The drive (sun) gear of the planetary reducer is put on the electric motor shaft;

- Reversible speed controller. The adjustment circuit is assembled on a PWM controller and a field-effect transistor. The reverse is carried out by switching the polarity of the power supply to the motor brushes;

- Planetary reductor. Made in a separate building. It got its name from its similarity to the solar system. Consists of a ring gear, a central (sun) gear, satellites and a carrier. The ring gear transmits the force through the spring loaded load regulator balls. There are models with two-speed gearboxes. The increased speed is enabled when using the device as a drill;

- Rotary force limiting mechanism. Serves to limit the force when tightening screws. Transmits torque through balls pressed by an adjustable spring;

- Removable battery. Consists of separate elements in one body. The voltage in different models is from 9 to 18 volts.

How to make a homemade power supply

First of all, you need to determine the required number of turns. The procedure is as follows:

- disassemble the transformer;

- unwind all secondary windings from the coil;

- wind 10 turns of wire;

- assemble the transformer;

- connect to a 220V network;

- measure the voltage on the secondary winding;

- divide the number of turns (in this case 10) by the measured voltage.

The resulting value is multiplied by the supply voltage of the screwdriver and the required number of turns is obtained.

Attention! The number of turns per volt can be obtained by measuring the voltage and counting the turns in the secondary winding.

The lowering winding is wound with a wire with a cross section of 1mm² to reduce the voltage drop in the transformer.

There is an alternating voltage at the output of the transformer, and the device needs a constant one, therefore, a diode bridge is installed in addition to the transformer. It is assembled from diodes on radiators, with a voltage of more than 20V and a current of 10A. It is mounted together with a transformer or in a battery case, from which the elements are removed.

Finding faulty items

The storage battery is assembled from individual cells. They do not fail at the same time, but even one defective element degrades the performance of the entire battery.

To determine the parts that have lost their capacity, it is necessary:

- charge the battery;

- work until power loss;

- disassemble the battery;

- measure the voltage on each element separately.

Batteries with noticeably less voltage or no voltage at all must be replaced.

Assembling a serviceable battery from two that have lost capacity

Two faulty devices can be assembled into one serviceable.

Important! By connecting the power supply unit to the case of the defective battery, the second repaired one will provide mobility when performing small amounts of work.

Alteration of a screwdriver for power supply from a 220V network

If the battery fails and it is impossible to repair it, the only way out is to convert the cordless screwdriver into a network.

In this case, the power of the power supply unit must exceed the power of the motor, taking into account possible overloads at the time of the completion of tightening. It is not indicated in the passport of the device, but this parameter is written on the body of the electric motor, or it can be calculated by connecting the device to a constant voltage source through an ammeter. For a 70W motor, a 120W power supply is sufficient.

Important! The charger is not powerful enough to operate. When converting a cordless screwdriver into a 220 volt mains screwdriver, you must use a different power supply.

Battery cell types

These devices use elements of different types and voltages, each of which has its own advantages and disadvantages.

The most common. nickel-cadmium (Ni. Cd) voltage 1.2V.

Advantages:

- low price;

- stored in a discharged state.

Disadvantages:

- have a memory effect;

- high self-discharge;

- small capacity;

- low number of charge / discharge cycles.

advanced 1.2V nickel metal hydride (Ni-MH).

Advantages:

- lower memory effect and self-discharge;

- large capacity and number of charge / discharge cycles.

Disadvantages:

- higher price;

- poorly tolerate low temperatures and storage in a discharged state.

The most advanced 3.6V lithium-ion (Li-Ion).

Advantages:

- lack of memory effect;

- very low self-discharge current;

- high specific capacity, allowing to reduce the weight and dimensions of the device;

- the number of charge / discharge cycles many times higher than other types of batteries.

Disadvantages:

- high price;

- loss of capacity three years after manufacture.