How To Make A Steering Wheel On A Tiller

Step-by-step device assembly technology

The assembly of the structure begins with the arrangement of the running shaft. To do this, a housing with a bearing is attached to it, an asterisk is welded on and overrunning clutches are mounted, which in the process of operation will perform the function of a differential. After that, the structure is equipped with wheels and a frame. A telescopic rod, plow and steering wheel are installed on the fixed frame.

The main elements of the running shaft: 1. shaft, 2. sprocket, 3. cover, 4. bearing housing, 5. support platform, 6. bearing No. 308, 7. freewheel housing, 8. here are the dogs, 9. the dog, 10. ratchet, 11. bearing No. 307, 12. washers, 13. wheel, 14. pawl spring

The agricultural tiller is equipped with special wheels, which, unlike rubber analogs, are able to provide better grip.

These metal wheels are not clogged with earth. When in contact with the ground, they DO NOT compact it, but rather loosen it

To connect the frame of the unit with the engine mount and the frame of the scooter itself, two arcuate pipes are used. There is a place between them for placing a fuel tank.

To equip the engine, a bracket is used, ending with a steel axle with a length of 150 mm. The bracket is welded cantilever to the U-shaped frame of the structure. A motor with a suspension is hung on itself. The assembled structure is connected to the arched arches of the frame. Only after that the secondary shaft is mounted, the control cables are pulled and the chains are pulled.

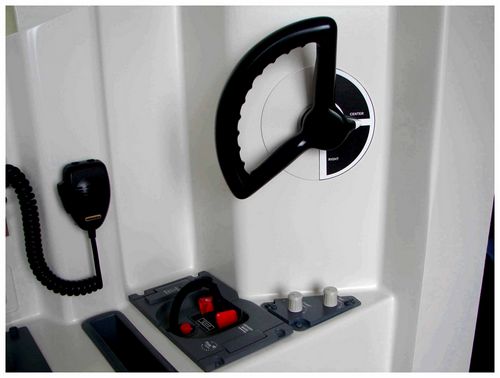

The main elements of the control unit: 1. connecting here, 2. strip, 3. pipe, 4. handles

Structural connecting elements: 1. main link, 2. control link

What can you generally build on your own?

The factory-made tiller market offers customers a fairly wide range of products for every taste. However, the for such agricultural machinery are not able to be mastered by many. Therefore, in the gardens in rural areas, you can often find a home-made tiller, which in terms of operational parameters is not nearly inferior to the factory analog.

Creating universal designs, craftsmen most often use parts of old motorcycles and scrap metal

Outdated motorcycle models often serve as the basis for the manufacture of various homemade products and small-scale mechanization useful in the household.

Since homemade tillers are often created from scrap old materials, the Druzhba saw motor, which is well known to many, is often used as the engine of the unit.

On the basis of homemade tillers, craftsmen create tools that are equally important in agriculture, for example: plows, as well as hillers for hilling corn or potatoes

One of these masters is the inventor Valentin Arkhipov, who is the author of the manufacture of a number of useful devices and the construction of all kinds of household equipment.

A talented designer has created a multifunctional device with which you can not only plow and harrow the land, but also plant, huddle tuberous crops, as well as harvest and rake tops

Therefore, when thinking over how to make a tiller with your own hands, it is better to opt for this proven and successfully applied option. Anyone can handle a simple and easy-to-use agricultural unit.

We build a tiller according to the instructions from Arkhipov

How this whole thing works. an example

An illustrative example of using a tiller:

What is this design good for??

There are more than a dozen analogs of such a model, but in comparison with them, the original model of the Kaluga master Tiller has a number of undeniable advantages.

- Swivel connection. The processing tools and tractors of most of these models have a rigid connection, which complicates the maneuvering of the unit and makes it difficult for them to work with it. The details of this agricultural unit are connected by means of hinges. This makes it possible to change the direction of movement in the process of work, if necessary, and not Take the plow out of the furrow.

- Offset of the axis to the direction of travel. Many owners, when cultivating the soil using a tiller, faced such a difficulty that in the process of moving forward under the influence of soil resistance, the unit is pulled to the side. A lot of effort should be made to align the furrow. To compensate for such a skid, the foreman placed the plow at a slight angle in the direction of travel. With the mouse, the structure is slightly turned to the left. The desired position can always be adjusted with the three link pivots.

- The level of the set plowing depth. If in other models the plowing depth is maintained by lowering or raising the plow, then when working with this tiller it is done automatically. Regulation is carried out by changing the angle of the plow in relation to the furrow. The structure is equipped with a field board that acts as a lifting force when burying the plow. If, on the contrary, a ploughshare appears above the surface of the earth, then its angle of attack instantly increases, under the action of which it again plunges into the ground to a given depth.

We make a tiller with our own hands using the example of a design from Valentin Arkhipov

It is not an easy task to process a plot with a large area, where a significant part of the territory is set aside for a vegetable garden, using only improvised tools. Loosening, digging, and weeding the garden by hand take a lot of time and effort. It’s good when there is an opportunity to purchase a tiller, which will become an indispensable assistant on the site. But you can make the work on the ground easier by making a tiller with your own hands.

Unit design features

The tiller‘s device is a self-propelled machine on two wheels, equipped with an engine removed from a VP-150M scooter. The reason for choosing this particular engine was that it has such a constructive solution, thanks to which forced cooling of the cylinder head with air is carried out.

Such a motor from a scooter is able to operate at the lowest speeds at fairly high loads.

For the construction of the tiller, the master used control cables, engine mounts, and also a double arc of the frame, handle and chain taken from the scooter. The rest of the construction details were manufactured

Separately, the designer made a U-shaped frame welded from pipes and a wheel axle turned on a lathe. He also made 3 homemade hinges for the main and control rods. They will be used as connecting elements between the tiller itself, its steering wheel and the plow.

A steel pipe is attached to the frame of the unit by means of a quarrel, ending with an axle, which is necessary to tension the cables going to the engine gearbox. The same tension is carried out by means of a swinging rocker arm, the gear lever of which is a welded piece of steel pipe.

The pitch of the chains used to create the device is 12.7 mm and 15.9 mm. Number of teeth in sprockets: output shaft. 11, output shaft. 20 and 60, running gear. 40.

How can you upgrade a homemade tiller?

Arkhipov’s tiller is multifunctional. It can be used as a plow, or as a cultivator. For this, it is sufficient to replace the detachable parts for the plow with parts with the removed tiller blade. the tiller will deepen the furrows into the ground as it advances and place potato tubers in them. To smell the tubers, you just need to put the dumps in place and walk the unit between the planted rows.

The agricultural unit is also convenient for harvesting. Using different plows, you can change the working width. The unit is also good in that it is able to collect missed potatoes and the tops of plants left after harvesting. For THESE purposes, it is equipped with a rake or harrow.

The versatile design can be used Not only for agricultural work. In winter, it is successfully used to remove snow. A faithful assistant is also useful for cleaning the paths of the local area. I installed a roller with a round brush and an additional sprocket on the tiller, the owner will make it easier for himself to work on clearing sidewalks.

Appointment

The main task of the technology with the front adapter is to speed up and facilitate the processing of the garden.

If you attach additional devices to the device, you can expand the range of applications:

- Remove hay;

- To cultivate the land. to plant and collect;

- Clears the area from snow;

- Level the ground surface;

- Transfer small-sized cargo.

Advantages and disadvantages

After the tiller has been modernized, the designers note the positive qualities of the front adapter:

- Easy to operate;

- Traction resource disclosure. existing abilities increase;

- The possibilities of work are expanding. tillage will be accelerated;

- If necessary, the unit is disassembled and assembled;

- Good balance in weight and axes;

- You can move around on your device.

The disadvantages include the fact that in the presence of a movable hitch, stability deteriorates.

The tiller adapter consists of the following structural elements:

Steering type adapter

How to make a steering adapter for a tiller? The type of structure in which the steering wheel is provided must be rigidly fixed. The steering gear is performed as a separate independent unit. A pair of wheels and behold, which serves as a steering gear, are installed in the front and rear. Fixation points are selected based on individual characteristics. The location of the steering gear depends on the type of part. When assembling, it is recommended to perform just such an improved model.

A motorized cultivator with steering has many positive qualities:

- The operator will not waste energy when moving around the unit;

- The equipment has maneuverability and increased functionality;

- Traction force is 100% realized;

- You can get to the workplace by tillering without the use of additional equipment;

- Ease of management compared to other options.

Algorithm of actions

To start assembling additional equipment for a motor-cultivator, you will need a drawing, in agreement with which the fastening elements and the construction of fragments will be completed. If you have special skills and experience, a homemade tiller adapter and drawing can be done independently. In case of fear of making a mistake, you should take ready-made drawings. Before designing, it is recommended to check and verify the compliance of dimensions and numbers.

Types of front adapters for the tiller

Converted technical devices are of the following types:

- With telescopic drawbar type. This detail adjusts the width of the tiller adapter.

- With drawbars of various lengths. The short clamp is designed for light weight devices, the long clamp is suitable for heavy mechanisms.

- The purpose of the equipment is the transportation of goods. Models have a special body, which is able to withstand increased loads.

- With lifting link mechanism. Equipment that has suspended equipment is easy to operate and move.

Do-it-yourself front adapter tiller

Tools and consumables:

- Metal corners, square profile;

- Steering wheel and column bearings;

- Metal sheets;

- A pair of wheels, preferably on an axle;

- Drills, electrodes, discs for angle grinders;

- Fasteners;

- Wrenches of various sizes;

- Welding Electric Apparatus;

- Lubricating compositions. solid oil;

- Angle Grinder;

- Screwdriver;

- Drill.

Varieties

Steering adapters can be classified by wheel arrangement. The steering gear is performed in a separate node format. The wheels with the steering drive option can be located at the front and rear. As for the position of the steering gear, it depends on the design features and spare parts, because during operation, repair and replacement of worn parts cannot be avoided.

Models in which the adapter is located at the front are called the front-steering variant. In such modifications, the engine is a kind of tractor of the entire unit. If the adapter is located at the back, and the tiller has to be pulled with you, such a device is called rear-wheel drive. In other words, if the adapter is in front of the tiller, this is a front type product, and if it is behind, then the rear.

The buyer makes the choice of one or another option himself, based on his own preferences.

However, you can look at the option where the adapter is closer to the drive axle. The operator’s weight in this case will create an additional load, and not allow the tiller to jump out of the ground while the equipment is operating.

Based on the variety, adapters can be classified into body and bodyless adapters. The former foresee the transportation of goods, the latter are more suitable for tillage. Depending on the power of the unit, the adapters are connected to the tiller by means of a long or short drawbar. The first modifications are used on heavy equipment, the second ones are used on light.

Adapter making instructions

Now let’s talk about how to independently make a front adapter with steering for your small tractor.

To manufacture the steering wheel tiller adapter, you will need the following materials:

- Two identical wheels on an axle. The radius of the wheels ranges from 15-18 inches. Even wheels from the old Soviet “Volga” can fit.

- Steering wheel and column bearings.

- Frame steel (channel, pipe or angle).

- Fasteners (washers, bolts, nuts).

- Lubricants (lithol or solidol).

- Consumables (drills, electrodes, angle grinder discs).

- Wrench set.

- Angle Grinder.

- Welding machine.

- Drill.

Before starting work, it is important to take into account that the wheels should not have a very large or small radius.

Types of adapters for tiller

There are several types of adapters for mini tractors, including homemade ones.

- With lifting arm. The presented type of suspended equipment will simplify control, movement around the site.

- For the transportation of goods. They are equipped with special bodies, capable of withstanding the maximum load.

- With long or short drawbar. Short type. for lightweight type, long. for heavy mechanism.

- With telescopic drawbar. This design allows for width adjustment.

This technique is also divided by the type of construction:

How to make a steering wheel for a tiller with your own hands

Tiller is a mechanized assistant to the gardener, which allows you to reduce labor costs and user health. When supplemented with a steering adapter, this device increases driving comfort and further reduces exercise.

In fact, the adapter allows you to convert the tiller into a kind of mini-tractor. From the material of this article you will learn the adapter device, its purpose, varieties, installation nuances and subtleties of operation.

Appointment

The main task of the technology with the front adapter is to speed up and facilitate the processing of the garden.

If you attach additional devices to the device, you can expand the range of applications:

- Remove hay;

- To cultivate the land. to plant and collect;

- Clears the area from snow;

- Level the ground surface;

- Transfer small-sized cargo.

Algorithm of actions

We start manufacturing attachments for the tiller.

Important! Before starting work on the drawings, be sure to check the compliance of the sizes and numbers.

To make a steering adapter for a tiller, you will need a frame with a bushing and a fork. This will allow the tiller to rotate freely through the steering wheel.

- Everything will start with making the frame. It can be made from cut pieces of the selected steel of the required length. The metal can be divided by an angle grinder and the elements can be electrically welded or bolted together.

- Next, we build the chassis. If your tiller’s motor is in front, then the track size must be determined by the main wheels. The rear ones are mounted to the frame using an axle. You can create it from a piece of pipe of a suitable width. At the ends of this pipe, we press in the bearings with bushings. Wheels will be installed on them. If the tiller’s engine is located at the rear, then the track width must be greater, otherwise the mini-tractor will not be able to keep running normally during operation. In such a situation, the base wheels of the tiller will be more optimally removed and reinstalled, but already on a more spacious bridge.

- To make the steering wheel to the unit, and not required to additionally remove the handle in the car or motorcycle. Stop using the handle. In other words, the operator will be able to control the Mini Tractor with a steering wheel, which looks like a motorcycle. However, the operator will not be able to backtrack normally with it. That is why it will be preferable to mount the steering column on a mini tractor.

- When using an all-metal frame, the steering will be integrated with the front axle of the tiller. It is possible to make articulated resistances, then the control column will rotate the entire front half-frame. To do this, the craftsman will need to attach the cogwheel to the front frame. The second gear is installed on the steering column.

- The seat, which can be previously removed from a passenger car, needs to be welded to the sled frame. The master needs to make sure that it is adjusted, especially when operating the front adapter attached to the tiller.

- If you intend to use a mini tractor to work with plows and cultivators, then you will need additional welding of the bracket. An auxiliary hydraulic system must be installed to operate the attachment. The pump for it can be easily dismantled from agricultural machinery. If you have to work with a semi-trailer, then you need to take care of additional welding of the towbar to the rear of the frame. It can also be successfully borrowed from a passenger car.

- Fastening (coupling) can be done by hand. To do this, you need drawings, which are easily searched for in articles on the top results of the desired topic. And we will talk about how exactly to implement the coupling.

To make a U-shaped hitch, you need a metal channel of suitable thickness and size. The hitch is attached to the tiller under the steering column through pre-drilled holes in certain places. A bracket and a pin are inserted into them. Important Make sure that the parts are of high quality, this will avoid unnecessary problems in the future and waste of time in the present. All parts Must be made of high quality high strength steel.

This shows the installation of the front adapter on the tiller type “Neva” finished. After the completion of the assembly, it remains only necessary to lubricate the mini tractor and test it for functioning. The adapter assembly can then be considered complete. Now you can safely deal with the required work on land plots with the help of new technology.

Steering type adapter

How to make a steering adapter for a tiller? The type of structure in which the steering wheel is provided must be rigidly fixed. The steering gear is performed as a separate independent unit. A pair of wheels and behold, which serves as a steering gear, are installed in the front and rear. Fixation points are selected based on individual characteristics. The location of the steering gear depends on the type of part. When assembling, it is recommended to perform just such an improved model.

A motorized cultivator with steering has many positive qualities:

- The operator will not waste energy when moving around the unit;

- The equipment has maneuverability and increased functionality;

- Traction force is 100% realized;

- You can get to the workplace by tillering without the use of additional equipment;

- Ease of management compared to other options.

Algorithm of actions

To start assembling additional equipment for a motor-cultivator, you will need a drawing, in agreement with which the fastening elements and the construction of fragments will be completed. If you have special skills and experience, a homemade tiller adapter and drawing can be done independently. In case of fear of making a mistake, you should take ready-made drawings. Before designing, it is recommended to check and verify the compliance of dimensions and numbers.

Movable hitch adapter

It implies a movable connection between the trailer and the tiller. This system is more difficult to manage, but making such a module with your own hands is much easier. Requires more effort when turning. The module can be mounted in the same way back and front. Even the primitive structure of the tiller assumes the distribution of loads. After that, it is recommended to place the seat in the module near the driving axle. Under the operator’s weight, the wheels of the tiller will be pressed against the soil, which does NOT allow slipping during movement.

There is nothing complicated in designing the adapter and working with the Mini Tractor. This is available to anyone who has set out to get a home tractor on his site, which will ease the work of a person every day. So try to design, build and create. and work the land with pleasure.

The do-it-yourself designed front adapter tiller will facilitate the work on the processing of the personal plot and garden. An additional device transforms a motor cultivator into a mini-tractor. If necessary, install such agricultural implements as a plow, a digger, a planter, a hiller on the converter.

Required materials and tools

Consider what you need to create an apparatus.

Materials and tools:

- Two wheels with an axle. The radius of the wheels should be 15-18 inches. You can take wheels from a car.

- Bearings for wheel and steering systems. Metal profile corner or channel, metal pipe.

- Nuts screws, washers.

- Lubrication: grease.

- Welding machine, drill with drill, wires, discs.

- Angle Grinder.

- Screwdriver, wrench, screwdriver.

- Frame for turning the cultivator using the steering wheel.

Varieties of adapters for tiller

There are several types of tiller adapter. The design is distinguished by the coupling method:

- Strong connection to the cultivator. The device has a separate steering wheel. Steering wheels located at the front or rear (Both options are possible).

- Movable connection. At the same time, the angle between the cultivator and the cart is constantly changing. Turning requires a lot of effort, due to the fact that the joint is movable.

Devices are also subdivided according to the presence of driving wheels into:

- Front. The hitch assembly is at the back.

- Rear. The hitch assembly is located at the front.

Trailers are divided into:

- Simple;

- Universal.

In addition to garden work, universal ones are useful for transporting crops.

Trailers are divided according to the drawbar size:

- A short;

- Long.

Low-power tillers are attached to structures with a short drawbar. Trailers with a long drawbar are attached to powerful cultivators.

There are 2 types of trailers: 1-axle or 2-axle. These couplings are factory designed by the manufacturer. The factory calculated such a structure and mounted a towbar on it. A spring was installed under the seat, designed for the smooth running of the car on rocky surfaces.

The APM has special footrests and a brake that is pressed by the foot to stop the cultivator. Pneumatic tires were mounted on the adapter, which provide a smooth ride at high speed.

If all components are working well, you can start using the device. When buying a structure, you also need to choose a soft seat pad. Then the driver’s work will become more convenient. The adapter Khors IS 1 to Tiller Magnum, adapters to cultivators PNO-1, AM-3 K, BUM-3, KTS-03 are very popular among farmers.

Front and rear adapters

There are several types of trailers, depending on which wheels are driving:

- Front-wheel drive. The unit is fixed behind the tiller. This is the simplest and most popular modification. It makes it easy to operate a cultivator and perform a large amount of work.

- Rear drive. The unit is located in front of the cultivator. This design makes it possible to carry out work when using a hitch located at the rear of the cultivator.

- Four-wheel drive. The trailer can be located both in front and behind the cultivator. This design differs from the previous ones in that NOT 2 wheels rotate, but all 4. Such a device performs the functions of a mini-tractor. This increases the maneuverability of the structure, its cross-country ability, additional adhesion to the soil is provided. 4×4 drive is considered the most efficient.

The rear adapter is the most common type of trailer for the tiller. It can be used as a trolley (lifting capacity about 100 kg), for aggregation with attachments for plowing, mowing, snow removal, etc.

Steering trailer allows maneuvering in different terrain, making the operator’s job easier. Operating the structure using the steering wheel of the cultivator itself can be inconvenient and dangerous. When working in a field with uneven terrain or in a vegetable garden, it is better to use a trailer with a steering wheel for a tiller, as it is easier to drive.

In order to make a back adapter with your own hands, readily available materials are suitable. The basis of the trailer design is the frame; it can be made of a metal profile or a metal pipe. The hitch assembly can be movable or rigid. In the second case, a change in the cultivator itself will be required, so the creation of a movable hitch is less complicated.

The rear adapter is used for work that requires constant supervision (hilling the beds), therefore, the design necessarily includes a seat for the operator’s convenience. It also facilitates the work of the presence of steering, which is made from the steering mechanisms of any vehicles.

Front (rear) adapter for a steering wheel tiller: how to do it yourself. Drawings and dimensions

Many farmers use tillers to work in their fields. The tiller adapter makes it possible to speed up its implementation. This unit is used as a trailer, which moves on wheels and is attached to a cultivator. You can add attachments to the device, mount a chair. Often gardeners themselves make such a unit.

Appointment

The adapter to the tiller was created for the convenience of working in the garden. If you attach a hitch to it, then you can expand the scope of the device:

- Harvest hay;

- Level the soil surface;

- Transport cargo;

- Protects the ground;

- Clear the area from snow.

An adapter is a device that is designed to be moved to a motor cultivator. With it, you can operate the machine while sitting in a chair, and at the same time Till the soil. Trailer for motor cultivators Neva is equipped with steering control. It makes it easier to use the tiller.

This trailer accelerates work in the field. With this design, you can increase the speed of the cultivator from 5 to 10 km / h. Consider the adapter device. The adapter for cultivators consists of:

- Frames;

- Operator seats;

- Two wheels;

- Wasps;

- Coupling mechanism.

After attaching the adapter, the cultivator looks and works like a mini-tractor. A frame is needed to create an adapter for a front steer cultivator. The operator’s seat is installed on it. The frame is fixed to the chassis.

The seat is fixed to the frame. This makes it easier for the operator to control the cultivator. The wheel system will help move the unit around the site. There are 2 types of wheels: metal (used in the field) and rubber (used for road traffic).

The tiller hitch is made of steel or cast iron by welding. She attaches the cart to the cultivator. The best is the U-shaped attachment system. With this design, the device will be stable.

- The highest travel speed for a trailer with a trailer is 12 km / h.

- Maximum lifting capacity. 100 kg.

- The track diameter is 67 cm.

- Dimensions are 130x70x71 cm.

- Device weight. 22 kg.

- Warranty period of work. 5 years.

Drawings and dimensions

First you need to complete the drawing. The first step is to calculate the kinetic scheme. Then they carry out the basic diagram, which indicates the dimensions of all parts. All parts, assemblies and fasteners of the structure will be manufactured according to this scheme. Before starting to create an aggregate, you need to clarify all the data available on the diagram and check their compliance with the indicators of all blanks.

Assembling the adapter for the tiller

First, make the frame. It is made from pieces of metal of the required length. The metal is cut by an angle grinder and the parts are connected by welding or screws.

Then they carry out the chassis. When the cultivator motor is located at the front, the base wheels determine the track gauge. The rear ones are attached to the frame using an axis. It must be made from a pipe of the required diameter. Bushings with a bearing are attached to its ends.

Then wheels are mounted on them. When the cultivator motor is at the rear, the tread should be wider. Otherwise, the structure will NOT be able to maintain balance during operation. Then the base cultivator wheels need to be removed and fixed to the wide axle.

To make your own steering wheel, you do not need to remove the handle of the car. If you use the handle from the cultivator, you can control the entire structure using the motorcycle handlebar. But it will be difficult to back up. Therefore, it is best to mount a sturdy steering column.

Consider the manufacture of a frame for a motor cultivator trailer. If you take a solid metal frame, the control will be directed to the front of the unit. You can make a frame on hinges, while the steering column will rotate completely onto the front frame. To achieve this, mount the gear to the front frame.

The second gear is mounted on the steering column. Then a seat for the tractor driver is made. It can be taken from a car. The seat is placed on the frame by means of a quarrel. It can be regulated. This is especially necessary for the front type device. The driver’s seat is now attached.

To attach the trailer to the plow tiller, a bracket must be installed. To work with the mower, you need to make a hydraulic system. To work on the device, you need to weld the towbar from the car to the rear, where the metal frame is located. The pump can be borrowed from any unit for agricultural work.

The hitch for the cultivator is U-shaped. This requires a channel profile. The hitch is installed under the steering column. In this case, it is necessary to drill the holes, which are marked on the drawing. A bracket and a pin are mounted through them. The components are made of high quality steel. You can also make a tracked mechanism.

Thus, all the necessary parts and assemblies of the adapter for the cultivator are made. Now you need to assemble the entire structure. After that, it needs to be checked and tested in work. If all components are operating normally, then you can start operating the unit.

How to make an adapter to the tiller with your own hands

For a gardener or farmer who wants to increase the volume of work, you can make an adapter for a tiller with your own hands. Let’s take a look at how to make your own front steering wheel adapter. To do this, a frame is made, a lever is welded to it, then a coupling unit is created, after that a trailer turning mechanism is made, then you need to weld the braces.

Thus, you can make a homemade four-wheel drive trailer for both small and heavy tillers. detailed step-by-step instructions for self-manufacturing of a trailer are discussed below.

Scheme and structural elements

To make an adapter with your own hands, the drawings and diagrams of this device must be completed first of all. And according to the ready-made scheme, indicating all parts, assemblies, structural elements and their dimensions, it will be easier to start the independent manufacture of the unit.