How to properly adjust the carburetor on a trimmer

The structure of the carburetor of a gasoline grass trimmer

Adjusting the carburetor of a brushcutter is a process that must be mastered for the full operation of the grass trimmer. Grass trimmer is a completely uncomplicated device, which can break only in a few places and require mechanical repair or replacement of a part. Adjusting the float-type carburetor device of a brushcutter may require knowledge of certain subtleties. Nuances, due to the model and the specifics of its functioning, will provide a clear mode of mixing and supply of fuel mixture.

Champion lawnmower carburetor, how to adjust? This is just the float-type grass trimmer, a common option designed to mix in the prescribed proportions of air and fuel. The main problems that arise during the operation of the motor are roughly similar to the malfunctions that overtake the carburetor in the car:

- The engine may shut down as soon as it is started. The reason is that not enough gasoline is being fed. This is called “poor” fuel;

- Excessive supply of gasoline leads to incomplete combustion, excessive mixture density and uneconomical consumption.

Repair of the carburetor

Important! Adjust the carburetor has to be under different circumstances: a change of temperature mode, the octane number of fuel or type of oil, after winter or the end of the running-in period, the load or spontaneous turning of the screws from strong vibration of the housing. Some owners prefer to tune the module before each use to make sure it works correctly.

Main malfunctions

Faults in the carburetor of brushcutter or grass trimmer, despite the relative ease of fixing them, sometimes require a long search by the method of elimination. The main causes are as follows:

The most recurring failure is deterioration, diaphragm rupture. As a consequence, its loose fit. The fuel passages are not sealed at certain stages of the engine cycle. The reasons here are as follows:

- you run the brushcutter or trimmer for too long without a break;

- Poor-quality fuel is in the tank;

- Exhaust gases enter the impulse line.

A deformed diaphragm has several bad consequences:

- Not enough gasoline or oxygen in the combustible mixture created;

- Starting the motor occurs after 10 or more unsuccessful attempts;

- the engine knocks, clangs when operating, etc. д.;

- The working piston becomes deformed.

Read How much citric acid per liter jar of cucumbers

Causes of clogged strainer. poor quality fuel cleaning, damage to the hose and/or discharge head.

Wear of the lever’s contact surface. the inclusion of particles of sand, clay, metal or other inclusions insoluble in liquid hydrocarbons into the fuel, which is not completely purified. Injection problems appear, and the engine does not run smoothly at no load.

Inlet needle breaks because of metal and stone particles in the gasoline. As a result, inlet needle seat is loose, fuel mixture leaks. There is too much air in the combustible mixture created by the carburetor, which can cause the engine to “sneeze” during operation. Finally, the needle can stall because of poor-quality gasoline, or the unit has been idle for a long time.

The power steering linkage is designed to work in accordance with the pulling system of the machine. The needle does not close the hole completely and a lot of gasoline enters the fuel chamber, the engine overflows it and perhaps floods the spark plugs. It will cause the gasoline-air mixture to contain an increased amount of gasoline vapor. The efficiency is noticeably reduced.

The membrane often becomes deformed (and sometimes tears) if you run your brushcutter or weed trimmer continuously for several hours. If you misuse the “shock” mode of operation, damage to the diaphragm is more frequent. New failures will come out of the horn of plenty:

- the piston will break;

- The number of unsuccessful starting attempts will drop dramatically;

- the fuel-air mixture will contain too little petrol;

- the power output will drop drastically.

Adjustment lever jams as a result of improperly installed or accidentally bent lever. The contacting edge becomes misaligned. This will disrupt the additional gasoline injection.

The choke shutter is worn out

Throttle and choke shutters become unusable because of dust, metal chips, etc. in the air stream. д. Damaged flaps look like parts that have been blasted with sand. Worn throttle valves reduce engine efficiency and cause malfunctions. The piston and cylinder wear out.

In some cases, this filter is simply not suitable for your brushcutter or grass trimmer model. The engine shaft will eventually be damaged. pieces of it will get into the engine channels and the piston will be broken.

If the adjustment is too rough (no precise setting), the springs on the adjusting screws are to blame. That the trimmer or brushcutter manufacturer may have made the springs too thick and too hard. Find others, you can either in shops where such equipment is repaired, or purchase from any dealer or an official representative of the company that released the motor for your trimmer for grass or a mechanical grass scythe.

The primer broke

Primer is a manual mini pump for forcing fuel into the carburetor. You may need to pump 20 ml of gasoline manually to get the motor to start successfully.

Spring might get in the way

My first attempt to adjust the lawnmower carburetor failed because the fuel mixture adjustment screw spring interfered. The factory spring was too thick in the compressed state and did not allow me to reduce the fuel supply to the necessary level. Had to pick up another spring and continue adjusting after replacing it.

Fuel mixture adjusting screw with spring

In the photo above is the factory spring, below is the adjusting screw with a matching spring. I am writing about it as I am not sure if it is the only case and there is someone else who might face the same situation.

From personal experience

Lawnmower or weed trimmer

grass trimmer is a broader concept than a lawnmower (lawnmower), as it can also be electric. Gasoline grass trimmer and lawn mower are the same thing.

Some authors assure that the grass trimmer is a weaker tool, unlike the more powerful lawnmower, which can be used to mow shrubs. Personally, I have a tool with a maximum power of 1.7 kW, which, as stated in the manual, is capable of mowing small shrubs up to 10 mm thick. The user’s manual is called “Gasoline grass trimmer”. “.

Proportion of fuel mixture

I read somewhere that if the lawnmower manual and the oil can indicate different proportions of the fuel mixture, you should use the proportion indicated in the manual.

For a long time, and did so. from the engine to the gas tank dripped with excess oil and the spark plug is constantly formed on the soot, because the manual was specified proportion for the running-in engine 1:25, and on the canister. 1:50. After switching to a 1:50 ratio, oil dripping stopped. The spark plug continued to burn, but with less intensity (the carburetor was still out of adjustment).

up to now some users of gasoline tools determine the proportion of the fuel mixture “by eye. If during the mixing the amount of oil will be underestimated, after a while you may hear some unusual noise immediately after starting the engine, but it will disappear gradually during the warm-up, and the engine will stop with a sudden jerk. Continued operation of the grass trimmer in this mode would result in its failure.

Cleaning the spark plug

In the worst times of trimmer operation with an unadjusted carburetor, the engine would stop starting after using each tank of fuel. And only after the spark plug was cleaned from soot could we continue working.

Fine sandpaper was used to clean the electrodes, and a thin paper clip with a bent end was used to clean the space between the insulator and the body. First, the electrodes were wiped from a lot of dirt with a rag, then cleaned with sandpaper. After that the plug was immersed in diesel fuel and the soaked sludge was scraped off with a paper clip from the insulator surfaces, the body interior and between them. Then the spark plug was immersed several times in diesel fuel, which was then shaken off together with the dirt. Sometimes the paperclip cleaning and flushing procedure was repeated. After that the plug was wiped dry and was ready for further use.

Unbelievable, but one tank of fuel mixture with unregulated carburetor can be used up in less than 10 minutes. tested in practice, when the grass trimmer was started and operated at high revs with maximum fuel supply (the adjustment screw was unscrewed much more than the norm).

About adjusting the carburetor of a brushcutter: how to tune and adjust with your own hands

Adjusting the carburetor of a brushcutter. a process that must be mastered for the full work of the trimmer for grass.

Grass trimmer is a completely uncomplicated device, which can break only in a few places and require mechanical repair or replacement of parts.

Adjustment of the float-type brushcutter carburetor device may require knowledge of certain subtleties. Nuances due to the model and the specifics of its functioning, will ensure a clear mode of mixing and feeding the fuel mixture.

What is the problem of malfunction of the grass trimmer

Champion lawnmower carburetor, how to adjust? It is just the float-type grass trimmer. a common option, designed to mix in the prescribed proportions of air and fuel. The main problems that arise during the operation of the motor, are roughly similar to the malfunctions that overtake the carburetor in the car:

- the motor may stall immediately after you manage to start it. The reason is that the gasoline is not supplied in sufficient quantity. This is called “poor” fuel;

- If the brake pedal is depressed, the brake pedal will return to idle mode and the brake pedal will stop revving.

Important! You have to regulate the carburetor under different circumstances: after the winter or the end of the running-in period, load or spontaneous turning of the screws due to strong vibrations of the body. Some owners prefer to tune the module before each use to make sure it is working correctly.

Grass trimmer device

The float carburetor consists of an aluminum body with a hole (diffuser). The air is injected through its air port, and gasoline is drawn through the fuel ducts along with the air flow. That is the basis of the device. the fuel chamber. Installed from the top jets, pump and mixture adjustment system provides not only its saturation, but also an even flow.

Note! The float carburetor has been used for decades, and the main problems with all types are similar. The principle of operation of the device depends on the quality of the mixture, and the adjustment is aimed at providing it.

How to adjust the grass trimmer on a brushcutter

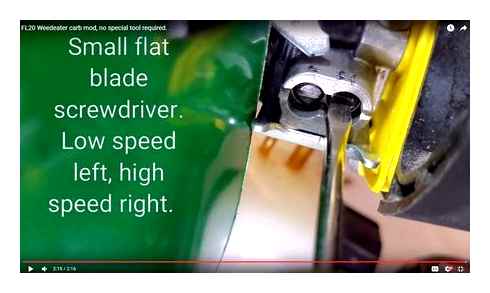

Most modules have adjustment screws, and to understand their functionality is usually helped by a diagram:

- L. for fuel supply of low-speed mode;

- H. fuel supply at high revolutions and its consumption;

- T. idle speed adjustment.

Adjustment brushcutter, production of which is Chinese, can cause difficulties due to the presence of only one screw, which is responsible for idle speed.

Important! The answer to the question of how to adjust the carburetor of lawn mower Champion, it is better to look at the video, where it does a professional.

Adjusting the carburetor on the Patriot lawnmower trimmer

Adjustment of the Patriot grass trimmer carburetor is carried out with screws by ear. No verbal explanation will give a complete picture of how this is done, so it is better to see a video instruction.

After proper adjustment, the engine should increase the speed, and when working at idle, the cutting tool will not rotate. Everything is simple and easy!

Adjusting the grass trimmer carburetor for grass trimmers with their own hands

Lawn mowers, like all power tools for mowing grass, are not considered complicated to operate. They can and should be adjusted, repaired with their own hands. For example, you can adjust the grass trimmer carburetor in five minutes of your spare time.

Often to adjust the engine you need to adjust the gasoline supply, and this is done exactly by the carburetor of the gasoline mower. Such a device requires special attention. If used improperly, it can refuse to work or it will perform inaccurately and with high power consumption.

Today we will discuss the main causes of failure and the step-by-step adjustment of the part with their own hands.

How the carburetor of a gasoline mower is designed?

What is a carburetor?? It is a very complex part of the mechanical device’s working system. In any model, air is mixed with gasoline for future delivery to the functioning cylinders.

Important! The most high-quality and recommended benzokosami can safely call the devices of such brands: Husqvarna, Hyundai, STIHL, Zama, Walbro.

At the base of the lawnmower engine is an aluminum base, which has a diffuser (notch with internal restrictions). It is through this notch that the air flow is heated. On the passage of the diffuser depends directly on the speed of oxygen.

The fuel lines are adjacent to the diffuser. Through them the gasoline is drawn in by the air flow. And on the outside of the engine, such parts are installed:

Important! The density of the air in the carburetor depends on the volume of the open to access flap. The more open the choke system, the more the unit consumes gasoline and the higher its power. That is, the adjustment of the carburetor on the trimmer is to create an optimal flow of fuel through the correct air supply.

When to adjust the carburetor in a trimmer?

You need to adjust the device in such cases:

- A new engine has used 5 liters of fuel in one go.

- The weather has changed (sudden change in atmospheric pressure).

- You bought a different brand of oil or gasoline.

- During long storage period.

- After vibration, the screws unscrewed on their own.

- Consumption of gasoline increased, the carburetor began to overflow.

- There is soot on the electrodes of the internal spark plug.

- No more gasoline enters the cylinders.

- The engine frequently stalls or does not gain enough speed.

What are the breakdowns and how to recognize them?

One of the problems of failure of the grass trimmer engine can be a mesh filter. Only two breakdowns can be attributed to this element:

To determine the exact cause, you need to do a number of the following steps:

- Unscrew the fuel air lock cover to remove the strainer. If you notice any dirt on the part you should wash it with fuel or blow it thoroughly. If you see severe damage to the strainer body, do not hesitate to install a new one.

- If the fuel pipe of the compressor is broken, check this part. It most often requires periodic replacement due to its low durability.

- To clean the starting part of the carburetor from clogs use acetone or gasoline. You can also blow components of the device with compressed air. this is the easiest and most convenient way of repair.

Important! The base of the throttle, inlet and outlet valves, the connection points of all parts of the carburetor can be checked with a simple action. to lubricate the problem area with soap foam.

Adjusting the carburetor on a trimmer by yourself

Before adjusting the gasoline mower device, we recommend the following steps:

- Clean and flush the engine.

- Check the spark plugs for suitability.

- Remove dust and dirt from the air filter or change to a new one.

- Install a cord with a suitable diameter in the trimmer’s roller or install well-sharpened blades.

After installing cutting parts and starting the fuel engine, the carburetor needs to warm up for 10 minutes. In case the cutting tool rotates when the motor is idling, reduce the engine speed.

Adjusting the carburetor on a trimmer is not a simple and time-consuming job. To set it up properly, all you need is the information in our informative article. And to accurately do everything qualitatively, use the video, which clearly shows the whole process.

Reference. Read it so you know what you’re doing!

The desired composition (quality) of the fuel-air mixture is adjusted (changed) by turning the fuel adjustment screws in the intake air flow (right and left). The amount of mixture going into the cylinder is dosed by the throttle. If they are turned clockwise, then the mixture sucked into the cylinder is impoverished (less fuel in the air/fuel ratio) and the engine speed increases, while the Husqvarna engine runs softer (picks up little) and power decreases significantly. In addition, having an increased speed, the cylinder on the lean mixture receives less oil with gasoline (worse lubrication) and so you can screw up the engine. Well, the grass trimmer will not start well. If the screws are turned counterclockwise, the mixture sucked into the cylinder is enriched (more fuel in the air/fuel ratio) and the engine speed decreases, while at lower rpm more gasoline and oil enter the cylinder (better traction, better lubrication), but the Husqvarna engine “untwists” badly (does not gain speed) and more soot is formed in the cylinder!

This is interesting: Carburetor cleaner

Operating principle

The carburetor is a power source in which liquid fuel and air are mixed before being fed into the engine cylinders. Depending on the tool and its operating mode, mixing and feeding is adjusted accordingly.

The structure of the carburetor is the same for almost all cases. Categorised as a floating device. The latter ensure stable parameters of the finished mixtures.

The principle of the module is as follows.

- Air enters the body of the tube with an air damper. The latter increases or decreases the air flow depending on its position.

- In the area where the gasoline orifice is formed, the tube has a constriction. diffuser. Here the flow speed increases.

- Fuel from the float chamber flows into the tube through a nozzle. The level of the float determines how much fuel is delivered. Because the pressure in the chamber is normal and low in the tube due to greater air rarefaction, gasoline is sucked in through the nozzle.

- Accelerated airflow collects fuel and atomizes it, forming a fuel-air mixture of the desired density.

- Mixture is drawn into the cylinder through a tube.

The more open the air valves in the pipe, the higher the airflow density, which means more fuel goes into the cylinder. Setting the brush carburetor comes down to establishing such a ratio of dampers, at which the density of the fuel mixture becomes optimal.

Adjusting the carburetor of a Chinese lawnmower. Practice.

The correctness of the carburetor option is determined by engine operation and the color of the spark plug. Adjusted

- Air supply tube with air baffle (damper). The baffle plate controls the intensity of the airflow.

- The fuel system is necessarily narrowed by a mixer to speed up the flow.

- Gasoline through the float chamber and restrictor tube. The chamber with a float regulates the temporary volume of gasoline. In the float chamber, the pressure level is neutral, but in the tube with a constriction, the pressure level is already low. Because of the pressure drop, the fuel flows through the nozzle.

- The acceleration of the air flow promotes the fuel (petrol) transfer and atomisation. The end result is an air-fuel mixture of the right proportion or density.

- The air-fuel mixture seeps into the engine cylinder through a fuel pipe.

A carburetor is a power system module that mixes liquid fuel and air before it enters the engine cylinders. Depending on the tool and its mode of operation, mixing and feeding are adjusted accordingly.

The design of the lawnmower carburetor is the same in almost all cases. It belongs to the category of float-type devices. The latter ensure stable parameters of the mixture.

- The air enters the tube body with an air damper. The button increases or decreases airflow depending on its position.

- In the area where the hole for gasoline supply is formed, the tube has a narrowing. a diffuser. Here flow velocity increases.

- Fuel flows from the float chamber through the nozzle into the carburettor tube. The level of the float determines the volume of fuel. Since the pressure in the chamber is normal, and in the tube is low because of the greater rarefaction of air, the gasoline is sucked through the nozzle.

- Accelerated airflow picks up the fuel and atomizes it, creating an air-fuel mixture of the right density.

- The mixture is drawn into the cylinder through the piping.

The more the air flap is open in the tube, the higher the density of the air stream and thus more fuel goes into the cylinder. Adjusting the lawnmower carburetor comes down to setting the ratios of the flaps at which the density of the fuel mixture becomes optimal.

The flow of air entering the throttle tube increases or decreases depending on its position. The gasoline from the fuel cell goes to a special tube through a nozzle. Float. a device that regulates the flow of fuel, its level determines the volume. The difference in pressure causes the gasoline in the nozzle to mix with the air. This is how the air-fuel mixture is created to run the engine.

Pay attention! Incorrect fuel composition can be due to a lack of gasoline or air. This means that the throttle or float position must be adjusted. The engine can also stall because of the nipple, but it is already a more serious failure.

Lawn mower carburetor adjustment

Starter and gearbox failures

Gear transmits torque from the motor shaft to the cutting tool, its gears in operation should be absolutely clean and must be lubricated with special grease.

Drovokolok their own hands. drawings, diagrams, dimensions. 120 photos of homemade firewood cutters

Septic tank Topaz. a detailed review and description of technical characteristics

In-house inspection once a season will eliminate the need for gearbox repair or replacement and the purchase of an expensive new assembly.

The starter is necessary to bring the grass trimmer into working condition, its diagnosis is to check the tension of the cord meshed with the teeth of the starter coil, which are often destroyed by a sharp start. A non-functional starter motor in a gasoline mower cannot be repaired and must be replaced with a working unit as part of a compulsory inspection or repair package. Separate attention and care require cutting elements, which should always be cleaned of dirt and grass clippings after operation. Regular inspection and thorough preparation of the device for work will help to avoid expensive and time-consuming repair and to be always sure in the lawnmower serviceability.

When you need to adjust the carburetor?

The operator needs to adjust the work of the working unit in certain cases:

- The new engine is run-in, using 4-5 liters of fuel;

- Changed fuel composition. the brand of engine oil and gasoline;

- Weather conditions have changed (winter, summer time);

- The level of air rarefaction has changed;

- The load on the propulsion system has increased;

- After prolonged storage of the unit;

- Persistent soot formation on the spark plug;

- The engine immediately stops after starting or does not develop the necessary revolutions;

- The tuning screws have loosened during vibration;

- The amount of fuel consumed has increased;

- No gasoline is pumped into the cylinder;

- Many exhaust fumes are coming out.

How to perform adjustment of the brushcutter carburetor with his hands?

Before adjusting the carburetor unit, a certain algorithm of actions is performed:

- The motor is washed;

- The spark plug is replaced or cleaned;

- The air filter is replaced or cleaned. It can be dipped in warm soapy water, after the filter is completely dry;

- A cord or knives are installed in the trimmer’s spool to increase the load on the power unit during adjustment. The gasoline engine should idle for at least ten minutes.

If the cutting attachment continues to rotate when idling, it is worth reducing the number of revolutions of the power unit. Adjustment is adjusted with the T screw, on some models it is labeled LA. The idle speed regulator is unscrewed counterclockwise until the cutting element stops moving.

Grass trimmer carburetor adjustment depends on three screws:

- L is responsible for the level of fuel mixture boost at lower rpm. It should be set first. You need to achieve maximum rpm by unscrewing the screw to the desired point. After that the regulator is turned a quarter turn to the left;

- T (LA). adjusts idle speed. When you twist the screw to the left, the engine speed decreases, to the right. increases;

- H enables fuel enrichment at maximum rpm. Adjusts high RPM, fuel economy and power level of the propulsion system.

Do not let the engine run at full speed for more than 10 seconds, because it can break.

Proper tuning prevents engine damage:

- With the engine running, you need to give full throttle;

- The H screw is unscrewed clockwise until the machine begins to reduce the revolutions;

- The H control is cranked to the left until the engine is stable.

If you follow all the instructions, the carburetor for the lawnmower is considered tuned: the motor works at the required speeds, slightly even at higher revolutions, the cutting elements do not rotate without load.

Lawnmower carburetor adjustment with your own hands

Regardless of the model of the garden tool, the adjustment of the grass trimmer carburetor requires careful preliminary preparation. The owner of the brushcutter will need to check the spark plug, air filter and the carburetor itself. All elements must be cleaned or replaced if dirty.

The grass trimmer comes standard with 3 adjustment screws. The first of them. marked with the letter L, and serves to adjust the engine when it works at low revolutions. The second bolt is marked with the letter H, and is necessary for adjusting the engine when it works at maximum speed. The third bolt can be marked with the letters T or LA. with its help the operator can adjust the engine operation at idle speed.

The process of adjusting the brushcutter carburetor is as follows:

- First you need to perform a series of actions with the adjusting bolt L. To do this, turn it clockwise until it stops. After that, the bolt L will need to turn half a turn in the opposite direction. This will allow you to adjust the optimal enrichment of the fuel mixture with oxygen when the motor works at low revolutions;

- Then it is necessary to adjust the work of the engine in idle mode. To do this, turn the T bolt alternately in different directions until the mowing head or blade stops turning;

- At the end you need to adjust the level of oxygen enrichment of the fuel when the motor works at maximum speed. To do this, the bolt H should be turned clockwise until it stops and then return it 1/2 turn in the opposite direction.

At the end the operator must turn off the grass trimmer engine and start it up again. If the knot has been adjusted correctly, the brushcutter engine will steadily gain speed by pulling the trigger, and quickly lose it when you release the trigger.

Signs of Imbalance

Adjustment of the carburetor is obligatory when making the machine. As a rule, the need to adjust the fuel supply with their own hands, the owners learn only after a fairly serious breakdown, in the process of fixing which, the module was removed and, for example, cleaned.

Signs of a malfunction in the settings are the following:

- engine starts but immediately stops. since the engine can run only with a certain amount of gasoline, if the fuel is too “poor”, i.e. the supply line is blocked, the engine will stop;

- the fuel consumption is too high and excessive exhaust fumes are the result of an incomplete combustion. In this case it is too much fuel and the mixture is too thick.

The carburetor lawnmower STIHL, Makita, Husqvarna and others are adjusted with the adjustment screws. Sometimes the cause of the malfunction is a failure of the fixation. due to vibration or damage to the protective cap. Such a failure can be detected simply by trying to turn the screw a little: if the fixation is not rigid, it is worth checking the setting.

Adjusting the lawnmower carburetor with their own hands

Adjusting the module is not a repair and there is no need to change parts. In this case, the lawnmower carburetor repair kit will not be needed.

- L. it is regulated by the first, as it is responsible for the fuel supply at low revolutions;

- H. it is responsible for gasoline supply at high rpm, as well as for fuel consumption and temperature;

- T. with this screw to adjust the idle speed.

There are variants, as a rule, this is the carburetor of a Chinese lawnmower, when only one screw remains on the body for debugging. to adjust the idle speed. This does not mean that the module is adjusted automatically. it means that even this kind of repair, such as debugging, will be difficult. On the photo: adjusting the carburetor of a Chinese lawnmower.

Adjusting the brushcutter carburetor in practice

You can buy carburetors for brushcutters here: http://pila.prom.How to adjust carburettor if it is not adjusted correctly and also depending on load. It’s not about repairing the carburetor, it’s about adjusting it.

How do you do everything in time? Maybe you can tell us about your time management?

I also noticed that it does matter how the cable is fixed to the frame trimmer for grass, after repairs, did not install the clamps, does not start, idle speed, and then noticed that the throttle control behaves differently if the cable is not fixed (may be someone useful).

Werk WB-494 brushcutter. I tightened the blade wrong, not straight. The mower shook at high revs. I fixed it later, of course, and everything was fine. Grass mower is new, mower worked 15 minutes with a screw loose, did I hurt the mechanism or not bad? Thank you.

Oh, my God. Here’s a rough pricing breakdown of your Husqvarna. (According to Shirokorad. (might be helpful to someone) So:.Husqvarna. 50% to the Swedes, you didn’t have to pay. ).25% to the manufacturer.25% to vendors and retailers. earned.Opinion? Bacili groszy sho kupovaly?

Today I mowed about 20 acres, grass on the waist, weeds are different, even small cherry trees and plums, but I got a couple of sections of the stables is so numuchilsya, winds, knife jams. How to mow it correctly?

Leonid, everything is fine, but it would be more understandable if you showed on camera this adjustment when the trimmer is running.

In Russia, as I understand it, such grass mowers are not sold?

Leonid, what can be replaced by or what to make thin washers, which are under the heads of bolts that hold the clutch pads (feet) in Chinese gasoline mowers?Like these http://instrument66.ru/product/item/boltyi-stsepleniya-jt-bc260b what are they made of

I have a STIHL grass trimmer work for 10 hours after another day does not start gasoline is pouring out of the exhaust I think the rings.advise what you think and possible repairs

If the oil is pouring out of the muffler and smoking a little bit. that’s a very rich mixture?

Change the carburetor kit please help tune the whole thing thanks

At your discretion, but I think the idle adjustment has little effect on high RPM performance. The principle of adjustment at idle, is to set the minimum sustained revolutions and all, do not touch again, until something goes wrong. The idle speed, if necessary, is adjusted with the quantity screw.

Oil dripping from the muffler. what to twist ?

Good afternoon, starter is hard to pull what may be the reason, unscrewed the starter itself, it is all right, thank you very much

Please tell me if I adjusted everything runs fine, heats up, shuts down and does not start, I went to the mixer screw only. What can it be?

Thank you for your advices. Didn’t start. Dancing with the carburetor helped. Started. Grass trimmer ELITECH BT33.

Hi Leonid Kovlitsky, the haymaker does not start at all approximately how many turns the screw should be turned to start the engine

You need to look at the color of the soot on the spark plug.It should be brown.If it’s black, it’s too rich.If you see white soot, the mixture is poor, you can kill the piston or weld the pin to the bushing (if it is on the bushing).

Thank you for the required information! Tell me how much compression in a 25 and 50 cubic inch engines?

Thank you, very useful video! Tell me what to do if the air filter is accumulating liquid, almost all wet?

All this is cool BUT! A couple of remarks video quality is terrible, please change the machine you shoot with. Secondly, why do you want to shoot with noise?? If you want to convey your thoughts to the audience, you have to take care that the view was thought, not noise garbage, you have to be a little sensitive to people who may watch the material. Otherwise it turns out like a Soviet-Chinese manual everything is drawn but nothing is visible.

Once again, thank you! It’s all very clear and with examples. I’m gonna have a tough day tomorrow. The field where the grass is sparse and the weeds are higher than 1.7 meters 🙂 Somebody must have started but gave up. It’s probably easier for me to pay 🙂

The fucking kid is fucking with the fucking sound. Bitch!

Please tell me what to do if the gasoline flows from the gas tank breather (live gasoline, not fumes).The filter in the lid is, all intact, not broken.

Would you mind transcribing what you just said??Then you could at least read what was said, instead of guessing from your lips.You posted the video without looking, or just decided to poke fun at the audience?

I started mowing the grass, everything worked and nothing seemed to portend trouble as suddenly the mower began to rattle and 3 seconds later turned off. I’ve tried it again, but it won’t start and when I pull the lever, it rattles

cold starts very badly, what’s the matter.

everything is well explained for those who understand it, but what about people like me ? How do I know which way to turn?? How high rpm they are, how low they are? And the engine is getting hotter. Thanks in advance

Good afternoon, I have a Lynx BTR-43, works fine when cold, and as soon as warmed up at idle, floats, when you add the revs and stops, filters washed, plugs changed, the throttle opens and closes.What is the reason?

It’s pretty confusing and unclear. I don’t think many people will understand what I’m trying to say, alas.Confusion in terms and concepts

If the mixture is not done correctly 20/1 to 1 liter 50gr of oil instead of 50/1 what should I do?? Change the mixture and do something?To flush something?And with a cold braid start first on OFF necessarily on ON for startup and idle?

Merry Christmas and a Happy New Year!

Class. Did you develop this technology to adjust the carburetor or has someone else invented before you? Maybe there is a reference to some kind of technical regulations ? Strongly interested in. I want to apply this method to other equipment. For example a chainsaw (I also have to saw light, thin logs sometimes (there is no need to use traction)?), and sometimes thick heavy (here already hey how it is needed)), and much more. pump, moped. I’m sick of this overconsumption. How do you think you can get up on fuels and lubricants e?

Hi, do you mind if I use your video in my group in classmates.

Leonid, Please tell me what the problem is, the engine does not start on warm! Just bangs either in the muffler or through the carburetor. I have so-called “flares” through the exhaust system even with half a flame. The reason in the ignition? The first tank of gasoline worked. Fill another one. Cranked and cranked, engine started. Perfectly finished the tank (not full of canister 600 g), tried to turn off and start at once. Starts like an old man! While pouring the third dose of gasoline. It took 5-10 hrs. starting. does not start and that’s all! It is still running! It rattles and rattles. no effect.

Adjustment of fuel supply. Low revolutions (L).

First of all, adjusts upper right L screw, that is adjusts amount of fuel at low revs. For STIHL trimmers fs series, screw L is turned fully clockwise, then returned one full turn counterclockwise. In addition, such adjustment, is also relevant for many other trimmers. Moving from the particular to the general, you need to achieve a stable idle rpm when turning the L screw, that is, the lawnmower should run smoothly and without unnecessary vibrations, once you have done this move on to the LA (T) screw. It should also be noted that turning the screw counterclockwise adds fuel to the mixture, turning it clockwise reduces the amount of fuel in the mixture;

The second stage of the adjustment is the adjustment of the idle speed with the LA (T) screw, here the setting is made only by ear. By turning the screw clockwise, you increase revolutions, by turning it counterclockwise, you decrease revolutions. it is important to make sure that the mower head does not spin idly. It should also be noted that the L and LA screws are adjusted in pairs, i.e. changing the setting of one screw may require changing the setting of the other screw. After you have achieved a smooth operation of the engine with a minimum of vibration. proceed to the adjustment H.

Adjustment of fuel supply. High RPM (H).

The third stage, adjusting the fuel rate at high rpm. H. For STIHL trimmers, turn the screw fully anticlockwise and then a quarter turn clockwise. Adjustment of trimmers of other manufacturers in general is almost the same. Turn the screw normally fully anticlockwise, start the lawnmower and throttle up fully. Then turning the screw clockwise (usually 1/4, 2/4 turn) reduces the maximum rpm by about 5-10%. The lawnmower adjustment is thus finished. When adjusting the carburetor with this screw, by turning clockwise you reduce the fuel supply, by turning counterclockwise you increase.

Remember, the correct adjustment of the grass trimmer not only allows a longer life, but also saves fuel. It is important to check that the grass trimmer is working correctly. The mower should run smoothly without any noticeable vibrations and should pick up speed evenly. At the same time the grass trimmer head should not rotate when idling.

Before any adjustment of the trimmer for grass, first check the condition of the fuel and air filters and the spark plug. These may be the problem. The fuel filter must be easy to blow and must not be visibly soiled. The spark plug should be clean, dry and have a light brownish tint. If the spark plug is wet and has a black tint, it means that it is flooded and it is necessary to decrease the fuel supply by adjusting screws. A whitish tint on the spark plug indicates that the mixture is lean, you need to increase the fuel supply.

If all the elements are in order, and the adjustment does not give the desired results, it may be time to clean the carburetor. How to clean the carburetor of a chainsaw, we will tell in one of our next articles.

The device of the carburetor of the grass trimmer gasoline

Adjusting the carburetor of a brushcutter is a process you need to master in order for a grass trimmer to work fully. Grass trimmer. a completely uncomplicated device, which can break only in a few places and require mechanical repair or replacement of the part. Adjusting the float-type brushcutter carburetor device may require knowledge of certain subtleties. The nuances due to the model and the specifics of its operation will ensure a clear mode of mixing and feeding the fuel mixture.

Champion lawnmower carburetor, how to adjust? This is just the grass trimmer of the float type. a common option, designed to mix in the prescribed proportions of air and fuel. The main problems that arise during the operation of the motor are roughly similar to the problems that overtake the carburetor in the car:

- The engine may stall immediately after you managed to start it. The reason is that not enough gasoline is being supplied. This is called “poor” fuel;

- Over-fed petrol leads to incomplete combustion, excessive mixture density and uneconomical consumption.

Carburetor Repair

Important! Adjust the carburetor is necessary under different circumstances: a change in temperature, octane number of fuel or type of oil, after winter or the end of the running-in period, load or spontaneous rotation of the screws from strong vibration of the housing. Some owners prefer to tune the module before each use to make sure it works correctly.

Basic troubleshooting

Faults in the carburetor of brushcutter or grass trimmer, despite the relative ease of fixing them, sometimes require a long search by the method of elimination. The main causes are as follows:

the most recurring failure is diaphragm wear, rupture. The consequence is that it does not stick. Fuel passages don’t seal at certain stages of the engine cycle. The causes are as follows

- You run the brushcutter or trimmer for too long without a break;

- low-quality fuel is filled;

- Exhaust gases enter the impulse line.

A deformed diaphragm has several bad consequences:

- Not enough gasoline or oxygen in the mixture created;

- Engine starts after 10 or more unsuccessful attempts;

- Engine knocks, clangs when running, etc. д.;

- the operating piston becomes deformed.

We suggest reading How much citric acid per liter jar of cucumbers

Causes of clogged strainer. poor quality fuel cleaning, damage to the hose and/or discharge head.

Wear of the lever’s contact surface. the consequence of not completely cleaned fuel in which there are grains of sand, clay or metal particles or other inclusions which are not soluble in liquid hydrocarbons. There is a problem with fuel injection, and the engine functions intermittently without load.

Inlet needle breaks because of metal particles and stone in the gasoline. As a result, the seat of the inlet needle is loose, the fuel mixture leaks. Too much air in the carburetor’s fuel mixture and the engine may “sneeze” as it runs. Finally, the needle may be stuck because of poor-quality gasoline, or the machine has been idle for a long time.

Deposits may collect in the adjusting compartment. The needle does not close the hole completely and a lot of gasoline enters the fuel chamber. the engine overflows it, possibly flooding the spark plugs as well. The gasoline-air mixture contains a large amount of gasoline fumes. The efficiency is noticeably reduced.

Diaphragm is often deformed (and sometimes torn) from operating the brushcutter or weed trimmer continuously for several hours. If you abuse such “shock” mode of operation, the diaphragm damage occurs more often. New failures will come out of the horn of plenty:

- piston will break;

- the number of unsuccessful start attempts will increase dramatically;

- The fuel mixture will contain too little gasoline;

- Effective (thermal) power will drop dramatically.

Adjustment lever jamming. caused by improperly installed, accidental bending. The contacting edge will be in the wrong position. This will disrupt the extra gasoline injection.

Flapper worn out

Throttle and air flap deteriorate because of dust, metal particles, etc. in the air stream. д. Damaged flaps look like parts that have been blasted with sand. Engine efficiency is reduced because of flap wear, breakdowns are detected. Piston and cylinder wear out.

The filter may not be compatible with your brushcutter or trimmer model. The motor shaft will eventually be damaged. pieces of it will get caught in the motor ducts, causing the piston to break.

The springs on the adjusting screws are to blame for too rough an adjustment (no precise setting). The manufacturer of the brushcutter or grass trimmer may have supplied unnecessarily thick and stiff springs. Find others can either be found in shops that repair similar equipment, or purchase from any dealer or an official representative of the company that produced the motor for your trimmer for grass or a mechanical grass trimmer mower.

The primer broke

Primer is a hand-operated mini-pump for forcing fuel into the carburetor. You may need to pump 20 ml of gasoline by hand to successfully start the motor.