How to make a shock hammer in the reverse action. Reverse hammer for the body…

DIY hammer

There are several types of this tool. This, in particular:

Of course, you can just go and buy a tool in the store. the benefit is their choice is currently very wide. However, there is an alternative option that is suitable for novice automakers, or if you need to do some single work. After all, the simplest reverse hammer can be made with your own hands. There is nothing complicated here, and you will spend a little time for its manufacture.

The most optimal option in this case is a simple gyreshny hammer. The first thing we need is a steel rod

It is important here its diameter. you need to take at least 2 centimeters. The thing is that the tool made from a thinner rod will be short.lived

However, for one rikhty this will be quite enough. Also, for the manufacture of a home.made reverse hammer, you need a rubber handle. Here you can use the no other tool removed from some other tool. If you want, tighten the handle from a whole piece of rubber. With the search for this material, there are hardly any problems.

The next important part of the hammer is a steel hook. At its end it will be necessary to cut the thread for subsequent screwing into the pin. It is very convenient to stretch the surface by the brackets with such a hook. In addition, this structural element will also allow you to use the tool when removing nozzles. We will also need 2 steel washers with a diameter of 3 centimeters. One of the most important elements of a hammer is a weight. In this case, it is recommended to take an ordinary store grandmother that does not have protrusions and angles, up to 15 with a cross.section of up to 6 centimeters. In addition, we also need a welding machine.

Now you can proceed directly to the manufacture of milk. First of all, it is necessary to inspect the rod. it should be even. If you count on a long use of the tool, this part should first be soaked in anti.corrosion solution so that it does not rust later. Also, the rod has to grind and degrease. Preparatory work can be considered finished on this. Next, take the puck and weld it on one end of the rod. She will act as a limiter, not allowing Gira to fly during the workflow. After that, you need to attach the hook to the rod. fasten or weld.

Then we proceed to the preliminary preparation of the weight. This part of our future hammer first will need to be drilled through the lathe. The diameter of the hole is selected based on the thickness of the rod. the latter should have a free move. It is best to check everything right away. If the rod goes tight, the hole should be slightly expanded. Next, you can put on the weight and fix the second washer. She will also act as a stopper, not allowing the grandmother to deform the handle. Now you just need to put on a prepared rubber nozzle prepared in advance, and everything is a simple home.made reverse hammer is ready. You can check it in the work on some unnecessary piece of iron-there will probably be something suitable for this in the garage.

By the way, you can make a home.made vacuum reverse hammer. For this, minor changes should be made to the design described above. In fact, we will need almost all of the above components, with the exception of a steel hook. Instead, a plunger should be attached to the pin. Just definitely take a new. The thing is that in this case it is simply impossible to work normally with an old batter. Such a tool is more convenient to work. After all, here it is no longer necessary to pre.weld special brackets to the repaired body.

Happy Hap for Removing the hub

Your goal is to remove the hub with a reverse hammer. So, it is necessary to cause a retractive effort of the tool. an impulse opposite to the one that creates an ordinary hammer. Start with the plan.

Device design

Think about the design of the mechanism, draw a device diagram. On the drawing, apply the size of the reverse hammer to remove a grenade with your own hands.

Ready.made schemes can be found on the Internet. But, as a rule, you will make your own adjustments to them, because the reverse hammer for removing the hub with your own hands is not created from store spare parts: the details are selected from the garage “good”.

Necessary details

Do.it.yourself mechanical reverse hammer to remove bearings can be made even from anchors, and a profile pipe of square section is used for hubs.

Do.it.yourself mechanical reverse hammer

However, the thorough design, which will serve more than once, make from backing rear car racks, for example, from VAZ 2108. They are needed:

- two metal pipes up to 12 cm long;

- old handle from power tools;

- a washer with an outer diameter of 60 mm and internal. 22 mm;

- lead.

Materials and tools are collected, now you can build a reverse hammer to remove the hub with your own hands.

Production algorithm

Removable tool, as the basis of which are taken racks, make it as follows:

- Retreat from the rod 2 cm, cut the rack.

- Remove the cylinder and stem.

- Do the same with the second counter.

- Combine two stems with ends on which there is no thread. Boil the details, clean, polish. the main core of the structure turned out.

- On one side of the pin, weld the harvested washer, put on the handle, fix it with a nut.

- Prepare the shock weight, put on the rod, fix the puck so that it does not slip.

A reverse hammer for removing bearings with your own hands is ready. At the end, opposite handle, fix the removable two- or three-fold nozzle.

How to make a handle

The handle should comfortably go to the palm of the left hand. Do not mess with manufacture: remove the rubberized handle from the side of the power tool.

If there is nothing suitable, cut a piece of the pipe that is tightly mounted on the pin, wrap it with island for convenience. use and against the sliding of the hand. It is necessary to fix the handle with a nut.

How to make a moving weight

Take two segments of pipes 12 cm long, one should enter the other with a gap. Weld the puck from one edge. Fill the space between the details with lead, heat the outer tube with a gas burner. Lead will melt. After cooling the weight is ready.

Make sure that the inner tube is a larger section than the main pin of the instrument: a load for a reverse hammer with your own hands should always move freely around the rod.

What is a reverse hammer and why it is needed?

This tool is a device that allows you to make a certain force to the metal area with limited access. A device is used to align small sections of a deformed car that suffered from small accidents.

Some sections of the car body can be leveled with an ordinary rubber hammer, using blows from the reverse side. However, most of the surface has no access. In such cases, a reverse hammer is needed. Its tip is fixed at the place of deformation, and the help of the cargo, which is located on the other end of the device, is transmitted to the surface with a pulling jerk force.

Before making a reverse hammer, it is necessary to describe the varieties of this tool. This will be needed to make a drawing of the device you need, and then make it.

What is this device

If you are at least a little familiar with the locksmith, then creating such a tool at home will be enough for you.

Self.manufacture of such a device will not take much time, and will not even require special equipment or knowledge. For a more visual understanding, we present a primitive drawing that will not be superfluous.

As noted above, the design of such a hammer is very simple. On a steel rod 50 cm long with a diameter of 10 to 20 mm, a metal sleeve is planted, which should have amenities for capture with a hand.

The diameter of its hole should allow to freely slide along the rod of the hammer, without creating a large backlash. The handle is installed on the upper part to hold the tool with the hand. A shock washer is tightly attached to the handle on the rod.

Method for using a reverse hammer

The method of aligning the body using the tool made is simple, but will require some effort. First of all, you should fix the tip on a curved surface. Further, the boards on the weight of the harvest is aligned as it should. With insufficient efforts, you should change the weight. To align a large section of metal, you can weld a couple of goals that will be on the same line. Then you should put on the pin. Next, the rod should be fixed with dick, which is pulled together with the iron, while smoothing everything to the desired state. But it is worth being careful, since you can damage the body part by causing additional damage.

The car body can have dents of different sizes. And at the same time make a reverse hammer with your own hands, suitable for different irregularities, is easy. It is enough to make the possibility of changing the weight to the mechanism. Just changing weight with big damage. Sometimes you should weld additional goals. Then the tool will work smoothly. But do not forget that you can damage the car by overdoing. Therefore, it is worth making smooth movements when repairing the machine. Thus, each motorist with proper repair will be a satisfied homemade device. After all, this mechanism is simple to manufacture and copes with its work perfectly.

Reverse hammer for body repair. types and manufacturing with your own hands

Many motorists restore the car body with their own hands. When performing this work, in order to eliminate defects, it is necessary to use special tools, including a reverse hammer. This device can be bought, but if the body repair is infrequent, then it will be much more profitable to design the tool on your own.

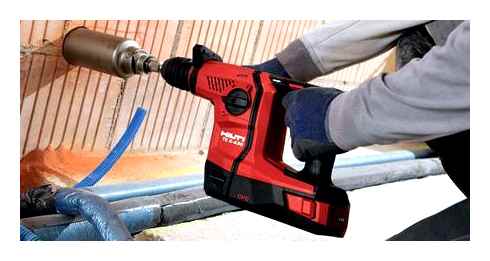

What is a reverse hammer

Reverse hammer for body repair. a tool designed to remove dents from the surface of the car. As a rule, these defects cannot be straightened with conventional tools, so the reverse hammer often is used for rikhty dents on the thresholds, arches and racks of the vehicle.

The tool in the classic version is a 50 centimeter pinproof pin. The diameter of the steel rod is two centimeters. Two elements are placed on it: a rubber sleeve on one side, and on the other. a metal washer.

12 BEST TESTS TO REVEAL YOUR PERSONALITY TYPE

It holds a hammer in a stable position and protects the tool body from vibrations that arise as a result of striking.

The tool is used for ri. small damage in area.

The device for raising defects is equipped with additional clamps and metal hooks, with which the brackets welded to the body of the machine are captured during the ri.

The use of the reverse hammer largely depends on the location and complexity of the defect. There are several types of tools:

For point.to.line ri. dents on the surface of the body of the new car, it is recommended to use vacuum hammers.

The scheme of its work is concluded as follows: with the help of suction, the tool is attached to the restored area, then the handle is pulled “on itself”, and as a result, due to the compression of the air, dent is aligned.

The principle of operation of this variety of the device allows you to eliminate defects without damage to the paintwork of the car body.

The use of pneumatic tools is necessary to eliminate serious damage. The hammer is connected to a powerful compressor, as a result, the mechanical effect on the damaged area is enhanced. The device is attached to the body of the machine using special hooks. Before using the device, if necessary, the paintwork is removed from the damaged area.

Liquid glass to cover the machine: all about the body protection tool

Spotter is a welding machine with which an additional element is welded to the car body. It can be an iron rod or a special hook. Then they cling to the protruding part with the back hammer, and the damaged area is aligned.

Before welding, parts are thoroughly washed, remove the paintwork and degrease from it.

The tool with adhesive overlays is attached without the use of a welding machine. Reliable fastening provides special adhesive composition, after eliminating the defect, the pad is cut off, and the damaged paint coating is restored.

The purpose of using the hammer is to equalize dents. However, with it, some spare parts dismantle it. So, to remove internal bearings, use a tool that has a special hairpin in their design.

Self.manufacture

The finished tool is not cheap, so in order to save money, many motorists are designing with your own hands. For independent creation, you will need:

- Metal steel rod (or pipe) 50 cm long and 2 cm thick.

- Rubber or ebonite handle.

- Stainless steel hook, having a thickness of 4-5 mm.

- Welding machine.

- Two steel washers with a diameter of 2.5-3 cm.

- Weights having a thickness of 6 cm and length 16-17 cm.

To make a reverse hammer is required:

- Clean and degrease the bar, using a grinding machine, polish the surface of the part.

- The hook is fixed for one end. In order not to waste time when creating a thread for removable nozzles, the part is welded.

- A small washer is put on the pin, which must be welded near the base of the hook. It is used so that the weight does not contact the working surface.

- A hole with a diameter of 2.1 cm is made in Gira. Thanks to this, the detail will freely move around the rod during operation. In the manufacture of the tool, it is taken into account that the shape of the part should be without protrusions and angles. Round sheets made of steel are welded to both ends of the element, thanks to this, the palm will not jump off the weights when performing the body of the body.

- They eat a weight from a free end. If the part moves tight, then the diameter of the hole is increased by another half centimeter.

- At the end of the work, the handle is put on, but before that, another washer is mounted that prevents the contact of the handle and weights when using the hammer.

TOP 4 airbrushes. what is it, the principle of operation, the instruction instruction

To straighten dents on the car body, different tools are used, including a reverse hammer. In many cases, its independent manufacture is more appropriate. Having spent 30-40 minutes of his time, the motorist receives a simple design but effective when raising a car body tool.

About stretching. Reverse hammer

Record about simple stretching devices. Almost everything is homemade. The reverse hammer is the most important for me to acquire the last time to repair a car. it solves problems with removing serious dents. I was going to make a reverse hammer for a long time. Gathered for a long time, but did it in half an hour. It was necessary to urgently stretch something.

The most interesting thing is that I had never seen the reverse hammer in the eye, but its very description was clear. Now my reverse hammer is sometimes taken by others, despite its wretched appearance. The combination of mass and long turned out to be very successful. A lot is knocked out. from crumpled thresholds to crumpled double metal in the rear wing (this example is just in the video).

Of course, such a home.made thing is not the most perfect (about this later found out). there is no set of several hooks on it at once. But sometimes the most irreplaceable for me. When it becomes completely very necessary, I will probably buy the same “figured” set and stop the bar of the hooks on my cargo. The principle of reverse hammer is simple.

There is not a very thick pipe (at the first stage it may turn out to be a “ski stick”) and there is a load that has a hole in the middle to plant it on this pipe. Next, you need to make a limiting platform for the cargo on one side of the “pipe” (the load will fight about it), and make a hook or other varieties of temporary “contact and hook” with the repaired metal on the other.

Maybe sometimes instead of a hook, it will be, for example, just a hairpin with a long thread (we pour the hairpin into the body of the body and from the reverse side through the puck or figure spacer we wind the fixing temporary nut. How I fasten the replaced nozzles. The pipe should end precisely with a thread with a thread (this long hairpin itself welded into the pipe).

The nozzle should also end with the same hairpin. You can take one in a construction store. they sell them around (?) meter- from it cut off the desired length. To connect them, you need to wind on one of them a dozen nuts and boil the nuts among themselves. At least I did not invent anything else.

“Having caught” the metal of the cargo on the “pipe” for the metal of the body. we disperse the cargo to the side “to ourselves”. The load beats along the limiting platform (for example, a very large pipe of the pipe) and an amazing force appears, transmitted to the stretched metal.

I have a load of 3 kg. When I made a similar design with a load of mass 0.5 kg- I didn’t like her.

A lot was invented for a long time, there were simply manufacturers who put the manufacture of such and similar streaming devices. They are more perfect and more pleasant in work than homemade. Immediately recalled expensive linings-forms for tiners (support). I also thought more than once to buy them. Then, as it was similar in time similar forms by themselves.

Again, an interesting story about a set of unique long rods for squeezing dents “from the inside”. I also scored such a variety of “hooks”. While you are at an amateur repair level, they can arrange their own. And when it will be important to save time, then it will not be up to reasoning. You have to purchase a professional tool.

That everyone is doing if they want to work quickly.

Added on August 3 in response to a comment. About the action of the reverse hammer can be understood from the video about Audi. The record is not impressive, but the principle of work of the hammer is clear.

Added March 2012 Progress does not stand still. And how do you like this record.

Added 3 February 2013.

And yet about my reverse hammer. I do not cease to be surprised at the simplicity of its design and what big things can be solved with its helpThe most obvious example of its use is the stretching of crumpled thresholds. In addition, this includes all cases when you need to return the metal by 0.5-5 cm outward. The design is really simple. one. Damn with weight 2.5-3 kg. 2. Guide (made from the old ammortiser and t.P.) on which the pancake moves. 3. Steaming a restrictive washer, according to which the pancake will fight. Photos show everything

Do.it.yourself reverse hammer. the community “Make yourself” on drive2

Hi all.I was impatiented with the body of my car, and therefore there was a need for a reverse hammer.The thing is quite cool and the household is necessary. Did not buy, since the price of reverse hammers is soft to say slightly high.

- This was what

- Bore with a burner for scale

- I chose a couple of shock absorbers with a thin rod from my friend for a hundred, the shock absorber sawed, cut out a piece the size of my palm that part with the hole,

- From another shock absorber removed the knot where the oil seal was located,

I inserted the stem, flooded with lead and walked along the hole where the rod would walk with a drill, the weight of the hammer turned out about 1.5 kg (I did not weigh, by eye, it turned slightly, corrected below, the mass is about 700 grams, but my scales are not much faith).The hammer was covered with a heat.shrinkage in 2 layers.

The back of the shock part consists of several goals, and two nuts mounted on the elbow, on which the spill holding the plastic handle is made of the handle made of a handle from an angular grinder or xs, found in a garage in a garage. Spring for an amateur, you can not put. A long nut on the working part serves as a holder of interchangeable nozzles.

- For those who are interested in what and how it screws onto the working part

- You can fasten anything, from the holder for fungi with glue to bolts and hooks of various types, including you can screw a spa to it and. But since I don’t have a spite yet, and my hands itch and the ass is looking for adventures, a piece of the bolt is screwed onto the hammer that I weld to the car hood, as in this video

, I tried fungi with glue cling, the hood does not lend itself. Old BMW, Iron is thick, if something I’ll completely bury another hood, this has already experienced a bunch of repairs.

I really tested this hammer, for those who want to repeat, I can report the following: 1. The hammer is lightweight, the mass of the box can be safely increased to 1 kg, or even more2.

Shortly, probably from two rods will be long through the chur, but out of one and a half just right.3.

The carving on the shock absorber rod is strong, but on the length of the nut I became unusable, not immediately, of course, I had enough, but it could not fulfill its function.

I will not redo my own, the work that I wanted to do it.

Reverse hammer. Types and work. Device and features

A reverse hammer is a hand tool designed to create a retractive force. If a regular hammer is used to clog or deform the surface from yourself, then the device with the reverse action drags the metal onto itself.

Such equipment is used in body repairs, in particular during rikhthovka, and it is also used if necessary to pull the bearing when it is not possible to hit it on the reverse side. Reverse hammers are rare, since they are designed to perform highly specialized tasks that an ordinary motorist or locksmith is not needed.

The tool can be found in automobile service centers, as well as among those drivers who have encountered independent arrangement of the body.

How the reverse hammer works and works

The reverse hammer is a metal pin about 50 cm long. Its diameter is 20 mm. On the back of the tool is the handle.

Directly on the pin itself, a freely moved weight is planted, made in the form of a thick.walled tube, the length of which is adjusted to the size of the palm. The front end of the hammer is fixed in various ways to the surface, which must be delayed.

To work, you need to take your right hand for the weight, and the left hand over the handle of the hammer. To create a stretching force, you need to take the right hand from the gyer to the hilt with a sharp movement.

In this case, a blow is created from which the pin of the hammer will move in the opposite direction, dragging a deformed surface behind him. Thus, almost the same effect is created if it were possible to beat with an ordinary hammer on the back of the dent.

Fixation of the working end of the hammer to the deformed metal is carried out using a vacuum suction cup, glued or welded nozzle. If you need to work with the edges of the car body, then hooks and clamps are used. Each type of fastening has its advantages and disadvantages, therefore it can only be applied in some cases.

The classic device of the simplest hammer with the reverse action is described. There are more advanced models that are equipped with additional devices that facilitate the work.

Most often, they have removable nozzles for fixing to the processed surface, as well as a set of weights of different weights. Thanks to this, you can select components to ensure more efficient work.

For example, if the installed weights are too heavy, and the body metal is thin, then instead of a straightened dent, a hump, which will have to be pressed back.

How to work with a hammer

It is worth noting that the reverse hammer refers to the tool with which you need to work very carefully. If you overdo it and deliver too strong a blow, then other defects can form when dent.

Casters of the body repair do not recommend using a reverse hammer on very large dents, which are present on the roof of a car or trunk. These parts are relatively easily accessible, so it is quite possible to remove the internal skin and put pressure on the back to squeeze the metal to the same place.

In the same case, if the dent is formed on the lateral part of the car, and especially on the thresholds, then the use of the hammer will be more than justified.

To conduct a neat richeat dent, it is necessary to fix the instrument pin at its beginning.

It is unacceptable to immediately fix for the center of the defect, because when delayed, the metal will doubt it, and sharp corners will turn out.

Often, when using a hammer on dents without acute excesses, you can level the surface so much that the previous defect will be completely inconspicuous. At the same time, putty and paint will not be needed.

On significant defects you need to work slowly and smoothly. First, the rim of the dent is delayed, as a result of which its diameter and depth will gradually decrease. At the final stage, the central part is delayed.

In the event that the tool is attached to the body by welding, after each stretching it is necessary to cut the fixation and sand the seam. It is unacceptable that the remains of the Navar remain on the metal, since it acts as an additional stiffener, which interferes with the work at other fixation points.

The use of a reverse hammer is a long process that does not tolerate haste.

Using a reverse hammer with fixing electric welding, after each welding you need to give the metal to cool, since the heated area stretches much easier and does not drag the cold part of the dent. It is also worth considering that it is unacceptable to start work if there is dirt, chips of paint and other layers on the surface treated.

Vacuum reverse hammer

Vacuum reverse hammer is the most expensive and at the same time very effective. The tip of this tool resembles a regular household plug used to clean the outfit of sewer pipes.

At the end of the hammer there is a rubber plate that is applied to the dent. The tool is connected to a compressor pumping air between a rubber plate and a car body. As a result of this suction cup is reliably fixed to the metal.

After that, the hand clamping the weight is sharply pulled and the reverse traction is created that stretches the dent.

Typically, in a set to a vacuum hammer there are 3 rubber linings of various diameters. Large is used to process wide dents, and the smallest for small defects. Such a hammer when connecting to a compressor creates a rather greater fixation power.

The plate is applied not only to absolutely flat surfaces, but also with gentle, which is especially important for cars with streamlined body. The vacuum type tool is quite light and often weighs no more than 1.5 kg.

over, the only inconvenience is the hose from the compressor.

The main feature of the reverse hammer on the vacuum suction cup is that it can draw a dent without the need to remove the paint layer. If the car received an insignificant defect, then it can be corrected with minimal costs without the need for putty and applying a varnish layer.

Reverse hammers

The reverse hammer is one of the most important tools for restoring the car body. It is used when there is no direct access from the inside for small dents to align. The device of such a device is extremely simple, and conducting body repair with it does not require special skills.

Before the work, careful prolonged cleaning of the damaged area to the metal is required;

It cannot be used for relatively large areas of the car body (central part of the roof, trunk lid and hood), since welding of the washer can greatly stretch the metal, and the final result will be very deplorable.

restoration of thresholds, racks and other body elements.

Varieties of the reverse hammer

Despite its simplicity, this device eventually acquired several options for execution. Each option is used in some cases, which depend on the type of damage and skill of the specialist. In general terms, the design of this device is the same, as well as its principle of action. Differences are available only in the method of attaching the tool to the body.

The most ordinary reverse hammer is a metal rod, at one end of which there is a hook, and on the second. a load with an emphasis. The hook is hooked by the puck welded to welding to the deformation site. Applying shock efforts on the load, the deformation is stretched until the right moment.

The second, the same simple version of the reverse hammer differs from the previous one in that at the end there is a conventional thread instead of a hook. To level the surface with such a device, it is necessary to make a hole in the center of deformation, put the end with a thread there, and fasten the washer and nut from the reverse side.

The most complex type of this device has a vacuum device at the end, which is fixed on the surface of the deformed part using a sparse air. Suction cup can be driven from both the compressor and the usual method. This variety of the device allows the Richteen to correct simple body damage, and at the same time preserve the paintwork of the site if it is not damaged.

Homemade reverse hammer with a change of nozzle

This device will be useful to everyone who independently engaged in body repair. using a reverse hammer with a change of nozzle, you can easily and quickly remove small dents in those places of the body of the car to which direct access is difficult (for example, arches, racks or thresholds). And you can make such an indispensable tool in the garage from improvised materials.

What materials will be required

An old steering rod will be used as the basis for this homemade, which has already “rejected” its life.

If necessary, the surface of the part is cleaned of rust and dirt with sandpaper or a grinding circle.

It will also require a piece of steel scrap 12 cm long, in the center of which it is necessary to drill a through hole with a diameter of 13 mm (this is better to do on a lathe).

Additionally, it will be necessary to use part of the steering tip and a steel plate with dimensions of 70×30 mm, which can be cut from a forty corner. On the front side of the plate you need to make notches for better adhesion with adhesive composition.

The assembly process of the device

We put a scrap segment on the axis of the steering thrust, to the upper part of which it is necessary to weld a “plug” so that the part is fixed. Part of the steering tip and a steel plate carved from the corner must be boiled with each other perpendicular to each other.

A detailed process of making a reverse hammer and its application in practice, see the video on our website.

How to make a reverse hammer with your own hands

For body repair, as you know, you need a number of special tools. Without them, it is simply impossible to qualitatively perform work. One of these tools is a reverse hammer. Its main purpose is to equalize small areas of the car body that received slight deformation. With the help of a reverse hammer, you can make a certain effort to places, access to which is limited.

Here you need to make one clarification. Separate sections of the car body in the event of their deformation can also be leveled with a conventional rubber hammer, striking neatly blows in the right place from the reverse side. However, the problem is that you can not always get such access.

In such a situation, the car mechanic is just useful to the reverse hammer. Also, this tool can be used as a supplement for a spotter (spot welding device), for removing the CVA. over, the reverse hammer is just right to use and when performing certain types of repair work related to the engine.

For example, in some cases it is used as a puller for nozzles.

DIY reverse hammer. Features of manufacture

There are several types of this tool. This, in particular:

Of course, you can just go and buy a tool in the store. the benefit is their choice is currently very wide.

However, there is an alternative option that is suitable for novice automakers, or if you need to do some single work.

After all, the simplest reverse hammer can be made with your own hands. There is nothing complicated here, and you will spend a little time for its manufacture.

ТОЛЬКО МОТОРИЗАЦИЯ ЗА СССР В HOI4 By Blood Alone

The most optimal option in this case is a simple gyreshny hammer. The first thing we need is a steel rod. It is important here its diameter. you need to take at least 2 centimeters. The thing is that the tool made from a thinner rod will be short.lived.

However, for one rikhty this will be quite enough. Also, for the manufacture of a home.made reverse hammer, you need a rubber handle. Here you can use the no other tool removed from some other tool. If you want, tighten the handle from a whole piece of rubber.

With the search for this material, there are hardly any problems.

The next important part of the hammer is a steel hook. At its end it will be necessary to cut the thread for subsequent screwing into the pin. It is very convenient to stretch the surface by the brackets with such a hook. In addition, this structural element will also allow you to use the tool when removing nozzles.

We will also need 2 steel washers with a diameter of 3 centimeters. One of the most important elements of a hammer is a weight. In this case, it is recommended to take an ordinary store grandmother that does not have protrusions and angles, up to 15 with a cross.section of up to 6 centimeters.

In addition, we also need a welding machine.

How to make a shock screwdriver with your own hands

Now you can proceed directly to the manufacture of milk. First of all, it is necessary to inspect the rod. it should be even. If you count on a long use of the tool, this part should first be soaked in anti.corrosion solution so that it does not rust later.

Also, the rod has to grind and degrease. Preparatory work can be considered finished on this. Next, take the puck and weld it on one end of the rod. She will act as a limiter, not allowing Gira to fly during the workflow.

After that, you need to attach the hook to the rod. fasten or weld.

Then we proceed to the preliminary preparation of the weight. This part of our future hammer first will need to be drilled through the lathe. The diameter of the hole is selected based on the thickness of the rod. the latter should have a free move. It is best to check everything right away. If the rod goes tight, the hole should be slightly expanded.

Next, you can put on the weight and fix the second washer. She will also act as a stopper, not allowing the grandmother to deform the handle. Now you just need to put on a prepared rubber nozzle prepared in advance, and everything is a simple home.made reverse hammer is ready.

You can check it in the work on some unnecessary piece of iron-there will probably be something suitable for this in the garage.

By the way, you can make a home.made vacuum reverse hammer. For this, minor changes should be made to the design described above. In fact, we will need almost all of the above components, with the exception of a steel hook.

Instead, a plunger should be attached to the pin. Just definitely take a new. The thing is that in this case it is simply impossible to work normally with an old batter. Such a tool is more convenient to work.

After all, here it is no longer necessary to pre.weld special brackets to the repaired body.

How to use a reverse hammer correctly

So you made the tool with your own hands. However, you still need to know how to use it correctly. Indeed, otherwise it is unlikely that you can count on obtaining the desired result.

For example, in order to eliminate large dents, work starts from its edges, then move along the spiral to the center. This is a very important point. If you move in the opposite direction, then the sides in the end will remain concaved, and only the center will shift.

Accordingly, the dent will not go anywhere. over, it will become even tougher.

Previously, it is necessary to carefully examine the problem area carefully. this will more accurately calculate the force of the tool application. If a hammer with a hook is used, then the problem area is first cleaned to the metal.

After that, repair brackets are welded there. Then you need to hook the hammer hook. The dent is stretched with neat non.senile blows. It is not necessary to rush here. all movements should be accurate and verified.

How to independently make a reverse hammer from an old shock absorber

VAZ shock absorber racks are best suited. After parsing the old car, do not rush to take the old parts in scrap metal. Having attached some effort and ingenuity, it is easy to make a reverse hammer from a shock absorber.

Device design

First you need to deal with the design. In the classic version, a mechanical reverse hammer is a pin 50 cm long and with a diameter of 15-20 mm. A handle is fixed on one side, on the other. a fixing device (hook, vacuum suction cups, a bolt with a thread). A steel sleeve is glides freely between them. a weight.

At the design stage, decide what other elements will be required to make a reverse hammer from the shock absorber. Make the product drawing, apply the necessary sizes. Ready.made schemes can be taken on the Internet.

Necessary materials and tools

After the correct disassembly of the rack, you will have the necessary material to build a reverse hammer with your own hands from the shock absorber.

Prepare a container for lubrication flowing from the pipe cavity during cutting.

Dismantling the shock absorber rack

The upper part of the old spare part and the rod is needed to create a useful adhesive device.

Squeeze the part in a vice, substitute dishes to the place where you will make a cut. Dip the pipe to a plate with a spring. Work carefully, do not hook the stem.

Remove fasteners from the rack, other details. You have a rod and top cover left. Remove from the last oil seal and sleeve.

Manufacturing a reverse hammer

The freed stem will serve as the basis from which a functional reverse hammer from the shock absorber will be obtained. It remains to supply the pin in three details: this is a hilt, a load-gyra and a nozzle.

- From one edge of the rod. where the thread is. attach the handle. Fix it by welding the nut from both sides. Process the spaces of the welds according to the rules: remove the corner grinder and unevenness, polish.

- From a piece of the shock absorber rack and the pipe of the desired diameter selected for it, make a movable weight. Mount the element on the main pin.

- On the opposite of the handle, the end of the rod attach the nozzle.

The latter can be changed according to the need: perhaps it will be hooks for leveling dents on the body of the car or you want to knock out sour grenades, hubs, nozzles. You can use vacuum suckers at the end of the device, hooks.

How to make a handle

For convenient use of the device, find and fix at one end of the main working rod rubberized side handles from power tools. If there were no suitable details, adjust any clamp that will be comfortable in the hand.

As an option, use a piece of fuel hose. Fasten it on both sides with nuts.

How to make a moving weight

This important detail will go the rest of the pipe from the shock absorber rack. The reverse hammer from the shock absorber rod is useless without cargo-giria: its weight should be at least 1 kg.

- Pick a pipe of smaller cross.section than a piece from the rack, but more diameter of the rod (the load should glide freely along the rod).

- Insert one tube into another so that they do not contact the walls.

- Distribute the details, brew one end, leave the second open.

- Melt the lead, pour into the gap between the pipes. After the metal metal is hardened, I am ready to work.

Return hammer from a shock absorber rod

Lead can be “mined” from the old battery and melted in the case from an unnecessary oil filter. Or by laying pieces of lead between the walls of the weight, direct the flame of the gas burner to the part.

Give a cooled gyra an aesthetic look (cut the influxes from welding, go with sandpaper), put on a beautiful heavy element on the stem. DIY reverse hammer from the shock absorber is ready.

Varieties

Despite the fact that the design of the reverse hammer is quite simple, over time, even it has several modifications. This or that option is used in different cases. it all depends on skill, as well as the type of deformation. But in general, the design is always the same, the same and the principle of operation. Differences are only in the methodology for attaching such a tool to the body.

- This is a metal rod, from one end of which there is a hook, and from the second. cargo and emphasis;

- They catch a hook for the washer, and the puck is welded to the place of deformation by welding;

- Provided that the deformation is eliminated to the right moment on the load of shock efforts.

But the second option (also quite simple) will be slightly different from the first. At the end, instead of the hook, there is a simple thread. In order to align the surface using such a device, a hole is made in the center of deformation, into which the end with thread is inserted, and a nut and washer are attached on it on it.

Vacuum hammer is the most difficult option for its performance. It is attached to the surface of the deformed area by means of rarefied air. Sucker begins to work both by the usual method and using the compressor.

Thanks to the vacuum device, you can fix minor body damage and save the intact varnish coating.

How to make a reverse hammer with your own hands?

Thanks to the simplest design, it is possible to assemble this device even in garage conditions. In the most primitive case, it is easy to do with a purchased hairpin as a pin, and instead of a continuous weight, use a set of washers of a suitable size and weight. We offer to study a good example of how to make a reverse hammer with your own hands:

- It is necessary to prepare a pair of metal rods with a diameter of 12 and 16 mm.

- From a 12 mm rod, cut off a workpiece 50 cm long.

- From a rod of 16 mm, cut 5 blanks 15 cm long.

- You need to grind or buy several long nuts with a thread of 12 mm.

- The nuts will serve as adapters, their lengths should be enough to connect hooks with the axis of the reverse hammer.

- For the manufacture of stops, goals with a hole of 12 mm are required.

- Before welding work for isolation and receipt of a gap, pre.wrap the future axis of the hammer with tape.

- Boil a cargo from several segments of a bar of 16 mm, after fixing them around a thin rod 12 mm with electrical tape or tape.

- From the side of the holder, a twisted nut is a limiter.

- At the end of the pin, you need to cut the thread, the length of which is enough to install a nut and adapter.

- Having retreated a little space for the future handle, to weld the second emphasis on the back of the rod.

- From the residues of the rod, make the tips in the form of hooks.

- From the long side of the hook, you need to cut the thread and wind up long nuts.

- Make a handle from a segment of a rubber hose.

- To fix the handle at the end of the rod, you need to weld or wind a nut with a puck.

Lighting PDR

Lighting and reflection is one of the most important components of PDR repair. PDR lamps are used indoors and allow a specialist to see more in detail dents on car body panels. Two types of lighting are currently used: fluorescent and LED. With the introduction of LED lighting, everything has definitely changed. LEDs allow you to have more compact, light and very durable lamps. LED panels can change the intensity of lighting, and even color. This is needed for cars of different colors. For example, light panels can be difficult to repair without painting when using a standard PDR lamp with white light.

PDR repair lamps may contain a special light dial. Usually, these are parallel lines or the so.called fog screen (Fog Board). The color and drawing used on the front side of the lamp is a personal preference of the master. Such dispersion or screens can be purchased separately and put on a lamp or replaced by an existing dispa. They help to achieve high detail of defects.

Reflective screens (reflex screens/panels) are a panel with a specific pattern (usually with parallel lines). They, unlike a special lamp with lines, do not give their own light, but reflect the available light (for example, sunny) and cast lines on the repaired panel, helping to better see damage.

Thus, the purpose of the light PDR (or the reflective screen) is that the master sees the structure of the damage, which occurs inside the dent. Reading shadows and distorted reflection, a specialist can determine where the elevation of the metal is and where is the recess. The master also uses a reflection to direct the instrument tip exactly to where it should be. Further, the reflection helps to monitor the repair process, prompted to develop an accurate effort and stop crushing in time. After manipulations with PDR tools, as soon as distorted lines become parallel in the reflection of the panel, the dent will be successfully straightened.

PDR lamps are of different sizes and variations. In general, they can be divided into stationary lamps for workshops and into portable.