How to make an ignition on a walkbehind tractor. How to set the ignition on a walkbehind tractor an algorithm for execution

Ignition of motor blocks

The ignition is a mechanism responsible for the formation of an electric pulse required by a walk.Behind tractor to ignite the refueling fuel. The first launch and subsequent operation of the agricultural load engine depends on the serviceability of the ignition system. Like the rest, this mechanism needs regular maintenance and timely repair. This will become the key to stable operation of the internal combustion engine under any weather and operational conditions.

The ignition system refers to the list of the most important nodes of both corporate and home.Made walk.Behind tract. Its main function is to generate a spark, which is needed to ignite and gradual combustion of fuel in the chrome ICE cylinder.

The simplicity of the factory device of the assembly allows you to perform your own ignition of a motor block, which, most often, consists in setting a gap between its elements. However, to do this correctly, you need to study the design of the node.

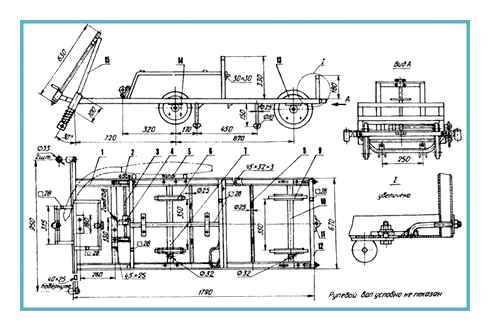

The ignition device of any household agricultural load includes a coil, which is originally connected to the electrical power supply of the system, as well as magneto and candles. During the launch of the power unit, the voltage is supplied, as a result of which a pronounced spark is formed between the magnetic “shoe” and the standard candle. It is necessary for instant ignition of fuel, which at this moment is in the combustion chamber of the motor. In more detail about the structure of the ignition system of the used motorblock will tell the photo.

The electronic ignition system of the walk.Behind tractor is also often equipped with interruptions that work in automatic mode when any of the malfunctions of the node appears. This leads to an emergency shutdown of electric power in the network.

Motoboga ignition setting

The ignition system is a very important design that ensures the formation of a spark in the internal combustion chamber for ignition of the air fuel mixture. In order not to encounter breakdowns and not call the master, you need to know how to properly set the ignition on a walk.Behind tract. This can be done in different ways.

- Thanks to the spark. Do the following actions:

- Turn the crankshaft so that the pulley label and label located at the base of the gas distribution mechanism coincide. In this case, the interruption-distributing runner should indicate a high-voltage wire of one of the cylinders;

- Weaken the nut, which is the position of the body of the mechanism that determines the moment of the creation of high.Voltage impulses;

- From the cover of the system, which determines the moment of creating high.Voltage pulses, you need to extract a high.Voltage wire located in the center, and place its contact at a distance of 5 millimeters from the “mass” of the walk.Behind tractor;

- Now turn on the ignition;

- The case of the mechanism of the determining moment of the creation of the aforementioned pulses, you need to turn the watch arrow to the mark 200;

- Now slowly turn the body in the opposite direction;

- The position of the mechanism should not change, but at the same time between the contact located in the center and “mass” you will see a spark;

- Tighten the interruption nut.

There is no spark: how to eliminate the problem

For ignition, all elements must be working in the ignition system. The most common problem is the absence of a spark. Among the various options there are two most frequent ones. The soot formed, or the candle is not good.

Diesel Engines 101. Class 1.

The reasons that there is no spark, there may be several

The first action is to twist the candle. After that, it is required to inspect it, including the electrodes of the lateral and central type. If there is a carpet, then, in addition to cleaning, it is necessary to check the entire fuel system of the walk.Behind tract. The use of inappropriate fuel and oil is also a frequent error, which leads to a soil and filling the candle.

Among the fuel for gasoline engines, both 92 and 80 gasoline can be used. The main point is the use of high.Quality and suitable oil.

A number of motor blocks are not demanding on oils, but with all.Season work it is worth using seasonal oil. For example, for the summer, a mineral type of 4TD standard SAE 30 is recommended, and for winter-4TD Ultra SAE 5W-30.

There is no spark on the walk.Behind tractor. Reasons and solution

Lack of sparks

This is one of the typical malfunctions of the ignition system of the walk.Behind tractor. The most common reasons for this are the formation of a pile on a spark plug or its breakdown. In this case, you should twist the candle and carefully inspect its lateral and central electrodes. If the spark plug is covered with a soil formed as a result of pouring the part by the fuel mixture, then the candle will be not enough alone. It will be necessary to check the tubes of the fuel system of the motor block for leaks. Examples of cases with highly planted fuel candle are clearly visible in the photo.

If a spark is gone, then in any case you will need to carefully clean the candle. To do this, it is best to heat it above the gas burner, and then scrape off the dried fuel from the surface. After cleaning the part on its upper part, the tip should be put on and bring the motor block to the body body. The candle must be held so that its electrode is about 1 millimeter from the engine housing. At the same time, try to launch a motoblock motor with the second hand.

If the candle is completely serviceable, then a spark is formed in its lower part, which will jump out and hit the motor body. If this does not happen, then you need to inspect the distance between the side and central electrodes. Between them should be placed a blade, and if it enters tightly between two electrodes, then the gap has the optimal dimensions. If the blade hangs, then you will need to knock on any hard object on the back of the central electrode. As a result of this, he shift, after which you need to try again to start the engine engine.

How to change the ignition switch on an Bolens 1050 Garden Tractor

Self.Check of magneto for a walk.Behind tractor

Another important element of the ignition system of the walk.Behind tractor is magneto. In case of malfunction of the node, it also lends itself to a careful inspection for performance. Checking the Magneto Motobobok is quite simple. To do this, it is necessary to clean the candle from the carbar accumulated on its surface and make sure of its serviceability. Then a cap with a good drive is put on the candle. Further, the lower part of the candle must be brought to the Magneto body, and start rotating the flywheel located in the motor with your fingers.

If the spark in Magneto did not appear on the walk.Behind tractor, then the element is out of order. In this case, it will be necessary to replace the magneto of the ignition system of the walk.Behind tractor in order to prevent wear of other unit mechanisms.

How to check the ignition coil on a walk.Behind tractor?

Check, and, if necessary, repair the ignition coil, follows the same principle as the Magneto Motobobok.

The following factors indicate the signs that the ignition coil of the walk.Behind tract is out of order:

- Weak spark or its complete absence;

- The presence of the smell of molten plastic in the area where the ignition coil is installed;

- The appearance of crackling sound when trying to start a walk.Behind tractor.

In any of these cases, you will need to carefully examine the ignition coil of the walk.Behind tractor. To do this, it is best to completely dismantle it. For this purpose, you should first unscrew the fasteners and remove the upper cover of the ignition system body. Then you need to turn off the high.Voltage wire and, gently prying the coil, extract it from the case. After that, you need to carefully examine the part on the presence of traces of melting. If black spots are visible on the coil, then most likely the current it created did not get to the candle, as a result of which the ignition reel itself succumbed to the voltage. Especially often, farmers are faced with this problem, in whose walk.Ashes, a contactless ignition is installed.

The reason that the current did not fall on the candle is poor contacts on a high.Voltage wire. In this case, the repair of the ignition of the walk.Behind tractor is reduced to cleaning the wires or their complete replacement. In the motoblocks where the electronic ignition system is installed, in case of breakdown, the wire is automatically turned off due to the presence of a special fuse. In agricultural machines with ignition systems of other types, disconnect the wire during breakdown manually.

Prevention of breakdowns of the ignition system of a walk.Behind tractor

In order to avoid the need to repair a motor block ignition system, you need to adhere to a number of simple rules. Their compliance will extend the deadlines for the use of the node and save the time and money of the owner of the equipment.

- To exclude the use of a walk.Behind tract in raw weather, during frosts, as well as under the conditions of sudden changes in temperature and humidity;

- Do not try to start the unit if there is a smell of molten plastic;

- If necessary, install the plates on the walk.Behind tractor that protect the parts of the ignition system from moisture from getting on them;

- Change the candle at least once every 3 months. In the case of intensive use of a motor block, the frequency of replacement of the part can be increased;

- Use high.Quality motor oil. The use of the inappropriate composition will lead to constant filling of the candle with a fuel mixture;

- Regularly inspect the parts of the ignition system in order to exclude the slightest possibility of operating a walk.Behind tractor with ragged wires or other breakdowns;

- Try not to give a motor block with a hot engine strong loads. This will lead to an accelerated wear of important components of the unit, including its ignition system.

Adhering to these simple rules, the owner of the walk.Behind tractor will increase the working resource of the ignition system and other important details and mechanisms of his unit.

All of the listed problems with the ignition system are typical of the production of Urals, Mole, Zubrov, Agro, Neva, Honda, Salute, MTZ and Cascade. The configuration and repair of the node is performed in the same manner for each of the listed agricultural units.

Breakage and ways to eliminate them

There are a lot of ignition system malfunctions. For this reason, the part of the ignition system should be checked and tuned regularly.

The main problem is the lack of a spark. When ignition, a spark should be formed. If this does not happen, then you need to check the entire ignition system. The absence of a spark is possible with a halter, as well as when breaking a candle. These malfunctions are most common.

In the absence of a spark, the candle is removed and examined. Lateral and central electrodes should be without soot. With soot, it is worth not only cleaning, but also check the fuel system for pipe leaks. The car is cleaned carefully. After the procedure, the candle is necessarily wiped with a dry rag.

Do not forget about the test of magneto

Standard procedure in the absence of a spark:

- Take out (twist) a candle;

- The candle heats up above the gas burner or other heat source;

- So far and the remnants of fuel are scrasped from the surface;

- The tip is put on and the spark is checking, that is, the electrode is located 1 mm from the engine housing. The motor itself at this time is launched by the hand;

- With a good candle, a spark will appear, if this does not happen, then there is a measurement of the distance between the side and central zone of the electrodes;

- If the blade enters tightly into the gap, then everything is within the normal range, if not, then you need to knock on the rear of the central part of the electrode. This will help change the size;

- Next is a secondary spark check.

You can check the magneto in the phased version:

- The candle is cleaned and checked for serviceability;

- At the end of the candle, a small special cap is put on, in which the drive is working;

- The lower part of the candle is brought to the body of the magneto;

- The flywheel rotates manually;

- If there is no spark, then you need to replace the magneto with the working mechanism.

Replacement is required, as this will not wear the rest of the engine mechanisms.

The coil is checked according to the standard system, which is used for magneto.

There are several signs of a reel malfunction:

- Lack of a spark or its actual weakness;

- A smell similar to the melted plastic at the location of the coil;

- Cracking sound when trying to start a technique.

Any repair begins with an attentive inspection. The initial step is the dismantling of the mechanism. For this, fasteners are removed, and the upper lid of the body type is removed. A high.Voltage wire is disconnected. Only after that the coil itself stretches. The first inspection should identify the places of melting (black places). Most often, there is such a disadvantage with non.Contact ignition.

A common cause of current supply to the candle is considered bad contact. Correction is regulated by stripping wires. In some cases, it is required to carry out a full replacement of all wires.

With standard launch systems, including manual ones, the wire disconnection is required to be carried out independently.

Why do not start a walk.Behind tractor

Video on how without problems, at home to adjust the ignition of a walk.Behind tractor, a gas generator with a 168F engine and its. 2:23. Installation of the coil.

Methods of exhibiting and adjusting

Now directly to the issue that concerns how you can set the ignition on your own walk.Behind tract and what you need to do for this.

The need to correctly and correctly configure the ignition in the walk.Behind tractor arises when signs of its problem begin to appear.

- The technique is poorly started. Yes, the motorcycle block can be launched, but it still takes more time and effort. The process is uncertain, the motor seems to be suffocated or choked.

- You have to pull the cord for a long time. Relevant in those situations when a manual system is used on technology. Numerous attempts to pull the cord do not give any result. There is a high probability that the ignition just lost.

- The motor is triggered, but with a delay. Another characteristic feature. This cannot be considered the norm. If the engine on the walk.Behind tractor starts with a delay, you need to check and adjust the operation of the ignition system.

Details about how to properly adjust the downed ignition on the motoblocks of a company is spelled out in the operating manual. But it happens that the instruction disappeared somewhere, or it was not originally, since the equipment was bought in the secondary market.

If there is no official manual at hand, then the independent installation of ignition on the walk.Behind tractor companies such as Agro, Neva or the same Lifan may well be done independently.

There are several ways to adjust the ignition on motoblocks. Which one is to use, here everyone will decide for himself.

Toyota Ignition Key Problem- Key Won’t Turn

Getting to the location of the ignition module and the flywheel directly is not difficult.

Several methods are distinguished by which you can configure the ignition on almost any walk.Behind.

But the first thing that all owners of the motoblocks need to do where suspicions of ignition came across is a check of the sparking itself. She could trite contaminate and worry. As a result, the spark is not formed, and the fuel will not be able to ignite for a quite objective reason. If the candle is serviceable, the fuel is high.Quality, you have to tinker a little with the settings.

On the spark

Many gardeners and gardeners will agree that the ignition installation is relatively easily performed by spark. Especially if it is a walk.Behind tractor like agro or a nonsense.

To set the ignition by this method, that is, by spark, it is necessary:

- Remove the protective casing from the walk.Behind tractor to get to the system itself;

- Crankshaft;

- Tags of the pulley and the gas mechanism when turning the crankshaft should ultimately coincide;

- The runner, which is responsible for the distribution of gas flows, must directly indicate the high.Voltage cylinder wire;

- Now it is required to unscrew a little nut, which changes the position of the node that determines the moment of the occurrence of a high.Voltage pulse;

- Next, it will be necessary to extract a high.Voltage from the system cover (located in the center);

- Place contacts about 5 mm from the walk.Behind tractor;

- Turn on the ignition;

- Turn the node that determines the moment of ignition in the direction of the clockwise movement;

- In the opposite direction, expand the high.Voltage;

- A spark should be clearly formed between the mass of the walk.Behind tractor and the central high.Voltage;

- Immediately after this, the torn nut is delayed to prevent random ignition.

The bottom line is to cover the candle itself with the square, press its body to the cylinder head, while turning this element of the system in the direction completely opposite from the hole in the end part of the cylinder. Then the crankshaft turn out.

When carrying out such manipulations between the electrodes, a bluish spark should occur.

If this does not happen anyway, you need to check the gap between the magneto and the starter. Normally, it is approximately 0.1-0.15 mm. If the gap does not meet the specified characteristics, then it will have to regulate it.

By sound

Many gardeners note that they managed to set without special problems the ignition of the cascade, Lifan and the equipment of other famous firms on the walk.Behind tractor.

The method is really good. But for its successful implementation you need a pretty good hearing. If you have it, then it makes sense to try.

When implementing the contactless adjustment method, you need to do the following:

- Run the engine of your walk.Behind tractor;

- A little weaken the trambler;

- On the 2nd side, slowly and gently turn the body of the resident;

- The design that is responsible for the moment of sparking is fixed in the maximum power and revolutions;

- Now the most important thing is to listen carefully;

- When the interruption system rotates, characteristic clicks should appear;

- Upon completion of the settings, the Trumbler nut is reliably twisted.

If you don’t hear anything, or you cannot catch the right moment, try another way.

According to the strobe

You can also set the right ignition on your walk.Behind tract Lifan or other brand using a conventional strobe.

- Run the engine engine and warm it to the operating temperature;

- So far stop the motor;

- Connect the strobe to the technique;

- A sensor that reacts to sound is connected to a high.Voltage wire;

- Remove the fixed vacuum hose and then drown out it;

- The light emitted by the strobe must be directed to the pulley;

- Once again, start the engine and leave it to work in idle speed, and not on the program;

- Twist the ignition trump;

- Fix it when the mark on the pulley will definitely match the mark on the device cover;

- Twist the interruption nut.

Methods of exhibiting and adjusting

Now directly to the issue that concerns how you can set the ignition on your own walk.Behind tract and what you need to do for this.

The need to correctly and correctly configure the ignition in the walk.Behind tractor arises when signs of its problem begin to appear.

- The technique is poorly started. Yes, the motorcycle block can be launched, but it still takes more time and effort. The process is uncertain, the motor seems to be suffocated or choked.

- You have to pull the cord for a long time. Relevant in those situations when a manual system is used on technology. Numerous attempts to pull the cord do not give any result. There is a high probability that the ignition just lost.

- The motor is triggered, but with a delay. Another characteristic feature. This cannot be considered the norm. If the engine on the walk.Behind tractor starts with a delay, you need to check and adjust the operation of the ignition system.

Details about how to properly adjust the downed ignition on the motoblocks of a company is spelled out in the operating manual. But it happens that the instruction disappeared somewhere, or it was not originally, since the equipment was bought in the secondary market.

If there is no official manual at hand, then the independent installation of ignition on the walk.Behind tractor companies such as Agro, Neva or the same Lifan may well be done independently.

There are several ways to adjust the ignition on motoblocks. Which one is to use, here everyone will decide for himself.

Getting to the location of the ignition module and the flywheel directly is not difficult.

Several methods are distinguished by which you can configure the ignition on almost any walk.Behind.

But the first thing that all owners of the motoblocks need to do where suspicions of ignition came across is a check of the sparking itself. She could trite contaminate and worry. As a result, the spark is not formed, and the fuel will not be able to ignite for a quite objective reason. If the candle is serviceable, the fuel is high.Quality, you have to tinker a little with the settings.

On the spark

Many gardeners and gardeners will agree that the ignition installation is relatively easily performed by spark. Especially if it is a walk.Behind tractor like agro or a nonsense.

To set the ignition by this method, that is, by spark, it is necessary:

- Remove the protective casing from the walk.Behind tractor to get to the system itself;

- Crankshaft;

- Tags of the pulley and the gas mechanism when turning the crankshaft should ultimately coincide;

- The runner, which is responsible for the distribution of gas flows, must directly indicate the high.Voltage cylinder wire;

- Now it is required to unscrew a little nut, which changes the position of the node that determines the moment of the occurrence of a high.Voltage pulse;

- Next, it will be necessary to extract a high.Voltage from the system cover (located in the center);

- Place contacts about 5 mm from the walk.Behind tractor;

- Turn on the ignition;

- Turn the node that determines the moment of ignition in the direction of the clockwise movement;

- In the opposite direction, expand the high.Voltage;

- A spark should be clearly formed between the mass of the walk.Behind tractor and the central high.Voltage;

- Immediately after this, the torn nut is delayed to prevent random ignition.

The bottom line is to cover the candle itself with the square, press its body to the cylinder head, while turning this element of the system in the direction completely opposite from the hole in the end part of the cylinder. Then the crankshaft turn out.

When carrying out such manipulations between the electrodes, a bluish spark should occur.

If this does not happen anyway, you need to check the gap between the magneto and the starter. Normally, it is approximately 0.1-0.15 mm. If the gap does not meet the specified characteristics, then it will have to regulate it.

By sound

Many gardeners note that they managed to set without special problems the ignition of the cascade, Lifan and the equipment of other famous firms on the walk.Behind tractor.

The method is really good. But for its successful implementation you need a pretty good hearing. If you have it, then it makes sense to try.

When implementing the contactless adjustment method, you need to do the following:

- Run the engine of your walk.Behind tractor;

- A little weaken the trambler;

- On the 2nd side, slowly and gently turn the body of the resident;

- The design that is responsible for the moment of sparking is fixed in the maximum power and revolutions;

- Now the most important thing is to listen carefully;

- When the interruption system rotates, characteristic clicks should appear;

- Upon completion of the settings, the Trumbler nut is reliably twisted.

If you don’t hear anything, or you cannot catch the right moment, try another way.

According to the strobe

You can also set the right ignition on your walk.Behind tract Lifan or other brand using a conventional strobe.

- Run the engine engine and warm it to the operating temperature;

- So far stop the motor;

- Connect the strobe to the technique;

- A sensor that reacts to sound is connected to a high.Voltage wire;

- Remove the fixed vacuum hose and then drown out it;

- The light emitted by the strobe must be directed to the pulley;

- Once again, start the engine and leave it to work in idle speed, and not on the program;

- Twist the ignition trump;

- Fix it when the mark on the pulley will definitely match the mark on the device cover;

- Twist the interruption nut.

Checking the magneto

When problems in the ignition system, a standard Magneto check for performance is used. The first action will be a visual inspection. Further, the candle is cleaned and checked for stable work, that is, serviceability. A cap is put on one end of the candle, and the second is brought to the body of the magneto. After that, the motor flywheel starts with the hand.

Lack of spark means a malfunction of the mechanism. It should be borne in mind that with any malfunctions with Magneto, it will have to be completely replaced. This is mandatory, since this approach prevents the wear of other elements of the unit.

Before setting the ignition and running system, it will be necessary to completely eliminate all the problems, as well as replace non.Working details. In order to avoid most ignition problems, you need to fulfill several rules: All these rules will help to avoid most problems with the ignition system.

If there is no spark in the cascade, then you will need to carry out a number of checks of the entire system. It is necessary to start with a candle, since its serviceability is the basis of further actions. After a full check and replacement of all the necessary elements, it is put up in conjunction with the ignition according to the standard plan similar to most motoblocks.

Electronic ignition scheme for a walk.Behind motorist cascade

An excellent tool for masters and needlework and everything for the garden, at home and cottage literally for nothing there are reviews.

Many people have motoblocks and motor cultivators that greatly facilitate the work in the garden. So I have such an unit. He was acquired back in the distant 90s and all this time faithfully served me, everything was, as they say, on the teeth. And I, in turn, tried not to offend him. So we lived with him soul to soul.

But recently, the motorcycle block suddenly began to start worse. I had to make a lot of effort to revive the engine. Began to figure out what was the matter. Suspicion fell on the ignition system. It was very weak spark.

Farmall IH H4 Magneto Rebuild: Easy Step-by-Step Tutorial Farmall A, B, C, H, M, etc Tractors

Having wandered over the Internet, I read many tips and stopped on one. So, the cause of a weak sparks may be the aging of magnets fixed on the engine flywheel. When they rotate, the magnetic field crosses the coils of the coils fixed on the case, which leads to the appearance of electric current.

All that is needed for this article is here

Upon learning about the price of a new flywheel that needed to be replaced, I decided to redo the ignition system of the walk.Behind tractor and make a battery from the factory transformer system of ignition.

I attended auto disorder and bought ignition coil from VAZ 2101-2107 for 300 rubles, took 10 batteries in the store (element 33), and at home found 2 m of PGVA wires with a section of 1.5 mm. The batteries grouped and wrapped it with island. He sold them together sequentially, t.E. On the weekend I got 15 volts. The minus wire was connected to the body block case, having previously cleaned the contact site, and collected the electrical circuit (see. Rice.)

If there is no suitable switch, then you can do without it. You just need to connect the wires during the work of the walk.Behind trash.

Then he pumped up gasoline, according to the instructions he wound a launch rope on the flywheel drum, pulled. And the walk.Behind tractor launched like a young. It was last fall, and I still managed to plow the entire plot for the potatoes. In winter, he put his iron friend in the barn. Spring has come. He pulled out a walk.Behind tractor, checked the oil in the crankcase, flooded gasoline, connected the wires. And the engine earned. With his help, I planted potatoes. That is, the batteries were well twitched.

DIY Lighting Settings on a walk.Behind tractor

Ignition requires periodic adjustment. In the case of a strong failure, more important parts of the system may fail, which will lead to impaired operability of all agricultural technology.

In order to independently cope with the setting, you should know which components are in the node and how they should function correctly. Due to the cover and lower part of the magneto, the spark is distributed and interrupted. Set up the system so that this principle of operation is triggered.

Stages of installation of ignition on a walk.Behind tractor:

- Check the work of the flywheel until the contacts of contacts in Magneto are triggered.

- Drive the distance between the anvil and the hammer.

- To compress the piston, cram the fly wheel.

- When the flywheel reaches the top, turn it again. You will have to catch a single knock that says that a overtaking coupling worked.

- Take the flywheel in the opposite direction so that 2 bags coincide with a label on the case.

- Adjust the distance between the breaker and the cam. In perfect condition, it should be in the range from 0.25 to 0.35 mm.

- In conclusion, fix the mounted fist with the upper screw.

Checking the ignition coil

Before checking the ignition coil of your unit for possible problems, you must understand how exactly it looks in a broken state. First, the farmer should conduct a visual inspection. Often breakdown are caused by the fact that cracks, dents or similar mechanical damage occur on this spare parts. If there are no such problems, the coil is a whole, without visible defects, you will need to perform some additional checks of this element.

To do this, you need to know about how to disassemble a walk.Behind tractor and, at the same time, simultaneously study the ways to eliminate problems and their reasons. The check is to change the reel resistance indicators.

This technique today is not the most popular, since not every farmer owns information about what the optimal parameter of the winding resistance on the existing unit should be. Another check difficulties may be due to the fact that the resistance indicator includes semiconductor elements used to form the necessary high.Voltage pulse. Against the background of such a situation, when trying to rally the coil of a motor.Cultivator through a high.Voltage or minus wire, a person will receive a too high resistance indicator if there is no rupture of the circuit before that.

Another way to check the parts of the ignition system is to use the candle. To do this, it should be turned and attached to the cylinder. Next, you need to pull the starter cable and see if the spark forms between the contacts. At the same time, the master must understand that such a technique will not allow to determine which of the elements is the cause of the breakdown.

This is due to the fact that during the check of the candle is under the influence of some pressure, due to which the flywheel is able to rotate faster than usual. Each of the above methods is advisable only in cases where the farmer does not have the opportunity to contact a highly qualified specialist. For this, a person must have skills in working with electricity, since otherwise there is a risk of current.

Block: 5/5 | Summer characters: 2127Source: https: // vsemotobloki.COM/Motobloki/Regulirovka-Zazhiganija-Na-Motobloke.HTML

Walk.Behind healing system: how to set the ignition with your own hands

The ignition system of a motor block is an important element of the agricultural unit. Its task is to form a spark for fuel fire.

Periodically, it is necessary to repair the ignition of a walk-behind tractor due to incorrect operation or wear of the main parts of the assembly. The breakdown should be eliminated as quickly as possible to prevent wear of other spare parts and systems.

How to act if there is no spark on a walk.Behind tractor?

The causes of malfunctions of the ignition system in most cases are associated with candles. Often the spark plug is oversaturated from an excess of motor oil. Getting on a part, it prevents the appearance of a spark.

When a spark disappeared, you need to act as follows:

- The candle is twisted with a special key. The element rotates and is removed with accuracy, and the sealing ring should also be released;

- If the candle is overdried, this indicates that the fuel is not supplied to the motor cylinder;

- If the candle is too wet, this indicates an excess of motor oil. The candle wipes, the cylinder is dried. For this purpose, the starter cable is pulled;

- In the presence of a solid carrier on the candles, you can use gasoline and large sandpaper to cleanse it.

Such manipulations can be performed on a diesel engine and on gasoline models. It is important to carry out all the actions as neatly as possible, without damaging the part.

Repair and ignition adjustment of the engine DM1K

The ignition system of the four.Stroke engine of domestic production DM1K electronic contactless with magneto. Such a engine is equipped with a MB-2K model with a capacity of 6.5 HP and 7.5 HP.

If the ignition does not work, follow the following actions:

- If, when checking the spark, the candle was faulty, it should be replaced with a new one;

- Check the nursing and wire coming to it;

- Check the serviceability of the ignition button and the integrity of the wiring;

- If all of the above is completed, and the system does not work, then it is likely that the ignition itself is faulty and it must be changed.

Ignition adjustment

During operation, sooner or later, a person will have to configure the ignition of a walk.Behind tractor. If you do this in a timely manner, the equipment will work with interruptions, which will affect the speedy wear of other mechanisms that are fundamental in the functionality of this unit. At first, so that the farmer has the chances of successful ignition adjustment on the walk.Behind tractor, he must study this system of agricultural machinery in detail, which operates on diesel fuel or gasoline.

In this video, you will learn how to adjust the ignition system:

If you configure this part of the unit correctly, the system will be able to create a spark in the place where it is necessary, and at the most suitable moment. It is worth considering that the spark is responsible for the distribution of the spark that has arisen, which should also not be forgotten to check. The setting must be performed, adhering to the following order of actions:

- First of all, the master checks the operability of the flywheel, which is located in the engine until the contacts located in Magneto open up.

- At the next stage, it is necessary to measure the distance between the so.Called “hammer” and “anvil” built into the ignition design.

- Next, turn the flywheel so that the piston is compressed. When the flywheel reaches the upper limit, it is turned again. As a result, a person should hear a one.Time knock. He will indicate that the overtaking coupling worked.

- At the next stage, the flywheel is turned counterclockwise so that the mark on it converges with the one that is located on the case.

- The next step is to adjust the distance between the fist and the next to the contactor contact. It should be borne in mind that the minimum distance for the working motoblock is a quarter of a millimeter, and the maximum is 0.35 millimeters.

- At the last stage, it remains to start fixing the built.In fist using a special screw on top.

What problems can arise?

The main problem is the lack of a spark. Most likely, the reason is in the candle. Either a dozen was formed on it, or it is faulty. Twist it and carefully inspect the electrodes. In the presence of a soot formed with gasoline pouring, in addition to cleaning the candle, it is necessary to check the fuel supply system, perhaps there are leaks there. In the absence of a spark, you need to clean the candle from the car. A good way out can be its heating over the switched gas burner, scraping from its surface of frozen flows of the fuel mixture.

After cleansing the candle, test its serviceability. To do this, put on the part on the top of the cap and bring it closer, holding it in one hand, to the body of the motor block at a distance of about 1 mm. With your free hand, try to start the engine.

Subject to the serviceability of the candle in the lower end of it, its long.Awaited spark is formed, which will fly to the engine body.

Otherwise, check the gap between the electrodes. Try to put a razor blade there, and if the electrodes are tightly clamped, the distance is optimal. If a free blade is felt, it is necessary to adjust the position of the electrodes. To do this, lightly tap the screwdriver on the back of the central element. When the electrodes take the optimal position, try to start the motor again. If the spark does not appear, test the serviceability of the magneto.

To verify the serviceability of the magneto, after the candle has been tested, put on the candle with the tip with a drive in good condition. Close the lower end of the candle to the magnetic shoe body and start twist the flywheel of the motor. In the absence of a spark, there is a malfunction and the detail requires a replacement.

Other problems with the ignition system are possible:

- Weakness or absence of a spark;

- A feeling of an unpleasant smell of burned plastic in the part of the mechanism where the ignition coil is located;

- Cracking when starting a motor.

All these troubles require inspection of the coil. The best way out is its complete dismantling and inspection.

To do this, unscrewing the mounting bolts, remove the upper part of the ignition system casing. Then turn off the power wire, put the coil element and pull it out. Carefully inspect the appearance of the part. The presence of black spots indicates that the current did not enter the candle, but melted the winding of the coil. This situation is especially relevant for motoblocks with contactless ignition.

The reason for this malfunction is in poor.Quality contacts at high voltage cable. It is required to clean or completely replace the wires. In devices with an electronic ignition system, an automatic fuse is provided that turns off the power in case of malfunction. If your car has any other ignition system, the cable will have to be disconnected with your own hand. If the spark is knocked out when you turn on, check the tip of the candle, most likely it is contaminated.

About how to adjust the ignition on a walk.Behind tract, see further.

It is forbidden to use any materials without our preliminary written consent.