How to power a screwdriver from a 220 V network

Denis

The LEDs are ok, I checked them. It burned out on two boards not labeled and nothing is written on it. A black square with 8 legs. The resistance of all the LEDs at once is why my multimeter cannot measure, but for one LED in the 200M position, the resistance of the LEDs is from 04.1 to 04.6.

I would like to install some kind of ice driver on them.

Denis

These two boards are identical, they were in the spotlights in the garage, but they both burned out due to power surges, the LEDs themselves are intact, their power controls, which are on the same board, burned out. I found this board on Ali, it is identical as on my spotlights. Link.

Tell me how you can revive them?

Dmitry Makarov (Expert)

If you decide to put any driver on the LED luminaire, then this will save the device in the event of any jumps and deviations of electrical values in the supply network. To select a specific driver, you need to pay attention to its characteristics, namely:

1) Device power;

2) Operating voltage range at the driver input;

3) Operating voltage range at the driver output;

4) Stabilized current at the output of the driver;

5) Dust and moisture resistant driver.

Pay attention to power initially. If the board matches what you specified in the link, the board consumes 30W. If you want to double-check this data yourself, you can divide the square of the voltage by the resistance obtained by measuring (P = U2 / R). If the calculation was made for one LED, then after that you need to multiply the power of one by their number. The voltage is also taken that which will fall on one LED.

According to the second parameter, as I understand it, you need a model for a standard alternating voltage in the network. 220V.

The operating voltage range at the driver output should provide a voltage drop across each LED of 3.2. 3.3V, that is, for 70 LEDs connected in series, you need to choose a model that will provide 220. 230V.

The output current must be between 120 and 150mA for your LED board.

In terms of the level of dust and moisture resistance, you need to select the most protected model, since its installation will be carried out in the garage, where the level of dust is quite large. Moisture also occurs due to temperature changes even when installed indoors, especially condensation is typical for the cold season. You need to pay special attention to this parameter, since the failure of the driver due to external factors leads to disruption of the operation of the entire LED board.

How can you power the SMD5730 directly from the 220 Volt network?

There are two boards. In each of which there are 70 pieces of SMD5730, which are connected in series with each other (that is, LED, LED, and so 70 pieces). This board has only SMD5730 and nothing else. The question is how can they be powered directly from a 220 volt network, or in what way? Thank you in advance.

Dmitry Makarov (Expert)

Before undertaking repairs, be sure to use a tester to make sure that the LED circuit is working. To do this, it is not at all necessary to double-check each of them in a serial connection. It is enough to connect the probes to the beginning and end of the strip. if there are no gaps in the circuit, then the circuit has really survived and the tape can be used further.

If you are not going to repair the device, but want to somehow light up the LEDs, then I recommend doing what was written earlier. measure the resistance of their circuit and the voltage at the outlet or at the output of the lamp. Divide the voltage by the number of LEDs connected in series, if the value is within the allowable range, you can directly connect the board to the network.

Naturally, you will have to solder the wires directly to the leads of the LED strip. Do all measurements under voltage in a dielectric glove in order to protect yourself from the effects of electric current.

social media

Dmitry Makarov (Expert)

This diode model has certain characteristics such as current and voltage. Of those proposed in the network, this is from 3.1 to 3.3 V or from 3.2 to 3.5 V, the nominal current can also vary from 120 to 150 mA, depending on the manufacturer or batch. These parameters should be checked for your LEDs as well. Then I recommend making the following calculation.

If you connect one board to a 220 V network, on which 70 SMD5730 LEDs are assembled in series, then when they are directly connected, each device will have 220/70 = 3.14 V. This means that if the board is directly connected to the network on each of the LEDs The SMD5730 will have a voltage of 3.14 V, which is completely suitable for a model for a voltage of 3.1 to 3.3 V and is quite acceptable for a model for a voltage of 3.2 to 3.5 V. Therefore, if you have just such models diodes, then each board can be directly connected to the 220 V network.

Both boards can be connected to the network in parallel so that each of them has a voltage of 220 V. However, you need to take into account the peculiarities of each board, so the parameters of the LEDs should be checked for each of them.

If after calculating for each LED you get a higher voltage, then a resistance of such a value must be connected in series to the board, at which a voltage within the specified limits will be provided to each LED.

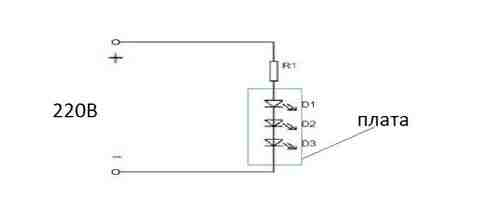

This voltage calculation is an indirect method, if you have a multimeter, then for each board you can measure its impedance. After that, the mains voltage should be divided by the resulting value of the board resistance I = U / R. This will give you the amount of current that will flow through the LEDs. If it is within the specified limits from 120 to 150 mA, then the board can be normally connected to a 220 V network.Otherwise, you will also need to introduce resistance into the circuit, as shown in the diagram above.

If you have frequent voltage surges in your network, then it is better to turn on these boards through a voltage regulator, which will provide stable 220 V. Otherwise, the boards may simply burn out.

Why convert a cordless screwdriver to a network?

Battery-charged equipment periodically discharges if left unused. This fact is a problem, since the main components deteriorate when the charge in the battery drops frequently. As a result, during the first signs of a breakdown, the battery holds less and less charge. In such a situation, complete breakdown of the part cannot be prevented, it is better to either replace it or change it to a new one. By the way, the cost of the first and second options will be the same.

Tip: If the user is going to work with hard surfaces, choose devices with rotation parameters of at least 20 Nm. This is the Sparky BR2 10.8Li-C HD mechanism.

The second reason is to remake the device. quality of work. Owners of such devices will easily confirm that the torque process is sometimes interrupted. It is also annoying that the power is not the best level. again, the partial discharge is to blame. The situation is saved by connecting the device to the mains supply. Here are the benefits we get in the end:

- Charging time will be shortened and you can start working at any time.

- Functioning without restrictions, confidence that the device does not sit down halfway to the job done.

- Financial benefit: no need to periodically change the battery.

Tip: On high-quality equipment, there is protection against breakages, which is located near the nozzle. Such protection is available for devices Bosch PSR 1200, Bosch GSR 12V-15.

How to convert a cordless screwdriver into a network: 3 basic methods

It is not surprising that almost every house or apartment has a screwdriver. Unfortunately, devices based on a wireless network source often run out of power and break down. Since it is expensive to buy a new battery, most owners convert their cordless screwdrivers to cordless ones. In this article, we will tell you how to remake the device using the parts at hand. We will also touch on the topic of why this type of equipment breaks down most often. Read carefully!

Choosing a power supply for a screwdriver

The task can be accomplished in several details. For example, with a laptop charger, this rework is considered simple and unassuming. Therefore, if an unnecessary network block from a laptop is left at home, you can use it. Second detail. network block from a computer. This option implies a certain amount of knowledge and skills to work with a soldering iron. Another option is how to convert a screwdriver to a network one. engage the desired inverter welding. In the next section, we will describe in detail how to implement our plans in all three ways.

Tip: Pay attention to the device parameters. For effective drilling, the rpm must be at least 1300. For example, Bosch GSR 1440-LI and Makita DF347DWE machines have this characteristic.

reconstruction based on laptop power supply

As already mentioned, this reconstruction method is considered simple and does not require much time. Check first what output voltage the device is designed for. The best option would be 12-19 watts. In the next step, remove the unusable batteries from the device with a screwdriver and disassemble the device.

- Disconnect the entry (sized for the laptop connector) and strip the wires.

- Take the contacts and simply solder them to the device.

- Select a location on the device for the wire and drill it. At the end of the action, fold the structure and check for operability.

Method number 2 (reconstruction based on a network unit from a computer)

For this type of reconstruction, only an AT class network unit is suitable. Such devices have a ventilation compartment, as well as buttons on. and off. The network block is used on many models of computers, so it will not be difficult for anyone to find an unnecessary part. Then check the output current, it should be at least 16 volts, and the power is 300.30 W.

- Disassemble the device and find the plate on which the wiring is fixed (board).

- Disable protection: locate the green electronic component on the board and attach to any other black wire.

- Find a design with two black, yellow and red wires (MOLEX pins). Attach or solder the extension cord to the yellow and black wires, and attach the other part to the screwdriver terminals. Now twist the mechanism.

Screwdriver alteration process

(reconstruction based on inverter welding)

Reconstruction of a screwdriver when using inverter welding involves lengthy checks and calculations for the fact that the necessary parts are working. The process of reworking itself is not complicated, it adheres to the same technology as in the previous methods. You just need to remove the old battery, and in its place, attach the cord entry to the contacts. In the case of inverter welding, you will also need to install a secondary coil.

Based on the article read, we can say that this goal can be achieved in different ways. For this, a number of items are used, such as: laptop charger, computer power supply and inverter welding. However, the most successful and uncomplicated reconstruction will be based on a laptop power supply. So, not a huge detail will not weigh down the apparatus and will work for a long time. Be careful, all actions related to electrical devices oblige you to follow safety rules.

See Converting a cordless screwdriver to a mains

How to turn a cordless screwdriver into a cordless one

Yes, there are many advantages to using cordless power tools. This is both practicality and autonomy, and the same aesthetics. But when using battery technology, the day certainly comes when the battery completely loses its original performance. That is, the battery power supply for the screwdriver ceases to hold a charge, which is why the battery is discharged literally in the first minutes of operation.

Everything would be fine, but manufacturers of cordless power tools, even from among the eminent ones, do not separately produce battery packs for their equipment. It’s all about the economy. Thus, manufacturers stimulate demand for their products.

Instead of a relatively inexpensive new battery, a person will have to buy a new cordless screwdriver, which in this case is beneficial only to a manufacturing enterprise.

The average service life of a cordless screwdriver does not exceed 2-3 years. After this time, the electrical battery almost completely loses its capacity. The owner of an old screwdriver has several ways: to dispose of the old tool or to try to restore its performance.

It should be noted right away that you won’t be able to put a “deflated” battery on your feet. But instead of the battery, you can try to use the household power supply. To do this, you just need to connect the 12 or 18 Volt screwdriver power supply to the cordless tool, depending on the type of its drive.

Connecting a screwdriver to an external power supply

Please note that a self-modified screwdriver can only be effectively used at home, when doing a small amount of work. If we are talking about a screwdriver for a large construction site or manufacturing enterprise, then in this case, a hand-made tool restored by a handicraft method will not help the master.

Working with electric shock is always dangerous. The instructions below are intended only for those readers who have at least basic knowledge in the field of electrical safety (the level of an electrical fitter is 2-3 categories).

The mains adapter for the cordless screwdriver can be created as follows:

- Disconnect the old battery and disassemble it. The battery pack is easy to disassemble. You just need to unscrew all the screws around the perimeter of the battery cover.

- We remove all the components of the battery. You only need to leave the adapter to which the network wires will be soldered.

- We compare the characteristics of the electric current of the external step-down transformer and the screwdriver motor. The author of the video used a 36 (V) step-down transformer, consisting of 2 coils of 18 (V) each. The transformer is marked TS-250-36. And the drive system of the power tool (screwdriver) is designed to operate on a 12 (V) network. The electrician had to get out of the situation in the simplest way, he disconnected the coils (36-18 = 18).

- In one of the coils, a part of the copper wire was additionally unwound, which made it possible to reduce the voltage from 18 to 12 (V). The master reduced the winding until the output voltage was 11.2 (V). This is done in order to compensate for the voltage rise that will occur after the rectifying capacitor.

- We solder the wires of the secondary winding to the middle terminals of the diode bridge. A diode bridge is required to convert direct current to alternating pulsating current. The current strength of the diode bridge must match the current strength of the screwdriver.

- We solder the rectified current output wires to the diode bridge. These contacts are located at the edges of the diode bridge.

- We solder a pre-prepared cable to the output wires of the diode bridge, which will connect the transformer and the screwdriver itself. It is better to take a longer cable, at least 2 meters.

- We connect the capacitor in parallel. The operating voltage of the capacitor should be 2 times the voltage of the screwdriver. The capacitance of the capacitor must be at least 470 (μF). Below is a diagram of the above circuit.

The diode bridge and capacitor are best fixed with hot melt glue.

- We connect the power wire directly to the terminals of the screwdriver. At this stage, you need to check the performance of the electrical circuit.

- We check the operation of the tool, in parallel we control the voltage. Without load, the voltage can reach 15 (V). This is normal, since with direct rotation of the spindle, the voltage drops to 11.5 (V), which fits into the tolerance field.

- Now you need to make wired connections more practical and secure. To do this, solder the network cable to the contacts of the plug-in unit, where the battery power supply for the screwdriver was previously located.

- We solder the wires observing the polarity.

- We check the operation of the screwdriver in real conditions.

A video is attached below, on the basis of which the instruction was created.

Additional Information

The above-described principle of powering a screwdriver with a dead battery is far from the only one. The instructions show the simplest method. As you can see, the presence of a large external transformer spoils the whole aesthetics and practicality of the instrument, which, according to the initial idea, should be mobile and lightweight.

A special board based on the IR2157 microcircuit will help to make the power supply scheme more professional. The master will only need to apply a transformer winding, a capacitor and a diode bridge in the board, corresponding to the parameters of a particular screwdriver.

Thanks to the board’s compact dimensions, it can be neatly placed in the battery pack housing. Below is attached an auxiliary video, the author of which assembles a board on an IR2157 microcircuit with his own hands, and also powers a cordless screwdriver with it.

If you cannot assemble this board with your own hands, then it does not matter. The IR2157 can be purchased from any radio market. It remains only to modify the transformer and the diode bridge with a capacitor.

Transformer

common power supplies that have proven to be reliable and efficient in many areas. The device consists of a step-down transformer and a rectifier through which the undervoltage passes. Rectifiers vary depending on the number of diodes used.

Such elements are easy to manufacture, cheap and reliable. Therefore, they are often preferred. They provide stable voltage without interference with high maximum power. But there are also a few downsides. The main disadvantage is bulkiness, with a much lower efficiency than that of pulsed sources. This fact requires the selection of a power supply for the screwdriver with a power greater than the tool needs. Since part of the capacity will go to side processes.

Pulse

The principle of operation of pulse systems is that the voltage is first rectified and then converted into a special pulse signal. In this case, it is important to achieve a stable voltage. This can be helped by a transformer winding or resistors.

Switching power supplies are quite effective and can be used in different conditions. At the same time, they have a high level of protection against short circuits and similar effects. However, in terms of power, impulse systems are clearly inferior to transformer ones. In addition, such units are very capricious to the input voltage. If it is lower than the set, then the element may simply not work.

We use laptop charging

An excellent option is to use laptop charging. Such devices usually operate with a voltage of 12 to 19 V. This is quite enough to ensure high-quality operation of the screwdriver. But do not neglect the output current indicators. The closer it is to the required, the better.

ПОДКЛЮЧИТЬ IP КАМЕРЫ БЕЗ POE И БЕЗ КАБЕЛЬЯ ПИТАНИЯ / INSTALL IP CAMERA WITHOUT POE OR POWER CABLE

In this case, reworking a screwdriver for mains power is reduced to an elementary soldering of wires from the charger to the board in the tool. It is advisable to isolate everything with electrical tape or other similar materials. After that, the wire is brought out and the tool can be used.

Converting a screwdriver to mains power: 5 ways

The value of a screwdriver as a home or construction tool, most often, lies in its portability. However, due to certain circumstances, portability sometimes has to be abandoned in favor of functionality. It is about converting a cordless screwdriver into a mains-powered tool. This process has a number of subtleties that it is advisable to observe.

Alteration of purchased blocks

It can also be powered from any other commercial power supplies. The alteration process in this case will be almost the same, however, in addition to the resistor, you may need to solder additional diodes. The most important thing is to achieve the required output parameters. And this can be easily done using a combination of components.

Alteration of the power supply unit made in China

Perfect for creating a power supply for a 12 volt screwdriver with your own hands, ordinary Chinese power supplies with an output voltage of 24 V and a current of 9 A. But since the tools use less voltage, you need to lower it first.

To achieve the goal, you need to replace the original resistor R10 with an adjustable resistor, with which you can achieve the desired voltage. This is done in several stages:

- a constant resistor is removed;

- in its place, a previously prepared adjustable resistor is inserted, on which a resistance of 2300 ohms will be set;

- so far, the voltage is still 24 V;

- using the resistor settings, you need to achieve the required voltage on the contacts.

After all the manipulations, you need to check that the output voltage is the required value (12 V, 14 V, etc.), and also that the current exceeds 9 A.

Power supply options

Any screwdriver requires much less voltage than a regular socket gives out. Therefore, for recharge, you will definitely need a special converter, at the output of which the required voltage will be obtained. All power supplies are divided into two large groups: pulse and transformer. Let’s consider each of them separately.