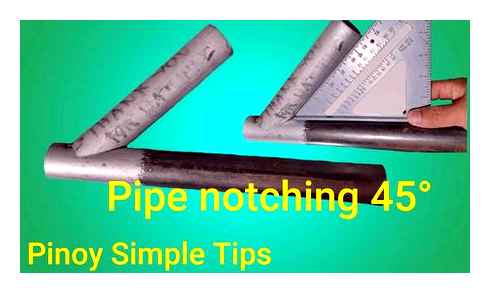

How to properly cut a pipe at a 45 degree angle

How to cut a profile pipe at an angle

In the course of installation and plumbing work is often required to perform cutting of blanks at a certain angle. Changing the direction of the cut line is necessary for further joining and welding with other pipes of the same configuration, or for the installation of shut-off and control valves.

It is worth considering that the accuracy of the cut at the right angle is necessary to obtain a high density of joints of rolled metal products. To do this you need to have the necessary tools, a quality pipe cutter and have the appropriate experience in processing pipe.

In this article we will consider methods of cutting pipes at different angles.

Methods of marking pipes at a 45 degree angle

Cutting pipe blanks at an angle of 45 ° is most in demand during the installation of heating pipelines, sewerage networks, gas piping systems. Pipes of iron or stainless steel of cylindrical cross-section, of small or medium diameter. 20-500 mm are used for this purpose.

One of the main tasks when cutting pipe at an angle of 45 degrees is to measure the angle and the flatness of the cut pipe, so that when joining the joined elements coincide with the accuracy of a millimeter. This is especially true for thin-wall pipes. if there is the slightest cutting error the walls of the pipes being joined will not fit together in the desired configuration. Therefore, close attention must be paid to the cutting accuracy.

In the absence of a production template, you can use a mold from a square paper sheet. To perform the marking of the pipe perform the following steps:

- Fold a square sheet strictly diagonally, aligning the opposite corners. The length of the pattern diagonal must be equal to the circumference of the workpiece.

- The folded sheet is wrapped around the pipe. It is important to check that the side of the template closest to the face of the workpiece is perfectly perpendicular to the central axis.

- In the place of the future cut is performed dotted line marking.

- Next you cut the pipe.

Marking square and rectangular section pipes

To make a template for marking a profile pipe it is more reasonable to use a similar billet with a larger cross section. Marking on the workpiece is performed once with an engineering ruler or protractor. A profile is inserted into the cavity of the prepared template, and the marking and subsequent cutting is performed.

Marking of pipes at an angle of 90 degrees

It is easy enough to make a 90 degree marking of the pipe. If necessary a sheet of paper can be used: the sheet is wrapped around the pipe, fastened and marked. It is important to ensure that the edges of the sheet coincide around the circumference, then the cut will be even.

How to cut a sectional tube at an angle of 90 degrees?

To cut a square or rectangular tube it is preferable to use a triangle. With this device, a marker is marked alternately on each side of the profile. After drawing the dotted line the pipe is cut.

Marking pipes at other angles

For cutting pipes at other angles you will need a template with corresponding dimensions. The template can be prepared with the help of Excel or other computer programs by entering the values of the pipe diameter, the necessary angle etc. in the appropriate interface.д.

In calculation programs it is possible to calculate the cutting of pipes of any diameter and angle. But more often this method is used to create a template for cutting small and medium size pipes. For larger diameters and larger quantities programmable pipe cutting machines are preferable.

How to cut pipe using the collar method?

Often when installing water supply systems it is necessary to have pipe billets with a triangular cut at the end. This configuration of pipes is necessary to connect with another pipe of circular section at right angles.

To make a collar cut, do the following:

- The size of the tube’s circumference is measured.

- The pipe is cut at an angle of 90 degrees.

- At the end of the pipe are marked equidistant points, which are relative to each other at angles of 90 and 180 degrees.

- Perform the calculation: the diameter of the pipe divided by three.

- Starting from the two diametrically aligned points, offset the calculated value and mark the points.

- These points are connected to the other welding segments by smooth arcs.

- After cutting, use the pipe-cutting tool to separate semicircular segments that are ready for welding.

How to order a pipe cutting tool

For advice on choosing pipe cutting equipment, please contact our managers:

When working on the installation of gas or water mains, it is often necessary to change the direction of the line, in which the pipeline is cut and then welded at the desired angle. Most often the direction is changed to 90 degrees, and the question arises. how to cut a pipe at 45 degrees to accurately connect the joints when welding.

To cope with the problem at angles of the cut edge in 45 or 90 degrees is possible with the appropriate knowledge and techniques that will help to save not only time but also materials during the work. At other angles of the spreading it is impossible to solve the problem with a ruler and a sheet of paper. you will have to call in computer technology to help.

How to properly cut pipes of different metals at 45 degrees and 90 degrees

How to cut the pipe at a certain angle? Straight-line cutting has already been mentioned. Next, let’s consider methods of cutting tubular blanks from different metals with the use of a metal locksmith’s plane. In addition to the convenience of cutting, the jig minimizes the amount of sawdust, which is important if the work is carried out at home.

The Locksmith’s Jigsaw consists of two assemblies:

- A hand-held hacksaw, which has top tubular guides that allow the tool to be held strictly perpendicular to the direction of cutting;

- A channel-like body that has slots on both sides to help the worker make precise angular cuts (usually 90° and 45°, but there are also angle-measuring saws that can make angular cuts from 100 to 1150 angles).

A distinction is made between cast and pressed jars. The former are cheaper, but do not work well under intermittent bending stresses.

It is important to choose the right hacksaw design. For angular cuts only precision tools with upper guides, which are additionally secured against bending by spring limiters, are suitable.

The following parameters are used to select the size of the locksmith’s chair:

- The width of the jigsaw, which determines the maximum diameter of the workpiece.

- The length of the jigsaw, which increases the accuracy of the cut.

- Angle gauge.

- depth and width of through cuts in the side walls of the channel: the deeper they are, the less sensitive the machine is to cutting conditions. the state of lubrication, the increased temperature of the hacksaw blade and the workpiece. On the other hand, when sawing pipes of large diameter, the increased kerf width will adversely affect the accuracy.

- Body material: steel (cast or stamped) chisels definitely should be used in preference to plastic chisels, though the latter are lighter.

How to cut a pipe at a 45 degree angle? When working with a metal pliers, you must first file the material, and then, making sure the wall is perpendicular, gradually increase the pressure on the hacksaw blade.

How to cut a square profile pipe

Saw a shaped tube can be done in about the same way, but it will be easier to use the angle piece. The device is applied in turn to each side, for which the element to be cut will need to be rotated, and the marking is made. After that you need to fix the pipe and you can start the work. For sawing, any suitable tool can be used. If it is necessary to cut a lot of pipe, it is reasonable to make full-fledged templates from scraps. In this case, measuring and marking work only has to be done once.

When it is necessary to cut a large diameter pipe, you can use a number of special devices and tools. This may be necessary if, for example, it is necessary to repair a pipeline.

- angle grinder. The use of an angle grinder is justified in terms of tool availability and comparative cheapness of the work. However, in this case, do not count on high productivity, in addition, the work in this way is associated with considerable risk.

- Roller machine. Such devices are also often called pipe cutters. In fact, such a device is the same as an angle grinder, but more adapted for this type of work. The machine includes a special base, where the element to be cut off is fixed, as well as a cage with installed cutting rollers that do the actual work. It is important to understand that each machine tool should be purchased for specific tasks, that is, the size of the pipe.

- Gas cutting. This cutter is most often used on big diameters. The cut is made with a high intensity flame and the waste products are blown out with a gas pressure. The method can be considered the most practical and efficient.

Gas cutting is the fastest option here

SEE The gas cutter on AliExpress

There are other variants of the implementation of the task, such as the use of plasma, waterjet or laser cutting, but in private use they are practically not used.

How to cut profile pipe with an angle grinder

The most popular way to cut in domestic conditions is the use of an angle grinder. How to cut a profile pipe evenly with an angle grinder? The main problem of carrying out the work is the correct marking.

For the marking you can use:

- tape measure, square, marker (pencil), construction level. The simplest tools allow you to mark the angle of the cut accurately enough, but during the performance of work the angle grinder can deviate from the specified line (the equipment is not supported on stands, and is on weight, that is, in the hands of the master), which will lead to an error. For this reason, this method is used very rarely;

Marking the cut with a square

The use of a paper template

The simplest device for correct cutting at an angle, for example, for making a greenhouse is a template made of thick paper.

To make a cut at a right angle (90°), it is necessary:

- a thick sheet of paper to wrap the pipe and achieve complete alignment of the edges;

- fix the sheet in this position;

- cutting profile pipe along the edge of the paper.

To make the cut Profile tube at an angle of 45 °, you need to fold a sheet of paper in half (the hypotenuse) and wrap the tube so as to align the sharp ends of the resulting triangle.

Professional craftsmen use special computer programs that allow more accurate creation of a paper template for cutting profiled pipes at any angle.

Computer-aided automatic paper template production

Using the construction diagonal cutter

Correctly cut the profiled tube at any angle allows construction pliers. The following is the procedure for using the construction diagonal cutter:

- the profiled tube is fixed inside the device and aligned at a certain angle;

- Using a built-in hacksaw a preliminary cut is made;

Cutting at an angle with a construction diagonal cutter

Finished measuring tool has a high cost. To reduce the financial cost of construction work, you can make an analogue of the chisel yourself. For this purpose, a wooden frame with a recess for pipes is made and notches are made at different angles with the help of measuring tools.

Chisel to cut profile pipe with his hands

What other ways can be used to cut profile pipes at an angle, see video.

Peculiarities of cutting pipes longitudinally

With an angle grinder, you can make not only a transverse, but also a longitudinal cut of the profile pipe. How to cut profile pipe longitudinally? The work is performed in the following order:

- As with the cross cuts, the work starts with a marking. It is important to determine as many reference points on the side surface of the pipe as possible to get the most even line for the trimmer;

Drawing a marking for the longitudinal cut

- to improve visibility and eliminate the possibility of obtaining an uneven cut, it is recommended to highlight the resulting line for the trimmer (with paint or masking tape);

- the pipe is fixed, for example, with clamps. If possible, you can also fix the angle grinder, as an option. with the help of a special stand;

- gradually making the cut along the set line.

Cutting pipe longitudinally with an angle grinder fixed on a stand

The same technology is used for cutting thick-walled profile pipes. Before you perform the work, it is required to fix the pipe, which eliminates the possibility of fracture of the workpiece under its own weight.

Welding modes selection

The quality of the expected seam largely depends on the correct setting of parameters of the mode. Its choice involves specifying the following parameters:

- what electrodes are planned to use for the work (their characteristics and diameter);

- The value of the parameters of the supplied current (including its type: direct or alternating);

- welding arc voltage;

- the speed of the process;

- the number of passes necessary to fill the seam.

Much of the quality of the connection depends on the choice of these parameters. Depending on the brand of metal from which the pipe is made and the thickness of its walls, choose what electrodes to make the connection. With the right welding mode the weld will be good and reliable.

A computer program is a great help

Computer program

I would also like to consider the method of marking with a computer program. This is quite a complicated method for those who are not used to working with a computer. It requires knowledge of PC, availability of programs for reamers and drawings. We begin by making a drawing with the size of the circle and the slope. We make the so-called virtual template.

Virtual cutting

Then use a printer to print the image on a sheet of paper. The larger the diameter of the pipe, the more sheets with markings will be. Use scissors to cut out all the parts of the drawing and, with the help of duct tape, glue them together. Ready template is attached to the pipe, and on the edge of the paper we do marking. This method of marking is considered one of the most accurate. If your computer does not have these programs, you can use the Internet. On the network you can download a template for marking. It must also be printed on the printer and cut out. Wrap the prepared template around the pipe and make a marking.

Cutting sheet metal with an angle grinder

To cut different kinds of metal, not thicknesses, use the appropriate cutting discs of different thicknesses not diameters. The algorithm for cutting sheets is as follows.

- For cutting by means of angle grinder sheet metal is laid on an even surface.

- Mark with a chalk (a marker) the exact size of the cut fragments on the sheet.

- Carry out sawing along the marked lines, without simultaneously changing the angle of the initial inclination of the disk to the work surface, so that it does not get jammed or the power tool breaks down.

If the skills of sawing sheet metal angle grinder does not exist, it is recommended to train on a delicate material. this allows you to feel the work of the tool.

You need to think about what cuts the metal more effectively the lower near segment of the disk.

Performing sheet metal cutting, to get a quality result, consider the following recommendations.

- To improve cooling it is necessary to water the place of cutting, which will also increase the life of the wheel.

- Start cutting metal only when the disk is rotating: do not turn on the tool if the stationary wheel is in contact with the surface of the workpiece.

- To saw tinplate (thin sheet metal) or cut different geometric shapes, it is more convenient to use small, exhausted circles (“stumps”).

- Press the angle grinder with considerable force is harmful: cutting should take place practically only under its own weight of the angle grinder.

- If the cutting wheel will stop in the slot (when you turn off the power tool), then resume the work of course only after its removal.

Cutting large diameter pipes

When it is necessary to cut a pipe with a large diameter, you can use a number of special devices and tools. This may be necessary, for example, if a pipeline needs to be repaired.

- angle grinder. The use of angle grinder is justified in terms of availability of the tool and the relative cheapness of the work. However, great performance in this case, do not count on, in addition, to carry out work in this way is fraught with considerable risk.

- Rolling machine. These devices are also often called pipe cutters. In fact, such a device is the same angle grinder, but more adapted for this type of work. The machine includes a special base where the element to be cut off is fixed, and a cage with mounted cutting rollers that do the actual work. It is important to understand that each machine must be purchased for a specific purpose, that is, the size of the pipe.

- Gas cutter. This option is most commonly used when working with large diameters. Cutting is performed by the action of a high intensity flame, and the waste produced in the process is blown out by the pressure of the gas. The method can be considered the most practical and efficient.

Cutting with gas in this case is the fastest option

SEE the gas cutter on AliExpress →

There are other options for the task, such as using plasma, waterjet or laser cutting, but in private use, they are practically not used.

Corner marking with a paper sheet

Marking with a paper sheet is one of the easiest ways to perform the task. Square sheet metal is required. It is folded exactly diagonally. The resulting template for cutting pipes should be wrapped around the product so that the long side runs parallel to its cross section.

Then a 45 degree angle is formed on the smaller side. It remains to mark the line for the cut trimmer with a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with a narrow adhesive tape so as not to accidentally erase it. This method is great for long, large pipes with a cut approximately in the middle of the pipe.

Marking method using a bowl of water instead of a template

This method of marking is appropriate for small diameter pipes that are planned to be cut at a certain angle close to the edge. First you need to prepare a deep container of water. The planned angle of inclination is marked on it. Now you need to carefully dip the end of the product into the liquid, tilt it to the mark, and then pull it out.

As a result of such actions on it will appear a clear line for the trimmer contact with water, it must be highlighted. That is where the pipe is cut at an angle. This method is best suited for work where multiple markings are required.

How to hold an angle grinder correctly

Many people have an angle grinder, but most people do not know how to properly use it and how to hold it. This does not only lead to malfunctions, but also to serious injuries. An angle grinder is a rather dangerous power tool. The wheel must be mounted with the pattern upward and secured with a special nut.

A right-handed person holding an angle grinder by the handle with his right hand. The wheel must be positioned on the left side of the machine and the guard must cover the wheel from above. The rotation is such that sparks fly to the worker while cutting. If the angle grinder has a jammed wheel and the angle grinder breaks free from his hands, it will not go to the cutter, but in the opposite direction.

The left hand holds the machine by the handle, which is screwed into a threaded hole on the body. There are several of them out there for special use cases, but the correct position of the handle is only the top one.

This position of the machine requires the use of protective equipment. To protect eyes and open part of face. safety glasses, and even better. a protective mask. To protect exposed body parts from sparks and small fragments while cutting, a suit of thick material must be worn.

How to weld a fitting properly

In order to perform a beautiful and reliable installation of the pipeline and weld the branch to the pipe 90 degrees it is necessary to choose correctly welding machine and electrodes. This information is better to search for profile forums where specialists will gladly tell what electrodes and welding machine operation modes they use in their professional work.

Pipeline parts are welded butt-welded, when the edges are close to each other. The thickness of the electrode for such work shall be 2-3 mm at a welding voltage of 80-110 Ampere. In order to get as little as possible burnt metal inside the electrode should be placed at an angle of 45 O to the surface. Round pipes should preferably be welded in one continuous seam. After welding you need to wait until the weld is completely cooled down and repulsed by the slag, and only after that move on to the next weld.

In order to get a beautiful and smooth joints you need to train your hand, so do not despair if you can not get it right away. Practice welding just small pieces of pipe beforehand. And only after that you should proceed directly to the welding of the pipeline.

When installing piping, it is often necessary to cut the pipe at a certain angle. When performing this task, accuracy plays a big role. There are a few simple ways to cut a pipe at an angle.

A wrong cut of the pipe will lead to the impossibility of assembling the construction of the shape that was originally conceived. For example, if you plan to bend the system by 45 degrees, it is necessary to make a 45 degree cut of the pipe. To perform the task, you will need tools for marking and an angle grinder (you can replace it with a metal saw).

Oblique cut

If the direction of the pipeline changes to an angle greater than 90 degrees, manual methods of making templates become too complicated. The use of a special program for calculating and creating patterns on the computer for any angle can be helpful. The method is good as it has a high accuracy of creating paper templates and is easy to implement if you have a printer.

To obtain a paper template, the necessary data about the bending angles and pipe diameter are entered into the program, and then a template is obtained, which is printed out on a printer at full size. All that remains is to cut it out, stick it on the element to be cut and mark the contour.

Further cutting is made with an angle grinder in a standard way. An important advantage of machine-made templates is that an infinite number of them can be cut to the same accuracy.

For quality connection of cylindrical elements of pipelines it is required to cut them precisely at angles of 45 and 90 degrees. To perform this work, special templates are used, the shape of the bends of which are calculated manually or constructed by computer. They are cut out on paper and glued to the pipe surface, then the element is cut along the paper contour with an angle grinder with a small disc. This provides a highly accurate fillet joint with edges which are as close as possible to the edge.

Using a computer program

To implement this method of marking pipes for cutting you will need a computer with special programs. To begin with, it is necessary to make a drawing in which the transverse dimensions of the product are indicated, as well as the planned angle of cut. It is necessary to obtain a virtual template.

Read also: How to work with assembly foam without a gun

Print it on a printer. And here it is worth understanding that the larger the diameter of the pipe, the more sheets will be needed to print it. Then you need to carefully cut out the parts of the drawing from all pages and glue, it is best to use for this purpose clerical tape. It remains to attach the template to the pipe and apply the markings.

This is a very precise way of doing things. All necessary programs are available online and are free to download and use. There you can also find a template for cutting pipes at an angle. All that remains is to print and cut it out. Simply wrap the template around the pipe to mark it.