How to properly cut a laminate for pipes

Laying sequence

Laying the laminate along or across is performed in the following sequence:

- We install wedges near the walls to ensure that the compensation space between the wall and the material is 10 mm.

- We measure the width of the room and mark how many boards will fit in width. If it turns out that more than half of the board will need to be cut on the last row, it is best to cut the same distance from the laminate of the first and last row so that they look like the same size.

- For the boards that we will mount in the first row, we cut off the ridge so that there is no difference in height near the wall. We fasten the second row with a board offset by ½ or 1/3, start with half of the board or trim more than 300 mm.

- The panels of the last row most often have to be sawed off so that they fit into the remaining space. Small irregularities on the cut line will be hidden by the skirting board.

We connect depending on the type of locks: Click we connect at an inclination of 45 degrees and click, lowering it to the floor, we connect the Lock in one plane, we knock it down with a rubber hammer. For details of the process, see this

The glue method is practically not used due to the high cost of glue, the laboriousness of the work and the inability to disassemble the flooring if necessary.

Laminate substrates

After leveling the base, we lay the substrate, which performs the functions of a heat-saving and sound-insulating material, smooths out small irregularities in the slab and protects it from squeaking when walking on the boards.

Materials used as a substrate:

- Dense polyethylene is used for laying under a budget-class laminate, has quite good characteristics, at the same time performs the function of waterproofing, overlaps, the joints are fixed with tape.

- Polyurethane foam roll material has increased strength, fits end-to-end, glue the joints with tape. To increase thermal insulation, you can use a material with a foil layer.

- Bituminous-cork materials are stacked end-to-end, retain heat well and do not transmit sound.

- Cork is used for the highest class laminate flooring, they are durable, combine the best qualities of all the substrates described above.

The type of material is chosen depending on the functional purpose of the room and the class of the laminate.

DIY installation

When you have decided in which direction to lay the laminate, you can proceed with the installation.

After the packages with the material are brought into the room, they must lie for several days in order for the boards to adapt to the conditions in which they will be installed and used.

Sometimes the question arises whether it is possible to lay the laminate on both sides?

It is necessary to lay the laminate along or across the room, otherwise it will not be possible to qualitatively dock the elements together.

We make holes for pipes

Heating pipes, pipes with hot and cold water can pass in the room. Regardless of how you decided to lay the laminate along or across the room, you will have to cut a hole under the pipes.

How to cut a hole in a board:

- First, mark on the board the distance from the wall to the riser, drill a hole a few millimeters larger than the pipe diameter.

- In the middle of the hole we cut the board, we put the smaller part to the wall behind the pipes, glue most of it to the board near the wall and join with the next board.

Instructions for drilling holes in the board

laminate floor installation around pipes

At the end of the installation, close the gap between the pipe and the board with a plug. After laying the laminate in the room, you need to install the skirting boards.

Laying options for laminate

Laminate has long won the trust of consumers, as it is a full-fledged replacement for expensive parquet. This material is used in offices, apartments and country houses. The laminated board has an excellent appearance, is unpretentious in maintenance and is easy to install.

When choosing this coating, the question often arises of how to lay the laminate along or across. The aesthetic perception of the room will depend on the correct installation. The flooring is mounted only on a substrate that has a flat smooth surface.

Surface preparation

Prepare the surface thoroughly before installing laminate flooring. If you put it on a slab with a difference in height, then the connecting locks will disperse, and during long-term operation, cracks in the material may appear on an uneven base. The direction of laying the laminate does not affect the quality of the flooring, but does matter in the overall appearance of the room.

To prepare the base, we repair the slab, seal all cracks and cracks with cement mortar, level it with a self-leveling mixture or mount a new screed.

Allowed a difference in height of no more than 2 mm per 2 m of the surface.

How to lay laminate flooring

Consider how to properly lay the laminate along or across. Most often, the coating is laid along a long wall. Directions for laying laminated boards:

- across the windows;

- along the windows;

- a diagonal arrangement will help to visually enlarge a small room, provided that it is not cluttered with furniture.

When laying the laminated board along the stream of light (solar or artificial), the coating looks like a solid canvas. If light strikes across the laminate, the joints become visible.

To visually expand the area of a narrow and long room, the laminate is laid in the transverse direction, perpendicular to the short wall.

Each new row is laid with an offset of the seams, this contributes to an even distribution of the load. For a more economical consumption of material, we use cut boards in the last row. For information on how to lay a laminate board on the floor, see this

The most attractive type is the scheme in which the material is stacked in a checkerboard pattern with an offset in each subsequent row by half or one third of the board.

Installation of skirting boards

We take out the wedges, which served as spacers, and fasten the baseboards with screws or clips to the wall.

- Cut the skirting board to size.

- We connect with the elements included in the kit.

- We try on the wall, if the dimensions are the same, we fix the clips on the screws.

- Glue caps and corner joints to the skirting board.

When attaching to clips, we mark the location of the clips on the wall.

The choice of the method and direction of installation depends on the location of the windows, the room and the presence of furniture in it. With proper installation, laminate flooring will last for decades.

What are these linings called

When looking for suitable overlays, you may encounter the following difficulty: on different sites and in catalogs, these decor elements are called differently. The most common names are:

- pipe lines;

- decorative overlays;

- pipe rings.

Making a Formica Laminate Table

Do not be alarmed. all this is the name of the same subject, and its essence does not change from the wording. Therefore, if you cannot find the part you need in the catalog, it is worth trying a search by other words.

Installation

Installation of such a device is simple and does not require special skills and tools. However, the installation of different types of rings has its own nuances:

- wooden ones are in two parts and simply snap around the pipe. Connecting joints are usually not visible;

- on plastic and metal there is a special gap with which you can expand and put on the pad. The connector is directed towards the wall so that it is not visible.

No additional commit is needed. This is very convenient, because if necessary, you can easily remove the bypass, and then return it to its original place.

How beautiful to close the gaps in the laminate around the heating pipes

When making repairs, we always strive for an aesthetic result. Even such a trifle as an inaccurate gap between the pipe and the floor can spoil the appearance of the room. To make the joints look beautiful, use special decorative pipe covers.

How to close the gap between the laminate and the pipe

If the gap is small, then you can fill it with a sealant. They come in a variety of colors, so you can easily find the one that matches your gender. But the best option to decorate the gap would be special pipe linings.

They can be different in shape, such as round or square. Also, there are bypasses with two holes, for cases where the pipes are located close to each other.

What materials are they made of, how much do they cost

Pipe lines come in three materials:

- plastic;

- wood;

- metal.

Most often they are selected depending on the floor covering. Wooden rings are better for parquet, plastic rings for linoleum.

But there are no strict rules in this matter, choose for yourself what you like best. In addition, plastic elements are produced with a wood-like texture, and from the height of a human being, you can hardly see the difference between wood and imitation.

Plastic pads cost about 50 rubles for a pack of 2 pieces. Wooden rings will cost more. about 120 rubles.

What to do if the pipe is too close to the wall

This situation complicates the installation of a decorative rosette. But nothing is impossible. There are several options for solving the problem:

- try to find the right size for the part. Perhaps the smallest pad will fit into this gap;

- cut the ring and make the connector wider, thus setting it close to the wall.

- if you are using wooden elements, you can take only one half of the outline.

In the last two cases, for additional fixation, you will have to use a sealant or liquid nails.

The main advantages of cork are its durability, environmental friendliness, good sound and heat insulation and fire resistance. In addition, the cork is hypoallergenic and.

I want to share how we replaced the floors in our apartment. It was a whole epic. I resisted this process for a long time.

Laminate is the material of the future. When starting a renovation, we invariably face one of the main questions, which floor covering should we use? Artificial.

User comments:

Nice article with well-chosen photos. As I understand it, earlier such holes were cut with a jigsaw, and now they are doing it with a radial saw. Well, basically, that’s how I imagined it. Good job.

I faced a similar problem many times, and I must admit that in such cases there were always noticeable cracks on the laminate, often not even round. It is strange that he himself had not thought of such a decision before. Next time I will definitely try to make holes according to your method. Many thanks!

Thanks Igor! You got it right. Actually, the new thing here is precisely in the use of a radial saw. And we only make auxiliary cuts with a jigsaw.

Glad to help you, namesake! I am sometimes surprised myself. I break my head over something, nothing works, and then once, and surely someone will have a very simple and logical solution.

But what if the cutouts are already there and they are not aesthetic?

How can this be closed?

Surely there are some overlays?

- Flexible stone what is it

- Basic rules for a successful repair

- How big cities store garbage

- Builders’ qualifications: how to improve

- Types of shower cabins

- Why buy luxury plumbing

- Minimalism in the interior

- Plaster molding: features

- Liquid wallpaper: features and benefits in decoration

- Household heaters, how to choose

Comments (1)

How to get around the obstacles when laying laminate flooring?

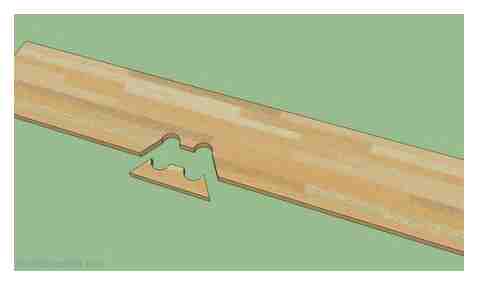

Last time I stopped at the fact that I promised to show a way to bypass pipes that go to a heating radiator with a bottom connection. It seems to many that it is very simple. Indeed, what’s so intricate. he took a jigsaw and cut it off, as God puts it on his soul. But many people forget that the appearance of such a cut is completely unaesthetic, and there will be nothing to repair the defects on the laminate. Many people know how to do this culturally, but in relation to the case when the holes fall on one panel of the laminate. It so happened that the holes fall on the adjacent panels. This is the most difficult case and I will show you how to get out of this situation with dignity.

In from it, the problem! It’s good that I managed to get to the pipes with a small tail. If I suddenly ruin it, it’s not the whole panel. The photo shows that first I put a mark in the center of the pipe on this very tail. In this case, you need to visually combine the edges of the trim and the last panel.

And now the highlight!

I attach the trim to the trim and continue the markup as if it were a real whole panel of laminate! Why is this needed? The thing is that I will cut the holes for the pipes with a radial saw on wood, which has a central drill. And he, of course, needs a fulcrum, like Archimedes for a lever.

“Wow, surprised! We’ve seen such a thing a hundred times!”. many will say. Right. Such saws are often used not only by professionals, but also by amateur masters. A very handy thing. The file holder has many channels of different diameters, designed for their different diameters, and there are also a lot of files in the kit and they cover a range of diameters from 20 to 70 mm. In most cases, this is sufficient. You can cut holes with such a saw not only in laminate, but also in wood, drywall and even in foam concrete and plastic!

For marking, I cut out two holes of a suitable diameter. Considering the fact that during construction the heating pipes were sunk too deep into the screed and only the PPR transitions were left outside to connect the metal supply and return valve for the battery, instead of leaving a small stock of the pipe, I take a file with a diameter of 40 mm. And if everything was done correctly, then a file with a diameter of 20 mm would be required. As you can see in the photo, we got two neat holes. The middle parts are no longer required.

Now I detach the trim and trim and make two more cuts to select the insert that will go behind the pipes. It would be possible not to do this detail. After all, the plinth will go behind the pipes. But it will not cover the entire distance from the wall to the pipes. Therefore, it is better to spend a couple of minutes to make everything beautiful.

It’s time to collect. No, not stones. piece by piece. In the photo, you can see that I edited the trim and the part that I cut last. Naturally, you can make a mistake when marking, or the saw will go a couple of millimeters to the side. Don’t be upset. Details can be tweaked with a jigsaw.

The work is completed by the fact that I install the next row of laminate. I cut the last panel to size, taking into account a tolerance of 10 mm. I cut a hole in it for a pipe and put everything together finally. In the photo, I specifically showed the details separately. The back insert will hold due to the fact that a fragment of the groove remains on it. But even if there was nothing on it, then, firstly, it will be pressed by the plinth, and secondly, it can be glued to “liquid nails”, for example.

Add comment Cancel reply

Advertising

Full or partial copying of materials is prohibited, with the agreed use of site materials, a link to the resource is required.

Information portal: renovation of apartments, offices, cottages

All rights reserved.

How to cut a pipe at an angle. marking options for round and profile pipes

When installing the pipeline, it is often necessary to cut the pipe at a certain angle. Accuracy plays an important role in this task. There are several easy ways to cut a pipe at an angle.

An incorrect pipe cut will lead to the impossibility of mounting a structure of the form that was originally conceived. For example, if you plan to rotate the system by 45 degrees, then you must cut the pipe at 45 degrees. To complete the task, you will need marking tools and an angle grinder (you can replace it with a hacksaw for metal).

Method of marking using a container with water instead of a template

This marking method is suitable for small diameter pipes that are planned to be cut at a certain angle close to the edge. First you need to prepare a deep container of water. The planned angle of inclination is marked on it. Now you need to carefully immerse the end of the product in the liquid, tilt it towards the mark, and then pull it out.

As a result of such actions, a clear line of contact with water will appear on it, it must be highlighted. On it, the pipe is cut at an angle. This method is best suited for jobs where multiple striping is required.

Marking the corner with a paper sheet

Layout on paper is one of the simplest ways to accomplish a task. A square sheet is required. It folds exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its section.

Then an angle of 45 degrees is formed on the smaller side. It remains to mark the line of the cut using a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with narrow tape so as not to accidentally erase it. This method is great for long, large pipes with a cut in the middle of the piece.

Using a computer program

To implement this method of marking pipes for cutting, you will need a computer with special programs. First, you need to draw up a drawing, which indicates the transverse dimensions of the product, as well as the planned cut angle. Need to get a virtual template.

Print it out on a printer. And here it is worthwhile to understand that the larger the pipe diameter, the more sheets will be required to print it. Then you need to carefully cut out the details of the drawing from all pages and glue it, it is best to use stationery tape for this. It remains to attach the template to the pipe and apply the markings.

This method of solving the problem is highly accurate. All the necessary programs can be downloaded from the Internet, they are free to download and use. It will also be possible to find a template for cutting pipes at an angle. All that remains is to print and cut it. To carry out the marking, the piece is simply wrapped around the pipe.

How to cut a profile pipe at an angle

The marking of the profile pipe differs from the round one. Its manual execution can lead to significant errors. The best way to solve the problem is to create a cutting template from the same profile, but with a larger diameter.

A small section of a shaped pipe will be required. On it, using a protractor, mark an angle of 45 degrees. Now, using an angle grinder, you need to cut off part of the workpiece along the marked mowing line. The edges of the cut must be sanded, defects must be eliminated. All that remains is to insert the original product into the bevel cutting template. Then you need to mark the mowing line for the cut of the larger profile. And already the pipe itself is cut along it.

The text describes how to cut a pipe at an angle of 45 degrees. When the marking has already been completed, it is recommended to use an angle grinder. With its help, it will turn out to make an even cut. You can replace it with a hacksaw for metal. It will also be possible to cut the product by welding, but experience in handling the tool is needed, otherwise there will be irregularities. “How to Cut a Pipe Straightly. Cutting Tools and Techniques”.

Power tools: circular saw

This tool will indeed give an equally perfect cut than a jigsaw, but it is much more difficult to work with it. Therefore, a circular should be picked up exclusively by those who have decent practical experience, or those who have read, reviewed a large number of materials on how to cut a laminate. There are a lot of videos with this name on the network.

Only those who have decent practical experience should pick up the circular.

If the choice fell on an angle grinder, a disc for metal should be installed. He will cut the tree best. Before cutting, the panels are fixed on a perfectly flat surface, but the wrong side in this case must be on top. The disc in the process will not get stuck in the board or slip. All movements should be performed smoothly, without haste, special pressure. However, skill is still required here. If there are no other options, it is better to first practice on construction waste, before cutting the material needed for laying, which is called “fill your hand”. But if you still want to learn how to properly cut laminate, but do not have experience with circulars, give preference to a jigsaw.

Anyone who has ever laid laminate flooring knows that it is impossible to achieve perfect coverage without cutting it. After all, no matter how hard you try, you won’t be able to reach any of the walls and keep the full length of the boards.

And the chess classics in drawing cannot be observed without cutting. Laminate is not the material with which you can work with an ordinary kitchen knife: not every tool is capable of making a high-quality cut. That is why, when starting to lay the laminate flooring, you need to decide in advance on the cutting unit. Perhaps it will be a revelation for someone, but there are many answers to the question of how to cut the laminate. Each of the tools has its own advantages, features, potential, operational nuances. And you need to know about all the intricacies so that later, in the process of work, to avoid several problems at once.

When starting to lay the laminate flooring, you need to decide in advance on the cutting unit.

Tool selection

How can laminate flooring be cut? Each craftsman has his own criteria by which he chooses a cutter for panels. Someone cares about its weight, work from the mains or exclusively by hand. Someone will choose from a variety of options the smallest tool, convenient and mobile. But for most masters of any level, thinking about how to cut a laminate when laying, an ideal cut, the ability to quickly execute it, will still be important. We list all the tools designed to work with laminate planks, designate the characteristics of each of them.

To get a plank of the right size, length, shape, there are several different electrical and manual units. When asked how to cut a laminate, experts give at least 7 answer options:

To get a plank of the right size, length, shape, there are several different electrical and manual units.

- electric jigsaw;

- circular saw;

- angle grinder or angle grinder;

- hacksaw;

- a cutter;

- construction knife;

- an ordinary clerical knife.

Almost any of these tools will be able to get a smooth cut. Naturally, if you have the appropriate experience of handling. There is no single recommendation on how to cut laminate flooring at home, what to use more correctly or professionally, in this situation. Each master is guided exclusively by his own experience and practice. Therefore, we will begin in order to disassemble each of the above.

Power Tools: Grinder

When pronouncing the word “angle grinder”, many will have one very persistent association with cutting metal. Most first got acquainted with this tool when they changed metal pipes at home to plastic ones. However, this unit has great capabilities. Grinding machines come in different sizes, capacities. Because of this, they have one main quality. versatility. Therefore, there is a certain category of craftsmen who do not have a question about how to cut the laminate. They automatically select an angle grinder, as they are used to cutting absolutely everything.

The angle grinder is very convenient to use, produces a perfectly flat, smooth cut. For everything to work out, you need to install cutting discs:

- metals;

- concrete;

- ceramic tiles.

Important! Planks should be laid and fixed face up before cutting.

When working with this power tool, there are two important points to consider: a large amount of dust, an unpleasant smell of burnt wood. If you are wondering if an angle grinder can cut laminate flooring, the answer is yes. You just don’t need to do it indoors. Better to go outside or to the balcony.

How to cut the laminate when installing the floor?

Hand tools: construction knife

You can use a construction knife especially when it is important to quickly decide how to cut the laminate.

When laying laminate, various situations arise in which you can be helped out. by a simple construction knife or even a clerical knife. For example, just a couple of planks are left to trim or cut, the power tool is out of order, and the work needs to be finished. A construction knife refers to tools, the use of which does not require skill or experience. However, they will need to cut with the application of physical strength. It can be used especially when it is important to quickly decide how to cut the laminate on the floor without securing the panels for a long time. The board is placed upside down with a foil. The cut is performed along a ruler and with some pressure. It will not be possible to completely cut off the fragment: only a deep trace will remain on the surface. Next, you just need to press a little to break off the cut piece.

Hand tools: hacksaw

Working with a hacksaw will require some physical effort.

If you are puzzling over which file or jigsaw to cut laminate flooring in small quantities, an ordinary hacksaw can help you. The only thing you should be prepared for is that working with such a tool will require some physical effort. In addition, it is a mistake to think that for cutting wood you should choose a hacksaw with large teeth for wood. They will only “rip” and crush the board, break the fragments out of it. To prevent this from happening, you should choose exclusively a hacksaw for metal. with small, often located teeth.

A hacksaw is not suitable as the main tool, so professional teams do not use it. The disadvantages of using are the following: low productivity, high physical costs, danger of material damage. But in some cases, when it is not advisable to cut the laminate with an angle grinder or a jigsaw, when the volume of material is small, a hacksaw can even come in handy.

Published on 20 October 2016 02:49 PM

How to lay laminate flooring with your own hands: methods and schemes

How to make the floor reliable, beautiful, easy to install and at the same time inexpensive? These seemingly incompatible qualities are combined in the laminate. This is why this flooring is being used more and more often. Nevertheless, in order for the floor to serve for a long time, you just need to know the intricacies of the technology. For example, before laying the laminate, you need to check how even the base is. The maximum permissible deviation is no more than 1-2 mm per meter of surface. Only under this condition will it lie tightly, will not bend and creak. If the differences are greater, the lock may even break or crack the board.

If the base has irregularities that exceed the permissible dimensions, it must be leveled. For cement floors, everything is simple. a leveling screed is poured. They begin to lay the laminate after the solution has gained at least 50% strength.

Laying the laminate is only possible on an even base.

If an old wooden floor is used as a base, it must be removed according to technology, then a full-fledged cement floor should be made, with all the necessary layers (bedding, hydro and thermal insulation, a reinforcing belt and a screed). You can install a heating system into this floor, and lay the floor covering on the warm floor. Only in this case it is necessary to use special types of laminate that tolerate heat well. The cost of such a floor is high, and it takes a lot of time to install it. Therefore, this is not always done. If the logs and boards are not damaged, you can level the wooden floor with plywood, and lay the laminate on it.

When leveling a wooden floor, all strongly protruding fragments are cut off with a plane or with the help of scraping, the cracks are sealed with putty. Sheets of plywood are laid on the prepared old wooden floor (it is used more often, although you can put any sheet material with a flat surface). They are fixed with self-tapping screws to the floor: around the perimeter after 15 cm, in the middle in a checkerboard pattern.

The joints of the sheets are shifted. they should not coincide (see the photo below). This way the load is transferred more evenly. One more thing. leave some gaps between the sheets. they should not be fitted closely to each other. Wood changes dimensions depending on humidity and temperature. And these gaps will give the necessary freedom to avoid “humps” and distortions.

Laying plywood on a wood floor underneath laminate flooring is a common way to prepare a subfloor during renovations. If the wood has not been damaged, and the plywood is laid flat, does not “play” and does not bend, such a base will serve for years

This is what an old wooden floor looks like, prepared for laying laminate.

One panel

When the holes for pipes are located on one panel, the following actions are performed:

- try on the panel to the docking point, make marks indicating the centers of the holes;

- measure the exact distance from the wall and the adjoining panel, taking into account the locking device, transfer the readings to the surface to be treated;

- using a drill with a crown of the required size (pipe diameter and technological intervals), the laminated panel is drilled on both sides to prevent the edges from collapsing;

- transverse cuts are made electrically with a jigsaw with a fine blade and separate the seats from the panel;

Important! Carrying out work is allowed only with a serviceable electrical tool, while ensuring compliance with technical safety measures. If chips get into the cornea of the eye, be sure to immediately contact a specialized doctor.

- the panel is laid in its regular place, on the reverse side the laminate is joined around the pipes, and the locking system of fastening is adjacent;

- when joining surfaces, it is permissible to use a small amount of adhesive;

Application of a joint sealant

- if there is no electric tool, use a regular jigsaw. the process will be long, but the result will be the same;

- the installation of subsequent laminate panels will give the required structural rigidity.

Laminate heating pipes

One of the most convenient materials for installing flooring is laminate. The assortment of colors and textures makes it possible to combine it with any interior. Locking fastening systems help to mount the coating without special preparation in a short time. However, transitions to an adjacent room, docking with another type of flooring, installing the last row of laminate, piping heating and water supply pipes requires knowledge of technology and installation features. In this article we will tell you how to place the laminate around the pipe.

Laminate floor

Installation features

Installation of laminate flooring is carried out in rooms heated by radiators with bottom pipe connections to the common system. Not every owner can afford to make constructive changes to hide communications by moving them to the surface of the floor and load-bearing walls. This kind of work takes time and investment. In some cases, it is justified by the device of a water heated floor. But in the overwhelming majority of cases, adaptation of the floor is carried out in the places where pipes are connected to heating radiators.

“Warm floors” with laminated coating

Depending on the distance of the pipes from the plane of the wall, the position of the joints of the laminated panel, various methods of cutting and mounting the structure are used.

Common to all options is the application of accurate marking of the position of the holes, since it is impossible to correct the error after cutting the material. Then it is important to take into account the technological gap between the pipe and the panel, which is at least 8.0 mm for the expansion joint, which ensures the movement of the coating during temperature extremes or due to other causes of deformation.

In this case, the proverb “measure seven times. cut one” is fully applicable.

Technological clearances

Important! For tight laying of the laminate panel at the point of abutment to the pipes, the surface of the rough coating at the joint is cleaned of concrete residues. The pipe is pre-painted or finished in another way.

The cases when the holes coincide with the placement of pipes on one panel seem to be quite simple, it is more difficult if at the junction of two.

Two panels

If the locations of the heating utility lines coincide with the surfaces of the two panels, the work is carried out in the following order:

- to ensure the rigidity of the coating, the panels are joined in a checkerboard pattern, therefore, the floor surface is assembled, but not secured with locks, to the point of joining with pipes;

Laying the panels

- measure the distance for both panels to the plane of the wall, carry out trimming (one will be longer, the other shorter);

- mark the joints with pipes, taking into account the previously given parameters, while the plane of the working surface is connected by a locking system without a lining;

- in any convenient way given above, make technological holes;

- with a perpendicular cut, the seating parts of the surface are separated in order to bypass the pipes;

- install the panels on the seats, circling around the heating pipes, place a part of the plate for docking;

- lay subsequent rows of laminate.

Laying laminate

For professional laying of laminated flooring near pipes, a method is used that excludes additional cross-cuts. For this, an accurate fitting of the canvas is carried out along the entire length of the installation at the location of the communications. Calculated in such a way that the joining points coincide with the location of the technical holes.

The pipes are usually removed from the plane of the wall by 60.0. 100.0 mm, so that it will not be difficult to find a cut of the required length after the previous fitting and installation of the panels. The surfaces are joined by locking systems without overlays, markings are carried out, and cut off. So the structure at the point of abutment to the pipes will become more rigid.

After installing the laminate flooring, the aesthetic design of the joints with the pipes is carried out throughout the room. For these purposes, acrylic sealants of the desired color are used by simply filling the joints. After that, it is possible to install decorative overlays, which are widely represented in the construction markets.

Decorative overlays

Careful attention to all stages of installation of laminate flooring, starting with the preparation of the base of the structure, will ensure its long-term use without changing the surface qualities of the material. If you do not have enough knowledge to carry out this work, the gaps can be easily filled by referring to technical documentation or professionals, which will save personal time and eliminate common mistakes.

The video below demonstrates the step-by-step installation of laminate flooring.

How to cut laminate flooring: choosing the right tool for cutting

In order to properly lay the laminate flooring, you need to be able not only to connect the laminate panels, but also to cut them correctly. Otherwise, it will be impossible to “fit” into the area of the room, as well as to observe the traditional chess pattern of the coating. Since you cannot take laminated boards with your bare hands, you can entrust cutting them to one of the hand or power tools.

Choice of cutting tools for laminate flooring

The main characteristics that a tool for cutting a laminate at home should have are:

- the convenience of use

- compactness and low weight

- the possibility of obtaining an even cut, without cracks and chips

The last point, the meaning of which is not to spoil the appearance of the laminate board after cutting, is decisive for most DIYers. However, its significance is still exaggerated. In any case, chips up to 5 mm in size on the finished coating will not be noticeable. defects along the edge of the panels will disappear behind the skirting boards.

So what are the best tools for cutting laminate flooring??

Jigsaw tool

The best result in cutting laminate can be achieved by using a jigsaw for this purpose. It is a lightweight, very easy-to-use tool that will quickly be approached by any newbie master. Even a woman or a teenager. Cutting with a jigsaw is carried out at high speeds, which avoids damage to the structure of the fiberboard. If you act at the same time quickly, confidently, then the cut will turn out to be almost perfect.

The main thing in using a jigsaw is the choice of the file. Modern tools are usually initially supplied with special files for cutting laminate. They are distinguished by a special shape, pitch and way of setting the teeth. However, ordinary metal files. narrow, with small teeth will cope with this business just as well.

In order not to damage the decorative surface, the cutting line is applied (with a pencil or chalk) to the wrong side of the laminate board. It is laid on a table (chair) with the wrong side up so that the part that is planned to be cut is in a suspended state. They fix the laminate lying on the table with one hand, and quickly cut off the excess part with the other.

Hacksaw tool

Laminate flooring can be successfully cut with a regular hacksaw for wood. But this will have to expend energy, because its teeth are large enough and will bite into the laminate, and not cut it out. Smaller teeth on a hacksaw for metal. this is what you need to use for cutting.

A hacksaw is very often used for cutting with small amounts of work. In construction teams, this method is not used, due to the increased time costs and labor intensity.

Laminate Cutter Tool

Laminate cutter, on the other hand, allows you to cut at a professional level. Most often, this tool works like a guillotine. a knife, which, with the help of a handle, is lowered onto the surface of the laminate and cut into it. The cutter operates easily, without chipping or noise. You don’t need to use force or skill to use it. Perhaps this is the easiest tool to use, allowing you to get excellent results in any conditions.

Since this cutter is used exclusively for laminate flooring, it only makes sense to buy it for professional installation. For finishing several rooms of an apartment, this option is considered impractical.

Construction knife tool

A regular construction knife can also be used to cut laminate flooring. For example, if you are almost finished with your flooring, there is only one board left to cut, but the angle grinder suddenly breaks down. There are no other tools at hand, but cutting needs to be done urgently. Then a construction knife will come to the rescue. Place a ruler on the front side of the laminate board, and make a deep cut along it with a knife. While holding the board on one side of the cut, press down on the other side. Laminate must break, just like ceramic tiles when hit by a tile cutter.

Tool Angle grinder (angle grinder)

The angle grinder is a handy tool, indispensable in the DIY’s drawer. It can cut almost anything, including laminate. For a beautiful edge, without cracks and chips, when cutting, you need to turn the laminate board with its front surface. In this case, discs are used for metal, concrete or ceramic tiles.

The disadvantage of using an angle grinder (and a circular saw too!) Is the large amount of dust that will be generated when cutting laminate. Also, this action can be accompanied by the smell of burnt wood. Therefore, you need to do cutting on an open balcony or on the street.