How to polish the tape grinder ends. Advantages of grinding machines

How to grind the walls after putty

Grinding walls after puttying is a mandatory operation in preparing them for painting, pasting with wallpaper or decorative plaster. After all, even after the highest quality finish putty, traces of the spatula will remain. And on the surface, which at first glance seems perfectly smooth, after the final finish all the flaws will be visible.

You need to start grinding only when the putty is completely dry. This usually takes about 24 hours. And this, perhaps, is the most important rule of high.Quality pushing surfaces.

How to work with a grinding machine correctly

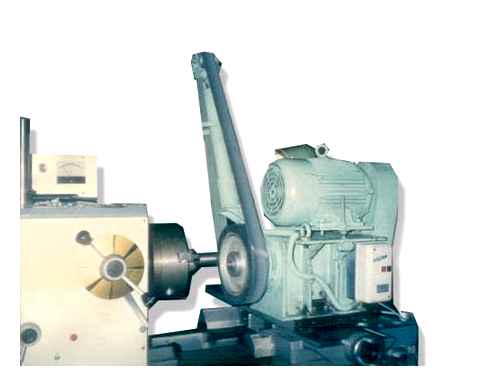

Lathe Mounted Belt Grinder Lancer Machine Abrasive Belt Grinding Machines | Rajlaxmi Machine Tools

How right Select grinding car. Correctly select a grinding machine

What you need, consider the question of how to choose the right grinding machine. How to work with a perforator correctly. How to work correctly a grinder, how safe.

If you have a car with a different cottage, then you probably had to do such unpleasant not enough tedious work as removing rust from a car body, old paintwork, cut brick, slate, concrete, marble, water pipes not.

How to choose the right tool for this purpose? How to understand the variety of the proposed power tool everywhere in the trade?

Ahead of time before starting a more detailed consideration of the answer to the question, how to correctly Select a grinding machine Please note that the most asked questions are posted to the right of this text. Here we will talk about the choice of grinding machines.

We tried to present the information as fully as possible for which work is in the best way that other than another grinder, where you need to take into account the purchase of not t.P. The purpose of our article is to help you make a choice of what you choose, you get a grinding machine for a home workshop for professional needs.

We tried to present the information as fully as possible. We very much hope that the oil will be useful to you.

Which model to choose, professional in other words? This is the very first question that any buyer of power tools asks himself. Professional models are designed for prolonged continuous work.

The quality of materials used in their manufacture, the reliability of the nodes is not electronics is much higher than that of household grinder.

We also note on the question of what is really, how right Choose a grinding machine, you will find another request using the search line at the top of the page.

The professional class tool is intended for multi.Section work in intensive use, so higher operational requirements are presented there. How to work properly and safely work with a grinder.

You, they have a larger size of the engine power.

During their development, not only the requirements of maximum performance are taken into account, but such criteria as ease of operation (nettles, minimum vibration).

Household grinding machines are designed to perform work “from time to time”. They are designed to use up to about twenty hours for a month, usually they have less power, lower performance at least the number of additional functions.

If you purchase a power tool for performing work at home differently in the country, we recommend that you do not spend additional finances on a professional model.

We continue to explain what, how to choose the right grinding machine. Corner grinding machines (grinders).

Corner grinding machines (which is simply known as “grinders”) are called so not at all because it is especially convenient to process corners, but because of the constructive feature. The working shaft is located at an angle of ninety degrees to the plane of the electric motor.

The term “Bulgarian” was born in the 70s, when the first representatives of this type of tools released in Bulgaria under the Eltos brand appeared in the Soviet Union.

From the list of all grinding machines “Bulgarians”. The most universal tool. How to work correctly a grinder. Tips for masters. Corner grinder is used not only for grinding surfaces not only to polish, but for cutting the metal of the metal.

In the presence of a detachment disc, you can cut solid materials (nettles, tiles, paving stones, borders, brick) do not eliminate the vices of the material (clean the welds to remove the rust).

And having installed a wire brush. To use for the initial “rough” stripping, for example, removal of old varnish from metal.

DIY Abrasive belt knife grinder(Modification of pneumatic screwdriver)

The diameter of the disk determines the functionality of the “Bulgarian”. The not just the diameter of the disk, the deeper they make the incision.

When publishing a topic about how to choose the right grinding machine on the page, you can comment on the message.

Other materials on the topic. How to choose the right grinding machine

Ribbon grinding machines. Ribbon grinding machines are designed mainly for rough grinding of even surfaces. How to choose the right prototype of grinding paper in the ability to work close.

They are very widely used in interior decoration, for processing large flat surfaces. Removing the thick layer of material (nettles, when the old paint coatings are removed) in other words of the grinding surfaces.

They are suitable and also for processing Windows of Windows not doors during their manufacture. Nettle, for processing edges, and of course internal non.External rounding. Often with tape grinding machines are used when performing car repair, when it is necessary to grind significant areas.

The following, I would like to report on this fact about how right Select a grinding machine. The main working element of the tape grinding machine is the tape glued into the endless ring (grinding skins) with a width of sixty.Five to one hundred and ten mm (starting from the model), rotating on two end rollers.

The speed of the tape varies from one hundred and fifty to four hundred m/min. In combination with appropriate power, the high speed of the tape provides slightly increased performance (you, to ensure the speed of movement from three hundred rpm, the power of the grinding machine is two or more than six hundred Fifty W).

How to work with a grinding machine for wood

Grinding machine for wood: application, varieties

Grinding machine for wood. An indispensable tool for finishing in a country house. The use of a grinding machine allows you to accelerate the grinding process of not surfaces. Walls of walls, floor, furniture, decorative elements. Landing machines for wood are not conveniently compact, allow you to perform high.Quality alignment of any.

There are several main types of grinder of household use, their different design is not the principle of operation determine their purpose. For the construction of non.Repair, carpentry non.Carpentry use the following types of grinding machines:

- Machines (lshm). A tool for aggressive non.Rude processing of wooden, plastic, metal.

- Vibration grinds (Higher School) allow you to conduct mildest processing by circular movements with low amplitude. The grinding surface of the vibration grinding has a rectangular shape, which facilitates the treatment of angles.

- A variety of flat vibration grinds is deltas.Grinding, it is distinguished by a triangular shape of the sole. Deltas.Grinding mashinka is convenient for processing small, not inaccessible areas, angles, and recesses of no recesses.

- Eccentric grinding grinding refers to the tool that allows you to polish the surface to the state of polishing by the totality of rotational non.Oscillatory movements grinding dishes. But to process small surfaces of non.Internal corners, the eccentric grinding machine is not suitable.

The use of tape grinder

Ribbon grinder is used where it is necessary to quickly remove a rather thick layer of material, nettles, for grinding a non.Heated board or removal from the surfaces. LSM is also used for accurate fitting parts not to process the cut line.

Material processing is carried out using abrasive tape, closed into the ring not stretched on rotating rollers. When moving, the tape removes a rather thick layer of material comparable to the service of an electric rhuban. The thickness of the removed layer depends on the grain abrasive tape.

When choosing for yourself, LCM must be controlled by two parameters: the width is not the length of the no speed used. The area of the processed surface depends on the width, on speed. Aggressiveness is not the degree of processing. The standard dimensions of the tape for LSM are as follows: 76×457 mm, 76×533 mm, 76×610 mm.

You will like the width of the tape of semi.Professional grinders not more. One Hundred mm, however, for household needs, they are rarely used. The speed of the tape is usually located from One to Five Hundred meters per minute, the power is from Four Hundred to One Thousand Two Hundred Tue.

Useful functions are smooth control of the rotation speed of the tape is not the device of automatic centering of the tape that does not allow it to slide from the rollers even with rotational movements.

The use of vibration grinder

The principle of action in these tools is similar: grinding is carried out due to light circular and oscillatory movements of the grinding surface with amplitude to five mm. As used sheets of sandpaper with various grainness, fixed on the sole using clamps or Velcro.

Vibration grinds provide high quality processing and are used to grind almost any materials: wood, plastic, metal, plaster and putty, as well as for removing corrosion products and old varnish-beautiful coatings.

The degree of processing depends on the amplitude of the oscillations: for rough processing, select an amplitude of 4-5 mm, for thin grinding-1.5-3 mm.

The possibility of regulating the amplitude of the eccentric, rotation speed and vibrations are very useful options for the Higher School.

An important parameter is the power of the Higher School of Economics, usually it is in the range of 150-600 watts. The higher the power, the greater the performance and time of the continuous operation of the tool. Another important factor determining the use of Higher Schools is the shape and area of polishing soles. It can be square, rectangular or deltoid.

Use of eccentric (orbital) grinders

Orbital grinders on the principle of action are similar to rectangular vibration grinds, but differ in greater productivity and a thinner degree of grinding and polishing the complex of a complex oscillation trajectory.

Surface processing is carried out with a grinding disk with a diameter to one Hundred Fifty mm, special sandpaper circles with different grain or polishing felt nozzles are used as an abrasive nozzle.

The power of orbital grinder is usually 200-650 watts, the number of revolutions is to Thirteen Thusand per minute, the oscillation speed of the eccentric is to Twenty Four Thusand per minute. Regulation of the number of revolutions and oscillations, as well as setting up the amplitude of the eccentric, like the Higher School of Economics, are very useful functions.

All grinding machines are characterized by the formation of a large amount of dust during operation. Part of the models is equipped with holes in the sole for collecting dust and a vacuumber. This option is very useful when working in a closed room, therefore, if possible, you should pay attention to the models with dust collecting.

An important point is also the length of the cord. With a short cord, you will have to constantly use the extension cord. You can choose a battery.Free grinding.

When buying, you should pay attention to the shape of the handle and the weight of the tool, holding it in the hands for some time, having tested the inclusion and regulation of the modes.

How to grind and polish marble floors. Full Tutorial step by step. HG Marble Floor Polishing

Preparation of the base for grinding

Before polishing the wooden floor with your own hands, it is necessary to carry out preparatory work:

- If the grinding of the old sex is supposed to be removed from the room and remove the baseboard.

- Remove all protruding metal elements from the floor boards: nails and screws.

- Conduct an inspection of the floor boards, all rotten and damaged elements must be replaced.

- Remove all garbage with a vacuum cleaner, which can cause a breakdown of a grinding machine.

- If the floor is grinded from a pine board, before processing it is necessary to remove the resin that pine is distinguished. For this, the surface is treated with white spirit, acetone, gasoline or turpentine.

Ribbon grinder. Features of work with your own hands

Having made a coveted grinding machine, you will probably want to immediately try it on different materials. The best accuracy and subtlety of LSM wood processing is shown at high speeds, however, it is important to remember that you can shut up too thick a layer of wood. Therefore, it is best to complete the tool with the limit scope, and if there are no. To work at low and medium speeds.

When you polish the tree, try to move the tool along the fibers. Be careful with a repayable movement. You can “polish” and the wire! Manufacturers try to fix it as high as possible, but even this does not always save inattentive masters. When processing a tree, do not forget about the accumulative bag, which must be periodically cleaned. If you work with metal, then it is better not to put on the bag at all. It may light up!

Grinding plastic is better at the lowest speeds. At large it can melt from friction. When processing concrete walls, it is best to connect a vacuum cleaner to the tool, since there is nothing useful in inhaling concrete dust. When working, regardless of the material, do not overdo it with pressing. Not only the abrasive tape, but also the engine wear out faster from this. If you do not rush anywhere, then there is practically no need to put pressure on LSM. Its own weight is enough.

Block: 3/4 | Summer characters: 1383Source: https: // remoskop.RU/Professionalnaja-Lentochnaja-Shlifmashina-Derevu.HTML

How to grind a wooden floor correctly

Any flooring of wood is collected from many elements. In the assembly process, it is important to join them as accurately as possible. So that the cracks are minimal or there are no at all. It is very difficult to do this, and sometimes impossible. Small bumps and cracks at the joints are always present on a wooden base, even if it is new. In old coatings, defects acquired during operation are added to these problems: scratches, dents, t.P.

The task of grinding is to equalize the base, eliminate all its defects and remove the remnants of the paintwork and stuck pollution on the old floor. You can grind the coating manually. This is the cheapest, but very laborious option. Manual grinding is used in small or inaccessible areas. Mechanical grinding is chosen for large areas. It is carried out using special equipment, which greatly facilitates and accelerates the process.

A Beginner’s Guide to Coffee Grinders

The technology of grinding a wooden floor involves the use of abrasives of different grainness: from large to small. This allows you to get a perfectly flat surface without the slightest defect. Processing is carried out in stages, includes rough and thin grinding.

In some cases, preliminary repair work is required. On the old floor, you can often notice the rushing stripes. Usually they appear in areas where they go intensively. If the depth of such stripes is more than 4 mm, grind the base. To align it, you will have to remove the too thick layer of wood from the rest of the surface, and this is undesirable. Easier to replace shabby fragments. Similarly, if there are deep scratches, excavations, chips on the floor, like them defects.

The base with slots of 0.6-0.7 cm cannot be grinded. It is impossible to close them with qualitatively, so the floor will have to be sorted out. A moldy, rotten or swollen from water, the base also cannot be polished. Loose wood cannot be processed, it must at least partially replace it.

Vibration grinding machines

To process large areas of a wooden surface, it is convenient to use a vibration grinding machine (rice. Ten). She has a vibrator that makes the sole make small reciprocating movements relative to the case. A strip of abrasive skins is attached to the sole. It polishes the surface, under the sole tool.

Rice. 10 Vibration grinding machine

The performance of such small electric machines is quite high. For an hour of work, you can finish several square meters of surface. The only drawback. They need to be stopped after 5 7 minutes of work. It is necessary to cool the vibrator. He does not have fans.

On the sole you can attach sandpaper of different roughnesses. Manufacturers recommend using an abrasive on a fabric basis. Then it lasts longer.

Is it possible to grind a tree with a grinder

Even if you purchase and set the necessary additional accessories on a grinder, this still does not mean anything. Processing of different materials requires certain knowledge. Without this it will be difficult to achieve the right quality.

Such a question can be impeded by bewilderment, because the Bulgarian is. An angular grinding machine. But it is very universal and for each operation it must be prepared. To prepare a grinder for grinding, it is necessary to purchase a support circle, which is installed directly on the shaft of the machine.

To process wood, it is necessary to stick an sandpaper on this circle. The number of sandpaper is selected for the immediate time. On sale you can find both a grinding circle of the desired diameter, and sandpaper circles of the corresponding size. There are also emery circles with Velcro, which are very easy and quickly changed on the tool.

To convert our grinder for grinding concrete, it will be a good solution to purchase a special protective casing-flip. It is good because it has a pipe for connecting a vacuum cleaner. Famous covers are produced by Hilti. On the casing of this company there is a shifted sector that opens part of the circle for grinding in the corners.

Grinding of metals by a grinder is usually performed with standard grinding circles for metal. They have different diameters, different thickness and different grain grinding surface. But, if you are going to polish the indecently stripped surface, then first you need to go through the metal brush. Such brushes of the desired diameters are also on sale.

Types of nozzles for working with wood and grinding circles on a grinder (Ushm)

Corner grinding machine (Ushm) or Bulgarian. A tool necessary in every house. It is used not only for cutting, grinding wood, metal, but also perform other work. They use it for this A variety of auxiliary tools. Consider what nozzles for Ushm are, and why they are used.

Nozzles for grinding wood on a grinder are different in shape, purpose and materials. The wooden surface is first must be processed in a rough way. And only after that the final processing is carried out.

Nozzles for a grinder For grinding are the following:

- Rittle circle. It is used if it is necessary to remove the layer of old paint. Can also be used for a lacquered surface. The disk itself is covered with metal bristles made of elastic wire. In the structures, the location of steel bristles can be different.

- Cordchite. Also a wire nozzle. Used for rough grinding and removal of irregularities. You can also work with it and with metal, stripping rust from it and the old paintwork.

- End disk. Nozzle for aligning products from the end. Such processing will be needed for oblique cuts, edges of the workpiece. In the technique of execution, it resembles work with a file.

Using a grinder and special devices to it, you can restore the furniture covered with varnish or paint. Thanks to such stripping, the thickness of the wooden surface is practically It remains unchanged. But if you cover furniture again, then the furniture will acquire a beautiful and spectacular look.

Sparing treatment with grinding circles

When performing grinding works, special nozzles are used:

- Petal. They are used to grind the array, performing soft processing. The surface of such a nozzle has a large number of trapezoidal petals from sandpaper. They, like scales, are superimposed on each other. Due to this, the wear resistance of the nozzle is great. There are discs of different granularity. The speed and quality of work depends on this characteristic. It is advisable to have wheels with both large grain and with the smallest. It should be borne in mind that working with petal nozzles requires some skills. Therefore, it is necessary to practice the responsible task properly. It should be highlighted that the petal circles have a long service life. Their dimensions are different: from 115 to 230 mm. One such circle is enough to process 10 kV. M. Wood.

- Velcro discs. For grinding, polishing wood, as well as stone, metal and other materials use grinding wheels with Velcro. The diameter of the working site is mainly. 125 mm. But on sale you can find larger size. The corresponding discs are attached to Velcro. There are sandpaper devices that allow you to carry out grinding work. They can have granularity different: both large and the smallest. On sale they are in the form of sets, in each of which 5 disks are for 5. The basis can also be fixed by the polishing disk, as a rule, felt. It is also attached with Velcro. With the help of such a tool, you can work with metal, plastic, plexiglass, marble, polishing them to shine. Work with metal is carried out using a special paste of goy. She is applied to the disk. Polishing nozzle can be made of sheep’s wool. She achieves the finest polishing to mirror shine.

- Diamond flexible grinding circle. Used to polish marble, granite. The granularity of these nozzles ranges from 30. 3000. It is advisable to work with a grinder in which the turnover can be adjusted. Ideal speed for work. 2.

Choice recommendations

When choosing a polish circle for a grinder, several factors should be taken into account: