How to properly cut a corner at a 45 degree angle

Cutting pipes at an angle: the advantages and disadvantages of different ways of doing the work

Pipes are a common building material. They are used in the installation of various systems. In the process of installation there are situations when it is necessary to join pipes at an angle. The technology of production of such works is not standard, but you need to know about it.

To create a complex connection configuration, pipe cutting at an angle is required. We will tell you how to perform such operations and what are the methods of cutting.

Cutting techniques for pipes at an angle

Considering the methods of work. cutting straight or at an angle. it is necessary to take into account the different material of products to be processed. Hoses made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes.

Plastic products of small diameters are cut at the desired angle using special scissors. You can control the angle with an ordinary protractor. Plastic pipes can also be cut with an ordinary fine-toothed hacksaw.

It is necessary to cut pipes during work with these mounting elements very often. A popular tool for such cases is the so-called angle grinder. This tool is used to cut straight and at an angle

The most frequent need in the installation becomes the cutting of water, sewer and ventilation pipes at an angle of 45º.

Cutting pipes for the assembly of pipelines is performed, if there is no fitting, which can solve the problem, or just a shaped final cut is needed

The junction is made by cutting the pipe if the angle between the adjacent pipes is less than 45º. For example, if one collector pipe is connected to three

In order to perform the cut with maximum precision make molds. Use them to mark the pipe

CNC machines cut metal pipes at an angle on an industrial scale. Privates cut with an angle grinder, fixing the pipe in a vice, or with an electric saw that fixes the pipe in the jigsaw

An excellent aid in spatial cutting of metal pipe is an electric jigsaw for metal. However, before the work it is desirable to “drum up” a hand with scraps of waste material

It is easier and simpler to cut profile pipe with an angle grinder. The profile can be clamped both in a vise and in a jigsaw

If it is planned to make one or two angled cuts in the pipeline assembly, it is enough to use an electric saw with a metal blade

Polymer pipe at an angle can be cut with an ordinary hand saw, but it is very important to fix it in a jig not to spoil the material

Let’s find out what fixtures can be used to cut at different angles.

A paper template for a pipe

To make a relatively precise cut, you can use a simple technique where an ordinary sheet of paper acts as a kind of template. For example, printer’s paper of A4 format is suitable for creating a mold.

The sheet is preliminarily marked as a square using a ruler. The size of the diagonal of the square must be equal to the length of the circumference of the pipe to be cut. Excess parts of the sheet are cut off.

The easiest way to get a line of sight on the pipe to make a 45 degree angle cut. A usual sheet of paper is used, which is put on the pipe body in the cut area

- Bend the sheet diagonally, aligning the opposite corners.

- Turn the resulting triangle so that the line for the hypotenuse trimmer was perpendicular to the axis of the pipe.

- In this position, wrap the paper around the tube surface, aligning the hypotenuse extreme points together.

- Mark the cut line of any of the triangle’s cathetuses with a marker.

- Cut the pipe along the marked line.

It is very convenient to use this method to mark and cut pipes at a 45º angle in the diameter range from 32 to 63 mm. It is recommended to use thick, but soft paper to make the marking more convenient. You can also use paronite and similar materials.

How to choose the right pipe cutter for plastic pipes and how to use it in practice is described in detail in our proposed article.

Competently made templates for shaped cutting of the pipe allow to make cuts with very high precision. In this case, a gap between the prepared blanks is not excluded. When joining metal pipes it is “closed” by a weld seam, when joining plastic parts a specialized cord for soldering is used.

The parts cut at an angle from the pipe should be aligned with a minimum gap. So that after welding it can completely fill the seam

If the templates for cutting have been made inaccurately it is easier to cut new elements than to make them fit with a file

Before welding shaped pieces together it is a good idea to “try it on” to see where the gaps require reinforcement

We recommend that you try the templates for cutting pipe at an angle on off-cuts of plastic pipe of the appropriate diameter first. Once they are precisely aligned, they can be transferred to metal workpieces

Programs for calculating cutting angles

The pattern-cutting technology allows for different cut angles. But in order to form a template for angles other than 45º you will need to do the math and cut out a template from paper or similar materials according to the calculated data.

It is true that there are computer programs designed to save the master from making calculations. Such programs print out templates for cutting pipes.

This is what the window of the computer program looks like for calculating the cutting angle for a pipe with a circular cross-section. The results are used to create a mold, which is then printed out by the printer. The template is used in the manufacture of templates

Easy calculation program, based on MS Excel application, allows you to calculate and create a template for almost any value of pipe diameter and required angles of cut.

All the user has to do is enter the appropriate values into the “Outer diameter” and “Angle of cut” boxes. According to these parameters a template will be formed, which can be sent for printing.

An example of a template obtained by calculations in a popular Excel program. Calculation of the points of curve passing is based on only two parameters given. the pipe diameter and the required cutting angleDisadvantage of the program. it does not take into account the thickness of the template sheet, which leads to minor inaccuracies.

The way to connect platbands without trimming

Roof moldings today are often not trimmed at an angle to be joined together, but the joints are made at right angles. This method of connecting trims does not require any special trimming, which is very convenient. In addition, this method looks more modern and attractive.

Trimming at an angle with a power chisel

If it is still necessary to angle-cut one or another part, then it is worth stocking up on the plier. the simplest device, which looks like a small box. The chisel has slots for a saw or long, sharp knife. Of course, these slots are made so that they form an even and accurate angle of 45 degrees.

However, a plier can have many cuts at once, at different angles. It’s convenient, because with one device, you can trim any parts at different angles.

Chisels are also available which are adjustable. Slots in such a chair can be adjusted, allowing the master to set the exact angle required at any given time. In particular, it is quite easy to move the slots of such a jig to the 45-degree position.

Now you can trim the workpiece elementary. Put a molding, a platband, or a baseboard in the jig, and then insert the saw into the slots, and cut off the excess material with a simple procedure. The angle is perfect, exactly 45 degrees.

What to do if you don’t have a jointer? Very simple. It is necessary to make a template by which it will not be difficult to transfer the necessary markings on the workpieces. As a template, you can choose thick cardboard or anything else that will be appropriate in this case.

Trimming the parts at an angle with the protractor

Angle trimming is done by using a protractor. It is a measuring tool that is easy to use and is designed precisely to measure angles or to make the necessary markings on certain parts. The protractor is placed on the part, the angle is marked, and the angle is marked with a pencil. It is easy to cut off the workpiece at the desired angle using these marks.

Using templates

If you do not have a protractor, a plane or ready-made angles, you will have to look for a suitable template. Of course the template must have the necessary angle. It is attached to the workpiece and mark out the workpiece with a pencil. This is one of the easiest ways to achieve the desired result.

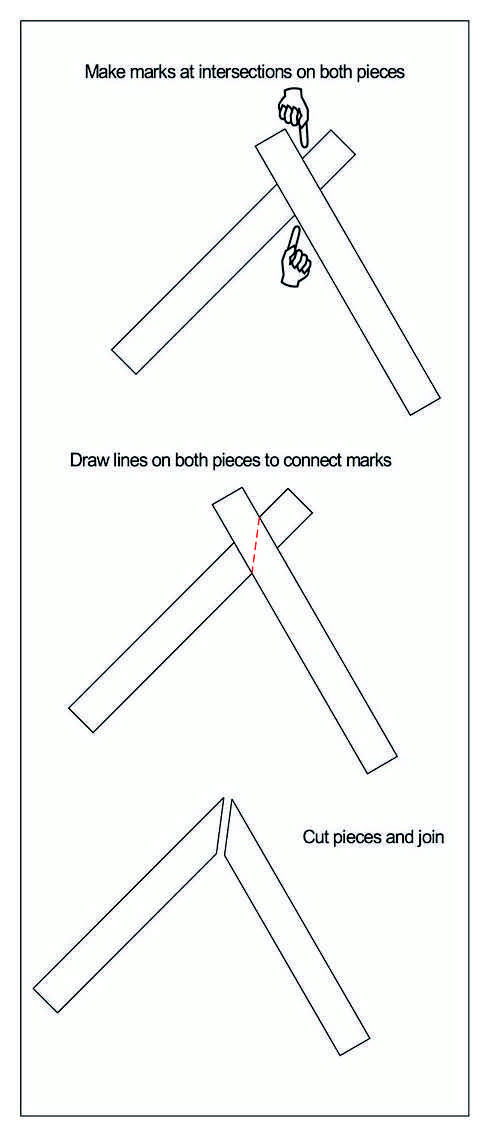

Trimming “on the spot”

The walls, floor and ceiling will not always be perfectly flat in practice. Most often they have irregularities. For this reason there is no need to trim blanks at precise and accurate angles, because they will not fit perfectly anyway.

Instead, it is sometimes convenient to trim the same ceiling plinth on the spot. That is, first glue one slat of the skirting board, trim it in the corner, and under it trim the second slat.

Of course, you can’t cut the piece off perfectly. However, if there is a small gap in the corner, it can always be covered with putty or gypsum plaster. No big deal.

How to cut the corner of a baseboard or baguette without a jigsaw

When installing baseboards, it is important to arrange the corners correctly. They often spoil the overall picture. How to make an angle on the baseboard. external and internal, how and with what to cut. All this we will discuss further.

Trimming details at an angle using a protractor

To trim a part at an angle, you can use a protractor. It is a measuring tool that is easy to use and is designed precisely to measure angles or to make necessary marks on certain parts. A protractor is placed on a part, the angle is marked, and a pencil is used to mark it out. It is very easy to cut a piece at an angle using this marking.

Using templates

If you do not have a protractor, a plane or ready-made corner elements, you will have to look for a suitable template. Of course the template must have the right angle. It is attached to the workpiece and a pencil to mark the workpiece. This is one of the easiest ways to achieve the desired result.

Trimming “on the spot”

The walls, floor and ceiling don’t always have to be perfectly straight in practice. Most often they have irregularities. For this reason there is no need to trim blanks at precise angles, because they will not fit perfectly anyway.

Instead, it is sometimes convenient to trim the same ceiling plinth on the spot. That is, first glue one baseboard plank, trim it in a corner, and under it trim the second plank.

Of course, you can hardly cut the workpiece perfectly. However, if there is a small gap in the corner, it can always be filled with putty or gypsum plaster. No big deal.

How to cut a corner of a skirting board or baguette without a chisel

When installing baseboards, it is important to properly design the corners. These are often the ones that spoil the overall picture. How to make a corner on the baseboard. external and internal, how and with what to cut. Let’s discuss all of this further.

Types of corners in the rooms

When installing the skirting boards must somehow design the corners. By their appearance, corners come in external (which protrude forward) and internal (such as corners in the room). In rooms with normal geometry, corners are right, t.е. 90°. When joining two pieces of skirting board in a corner, they are cut so that each has a 45° angle.

To form an outer and inner corner, the skirting board must be cut

But how to make the corner on the baseboard, so that it was exactly forty-five degrees? To do this, use a special carpentry tool. the plier.

Types of corners in rooms

When installing baseboards need to somehow arrange the corners. By their appearance corners are external (which protrude forward) and internal (eg, the corners in the room). Premises with normal geometry have right angles, t 90°.е. 90°. When joining the two parts of the skirting board in a corner, they are cut so that each has a 45° angle.

To design an outer and inner corner, the skirting must be cut

But how to make a corner on the baseboard, so that it was exactly forty-five degrees? To do this, they use a special carpentry tool. the plier.

Baseboard plier

A carpenter’s frame is a device for making cuts at a certain angle. It’s used with a hacksaw. In principle, you can make a crosscut yourself, collecting the guide from boards and making cuts in the walls. On sale there are different models costing from 15 to several hundred dollars. They differ in features, materials, although they are all called “the jigsaw”. Professional models are made on the basis of a good hacksaw, have a scale that allows you to set the saw just right. With this tool, it’s no problem to set any desired angle of cut to properly cut the baseboard for a perfect fit.

The professional carpenter’s chair is a tool with a wide range of uses

The simplest beam is a plastic U-shaped profile, with slots cut into its sides. These slots are used as a guide for the hacksaw. They do not allow the blade to deflect. In any variant there are two cuts. straight and under 45 degrees. Some may have a couple of other options.

How to cut a skirting board under 45 degrees? One way to do this is to use a wire cutter

Sometimes a hacksaw is included, sometimes it is not. Usually the ones in the kit are not too good. Any hacksaw can be used, selecting the blade under the material to be cut. It is important that the blade moves freely in the cuts.

Characteristics of plastic corners

Plastic corners are a construction that is flexible, strong and flexible material. The products are made of synthetic polymers that give the corners a rigid structure.

All these qualities allow you to work with the material without fear of damaging it, which ensures a quality repair. But that’s not the only reason why corners are so popular.

To mount them does not require special equipment, any sharp object (knife or hacksaw) will be enough.

Advantages

- Ecological composition;

- Long service life;

- The presence of external coating;

- Does not depend on changes in temperature regime;

- Does not require special care.

Application

- When installing the niches of door and window openings;

- For finishing arches;

- For closing inner and outer corners;

- To save the corners of walls pasted with wallpaper.

What are the corners

With this design you can realize any fancy idea. Since the corners differ not only in tone and shape, but also in application.

- Equilateral product. Has an angle between the shelves of 90 C. Available in the following sizes: 1515, 2020, 2525, 3030, 4040 и 5050. When fixing the corners, they are cut at an angle of 45 degrees. Finishing with such a product always looks neat;

- Not a symmetrical product. The angle between the shelves is also 90 degrees. Manufactured in a variety of sizes. It is advised to use for arched structures;

- External and internal corners. The first have the angle of 90 and 105 C. When attaching the 90 C corner with the outer side there is one shelf, and when mounting 105 two shelves outward;

- T-corner. Essential for closing the joint between different materials. The product provides the smooth change of tones. Produced in the following sizes: 1210, 1810, 2010 and 2210;

- Product with snap fasteners. Used to hide the joint between the panels, also having a protective function. The role of which is played by special overlays equipped with snaps;

- F-shaped brackets. Necessary for angular and straight joints of plastic panels;

- A product on an adhesive basis. They are characterized by high elasticity and the presence of an adhesive base. Suitable for universal use. Help to avoid joints completely. Sold in large rolls of 50 meters.

Template 45 degrees. 45 degree corner template

Often the home handyman has an urgent need to make some measurement or marking at a certain angle, and either an angle or protractor is not at hand. In this case, a few simple rules will help him out.

If it is necessary to construct a right angle urgently, and there is no angle book, it is possible to use any printed edition. The angle of the paper roll is a very precise right angle (90 degrees).). Cutting (punching) machines in printers are set up very precisely. Otherwise, the original roll of paper will begin to cut crookedly and askew. So you can be sure that this angle is a right angle.

And if you don’t even have a printout or need to build an angle on the ground, such as when marking a foundation or a sheet of plywood with uneven edges? In this case the rule of the golden (or Egyptian) triangle will help us.

A golden (or Egyptian or Pythagorean) triangle is a triangle with sides that relate to each other as 5:4:3. According to Pythagoras’ theorem, in a right triangle, the square of the hypotenuse is equal to the sum of the squares of the cathetuses. Т.е. 5×5 = 4×4 3×3. 25=169 and it is undeniable.

Therefore, to build a right angle, it is sufficient to draw a straight line for the trimmer on the workpiece with a length of 5 (10,15,20, etc.д. multiple of 5 cm). And then, from the edges of this line begin to measure off on one side 4 (8,12,16 etc. divisible by 4 cm.etc. in multiples of 4 cm) and on the other side 3 (6,9,12,15 etc.д. (3 cm divisible by 3 cm) distance. You should get arcs with a radius of 4 and 3 cm. Where these arcs intersect each other will be a right angle (90 degrees).

Such corners are usually used in the manufacture of rectangular frames. The material from which the frame (baguette) is made is sawn at an angle of 45 degrees and docked. If you don’t have a straightedge or protractor handy, you can get a 45-degree angle pattern as follows. It is necessary to take a sheet of writing paper or any printed edition and bend it so that the line for the bending trimmer passed exactly through a corner and the edges of the bent sheet coincided. The resulting angle will be equal to 45 degrees.

House lamp out of wood with his hands

An angle of 60 degrees is required to construct equilateral triangles. For example, you need to saw these triangles for decorative work or accurately set a power swath. The 30-degree angle is rarely used in its pure form. However, it (and the 90-degree angle) is used to construct a 120-degree angle. And this is the angle needed to build equilateral hexagons, a figure very popular with carpenters.

To build a very precise pattern of these angles at any time, you need to remember the constant (number) 173. They follow from the ratios of the sines and cosines of these angles.

Take a sheet of paper from any publication. Its angle is exactly 90 degrees. From a corner on one side measure off 100 mm (10 cm).), and by the other, 173 mm (17.3 cm). Connect these points. Thus we obtained a pattern which has one corner of 90 degrees, one of 30 degrees and one of 60 degrees. You can check it on a protractor. everything is exact!

Remember this number. 173, and you can always build angles of 30 and 60 degrees.

At the marking of blanks or constructions on the details except for corners very important and their parity. This is especially important when making rectangular details or when e.g. marking foundations, cutting large sheets of material. Incorrect construction or marking brings a lot of unnecessary work later or to the appearance of a lot of waste.

Unfortunately, even very accurate marking tools, even professional ones, always have a certain margin of error.

Meanwhile, there is a very simple method of determining the rectangularity of a part or a construction. The diagonals of a rectangle are exactly equal! So, after drawing, you need to measure the diagonal lengths of the rectangle. If they are equal, it’s okay, it’s really a rectangle. And if not, you have built a parallelogram or rhombus. In this case it is necessary to “play” a little with adjacent sides to achieve exact (for this case) equality of the diagonals of the marked rectangle.

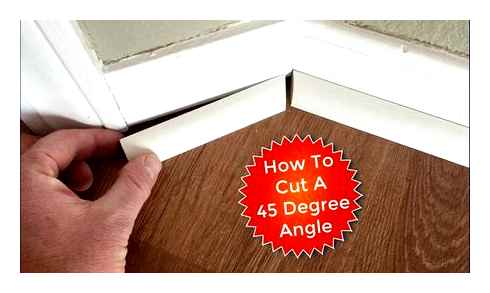

Ending at a 45 degree angle. How to saw at a 45-degree angle

During home repairs you may need to saw materials at a 45-degree angle. This is usually done to join two parts “in the whisker”, that is, the angle of 90 degrees (frames, skirting boards, door trims, etc.). To make you happy with the result of the work, it is important to absolutely precisely fit adjacent parts of blanks. Make it without a special device. a plier. is extremely difficult, especially for the novice craftsman.

Prepare an angled jig to help you make an accurate 45-degree angle sawing of the wood without any problems. This device is an inverted U-shaped profile with slots on each side for the hacksaw. Usually they are arranged at angles of 45, 60 and 90 degrees. The more complicated machines can be fitted with optional fixed slots, or have a swivel design that enables the saw to be positioned in the optimum position.

Buy a ready-made joinery tool at a building supply store with a wooden, metal or plastic tray. For the novice craftsman this is the best option. If you want, you can make a simple crosscut with your own hands from three boards or plywood strips (thickness. about 1.5-2 cm).

Drill a few holes in the walls of the future jigsaw, apply glue to the ends and assemble the box (tray) of the jigsaw. Fix the corner template with screws. The walls of the tool should lie strictly parallel one to the other; the bottom and each sidewall make clear perpendiculars.

Mark the angle of 45 degrees with a pencil, add additional groove lines if necessary. Use a protractor to keep your calculations straight.

The most responsible thing is the slots. It is recommended to perform them with the same hacksaw that will later be used to make cuts in the finished jigsaw. Start cutting without exerting too much pressure on the tool, hold the blade. First saw through one sidewall, then the opposite sidewall.

Begin machining the lumber. Use wood screws or wire clamps to fix the baseboard to the workbench or work table. Then make a mark for the future sawing on the lath (board, baseboard) and put the workpiece into the box. Press it firmly against one of the side walls of the template, aligning the marks with the 45 degree corner cutout.

Insert the hacksaw into the slots of the jigsaw and cut the workpiece. The saw’s operation will be limited to fixed cuts, and you will make a smooth and accurate cut.

When sawing baseboards, make sure the corners of the room are really right. If the walls are very uneven, the angle of cut on the workpieces should be corrected. Measure the joints of the interior walls with an angle gauge and divide the result in half (baseboard joint “in the whisker”). To make an accurate cut, it is recommended to make grooves with a given angle in a homemade jigsaw. Another option. a store rotary tool that allows you to change the angle from 0 to 180 degrees in increments of about 15 degrees.

The final part

The installation of the platbandings cannot be called too easy, especially if the domestic master has no work experience in this field. However, with the proper diligence and accuracy, anything is possible. If the home craftsman doubts his abilities, it is better to ask for help from the professionals. After all, if you sawed off an extra half centimeter you can spoil the leaf of the platband completely. In this case, it is not certain that the right color can be found in the store. If the master decided to do all the work himself, then the best option would be first to practice on unnecessary boards.

We hope that the information above will be useful for new masters at home. The editorial staff of our online magazine will be happy to answer your questions, if any during the reading process. All you have to do is state them in the Комментарии и мнения владельцев below. There you can also share your method of sawing the architraves at the right angle. If you liked the article, do not forget to rate it. your opinion is very important to us. And finally, as usual, we offer you a short video, which will help to better disclose today’s topic. Take care of yourself and your loved ones, and stay healthy!

Trimming the fillet

Pruning with a wire cutter

How to evenly cut the corner of the ceiling plinth with it?

Chisel is a simple tool used by carpenters. With it you can cut any workpiece at the desired angle.

It is usually a wooden, metal or plastic tray, which are made to cut at an angle of 45 ° and 90 ° special vertical slots.

There are also complicated designs which, in addition to the corners mentioned above, also have a 60-degree opening to make a 60-degree cut.

For professional work, there is a special plank. Its swivel mechanism allows you to fix the cutting blade in relation to the workpiece at any given angle.

Inner angle

The prepared skirting board is put against the ceiling and the required length is marked off.

Then this same plank is inserted into the jig precisely as it will be positioned on the ceiling. It must be pressed against the far wall of the device. In this position, the baseboard is held by the left hand.

The blade of the hacksaw should be in such a position that its angle is 45 degrees, and the handle would be as close to the hand as possible. Trying not to exert pressure on the saw, we carefully cut the slab.

Next, the skirting board must be cut off the counter batten. It is also placed at the far wall of the tool, held and pressed down, this time with the right hand.

The position of a hacksaw is similar to the previous procedure. its handle is close to the hand at an angle of 45 degrees. The skirting board is cut.

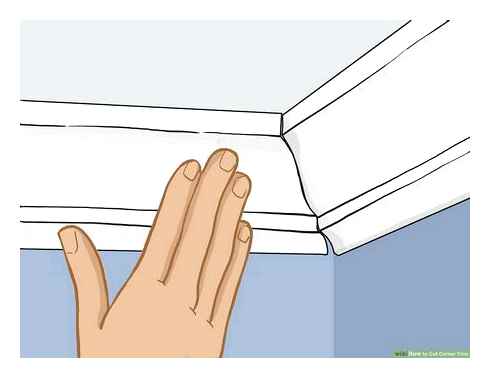

Then the finished, already trimmed strips are docked. to check the accuracy of fit. It is believed that for better orientation, in the manufacture of the inside corner, cutting is better to begin with the front of the product. The places of cuts usually need to be further adjusted with a file.

Outer corner

The correct way to observe more precisely the measurements, at first to begin to mark an internal corner, and only then proceed to the external corner.

Otherwise, it could be that there is insufficient length along the entire length of the plank.

The strip is attached to the ceiling, according to the size made marks. Holding the ceiling plinth with the left hand, the ceiling plinth is pressed to the closest wall, with the handle of the hacksaw close to the hand. The workpiece is cut.

The responsive plank is pressed against the nearest wall, holding it with the right hand. The blade of the hacksaw must be at a 45° angle, with the handle of the tool close to the hand of the master. A piece of the workpiece is cut, and the corner is accurately joined together.

Such processing of the edge of the parts with a mash is good in cases where the angle between the walls is even and straight (90 °).

If its performance leaves much to be desired, it is worth using another method.

Marking on the ceiling

The method with the marking on the ceiling allows you to cut the corner exactly and straight. It has one drawback. it is rather inconvenient to hold the baseboard on weight during the procedure.

Otherwise, with this method, you will be able to estimate the angle of the cut even more accurately than with the other methods.

When the skirting board is put to the intended installation place, all size deviations and inaccuracies are visible and are immediately taken into account.

Cutting a corner

First you need to take a pair of blanks, then cut them at right angles. Marking the end of the slat against a perpendicular wall, we put one slat. We outline a trimmer line on the ceiling along the contour of the skirting board. We take away the first bar, then we put the counter bar by pressing its end against the wall. Exactly the same way we mark on the contour line for the trimmer.

The intersection point of two separate lines is the mark at which the workpiece is cut. Each skirting board is placed against the surface again, on both of them the point of the future cut is marked. From the found point to the other edge of the skirting board, draw a trimmer line. We cut the skirting boards along the previously made marks, accurately join them, and place them in the place where they will be installed.

This method allows for a neater treatment of internal corners.

How to cut a ceiling plinth correctly. Important details

Measurements necessary for trimming the skirting boards on the ceiling, should be made in a special way. To determine and mark the inside corner, the length must be measured from the corner itself. To mark an outside corner, it is necessarily taken into account that deep into the room, the baseboard will protrude at a distance that equals its width.

It is not desirable to fasten the skirting boards before their exact position is verified and the counter skirting board is cut. Only when the two mating strips are perfectly flush in the corner can you begin to fit and fasten them. If you work with polyurethane or wooden skirting boards, defects and errors can be corrected with a file or file. To fit the foam product you need a sharp knife.

If even after finishing the skirting boards even a small gap remains, do not rush to upset. it is not difficult to seal it with an ordinary putty. It is not that difficult to cut a ceiling plinth accurately and neatly. But in order to acquire at least a small skill, first try to practice on small workpieces.