How to make an arrow on a single-axle tractor with their own hands

How to make an arrow for a power tiller with his own hands: disc, two-row, hedgehog, propeller, drawings and dimensions

In potato cultivation, one of the most time-consuming and labor-intensive processes is hoeing 2-3 times. Performed on large plantations tractor towed cultivators at suburban areas in the absence of a power tiller or tractor, it is made by a homemade or factory-made hand-pulper for potatoes.

What is this agricultural tool and how to make it with your own hands will be discussed in this article.

Purpose and principle of operation

A handheld potato tiller (plough, furrower, marker) is a relatively small and light agricultural tool, driven by human muscle power.

The most common plowshare handplow consists of the following parts:

- The working body, the share body, is made up of a wing share and a double-sided share with wings;

- rack. a thick strip of metal, which is welded at one end to the body of the toolbar and the other end is attached to the frame;

- frame made of round or shaped metal pipe;

- depth wheel.

Instead of the ploughshare body of the tool, two spherical discs, angled to each other, are mounted on the frame in the disc planters.

When growing potatoes, this agricultural tool performs the following operations:

- making planting furrows;

- working body. hoeing and formation of ridges at inter-row cultivation;

- destroying weeds and breaking the soil crust formed after heavy rains or drought;

- dispersing rows during potato harvesting. this is done with a special potato picker body. instead of the continuous double-sided spoil bank, two or three rows of bars are used.

Gardener with 17 years of experience and our expert

Important! To fill the planting furrow with seed potatoes use a special device. two rectangular blades, welded to a vertical stand, located relative to each other at an angle of 15-200.

Getting to know how to make an arrow

For an easy breakdown of how to make a handheld potato perch on a machine, let’s first break down how to make a handheld potato perch.

As can be seen from the drawing, to facilitate the work without a motor, you must also try to. But not as much as you might think. Above all, you need tools for work:

- hammer;

- vise;

- welding machines, preferably both electric type and autogenous type;

- caliper;

- taps for tapping internal threads;

- screwdriver for taps;

- A grinder with replaceable discs;

- a gas torch for heating metal when it needs to be bent;

- workbench;

- all kinds of auxiliary tools.

Block: 2/6 | symbols: 622

Types of planter

You can buy the tool in an agricultural equipment store or assemble it yourself. It can be used for planting potatoes, beets, carrots and turnips. The most famous varieties of this technique:

Types of planter

You can buy the tool in an agricultural equipment store or assemble it yourself. It can be used for planting potatoes, beets, carrots and turnips. The most famous varieties of this technique:

Let’s look at the features of each of them.

Fixed and adjustable angle Lister

These have a fixed angle and are used on very light tillers up to 4 hp. Capable of cultivating seedbeds 25-30 centimeters wide, equipped with two side wings and a thin stand. A rack protects the implement from overloading and mechanical damage. This tool can be used only on dry soils, because the clinging soil will interfere with the work of the moving elements of the design. There are lister devices with adjustable width of cultivation. They are installed on motor vehicles of higher power. from 4 horsepower. These implements can also be used on wet soils with no fuss.

Propeller

The principle of operation is the activity of propeller parts. They are used to first dig into the ground and remove weeds before tilling out the seedbed. These modifications are mainly practiced for power tillers with front drive and two speeds. This is because the second speed increases power to 180 rpm. Once the power level reaches the maximum, this tool can be used not only for ditching the soil, but also for throwing soil into the furrows from the space between the rows of plantings.

Double (2-row)

Carries out the cutting of two furrows before planting, and is also used for dip and loosening the soil. Includes a frame on which two riders are fixed. Great time-saving, because it has two working parts when working the ground. Is mounted on the power tiller via a drawbar hitch. Because it requires more resistance to work, it is often used in combination with power tillers.

Rotary Active

This tool is equipped with propeller-type tine rotors instead of wheels. Demonstrates high efficiency in the creation, loosening and hilling of potatoes. Suitable for operation with 3-speed sets (two in front and one in reverse). In first gear, it covers the plants; in second gear, it shovels the soil out of the space between the rows of plants.

Single row

The most common type. Applicable for use with light types of soil. trenching is carried out after the preliminary loosening of the ground by means of a cultivator.

Block: 3/10 | Number of characters: 3645

Homemade Rake for Moto-Block

If you wish, you can easily make a homemade rake for your power tiller. For a rake with a wide grip for hay, you can use ordinary water pipes with different diameters. You need to put a special sleeve on the round rod and then tap the surface of the rod by lightly turning it.

The best method is to use a round rod. Most of the rake parts are fastened by electric welding, because this method is very simple and makes a reliable construction.

structural simplicity is achieved by mounting pivoting parts on axles without roller bearings.

The hay rake for the power tiller is best made foldable, as this will make it easier to transport.

Block: 3/9 | Number of characters: 753

Manufacturing stages

The entire process of manufacturing units for a motor-block with their own hands can be conditionally divided into several stages. To begin with, it is necessary to determine what equipment is necessary and what functions it will perform. For example, if we are talking about a trailer, then depending on the type of work performed, the design can change. Self-made cart for a power tiller can have the ability to unload loads independently. This is very convenient when it comes to transporting bulk fertilizers, soil, harvested vegetables. In such cases, it is much easier to lift the body and pour everything out than to unload it manually.

The next step is to calculate and make a drawing. At this stage, it is important that the single-axle tractor and the resulting equipment can work “in tandem”. This applies to power, size, method of attachment and many other factors.

After preparing a drawing, when the necessary materials and tools are known, you can begin to prepare them. The work will be performed faster if everything is prepared in advance. In this case you don’t have to give up your work and go to the store for the missing parts.

And only when all the stages of preparation are passed, you can proceed to the actual fabrication. Construction can take a lot of time and effort. But the result is worth it.

Block: 3/9 | Number of characters: 1255

Manufacturing stages

The whole process of manufacturing units for a motor-block with their own hands can be divided into several stages. First we need to determine what equipment is needed and what functions it will perform. For example, if we are talking about a trailer, then depending on the type of work performed, the design can change. Self-made cart for a motor-block can have the ability to unload loads independently. It is very handy when it comes to transporting bulk fertilizers, soil, harvested vegetables. In such cases, it is much easier to lift the body and pour everything out than to unload it by hand.

The next step is to calculate and make a drawing. At this stage it is important that the single-axle tractor and the resulting equipment can work “in tandem”. This applies to power, size, method of attachment and many other factors.

After preparing a blueprint, when the necessary materials and tools are known, you can begin preparing them. The work will be done faster if everything is prepared in advance. In this case, you will not need to give up work and go to the store for the missing parts.

And only when all stages of preparation are passed, you can proceed to the actual production. Construction can take a lot of time and effort. But the result is worth it.

Block: 3/9 | Number of characters: 1255

The best homemade equipment

Self-made equipment with an engine from a power tiller (read harrow for power tiller with your own hands) is also of some interest. Among them, the most interesting is to make a snowmobile. As the undercarriage can be used as a conveyor belt, on which you need to attach snow hooks.

In addition, interesting are the options for making other different types of equipment from a power tiller:

- ATVs. Their construction resembles that of a minitractor, but has higher-diameter wheels. It is necessary for the machine to pass over the most and difficult terrain.

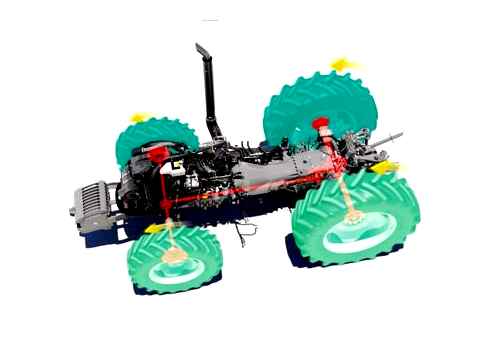

- Minitractors. We have already considered this design, which includes an additional part of the frame for the second pair of wheels, as well as the handlebars and the driver’s seat.

Block: 4/5 | characters: 780

Hiller for tiller with his hands

It is not so difficult to make a homemade planter for a power tiller. It will consist of such basic assemblies as 2 disks, 2 stands, 2 screw adjusting turnbuckles, a T-bar for fixing the structure.

Before starting work, prepare the necessary blanks:

- metal sheets for making the discs (or prefabricated discs);

- The square metal profile for making the boom;

- parts for making the bar.

The photo below shows exactly how the adjustment of the vertical axes of the toolbar will be carried out with the help of the tarleps. The letter “B” marks the adjustment screws, the letter “C” marks the stands:

If the necessary blanks are available, the manufacture of the rocker arm should be made according to the drawings below. Don’t forget to stick to the dimensions in order to get a quality product.

To attach to the tiller headstock will bracket, the leash in turn is attached to the bracket with screws with a stopper.

We also suggest you read the video on the intricacies of making a homemade handrail for power tillers: Such an arrow will be compatible with these models of power tillers such as Neva MB-1, MB-2, Agro, MTZ, etc. д.

How to use

The equipment will allow you to have fun at work

The disk hoe for the power tiller is easy to use. It’s important to set it up properly before hoeing. Double the distance between the lower and upper corners by moving the uprights and bolts from the discs into the guide’s recesses. To maintain the balance of the machine, rotate the single-row clamp by the same swivel angle.

- Adjusting the width between the discs. To make it easier to turn the clamps, put a large washer between their ears and the leash bar. A bolt is threaded through it, and another washer is tightened over the angle of attack. The second one is lowered by half a turn and covered with the third one.

- Fastening of the clip and bar to the disc coulter. The attachment is connected to the power tiller through the hitch fastener without the longitudinal bar. The leash is held in place by a stopper and flat bolts that hold the leash to the outer tube of the mount, and the bolts hold the leash to the outer tube. So the bracket along the longitudinal line is turned to the required level.

- Attaching a disc mower to a power tiller. Optimum power transmission at reduced speed. The traction increases. To keep the wheels from slipping, they are paired beforehand.

The working principle of the automatic disk hoe is based on the principle that the discs grip the soil as they move and form a roller as they hoe and roll up the soil. The advantage is compactness, high operating comfort, less energy consumption for hoeing and even ridge work. The price of the equipment varies depending on the size of the discs, the material, the adjustment mechanism and whether it is equipped with a Cascade-shaped hole or rolling bearings.

Getting to know how to make an arrow

For an easy breakdown of how to make a tractor-mounted rocker on a machine, let’s first break down how to make a manual rocker for potatoes.

As you can see from the drawing, to make it easier to work without a motor. But not as much as it seems. First of all, you need tools for work:

- hammer;

- vise;

- welding machines, preferably both electric type and autogenous type;

- caliper;

- taps for tapping internal threads;

- screwdriver for taps;

- grinder with interchangeable discs;

- a gas torch to heat the metal when it needs to be bent;

- workbench;

- all kinds of auxiliary tools.

disc coulter

Let’s proceed to how to make an okuchennik for potatoes with their own hands. In the drawing you can see that the main tool is the mouldboard. They should be within 400 mm. This is optimal. Because we plant potatoes usually to a depth of 60-80 mm, and the roots then grow about 200 mm. It turns out, having passed in the inter-row with tilted discs of the specified size, we fully perch a row of potatoes.

So, we make 2 disks of steel sheet of 2 mm thickness, diameter 400. Some people make it out of old pot lids. Let. But it is desirable to make good discs which will serve for a long time. You can take it from the scrap of agricultural machinery. But best of all is stainless steel. Sharpen the edges of discs, where there will be cutting edges. Now we make a bridge with stands on which discs will be fixed. Calculate dimensions. Put a pipe connector on both sides of the steel sturdy pipe (sold everywhere). The free ends of the mounts point downwards. From above we drill through the holes in the mounts. Each mount is drilled on both sides. Secure with bolts and nuts.

If you want to make grips of different width, then drill on both sides two more holes. To change the grip width, simply move the struts farther or closer to the ends of the bridge, and fasten through the holes. Then we insert the tubes (stands) into the mounts from below. Also drill, fasten in the connection. Two bolts and nuts for each strut. Then, at the bottom of each stand, we make a mechanism for tilting the sliding discs. First we fix the bracket for the disc. Also make two to three positions for drilling the pipe. So you can change the tilt of the discs.

On the other side of the bracket, weld a short, thick steel bar. At its other end, in the hub ring, press in a closed plain bearing. From the inside of the hub, weld a wide washer with holes to hold the disc. Weld the same wide washers with holes in the center of each disk. Let’s fix the discs with bolts with nuts. We have two movable disks tilted at a certain angle, attached to the struts on one axle. You can come up with an additional device to tilt the discs left and right. For this you need to find a hinged bracket mechanism. These are also commercially available. You can also find these in old parts of agricultural machinery.

We will not consider further the creation of a manual mower. We don’t need to make handles for our unit.

Attaching the hoe

The tiller for the power tiller must be connected, hinged to the machine in the way shown in this drawing:

From the drawing you can see that we need to connect the device to the axle through the brackets and strong steel pipes. Reinforce the connection with a crossbar. Turn on the motor. The wheels move. You hold on to the handles of the power tiller. Attracted by the movement, the tool of planting ridges, created with our own hands, comes into action. The discs have to be made at a symmetrical angle in order to prevent rolling to one side while hoeing. This tool example is not the only one. There are others. Let’s look at them one by one.

How to make our own ouches

To make this necessary tool in agriculture, it is very important to adhere to certain rules. And also, if possible, use the drawings. This way you will be able to install all the elements much faster, and most importantly, correctly. So that as a result you do not have to redo anything. With their own hands gardeners make mostly disc and lister types.

Lister

This is a classic non-adjustable variant of the field planter for the power tiller. It is he who is used by gardeners more often than others. Drawings will greatly simplify the manufacturing process.

- Metal sheets (2 mm, 3 mm, 5 mm, 8 mm thick);

- A 4 mm wide strip of steel;

- gas torch;

- Welding machine or fasteners.

- Make the base from a sheet of metal not thinner than 3 mm. On this element will have the resistance of the soil, so its strength should be the maximum possible.

- The bracket should be made of a 4mm wide strip of steel. It is important not to forget about hardening this part.

- Next, make a field board. To do this, take a metal sheet with a thickness of 5 mm. The finished piece should be hardened by means of a gas burner in several steps.

- The buttress should be made of metal sheet with a thickness of 8 mm. This part is made of the thickest sheet, as it will bear the brunt of the load.

- It remains to make the fenders from the thinnest (2 mm) steel sheet. The wings must be the same size as in the selected drawing. Otherwise it will not be possible to attach them to the base correctly. The metal should be slightly bent and fixed to the base with welding.

Disk

If you get down to making such an oscillator, special attention must be paid to shaping the discs themselves. They can be made from circular saws or used torches from the planter.

- The discs must be placed at an angle, observing the distance between their lower points. It is important that they are positioned symmetrically. Otherwise the single axle tractor will drive in different directions.

- All parts, including starter rods, stanchions and leash, should be secured with welding machine or bolts. Connect the discs with controlled adapters.

- You need to use a beam with wings to fix the tool to the tiller.

Choosing the right tilt angle and plunging depth is another key factor. To make this choice, it is enough to put moving parts with bolt fixation on the bracket.

After reading the video below, you can learn how to make other types of ridgers, including one-row manual:

How to attach and use the tool

Installing the rocker on a single-axle tractor, it is important to orient it correctly. parallel to the line of seedbeds.

Before you start, mount the tool in the hitch of your power tiller and secure it with bolts or pins. To make setting up quicker, it is convenient to use hollow shafts with cotter pins.

Adjust the angle of, for example, a disc-type tool by tilting the frame in relation to the tiller. This partly affects the depth of the furrows. Adjustment of the perch by moving the sole in the vertical plane with the help of fixing holes made in the stand. And by moving the brackets you can control the width of the aisle.

It is a good idea to check the bolt tightening prior to starting work. You should carry out a test field, where there are no plants. Monitor closely the operation of individual sub-assemblies in the tractor. If faults are found, loosened connections must be retightened or the sprayhead adjusted.

If using a single-axle tractor for the first time, it is very important to carefully study the instructions for use and special recommendations for safe operation of the equipment.

In particular, during the processing of beds you need to observe the following rules:

- transport the equipment over long distances only in disassembled form;

- do not make steep turns;

- run over in a transport position.