How to measure a chainsaw chain

How to find out

There are several ways to find out the pitch of the chain:

- View the pitch value on the guide bar. Manufacturers of the saw headset must indicate the length of the bar, the width of the groove and the pitch of the driven sprocket on the shank of the saw blade.

- Measure the distance between the shanks of adjacent teeth or the centers of three adjacent rivets.

- The method that works for chains in branded packaging is to look at the characteristics of the chain on the box.

The branded packaging of Stihl chains contains comprehensive information about the products, after reading which you can find out not only the distance between adjacent links, but also the type of teeth, the width of the link, the recommended file size for sharpening.

3/8 or 0.325 which is better and why

Determine which parameter is better and which is not worse, since each of them has its own characteristics and is intended for chain saws of a certain power. Depending on how the saw head is correctly selected, the performance of the tool will have different indicators. If the headset is selected optimally, i.e. the distance between the links corresponds to the recommended power, then the performance of the chainsaw will be maximum. If selected incorrectly, the motor will experience overloads that can lead to malfunctions.

The optimal power ratings for 0.325 inches are 1.8-2 kW. It is for this reason that chains with such a pitch are used on the Husqvarna 142/137 chainsaw.

For parameter 3/8, a tool with a power of up to 3 kW is required. In this case, the question arises, why on the Stihl 180, with a power of 1.5 kW, 3/8 inch chains are used. The answer is simple: for Stihl chainsaws, power is not the most important thing, the maximum number of revolutions is of great importance. The Stihl 180 delivers over 13,500 rpm, so it can cut with a 3/8 ” headset.

For 0.404 inches, optimum power 4.5. 5 kW.

Important! The indicated values of power and chain pitch are not necessarily character, the user himself has the right to choose the parameters of the headset, which he plans to use on the chainsaw.

Chainsaw chain table

articles, we suggest that you familiarize yourself with the table, which indicates the technical parameters of popular models of chains for chainsaws of different power.

Based on the recommendations of the manufacturer of the chainsaw and taking into account the technical parameters from the table, you can find out the model of the chain that is suitable for your tool and avoid mistakes when buying.

What does the distance between the teeth affect?

In a saw chain, the distance between the cutting teeth directly affects its performance. The more, the deeper the cutting edge can cut into the wood, provided that the stop is sharpened correctly.

Accordingly, on more powerful chainsaws, it is permissible to install a headset with a large distance between adjacent links and vice versa.

If you put a ¼ ”saw headset on a powerful chainsaw, then the performance will drop significantly, and the load on the engine will increase, because the saw will run at a speed and exceed the maximum permissible speed, which ultimately can lead to overheating and seizure of the CPG.

And vice versa, installing a chain with a large pitch on a weak chainsaw will lead to the fact that the saw power will not be enough for normal cutting, of course, this will not entail serious consequences, as in the first case, but it is not comfortable to work with such a tool.

Also, the quality and accuracy of the cut depends on the distance between the links. The farther from each other adjacent cutting teeth, the stronger the vibration during work and the lower the cutting accuracy. For a more accurate cut, choose a saw head with a smaller pitch. This factor must be taken into account by those who are engaged in curly carving with a chainsaw on wood.

The chain pitch has a great influence on the so-called “rebound”. The greater the distance between the teeth, the more likely the chainsaw will bounce.

Important! Most often, “rebound” occurs when working with the tip of the tire, for example, when making internal cuts. In this case, you need to be extremely careful, regardless of the step with which the chain is used.

When choosing a chain, the rule is that the pitch (distance between the teeth) is proportional to the power, but the cutting accuracy is inversely related, i.e. the greater the distance, the lower the accuracy.

All you need to know about chainsaw pitch for efficient operation

There are several basic parameters for choosing a chainsaw, one of them is the pitch of the saw headset. The pitch depends on the power of the chainsaw, and greatly affects the cutting speed.

How much the step matches the power determines the performance and service life of the chainsaw. Also, the consumption of fuels and lubricants depends on its correct selection.

- Step concept

- What does the distance between the teeth affect?

- 3/8 or 0.325 which is better and why

- How to choose

- How to find out

- Chainsaw chain table

- Conclusion

Step concept

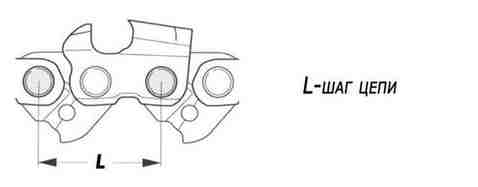

Pitch. half the distance between adjacent shanks or between three adjacent rivets.

There are several sizes, 1/4 “is the smallest, 3/4” is the largest and 3/8 and 0.325 “are the most popular.

Step. a parameter that is available not only in the headset, but also in the sprockets of the tire and chainsaw.

Important! All three elements, chain, sprocket and bar, must have the same pitch parameter, otherwise installation and correct operation is impossible.

How to choose

In the case when it is necessary to choose the optimal chain pitch for the chainsaw, it is best to take into account the manufacturer’s recommendations and, based on them, choose the type of saw headset.

If the manufacturer’s recommendations are not known, then you need to choose according to the engine power. We have provided the recommended values corresponding to a certain step just above.

Important! When choosing, do not forget that the distance between the links is not the only parameter that you need to pay attention to.

It is also worth choosing the thickness of the link, the type of cutting tooth, the number of links. Performance is largely dependent on the angle of sharpening, depth of cut and the shape of the stop teeth. The sharper the restraining tooth, the higher the cutting speed and the lower its quality.

Below we offer you to watch a video on choosing the pitch of the chainsaw chain. The video tells and shows how to determine it, for which chainsaws, which chain step to use.

The distance between the chain links of a chainsaw is one of the most important parameters that in no case should be neglected. When buying a spare headset, you need to know which pitch is suitable for the tire and sprocket installed on your chainsaw, or change the chain, tire and drive sprocket as a set.

How to choose a chain for a chainsaw: types, sizes, nuances

How to choose a chain for a saw with a gasoline engine step by step

Chain pitch is measured in inches. It is indicated on the product and affects the quality of the cut. The higher the saw power, the more you adjust the step. For non-professional instruments up to 2500W, standard 0.325 ” pitch.

The chain pitch must match the pitch on the drive sprocket of the engine and tire. If you change it together with the tire, replace the engine sprocket with a collapsible one and install the drive ring on it with the desired pitch.

How to choose a chain for a chainsaw in the shape of a cutting tooth

The choice of chain for a chainsaw should take into account the shape of the cutting tooth. When viewed along the tooth, the cutting edges form a similarity to the number 7. The rounded tooth is called Chipper, with an acute angle. Chisel.

Chisel teeth are characterized by high productivity and cutting speed because their configuration reduces the contact area of the tooth with the wood during operation. A serious drawback of the “chisel” tooth is that it quickly becomes blunt on wood contaminated with grains of sand. Resharpening such a tooth requires very precise adherence to all standard angles and parameters.

The Chipper tines have a larger cutting area with the wood and therefore lower cutting speed. But this drawback compensates for the undemanding quality of regrinding. The rounded corner of the “chipper” will tolerate sharpening errors more easily and shows itself well in working with contaminated wood.

How to choose a chain for a chainsaw according to the thickness of the shank

The shank is the part of the chain link that fits into the guide bar. Its thickness must strictly correspond to the groove of the tire so that the chain moves as smoothly as possible, the cut is smooth and there is no excessive tire wear.

How to choose a chain for a chainsaw in length

Its total length is determined by the number of links that make it up (it is equal to the number of shanks). The chain for one bar may not fit on a bar of the same length on another saw. Therefore, see what length the manufacturer recommends in the instructions for the saw.

Watch the video review of Makita chainsaws

Leave your opinion and wishes to the article “How to choose a chain for a chainsaw: types, sizes, nuances”

Measuring Your Chainsaw

We will tell you a little secret. There are two ways to determine the size of your replacement chain without even having access to the product manual: measure the chain yourself and see measurements on other parts of the saw. How to measure a chain saw yourself.

Pitch: distance between chain links

Gauge: the width of the groove in which the chain enters the bar

To determine the pitch (chain size), you need to measure the distance between any three consecutive rivets and then divide the result by 2. Rivets. These are the little round pegs of the studs that hold the chain segments together. Measure from first to third, then halve that number to get the chain pitch. The most common pitch measurements you’ll see on a replacement chain are 3/8 “and 325”.

To identify the circuit sensor, you can use this simple trick:

Find a quarter, dime and a penny

Use a flat blade screwdriver or stem cleaning tool and remove as much debris as possible from the stem groove.

Insert each coin into your chainsaw groove

Determine which one fits snugly against the groove of the bar

Use the image below to identify the sensor

Where to find circuit measurements

Your saw blade may have the information you are looking for right there. It can usually be found near the back panel where it attaches to the saw.

For example, on the right you can see a chain that is 3/8 “and.050” pitch with 72 drive links. This should be all the information you need to get the correct chain to replace your saw.

You can now enter this information along with the bar length into the Bar and Chain Calculator to find the perfect chain for your saw.

How to measure a chainsaw chain

The saw body holds and protects the motor and all of its components, but the importance of the parts that are not protected by the body should not be underestimated: bar and chain.

Not every bar or chain fits every saw. For example, larger chainsaw bars work best with more powerful saws because it takes more energy to move the chain around a long bar. This is why electric saws use 18 “and shorter bars.

Likewise, chainsaw chains are measured to fit certain tires. Try setting the chain on a bar that is too narrow or too long and you will find that your saw simply won’t work.

You may be able to find the information you need to find a replacement tire or chain in your chainsaw manual, but what if the manual is long gone, or you work on the street and can’t find it? Don’t worry, you can measure both your bar and chain to determine which spare parts you should get.

Measuring your tire

If you are looking for a spare tire for your chainsaw, you need to determine the size. You will measure the used length of the piece.

To determine the length of your chainsaw bar, measure it from the front end to the cutter closest to the saw body. Round this measurement to the nearest even number in inches. For example, a part that measures 18 3/4 will actually have a named length of 20 “.

You can then find a new part with a length of 20. You can also enter this measurement into the Bar and Chain Calculator to find the correct bar replacement for your chainsaw.

The right parts for the job

The bar and chain sizing calculator is incredibly useful if you need to quickly find replacements for the chain you already used.

But what if you want to explore other options, say you want to find a laminated tire with a more corrosion resistant coating, or you want to see if there is a carbide chain that can handle the tougher jobs.?

When you know how to measure your bar and calculate your chain parameters, you can find different kinds of replacements for the most important parts of your saw, no matter how far from home (or Wi-Fi) you are.

On our website you can find even more useful information.

Chain pitch

It is customary to designate the chain pitch in inches, calculate it as follows: measure the distance between the nearest drive links of the chain, or the distance between the three nearest rivets of the chain (from the center of the rivet), divide by 2 and convert to inches (1 inch = 25.4 mm).

The chain pitch must always match the pitch of the saw sprocket and the driven bar sprocket.

- Chain with a pitch of 0.25 “aka 1/4”. The distance between three rivets (leading links) 12.7 mm ÷ 2 = 6.35 mm is converted into inches (÷ 25.4) in inches it is 0.25 “(more often denoted as 1/4”).

- Chain with a pitch of 0.325 “. The distance between three rivets (driving links) 16.5 mm ÷ 2 = 8.25 mm is converted into inches (÷ 25.4) in inches is 0.325”.

- Chain with a pitch of 0.375 “aka 3/8”. The distance between the three rivets 19 mm ÷ 2 = 9.5 mm is converted into inches (÷ 25.4) in inches this is 0.375 “(usually denoted as 3/8” so as not to be confused with 0.325 “).

- Chain with a pitch of 0.404 “. The distance between three rivets 20.5 mm ÷ 2 = 10.25 mm is converted into inches (÷ 25.4) in inches is 0.404”.

- Chain with a pitch of 3/4 “. The distance between three rivets 38.1 mm ÷ 2 = 19.05 mm is converted into inches (÷ 25.4) in inches this is 0.75” (usually denoted as 3/4 “).

The third main parameter when choosing a chain: Chain length (Number of drive links).

The chain length is determined by counting the number of drive (inner) chain links. Important:

- the cutting links do not determine the length of the chain (do not count them).

- the length of the guide bar does not determine the exact length of the chain (for example, on a saw with a 16 “(40 cm) bar, a chain length of 55, or 56, or 57 links can be installed, depending on the chain tensioning mechanism of the particular saw model).

- a chain with a length of about 55-57 links will not suit you, only a certain size recommended by the saw manufacturer will do.

How to measure a chainsaw chain

If you are unable to decide on consumables for your chainsaw, send a request through the form below. Our experts will select everything you need and contact you.

No results were found for your search. Fill out the form below to find consumables by a specialist

If you want to purchase a saw chain, or a guide bar for an electric or chainsaw, but do not know which saw headset will fit your saw model, fill out the form with the parameters you know. Our technician will select consumables for your saw and contact you.

Thickness

Chain thickness is the thickness of the drive link (can be measured with a vernier caliper). This dimension must always match the groove thickness of the guide rail.

In total, for electric and gasoline saws, as well as harvesters, there are 6 sizes that determine the thickness of the drive link:

- 1.1 mm (0.043 “);

- 1.3 mm (0.05 “);

- 1.5 mm (0.058 “);

- 1.6 mm (0.063 “);

- 2.0 mm (0.08 “);

- 3.1 mm (0.122 “).

To choose a chain for a chainsaw, you need to know three parameters:

- Chain pitch;

- Chain thickness (drive link thickness);

- Chain length (number of drive links).

Knowing these three parameters, you can easily choose a chain for your saw, pole saw or harvester head.

How long is the tire on my chainsaw?

The cutting length of the bar differs from its total length. The length of the bar is considered to be the length of the cut (working part). this is the distance from the front of the saw to the rounded tip of the nose of the bar. This dimension is rounded to the nearest inch or centimeter. An inch is indicated as “equals 2.54 cm.

For example, the length of the cutting part of a bar for a Stihl MS180 chainsaw is 40 cm. 40 cm ÷ 2.54 = 15.7 inches. Rounding to 16 “(inches).

For Stihl MS180 chainsaw fits 16 inch (40 cm) tire Oregon article 160SDEA074.

Choice by depth of cut

The depth of cut (depth of cut) is an important characteristic of a chainsaw that determines its performance. The cutting depth is determined by the parameters of the cutting tool, i.e. the height of the chain tooth profile. Increasing the tooth height increases the depth of cut in one pass, which increases the cutting speed. It should be borne in mind that an increase in the height of the tooth reduces its strength characteristics and requires an increase in effort when sawing wood.

Saw chain structure.

In a conventional chainsaw chain, such a characteristic as the tooth height is determined by the profile and parameters of the cutting depth limiter, which is installed on any working tooth. In a new circuit, this parameter is set by the manufacturer. The consumer can change the height of the tooth by grinding the stopper, but this operation should be treated with caution.

The chains are serially produced with two tooth profile heights. 0.635 mm and 0.762 mm. The chain with a lower tooth height is called low-profile, the second is called high-profile. For household chainsaws, low-profile ones are mainly used. Chainsaws with high-profile chains require increased effort and vibration during operation. To reduce the impact of negative factors, you can use an alternative approach. for high-profile links, the pitch of the links is reduced, and for low-profile links, vice versa.

Taking into account the thickness of the tail

The next important parameter in order to choose a chain for a chainsaw is the thickness of the tail, which determines the thickness of the elements and the width of the entire drive link. This characteristic is directly related to the dimensions of the groove on the bar of the chainsaw for pulling the chain. Naturally, when choosing a new copy according to the size of the tail, you need to check whether it fits into the groove of the tire.

Saw chain design.

This parameter itself determines the strength of the chain, its quality, reliability and the ability to ensure the cutting process under heavy loads. Variants with five tail sizes are available. 1.1; 1.3; 1.5; 1.6 and 2 mm. The narrowest chain for a chainsaw with a tail thickness of 1.1 mm is used for miniature household chainsaws of low power. Small-sized specimens with such links are not able to withstand significant loads when sawing.

The most common tool for domestic purposes is a tool that uses links with a 1.3 mm ponytail. Their capabilities are expanding and they can be used at a semi-professional level. In terms of quality and reliability, they fully meet the basic requirements for household chainsaws. Chains with a tail thickness of 1.5-1.6 mm are widely used in professional chainsaws with their frequent and prolonged use. The 2 mm ponytail chain is only suitable for powerful high performance tools.

Sequence of links

In any high quality standard chain, all cutting links have two tails. Typically, cutting teeth are made from high strength materials and will largely determine the overall cost. Despite the high cost, it is better to choose a chain based on its quality. At the same time, options should be considered that reduce the cost of the tool, especially if the chainsaw is rarely used.

In order to reduce the cost of chains, they can be made with skipping or half-skipping cutting links. With a half-pass, additional connecting links are installed in every second pair of cutting teeth. If skipped, additional links are installed after each cutting tooth. In a standard chain, the number of cutting teeth is 50% of all tails, in a half-pass. 40% and with a pass. 37.5%. Naturally, the load on the cutting teeth increases, and they fail much faster.

Selection by link type

Chainsaws for professionals use many specific forms of chain working elements. The main ones that have found widespread use are chisel and chippel types. Each of them has its own advantages and disadvantages, but can be successfully used in chainsaws and most often in household.

The cross-section of a chisel-type link is shaped like a number 7. Experience with such chains shows that they provide high productivity and high-quality sawing of wood. With such a profile, the working section of the link has a straight surface, which allows it to evenly penetrate into the material being cut. The disadvantages of chisel options include the complexity of sharpening. Even small deviations from the specified profile angles significantly reduce the cutting ability. In addition, during operation, closed areas arise, which become a reservoir of dust and dirt.

Chainsaw Performance Comparison Chart.

The cross-section of a chip-type link is shaped like a sickle. The working area of the link has no pronounced corners. they are rounded. Due to this, the total area of the working area increases, which leads to an increase in loads during sawing and somewhat reduces the functional capabilities of the cutting element. At the same time, the chippel type gains advantages when sharpening teeth, since it does not require strict adherence to dimensions and angles, and also does not have the disadvantage associated with the accumulation of dirt and dust, which is important when working with wood.

How to choose a chain step by step: basic rules

The chain pitch is the distance between the centers of adjacent links. It is one of the main parameters of the chainsaw chain. In practice, the pitch is measured as the distance between the centers of the first and third rivets in a row. The pitch determines the dimensions of the link: the larger the pitch, the greater the length and width of the link. As the pitch increases, the distance between the cutting teeth increases. These circumstances lead to the fact that with an increase in the step, the productivity increases, but also the effort required when cutting increases. Thus, this parameter is directly related to the power of the chainsaw itself.

The main parameters of the chainsaw chain.

Chainsaw chains are available in five different pitch options. This parameter is usually expressed in inches, and its value is indicated on the side of any product. The following steps are used:

- 0.25 (1/4);

- 0.325;

- 0.375 (3/8);

- 0.404;

- 0.75 (3/4) inch.

For household chainsaws, chains with a pitch of 0.325 (for 3 hp chainsaws) and 0.375 (4 hp chainsaws) inches are common. The 0.404 inch pitch is used in professional chainsaws with at least 5.5 hp. Pitch 0.25 and 0.75 inches are currently used extremely rarely.

The choice of chain step by step is determined by the purpose of the chainsaw. If you plan on sawing small wood products (beams, light logs, etc.) or trimming branches and limbs, a 0.325 ” cutting element is recommended.

How to choose the right chain for a chainsaw?

The chain is the most important part of any chainsaw. It is she who perceives most of the loads, and therefore wears out faster. Very often, the question of how long a chainsaw will last is how to choose a chain for a chainsaw.

Chainsaw circuit diagram.

Many people believe that the performance of a chainsaw depends entirely on its power. But this is far from the case. Performance depends more on which chain is selected for the chainsaw. It is she who can determine both the quality and the cutting speed. Inconsistency of the parameters of the leading elements of the saw can make the tool practically inoperative.

Taking into account the chain length

The length of the chain depends entirely on the parameters of the chainsaw itself: dimensions, sprocket sizes and power. With a standardized tension, the length for a specific chainsaw is determined and indicated in the passport.

Another question is the number of links, i.e. number of cutting teeth, at this length. This parameter depends entirely on the pitch of the links. Thus, the problem of how to choose a chain taking into account the length is solved in a complex, taking into account the pitch of the links. In general, increasing the length requires an increase in the power of the chainsaw, but increases productivity.

When using household chainsaws, they usually strive to reduce their dimensions, therefore, preference is given to chainsaws with a short chain length.

Step and its dimensions

A step is an intermediate distance between three rivets, which are located side by side. To correctly calculate the chain pitch, measure the distance between the axes of three rivets placed close to each other. In the form of a formula, it looks like this:

L = S / 2

Where, L is the step length, which in chainsaws characterizes the degree of distance between two teeth in relation to each other;

S. the value of the gap between the two extreme rivets of three.

The step size can also be equal to the length of the distance between two adjacent shanks.

Regularity: the greater the distance between the cutting teeth, the deeper they will enter the material being cut

By increasing the chain pitch, it becomes possible to increase the performance of the chainsaw. However, in such a case, the amount of force applied to rotate the drive sprocket changes. And the higher the chain pitch, the greater the power of the motors should be and the more physical forces are expended to pull it when cutting materials.

Chain marking for chainsaws

In some situations, owners of chainsaws may have some confusion in understanding all the chain markings for these tools. As a result, this leads to unsuccessful purchases. The choice of chainsaws is often determined by just a few basic criteria, one of which is the chain pitch. This indicator helps to highlight the future capabilities of the tool, including its cutting speed, and also, according to the norms, should correspond to the level of engine power. How are chains marked? Let’s figure it out!

Chainsaw chain pitch. Table

Taking into account the step size, at the moment the chains are divided into several subtypes:

| No. | Distance between rivets | Chain pitch (width in inches) |

| one | 6.35mm | 1/4 |

| 2 | 8.25mm | 0.325 |

| 3 | 9.3mm | 3/8 (0.375) |

| four | 10.26mm | 0.404 |

| five | 19.05mm | 3/4 |

As you can see from the table, the chain pitch is designated as an ordinary number (3/4) and decimal. “0.375”. This division is due to the similarity of the decimal values - “0.325” and “0.375”, since the difference of one digit created confusion when choosing a saw. Therefore, at one time it was decided to establish two different designations: decimal and ordinary fractions.

The pitch is stamped in the area of the special cut depth stop on each tooth.

The pluses of chains with a large pitch include:

- high level of productivity due to wide cut;

- the ability to perform complex work (felling large trees).

But it should be borne in mind that a wide cut requires the use of a more powerful engine, which in turn significantly increases resistance.

The advantages of small pitch chains are:

- low vibration;

- smooth movements when cutting;

- cleanliness of cut.

Benefits are achieved due to the large number of teeth and the small distance between them.

All known classification of circuits is based on the features of their marking, depending on the step, which is designed for specific needs and is produced for a specific power of electrical equipment. For a better understanding of each type of step, they should be considered separately.

Main parameters of chains

Applying the marking of the chain assumes the presence of the following parameters:

- Step:

- “0.325” is the most common and minimum step size that is used in semi-professional and household chainsaws with low powers. The standard value of power for such a step ranges from “0.325” to “3hp”, but not higher than “3.5hp”. When working with this type of chain, the sawing is smoother, more comfortable, without “gusts” of the processed products.

- “0.375” (“3/8”). applied to chainsaws with a capacity of “4hp”. This chain is used when sawing wood of medium and small thickness.

The accuracy and quality of the created cut depends on the value of the step. In cases where it is not important to achieve high quality when working with a chainsaw, the accuracy of the cut is sometimes of particular importance. To do this, it is imperative to take into account the dependence of the step for the release of wood according to pre-applied markings.

- The thickness of the leading links (tails). When the chainsaw is working, its chain accounts for most of all the loads. Considering this, another main characteristic of the saw is the thickness of the link elements, which enters the grooves of the bar. This parameter also determines the overall thickness of the fastening links, which is measured with a standard caliper. Standard thicknesses include:

- “1.1 mm” (“0.043”) and “1.3 mm” (“0.05”) are used in the production of entry-level chains, which are designed to carry out small amounts of work. Often, with such values of the link thickness, the chain pitch length can be “0.325”, which implies the presence of low loads and a gentle mode of operation. Therefore, they are used in household and semi-professional devices;

- “1.5 mm” (“0.058”) is the most common thickness on the market for chainsaws and accessories. This value is able to ensure safe operation with a step size of “3/8”. The 1.5mm chain is not suitable for professional cutting;

- “1.6 mm” (0.063) and “2.0 mm” (0.08). designed for the most difficult work. The metal in the manufacture of such chains is steel of special grades, and the characteristics of increased strength are laid in the design.

The greater the thickness of the link and the wider the groove of the tire, the higher quality the chainsaw is considered, since it is able to withstand heavy loads.

- Depth of cut is a distinctive feature of the produced chains and is characterized by the height of the profile of the cutting teeth. It is measured by the gap between the stops and the cutting top edge. Both high-profile (0.762 mm) and low-profile (0.635 mm) types of chain products can be presented on the market.

The higher the profile height, the higher the entry into the material (depth) and the cutting speed

High-profile chains are installed on chainsaws with increased engine power. Information about the height of the profile, as a rule, is written in the characteristic for the instrument.

Household types of chainsaws are equipped with a low profile. In semi-professional devices, different variants of the types of chains can be combined. However, in most cases, they adhere to the principle:

In a chain with a large pitch, a low profile is set, and with a pitch of “0.325”. a high

Such variations increase the cutting speed not due to the step, but due to the change in the depth or height of the profile. Although in professional tools, the emphasis is on increasing the step, explaining this by the fact that the chainsaw becomes more controllable.

- Cutting Teeth Geometry. Profile can be of two main types:

- chipper (popularly “sickle”). has a crescent shape and has a high performance. It is easier to sharpen during operation and does not require strict sharpening angles. Disadvantage: risk of high loads and deterioration of cutting performance;

- chisel (popularly “seven”). has a straight working surface in the form of the number “7”. They are used in chains with a pitch of “0.404” or “3/8” on professional saws. The main disadvantage of chisel links is the difficulty of sharpening the cutting elements and sensitivity to dirt.

- The number of cutting teeth is defined as the ratio of the number of teeth to the number of rails in the tire. Chainsaws of good production should combine two guide links in the cutting part of the tool.

- The type of link sharpening. directly depends on the type of future work. Classic types of chainsaws are used mostly for cross-cutting trees and are rarely used for longitudinal sawing. Taking into account the resistance of the tree in both cases, the chains can use a different angle of the links. On construction counters, you can now find chains with the following types of cutting links:

- longitudinal type of chain. involves cutting the tree along its fibers. The cutting angle reaches 5-15 degrees.

- transverse type. the cut is carried out across. The cutting angle in the chains is 25-35 degrees.

- Chain length. depends on the parameters and technical characteristics of the chainsaw itself: power, dimensions, etc. With standard or normalized chain tension, its length is most often indicated in the passport.

- The order of the links. the sequence of the links can be different:

- standard. there are two driving links for each cutting link in the chain;

- with a half-pass. every third link in the chain in terms of placement is replaced by the so-called connecting link;

- with a pass. at the locations of every second link for cutting, a connecting.

Why skip links in a chain? In the chains themselves, the most valuable is the quality of the cutting links, since they are manufactured using special technologies and are more expensive than connecting links. If it is impossible to shorten the chain, the only option to reduce the cost of the chain is to skip the cutting elements. In operation, chains with skipped links show reduced performance and wear quickly.

In general, if you want to purchase a tool for cutting wood with maximum efficiency, do not be too lazy to additionally study the marking of chains for chainsaws, which is also indicated in the instructions for the tool.

Reliable and inexpensive chain saw chain is sold here

Saw chains

- default

- default

- from cheap to expensive

- from expensive to cheap

- last added

- name A-Z

- name Z-A

Tire length: 12 “(30cm)

Chain pitch: 3/8 “

Link thickness: 1.3mm

Number of links: 44 pcs (cutting teeth 22)

Tire length: 14 “(35cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 52 pcs (cutting teeth 26)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 45 pcs

Tire length: 16 “(40cm)

Chain pitch: 3/8 ”

Link thickness: 1.5mm

Number of links: 57 pcs

Tire length: 16 “(40cm)

Chain pitch: 3/8 ”

Link thickness: 1.5mm

Number of links: 56 pcs (cutting teeth 28)

Tire length: 14 “(35cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 52 pcs (cutting teeth 26)

Tire length: 16 “(40cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 56 pcs (cutting teeth 28)

Tire length: 16 “(40cm)

Chain pitch: 0.325 ”

Link thickness: 1.3mm

Number of links: 64 pcs (cutting teeth 32)

Tire length: 16 “(40cm)

Chain pitch: 0.325 ”

Link thickness: 1.5mm

Number of links: 72 pcs (cutting teeth 36)

Tire length: 16 “(40cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 56 pcs (cutting teeth 28)

Tire length: 14 “(35cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 50 pcs (cutting teeth 25)

Tire length: 14 “(35cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 52 pcs (cutting teeth 26)

Tire length: 16 “(40cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 57 pcs

Tire length: 16 “(40cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 56 pcs (cutting teeth 28)

Tire length: 16 “(40cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 59 pcs (cutting teeth 29)

Tire length: 14 “(35cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 52 pcs (cutting teeth 26)

Tire length: 18 “(45cm)

Chain pitch: 3/8 ”

Link thickness: 1.6mm

Number of links: 68 pcs (cutting teeth 34)

Tire length: 18 “(45cm)

Chain pitch: 3/8 ”

Link thickness: 1.6mm

Number of links: 66 pcs (cutting teeth 33)

Tire length: 16 “(40cm)

Chain pitch: 3/8 ”

Link thickness: 1.6mm

Number of links: 60 pcs (cutting teeth 30)

Tire length: 14 “(35cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 50 pcs (cutting teeth 25)

Tire length: 14 “(35cm)

Chain pitch: 3/8 ”

Link thickness: 1.3mm

Number of links: 52 pcs (cutting teeth 26)

Here you will find durable chainsaws for chainsaws, the price of which is modest

Let your colleagues, friends and acquaintances know that chainsaw chains (the price of which does not bite) are for sale here. They will be grateful to you for the invaluable information and, who knows, maybe in the future, they will also help you with recommendations.

From this moment, you know where the highest quality and most reliable chains for chainsaws are sold (we have set the price for them low in Ukraine). The design of the device provides for the presence of a tank with oil for automatic lubrication of the bar and the saw chain. without the latter, it will quickly fail. You can also purchase all kinds of lubricants of famous brands from us.

Chainsaw table

Which chain is better to put on a chainsaw

A roller chain with curved plates can only have an odd number of links.

| PRI-78.1-360 | 78.1 | 33.3 | 38.10 | 17.15 | 102 | 45.5 | 51.0 | 360/36000 | 14.5 |

| PRI-78.1-400 | 78.1 | 40 | 38.10 | 19 | 102 | 56 | 51.0 | 400/40000 | 19.8 |

| PRI-103.2-650 | 103.2 | 46 | 49,00 | 24 | 135 | 60 | 73.0 | 650/65000 | 28.8 |

| PRI-140-1200 | 140 | 65 | 80,00 | 36 | 182 | 90 | 94.0 | 1200/120000 | 63 |

Example of circuit symbol: PRI-103.2-650

DRIVE. driven roller with bent plates

103.2. chain pitch in mm

650. breaking load in KN

to the top of the page

Sizing charts for saw chains and chainsaw bars by model

This is a defining parameter, and depending on its value, all existing chains are subdivided into five groups with steps of 1/4 ”, 0.325 ”, 3/8 ”, 0.404 ” and 3/4 ”. Step 1/4 ‘ ” (6.35 mm) typical of small chains mounted on low-power single-handed saws.

Chains with 0.325 ” (8.25 mm) and 3/8 ” (9.3 mm) pitches are the most common options. than 80% of the saws produced worldwide are equipped with them.

Pitch 0.404 ” (10.26 mm) and 3/4 ” (19.05 mm) feature larger chain links and higher performance. For several decades, they were used to complete Russian-made saws, but now they are installed only on powerful felling saws and harvester equipment.

The larger the chain pitch, the larger the links that make it up and the higher its productivity, but the wider the cut. A more powerful saw is required to overcome the increasing cutting resistance. Chains with a small pitch have other advantages. more teeth per unit of length, smoother movement in the cut and, accordingly, less vibration, cleaner cut.

Drive link thickness. During operation, the chain slides in the groove of the tire, and this sliding should be smooth, without snags and at the same time without unnecessary “bumpiness”. The thickness of the shank and the thickness of the groove must strictly correspond to each other, which increases the reliability of the chain fit and excludes the possibility of its “dismounting”. Everything is provided in five standard sizes:

- 1.1 mm (0.043 ”) for low power saws

- 1.3 mm (0.050 ”) household and semi-professional chains,

- 1.5 mm (0.058 ”) powerful and productive saws,

- 1.6 mm (0.063 ”) and 2.0 mm (0.080 ”) high performance saws.

CHAINSAW 101. How to buy the proper chain for a saw. Drive Links Pitch Gauge Cutter correct size

The intended use imposes its own requirements on the circuits used. For example, when sawing hard and dirty wood or when demolishing and building structures, it is better to use the special carbide chains Picco Duro or Rapid Duro, which have carbide teeth or pads that give them unsurpassed strength and durability of use. Some work simply cannot be done without their help.

It is also known that for longitudinal sawing of wood (along the grain) it is desirable to use special chains. The main difference between longitudinal and transverse type chains is the angles of attack of the cutting links. For crosscut chains, they are 25-35 degrees. Rip saw chains (e.g. Stihl Picco Micro X chains) have sharper angles. from 5 to 15 degrees.

The use of chains inconsistent with their purpose leads either to reduced performance, or to increased “aggressiveness”, strong vibration and additional load on the chainsaw engine.

Additional chain characteristics include profile height and cutting depth.

Profile height.

Chains come in high and low profile, depending on the height of the cutting edge above the plane of the guide bar. High profile chains are typically used for professional purposes to get the best cutting performance. Low-profile chains are installed on household and amateur chainsaws, because they are safer thanks to the increased bearing area of the cutting links and the reduced chip thickness.

Depth of cut is the amount of clearance between the top of the tooth and the cut stop, which controls the thickness of the chips. Most often there are samples with gaps of 0.025 inches (or 0.635 mm) and 0.030 inches (or 0.762 mm), less often. with gaps up to 0.07 inches (or 1.778 mm), the latter are intended for machine felling units.

The depth of cut determines the cutting performance to a large extent. The larger the gap, the higher the performance. The downside to performance is vibration. So chains with a shallow depth of cut in the cut move softer, less “twitch”. Therefore, to balance vibration and productivity, cutters with a shallow depth of cut are often installed on a chain with a large pitch, and vice versa.

OREGON is a major manufacturer and one of the main innovators in the saw chain industry. We believe that not only the quality of the tool is important for a perfectly performed job, but also its competent selection. Let’s take a look at what you need to look out for in this matter in order to make a choice that will suit your needs.

This is the distance between the axes of three adjacent rivets, divided by two. It should match the pitch on the saw sprocket and on the nose sprocket.

Pitch is measured in inches, the most common values are:

“325 is one of the most popular options, often installed on small and medium power saws for household and semi-professional saws;

3/8. comes with a low profile for the most common light saws and just 3/8 for powerful professional saws;

“404. used on professional saws with a capacity of at least 5.5 liters. with., it is economically inexpedient to put on low-power saws.

In order to choose the right chain for a chainsaw, taking into account this factor, it is enough to read the instructions. it will indicate what step it is designed for. With the exception of some professional models, most saws are designed for one specific step.

Drive roller chains three-row GOST 13568-97 (3PR)

| 3PR-12.7-45.4 | 08B-3 | – | 12,700 | 8.51 | 7.75 | 4.45 | 50.0 | 11.8 | 45.4 / 4540 | 2.00 |

| 3PR-15.875-68.1 | 10B-3 | – | 15,875 | 10.16 | 9.65 | 5.08 | 57.0 | 14.8 | 68.1 / 6810 | 2.80 |

| 3PR-19.05-96 | 12A-3 | 60-3 | 19,050 | 11.91 | 12.7 | 5.94 | 76.2 | 18.2 | 96.0 / 9600 | 4.30 |

| 3PR-25.4-171 | 16A-3 | 80-3 | 25,400 | 15.88 | 15.88 | 7.92 | 98.0 | 24.2 | 171.0 / 17100 | 7.50 |

| 3PR-31.75-265.5 | 20A-3 | 100-3 | 31,750 | 19.05 | 19.05 | 9.53 | 120.0 | 30.2 | 265.5 / 26550 | 11.00 |

| 3PR-38.1-381 | 24A-3 | 120-3 | 38,100 | 22.23 | 25.4 | 11.1 | 150.0 | 36.2 | 381.0 / 38100 | 16.50 |

| 3PR-44.45-517.2 | 28A-3 | 140-3 | 44,450 | 25.4 | 25.4 | 12.7 | 160.0 | 42.4 | 517.2 / 51720 | 21.70 |

| 3PR-50.8-680.4 | 32A-3 | 160-3 | 50,800 | 28.58 | 31.75 | 14.27 | 190.0 | 48.3 | 680.4 / 68040 | 28.30 |

An example of a circuit symbol: 3PR-38,1-381

3. chain row GOST 13568-97

PR. driven roller

38.1. chain pitch in mm

381. breaking load in kN

An example of a conventional designation of components:

S- 3PR. 38.1. 381. connecting link to the chain

P. 3PR. 38.1. 381. transitional link to the chain

P2. 3PR. 38.1. 381. double transitional link to the chain

to the top of the page

Drive roller chains four-row GOST 13568-97 (4PR)

| 4PR-19.05-128 | 12A-4 | 60-4 | 19.05 | 11.91 | 12.7 | 5.94 | 101.9 | 18.2 | 128/12800 | 5.75 |

| 4PR-19.05-155 | – | – | 19.05 | 11.91 | 12.7 | 5.94 | 101.9 | 18.2 | 155/15500 | 6.80 |

| 4PR-25.4-228 | 16A-4 | 80-4 | 25.40 | 15.88 | 15.88 | 7.92 | 129.9 | 24.2 | 228/22800 | 10.90 |

| 4PR-31.75-355 | 20A-4 | 100-4 | 31.75 | 19.05 | 19.05 | 9.53 | 157.5 | 30.2 | 355/35500 | 14.70 |

| 4PR-38.1-508 | 24A-4 | 120-4 | 38.10 | 22.23 | 25.4 | 11.1 | 197.1 | 36.2 | 508/50800 | 22.00 |

| 4PR-50.8-900 | 32A-4 | 160-4 | 50,80 | 28.58 | 31.75 | 14.27 | 252.3 | 48.3 | 900/90000 | 38,00 |

An example of a circuit symbol: 4PR-50.8-900

4. chain row GOST 13568-97

PR. driven roller

50.8. chain pitch in mm

900. breaking load in kN

An example of a conventional designation of components:

S- 4PR. 50.8. 900. connecting link to the chain

P. 4PR. 50.8. 900. transitional link to the chain

P2- 4PR. 50.8. 900- double transition link to the chain

to the top of the page

Saw chain technical parameters

When choosing a chain for a chainsaw, you need to pay attention to several important characteristics:

- number of links;

- chain pitch;

- the thickness of the driving link;

- purpose of use.

In addition, on our website you can choose a chain according to the saw model through the chain saw guide.

Number of chain links. Determined by the internal teeth of the chain.

Chain pitch. the distance between three consecutive rivets divided by two.

How to measure and choose the step, size, chain length for a chainsaw, what exactly you need to know about them?

Incorrectly selected tool accessories are a waste of money and time. Difficulties with choosing a tire for chainsaws arise primarily due to the fact that the parameters of the headset are usually marked in inches. Therefore, users accustomed to the metric system do not always correctly calculate the required part sizes. Experts point out typical mistakes when choosing a saw headset for a tool and give recommendations for determining the optimal characteristics of accessories.