How To Properly Adjust The Carburetor On The Trimmer

First stage

The adjusting screws for the highest and lowest speed should be moved clockwise until the highest resistance is encountered. When the screws reach the stop, you need to move them in the opposite direction and leave them after 1.5 turns.

Instruction for Chinese

To properly configure the carburetor of a Chinese chainsaw, you must first remember the factory settings of the device, then turn on the engine. Subsequently, you will have to leave it to work for several hours in order to accurately set your own parameters. Sometimes work is performed once after a ten-minute operation of the engine, however, many Chinese-made models require special handling.

Chinese Chainsaw Model

Adjustment procedure:

- Activities start in idle mode. With the help of the adjusting screws, you need to achieve a systematic set of revolutions by the engine, so you should first let it run at low speeds. The deviation from the norm is the movement of the chain along the tire. In this case, you need to adjust the extreme screws to the optimal position so that the chain remains stationary.

- The transition to average speed turns is carried out. Sometimes the engine will smoke. This defect can be eliminated by tightening the screw to supply a leaner fuel mixture.

In this case, the smoke will disappear, but the engine speed will increase. It is necessary to adjust the settings until the level is reached when, when pressing the throttle, the engine smoothly picks up speed, no sudden jerks or interruptions are heard.

Take a look at:

How To Adjust Carburetor On Carver Trimmer

DIY chainsaw carburetor setting

For an independent carburetor option, you must familiarize yourself with its device and understand the order of work that is carried out to adjust the parts responsible for the correct functioning of the component parts of the device and parts close to it.

It is necessary to carefully handle the items for the system option, also to determine whether the set characteristics correspond to very permissible values.

Adjusting the carburetor for lawn mowers

Before proceeding with the adjustment, you need to clean the filters very thoroughly. This work must be carried out in accordance with the instructions from the manufacturer. Further work with the carburetor is done by adjusting the three screws.

- Right screw. air-fuel mixture adjustment. Turning the screw to the right and left is performed at idle speed. It is necessary to determine the maximum speed.

- Left screw. air / fuel mixture adjustment. The work is performed at high speeds. The screw is adjusted last, the engine power and gasoline consumption will depend on its correct setting.

- Bottom screw. adjustment of engine operation. The work is done at idle speed. Clockwise rotation indicates increase, counterclockwise. decrease.

The main stage

The engine starts at medium speed and warms up for about 10 minutes. The screw responsible for adjusting the idle speed must move clockwise. This is how it looks in the diagram: how to adjust the carburetor on a chainsaw. It is released only when the engine comes into stable operation. It is necessary to check that the chain does not move during this process.

The last left screw is adjusted as follows:

- The throttle valve is fully opened and full throttle is squeezed out;

- The screw rotates clockwise until the revolutions decrease (orientated by ear);

- We turn the screw counterclockwise until the engine operation becomes uneven. intermittent;

- We turn the screw to the position in which it ensured stable and smooth engine operation.

Do-it-yourself lawn mowers carburetor adjustment

Lawn mowers, like all gas powered garden tools, are not difficult to maintain. It is possible and necessary to repair, configure yourself. For example, adjusting the carburetor of a lawn mower with your own hands is a matter of five minutes.

A lawn mower carburetor is a unit in the power system. In it, like any carburetors, there is a process of mixing air and fuel (gasoline) for further supply to the engine cylinders.

Lawn mowers carburetor device

The basis of the carburetor for lawn mowers is an aluminum body. It contains a diffuser (hole with internal contours). Air is blown through this hole. The flow rate of oxygen (air) depends on the cross section (orifice) of the diffuser.

The diffuser is equipped with fuel channels. Fuel is drawn in from them using the air flow.

Outside the carburetor is installed:

- Fuel pump;

- Jet system;

- Air-fuel mixture control system;

The main problems and malfunctions of the carburetor.

Mesh filter. There are often only two problems with this element:

- Blockage.

- Breaking.

In order to find out the cause of the breakdown, the fuel filter cap is unscrewed to remove the strainer. If dirt just accumulates on it, then flushing in gasoline or blowing will help.

If there is visible damage to the mesh filter, it is imperative to install a new one. There may also be damage to the fuel supply pipe (during repair, they practice checking this element).

The carburetor starter in most cases does not function due to blockages. Use acetone or the same gasoline for flushing.

Blowing out carburetor parts with compressed air is an acceptable and convenient repair practice.

The principle of operation of the carburetor lawn mowers

The throttle valve determines the amount of air to be supplied, and the engine power directly depends on this.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the union in the carburetor. The fluid then flows through the pump inlet and outlet valves. Filtered by the grid. Moves through the needle valve into the diaphragm chamber.

Phased operation of the device:

- Air supply to a tube with an air baffle (damper). The baffle regulates the air flow rate.

- The fuel supply system is necessarily narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and the nozzle tube with a constriction. A float chamber adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with a constriction it is already low. Due to the differential pressure, the fuel penetrates through the jet.

- The acceleration of the air flow facilitates the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the required proportion or density is formed.

- The air / fuel mixture enters the engine cylinder through the fuel pipe.

How does a lawn mowers carburetor work or how it works

The carburetor adjustment of the Chinese lawn mowers is completely identical to the adjustment of the European, Russian and manufacturer’s lawn mowers. To cope with the task of adjusting the carburetor on lawn mowers and petrol trimmers, it is necessary to understand the principle of their operation. How the carburetor works on a lawn mower is described step by step and accessible below.

- The carburetor of lawn mowers begins with fuel supply through the channel, as shown in the diagram

- The suction of fuel into the carburetor takes place using a pulse channel connected to the crankcase. Due to the rarefaction of air, the flexible membrane moves at number 4 in the diagram above.

- Fuel is supplied through valves 3 and 5. Valve 3 is inlet, due to which fuel is supplied to the under-membrane space, and valve 5 is outlet

- Further, the fuel moves along the channel and, passing through the fine filter, reaches the needle valve 14

- The needle valve is connected via a lever to the control diaphragm 18

- The needle valve is actuated by acting on the diaphragm. When it is necessary to pump fuel to start the engine, it is necessary to act on the soft cover of the hand pump. Upon exposure, the needle opens, and the chamber is filled with a fuel mixture

- When the engine starts (cold), the opening of the needle occurs due to the vacuum with the air damper closed. This vacuum acts through the idle and high speed nozzles on the membrane 18

- The membrane acts through a lever on the needle valve, whereby the chamber is filled

- After starting the engine, the air damper opens, as a result of which the engine runs on a lean mixture, as the fuel mixes with air

- When the chamber is full, the fuel mixture is supplied (sucked in) through the idle and medium speed jets (when the engine is running)

- At the same time, the throttle valve is displaced from the initial position by 10-15 degrees

- When the work is carried out under load, the fuel begins to flow into the chamber through the high speed jet, and at the same time the throttle valve rotates through an angle of up to 90 degrees (depending on the pressure on the gas). In all operating modes, the air damper must be open, through which the fuel is mixed with air, and thus the mixture in the cylinder is ignited

Below is a diagram of how the lawn mower carburetor works. Based on the diagram, you can not only understand the principle of operation, but also identify breakdowns and other malfunctions of the mechanism.

When operating the tool, it is necessary to take into account the presence of another jet. This jet is located between the idle and full power channels. It is necessary in order to exclude a strong depletion of the mixture, which happens when the engine is running at partial load. In such a situation, the occurrence of a badass couple is not excluded. Through an additional channel (jet), fuel is sucked into the chamber, whereby the fuel-air mixture is enriched. The diagram below shows an additional jet, which is indicated by the number 1.

Having an idea of the design of the membrane carburetor for lawn mowers and the principle of operation, it will not be difficult to customize it yourself. The lawn mowers use adjusting screws to adjust the carburetor. The diagram above shows two adjustment screws, however most modern petrol trim models have three screws. The presence of three adjusting screws allows for more accurate adjustment, while achieving a stable and smooth operation of the internal combustion engine.

The design of the gas trimmer carburetor and its purpose

Lawn mowers are equipped with two-stroke internal combustion engines. A carburetor is used to supply the air-fuel mixture to the engine cylinder. In the design of gasoline units, this is a key element, without which the operation of the internal combustion engine is impossible. over, this carburetor differs from a car device not only in size, but also in the principle of operation. In particular, this difference lies in the presence of a membrane that plays the role of a gas pump. It is due to the presence of a membrane that the considered devices in the design of two-stroke internal combustion engines are called membrane.

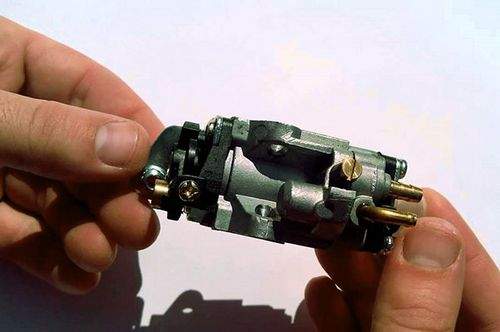

Structurally, the entire mechanism is a small piece with channels, valves and diaphragms inside. The carburetor body is made of aluminum, and the internal structure is shown in the photo below.

Before adjusting the carburetor of the lawn mowers with your own hands, you need to deal with all the constituent elements of the device in question. The lawn mower and trimmer carburetor consists of the following parts:

- Diffuser or Venturi nozzle. through this nozzle air is sucked into the system

- Air damper. opens and closes the filtered air supply

- Fuel channel of maximum speed

- Fuel channels (jets) of idle speed XX and medium speed

- Throttle valve. the amount of opening is adjusted by pressing the gas

- Impulse channel fitting. connects to the internal channel of the engine crankcase

- Fuel inlet (union) (2). provides fuel supply from the gas tank

- Membrane (4). is responsible for sucking fuel from the gas tank

- Fuel suction valve (3)

- The valve for supplying fuel to the carburetor channel (5)

- Filter element (6) or fine fuel filter

- Fuel pipe (10)

- The needle of the needle valve (14). is responsible for supplying fuel to the control diaphragm chamber

- Chamber. the fuel mixture, which is fed through the jets and the throttle valve to the cylinder

- Control diaphragm (18). provides manual fuel suction with primer

- Diaphragm Connected Lever (17)

- Idle speed screw (15)

- The screw for adjusting the amount of fuel supplied to the diffuser (13)

Having an idea of how the carburetor works inside, you have to figure out how it works. A detailed description of how the carburetor works on a two-stroke internal combustion engine using the example of a chainsaw is described in this material.

The device and adjustment of the carburetor on lawn mowers and trimmers

A lawn mower or a trimmer with an internal combustion engine requires not only constant refueling of the fuel mixture of gasoline and oil, but also periodic adjustment of the supply of this fuel. The carburetor is responsible for supplying fuel to the cylinder of the lawn mowers, the efficiency and performance of the tool depend on the correct operation of which. If, during operation, a faulty (abnormal) engine operation is detected, then the first step is to adjust the carburetor of the lawn mowers. Before setting up the carburetor of the gasoline trimmer, let’s first understand its design.

How to know if a lawn mower carburetor needs adjustment

Many lawn mowers use lawn mowers for a long time without thinking about the need to adjust the carburetor of the tool. When is it necessary to adjust the carburetor on a lawn or lawn mower? If you are asking such a question, then for sure there are changes in the operation of the motor not for the better. In order not to guess, and not to miss the moment of the need to adjust the carburetor, you should adhere to the following recommendations about the need for adjustment measures:

- After the engine has run in. Usually, the break-in lasts during the combustion of 4-5 liters of fuel

- When a fuel mixture of a different composition is poured into the tank, that is, the type of oil (even its color) and the brand of gasoline change

- When weather conditions change, however, this is more relevant for chainsaws, gas generators and motor pumps, which are operated not only in summer, but also in winter.

- If the mower has not been used for a long time. The reason for the need for adjustment may be a winter break

- When fuel consumption increases

- If black carbon is found on the spark plug electrodes

- In the absence of gasoline entering the cylinder or poor engine start

- If a large amount of exhaust gas is detected

- Unstable engine operation, as well as its difficult start and "sluggish" set of revolutions

As you can see, lawn mowers have enough reasons to adjust the carburetor. Usually, craftsmen who work with the tool for a long time detect changes in the operation of the motor by ear, which promises the need for an adjustment process. Even if you are not sure of the need for adjustment work, then their extraordinary performance will definitely not be superfluous.

Adjusting the carburetor on lawn and lawn mowers. setup instructions with step-by-step description

The very process of adjusting the carburetor of a lawn mower or trimmer is not difficult, however, its implementation should be carried out step by step in compliance with the recommendations. Before starting work, it is necessary to carry out preparatory actions, namely:

- Flush the engine. desirable but not required

- Check the spark plug, and if necessary clean it, measure the gap and replace it. Do not forget that candles have their own resource and are consumables. Sometimes the unstable operation of the internal combustion engine can be associated precisely with a malfunctioning candle

- Check if the carburetor is properly attached to the cylinder-piston group, since the fastening very often weakens (or the gasket wears out), which leads to air leaks or primer. After tightening and replacing the gasket, the carburetor may not even need to be adjusted

- Check the serviceability of the connecting adapter, which stands between the carburetor and the CPG

- Clean the air filter or replace it. It all depends on the condition of the filter element. If the element is suitable for use, then the filter can be washed in soapy water, and then dried, and continue to operate

- Attach the spool or cutting knives to the tool spindle. Adjustment is carried out under load, even if only slightly

When all the preparation points are completed, we proceed to the direct process of setting up the carburetor. First, you should start the motor and let it run for 5-10 minutes, depending on the ambient temperature. When starting the motor at XX, the spool or knives on the trimmer should not rotate. If they move, then it is necessary to reduce the idle speed. The photo below shows an example of the location of the adjusting screws that perform the adjustment.

Using a slotted or Phillips screwdriver, we proceed to the direct process of adjustment work. To begin with, we identify the number of screws for adjustment, since there can be 2 or 3 of them, depending on the manufacturer of the instrument. Usually Chinese trimmers are equipped with two screws. Below is the process of tuning the carburetor, which has three tuning screws:

- Regulator marked L. you need to start tuning manipulations with it. It is necessary to rotate the screw while the motor is running. This screw is responsible for enriching the mixture at low rpm, so it should be screwed in so as to reach the maximum value. Typically, this bolt rotates until it stops and then looses turn. If dips are found, it is necessary to tighten the bolt again until it stops, and loosen it by 1/8

- Screw marked T or LA. this is used to adjust the idle speed. Turning the bolt to the right (tightening) increases the idle speed, and to the left, decreases it. When the speed of XX is increased, this means that more air is added to the combustible mixture. The mixture becomes leaner and power or thrust is lost. Reduced speed at XX indicates an excess of air in the mixture, so it is necessary to find a middle ground. The setting must be done so that the lawn mower engine runs stably at XX, and the line spool or steel cutting disc does not rotate. The rotation of the cutting elements contributes to the rapid wear of the clutch

- Screw marked H. this screw is responsible for adjusting the fuel mixture at high speeds. It is with this screw that adjustment manipulations end. The maximum speed is indicated in the technical description for the tool. To determine the maximum speed value as accurately as possible, you should use a tachometer. If there is no tachometer, then the tuning is performed by ear. As soon as the maximum number of revolutions is reached by ear, the valve must be returned half a turn back (counterclockwise). Bolt H is responsible for power, temperature and fuel consumption

Often it is with the setting of the maximum speed that difficulties arise. To prevent this from happening, the following actions are performed:

- While pressing the gas, it is necessary to rotate the screw until the speed decreases (clockwise or to the right)

- After reducing the speed, it is required to turn the bolt so (counterclockwise or left) to detect unstable engine operation

- As soon as this unstable operation is detected, turn the screw clockwise until smooth operation of the internal combustion engine occurs.

- This completes the adjustment process.

If the setting work is done correctly, the tool will work stably, the cutting element will not rotate at idle speed, and the fuel consumption will be the same as on the new trimmer. Tuning a carburetor with two screws is much easier, but the tuning accuracy is much lower. Usually 2 screws are equipped with Chinese gasoline-powered tools, as well as household units.

Summing up, it should be noted that you can not understand the principle of operation of the membrane carburetor lawn mowers and trimmers. It is important to have a screwdriver and a tachometer for adjustment. However, in order not only to adjust, but also to understand what you are doing, it is imperative to know the design and principle of operation.