How to properly cut corners on slopes

Required tools and materials

How to cut correctly

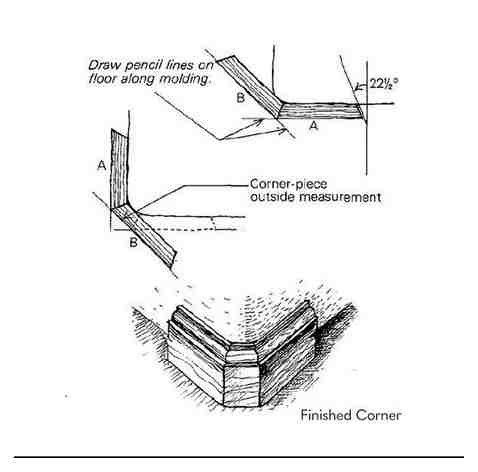

Before discussing how to attach the corners to the slopes, you should learn how to cut them correctly. After all, this stage of everything is the most time consuming and, perhaps, even the most important, since it depends on how much their edges will join, and this directly affects the aesthetic appearance of the entire room. The best way to do this is with a fine-toothed hacksaw. First, you need to measure the length of the opening, then we put marks on the corner itself so that the segment corresponds to this parameter. Then we cut off the part that will adjoin directly to the slope strictly according to the marks, and the part that will be against the wall at an angle of 45 °.

Use a fine-toothed hacksaw to trim the corner.

Installation of corners on the slopes of a window or door

Having figured out what such products are made of, what are their features and having decided on the choice, you should study how to install the corners on the slopes. Detailed instructions are given below.

Why do you need to fasten the corners to the slopes

Let’s start with the most important. why is it necessary? What role do the corners play. only decorative or do they have more serious functions? Let’s not argue with the fact that if you frame the slopes of doors or windows with special decorative elements that fit perfectly into the design of the room, then the interior will immediately change for the better.

Corners protect slopes from damage

But besides this, they also perform a very important protective function. Sooner or later, you have to carry bulky things through the opening, which is fraught with damage to the corners, and you can simply accidentally touch the outer corner and damage it. There can be a lot of situations, most importantly, the result is the same. a damaged surface and, accordingly, a view. In addition, as practice shows, most often the wallpaper begins to flake off precisely in these places. So it is best to protect the outer corner of the slope with a decorative element that will also transform the interior.

Corners are not only protection, but also a neat aesthetic appearance

How to cut and glue corners to door and window slopes

Photo gallery: finishing materials

It can be seen that the assortment is quite extensive, and there is plenty to choose from. But what should be guided by this? Of course, no matter how we would like, but almost always the budget is limited. Therefore, first of all, we have to proceed from our financial situation. As mentioned above, plastic products have a very reasonable price, while their appearance is not much inferior to analogues made from natural materials. But, in addition to the price, you should also pay attention to the fact that these decor elements harmoniously fit into the design of the room.

For arches, you should purchase special arched corners of different sexes, they ideally retain their position when bent. Please note that the wider the sides of this element are, the more loads it can withstand.

Plastic, wooden or MDF. which ones to choose?

Making sure that the installation of corners is not just a whim, but a necessity, we will study the construction market in order to make the right choice. These products are divided into types depending on the material from which they are made. So, the corner can be plastic, wooden, bamboo, made of cork or MDF. Absolutely each type has its pros and cons, we will consider them in more detail.

Plastic corners are made by hot folding a sheet of polyvinyl chloride. Basically, they have the same shelf width. from 10 to 40 mm in 5 mm increments. However, there are asymmetric specimens, for example, 10×25 mm, but regardless of this parameter, the angle between the sides is 90 degrees. If it is necessary to transform the arched opening, then this is done by means of a special flexible profile. Their advantages can be called a relatively low cost, they do not need painting, unlike the same tree.

The next type is cork corners. Such decorative elements are quite often used for arched openings, but this does not mean at all that their use is limited only to this area. They can also be used for finishing slopes of various shapes. The cork has a number of advantages, including strength, fire resistance, practicality and environmental friendliness. In principle, this material has practically no drawbacks, except that if your pet wants to sharpen its claws on it, this will damage the surface.

It is also worth noting wooden and bamboo products, which will always be signs of excellent taste and will fit into almost any interior. In addition, we must not forget about their environmental friendliness. True, such elements are somewhat more expensive than their counterparts from other materials, and besides, they often need painting. A material such as MDF can also be compared with natural wood, only it costs significantly lower, because wood dust is used to create it.

Features of the

To give the inner corners of window and door openings the desired and neat shape, special plastic corners for the slopes are installed. This finishing material is part of the decoration and is needed to hide the corner gaps that arise when using materials of different textures. The corners are assembled at the final stage of the renovation and completely transform the decoration of the windows and doors. They not only bring a graceful touch to the general atmosphere of the house, but also create a protective function.

Corner parts for slopes are made by hot bending PVC sheets using a special technology, due to which they become strong and durable.

They are used in various home decorating jobs and are necessary for:

- facing of window and door slopes, arched openings inside the apartment;

- protection of corner wall panels during plastering or wallpapering;

- when laying tiles.

PVC corners have many advantages:

- they can close the gaps of any materials at an angle of 90 degrees;

- can be used for a long time (service life. up to 25 years) and at the same time do not lose their basic properties;

- easy installation using glue, which can be done on your own, subject to the correct calculation of the cutting;

- plastic material, convenient for cutting;

- relatively low cost;

- insignificant mass that does not load the slopes;

- do not require additional painting and processing;

- protect corners from wallpaper wear;

- do not lend themselves to the influence of ultraviolet radiation, therefore they do not fade and can be used for a long time;

- thanks to the huge number of colors and shapes, they perfectly match any interior and add integrity to the entire design of the room.

The disadvantages include some fragility of the material, so you need to cut it carefully and with special tools. Also, corners do not tolerate high temperatures and, when ignited, emit toxic gas, which negatively affects the state of human health.

Manufacturers offer different types of PVC plastic corners according to the size and scope.

- Standard, or P-profile. It is used to strengthen window and door slopes, and it is recommended to install it at the initial stage of installation of slopes. The purpose of this profile is to decorate and protect the outer corners from deformation. It also helps to hide gaps between coatings, which do not connect very tightly.

- Versatile, or L-profile. It is used when installed on curly or arched openings. Such a profile is a flexible angle, the flanges of which converge at an angle of 90 degrees. Very easy to mount, because when bent, it keeps the desired position for installation well.

- F-shaped. It can be easily attached to the end sides of the panels, even without glue, since it has a special jumper. Unlike other types, such a profile can be easily removed while painting walls or gluing wallpaper. The main purpose of this piece is to hide the gaps between the wall panels, as well as the decor of the openings. In addition, it acts as a platband, which frames a door or window along the perimeter.

- T-profile. It is used if you want to achieve the perfect joint boundary between the slope and the panels. It flawlessly combines various finishing materials, which have different types of texture, and can be easily fixed on any surface. When laying tiles, it hides the unevenness of the tile at the joints with a flat base of the floor.

- Removable. This type of corner piece has a latch and has increased ductility. It can be easily bent 3–6 mm. It is not necessary to remove them during repairs. you just need to fill the wallpaper with a spatula under the corners. This allows assembly to be carried out much faster.

There is also a self-adhesive version of PVC corners on sale, which is versatile, since you do not need to buy glue separately for it. In addition, it has good flexibility, which makes installation extremely easy. For the convenience of the user, they are often sold in rolls up to 50 meters long, and a part of any desired length can be purchased to avoid seams.

In repair work, plastic perforated corners are also used. Their purpose is to strengthen and protect the inner and outer corners from damage and cracks. Often this type of material is used to give greater strength to protruding joints and level the surface.

By the type of finishing processes, internal and external PVC corners are distinguished. In turn, the outside angle can be 90 or 105 degrees. The 90-degree corner is attached so that only one side of the edging is visible, and the 105-degree corner is mounted with both shelves up.

By their structure, the products are divided into a rigid structure and a soft, or flexible, folding profile. The rigid structure is a classic rectangular profile, both shelves of which are formed into one piece. Such products are used when making corners where you need to make a bend of 90 degrees.

To embody the final image of the interior, white or colored decorative details are used that fit the overall design of the room.

All parts are manufactured in accordance with the standards of Building Codes and Rules (SNiP).

How to glue

Finally, we got to the main question, how to stick the corners on the slopes. However, before proceeding directly to fixation, you should carry out, so to speak, fitting. After making sure that everything is cut correctly, you can move on. We apply an adhesive solution on the inside of the corner, at the junction of the sides, with a step of approximately 10 cm. At this stage, an assembly gun will be an indispensable assistant. After that, quickly press the product to the surface and fix it in this position with masking tape. You should start with a horizontal slope, and then proceed to the side ones. We remove excess sealant from the surface of the walls with a damp cloth and let it dry thoroughly. You can remove the tape only after 24 hours.

When completing repair work, the question often arises of how to choose the right plastic corner for the slopes. After all, you always want the interior of the house to please the eye with an elegant and relaxed design.

Installation of corners on the slopes of a window or door

Having figured out what such products are made of, what are their features and having decided on the choice, you should study how to install the corners on the slopes. Detailed instructions are given below.

Why do you need to fasten the corners to the slopes

Let’s start with the most important. why is it necessary? What role do the corners play. only decorative or do they have more serious functions? Let’s not argue with the fact that if you frame the slopes of doors or windows with special decorative elements that fit perfectly into the design of the room, then the interior will immediately change for the better.

But besides this, they also perform a very important protective function. Sooner or later, you have to carry bulky things through the opening, which is fraught with damage to the corners, and you can simply accidentally touch the outer corner and damage it. There can be a lot of situations, most importantly, the result is the same. a damaged surface and, accordingly, a view. In addition, as practice shows, most often the wallpaper begins to flake off precisely in these places. So it is best to protect the outer corner of the slope with a decorative element that will also transform the interior.

Corners are not only protection, but also a neat aesthetic appearance

Plastic, wooden or MDF. which ones to choose?

Making sure that the installation of corners is not just a whim, but a necessity, we will study the construction market in order to make the right choice. These products are divided into types depending on the material from which they are made. So, the corner can be plastic, wooden, bamboo, made of cork or MDF. Absolutely each type has its pros and cons, we will consider them in more detail.

Plastic corners are made by hot folding a sheet of polyvinyl chloride. Basically, they have the same shelf width. from 10 to 40 mm in 5 mm increments. However, there are asymmetric specimens, for example, 10×25 mm, but regardless of this parameter, the angle between the sides is 90 degrees. If it is necessary to transform the arched opening, then this is done by means of a special flexible profile. Their advantages can be called a relatively low cost, they do not need painting, unlike the same tree.

The next type is cork corners. Such decorative elements are quite often used for arched openings, but this does not mean at all that their use is limited only to this area. They can also be used for finishing slopes of various shapes. The cork has a number of advantages, including strength, fire resistance, practicality and environmental friendliness. In principle, this material has practically no drawbacks, except that if your pet wants to sharpen its claws on it, this will damage the surface.

It is also worth noting wooden and bamboo products, which will always be signs of excellent taste and will fit into almost any interior. In addition, we must not forget about their environmental friendliness. True, such elements are somewhat more expensive than their counterparts from other materials, and besides, they often need painting. A material such as MDF can also be compared with natural wood, only it costs significantly lower, because wood dust is used to create it.

What glue to use

In addition to the corners themselves, we also need an adhesive composition with which we will fix the selected element. When choosing it, it is worth remembering that quite often, especially if it is necessary to glue a narrow product, the glue seeps out from under it and, naturally, falls on the walls. As a result, the latter can be damaged, which, accordingly, will negatively affect the appearance of the room as a whole. Therefore, you should choose such an adhesive composition, the excess of which can be removed from the surface.

Basically, the corners are glued to new slopes, but nevertheless, check that the surface is relatively flat, since no decoration can hide large bumps. It should be free of foreign objects such as nails, self-tapping screws, etc. It also needs to be degreased, for this purpose white spirit is suitable.

How to cut correctly

Before discussing how to attach the corners to the slopes, you should learn how to cut them correctly. After all, this stage of everything is the most time consuming and, perhaps, even the most important, since it depends on how much their edges will join, and this directly affects the aesthetic appearance of the entire room. The best way to do this is with a fine-toothed hacksaw. First, you need to measure the length of the opening, then we put marks on the corner itself so that the segment corresponds to this parameter. Then we cut off the part that will adjoin directly to the slope strictly according to the marks, and the part that will be against the wall at an angle of 45 °.

Use a fine-toothed hacksaw to trim the corner.

Dimensions

Corner parts go on sale with narrow strips with lengths of 2600, 2700, 2800 and 3000 mm with shelf parameters from 10 to 100 mm.

Depending on the scope of application, corners with different sizes are used:

- for arched openings take 517 mm, 1020 mm, 1525 mm;

- to create a flawless joint, you will need a T-profile with dimensions of 1210 mm, 1810 mm, 2010 mm, 2210 mm;

- to strengthen the slopes, you will need a corner from 2020 mm to 5050 mm in size;

- for slopes on windows, small corners of 1010 mm or 1515 mm are taken.

Plastic, wooden or MDF. which ones to choose?

Making sure that the installation of corners is not just a whim, but a necessity, we will study the construction market in order to make the right choice. These products are divided into types depending on the material from which they are made. So, the corner can be plastic, wooden, bamboo, made of cork or MDF. Absolutely each type has its pros and cons, we will consider them in more detail.

Plastic corners are made by hot folding a sheet of polyvinyl chloride. Basically, they have the same shelf width. from 10 to 40 mm in 5 mm increments. However, there are asymmetric specimens, for example, 10×25 mm, but regardless of this parameter, the angle between the sides is 90 degrees. If it is necessary to transform the arched opening, then this is done by means of a special flexible profile. Their advantages can be called a relatively low cost, they do not need painting, unlike the same tree.

The next type is cork corners. Such decorative elements are quite often used for arched openings, but this does not mean at all that their use is limited only to this area. They can also be used for finishing slopes of various shapes. The cork has a number of advantages, including strength, fire resistance, practicality and environmental friendliness. In principle, this material has practically no drawbacks, except that if your pet wants to sharpen its claws on it, this will damage the surface.

It is also worth noting wooden and bamboo products, which will always be signs of excellent taste and will fit into almost any interior. In addition, we must not forget about their environmental friendliness. True, such elements are somewhat more expensive than their counterparts from other materials, and besides, they often need painting. A material such as MDF can also be compared with natural wood, only it costs significantly lower, because wood dust is used to create it.

Compare types and sizes

Framing always starts with choosing the type and size of the plastic element. The table shows data about plastic corners, their sizes and types for slopes:

| Equilateral: | 2020. 5050 mm, standard length, fixed for strength. |

| Not equilateral: | 517 and 2025 mm, facing of arch openings, it is customary to install on curved compositions. |

| T-shaped: | 1210, 1810, 2010, 2210 mm, installation is necessary to hide the seams. |

| Removable (there is a latch): | Standard, the shelf is folded back for dismantling. Simple attachment, no need to stick. |

During installation, you need to cut the corner to form the desired length. A sharp stationery knife will help with this. If you need to cut at a clear angle, you will need to prepare a miter box and a hacksaw for metal.

Important! Color plastic corner for internal slopes is produced in lengths of 2.6 m, 2.7 m, 2.8 m, 3.0 m.

Required tools and materials

When the doors and windows are installed, it is necessary to deal with the finishing of the slopes, as a rule, this is the final stage. To hide small roughness and give a complete aesthetic look, many use ready-made corners. How to properly cut and glue a corner made of plastic, cork or MDF? Below are detailed recommendations for their installation.

Photo gallery: finishing materials

It can be seen that the assortment is quite extensive, and there is plenty to choose from. But what should be guided by this? Of course, no matter how we would like, but almost always the budget is limited. Therefore, first of all, we have to proceed from our financial situation. As mentioned above, plastic products have a very reasonable price, while their appearance is not much inferior to analogues made from natural materials. But, in addition to the price, you should also pay attention to the fact that these decor elements harmoniously fit into the design of the room.

For arches, you should purchase special arched corners of different sexes, they ideally retain their position when bent. Please note that the wider the sides of this element are, the more loads it can withstand.

Why do you need to fasten the corners to the slopes

Let’s start with the most important. why is it necessary? What role do the corners play. only decorative or do they have more serious functions? Let’s not argue with the fact that if you frame the slopes of doors or windows with special decorative elements that fit perfectly into the design of the room, then the interior will immediately change for the better.

But besides this, they also perform a very important protective function. Sooner or later, you have to carry bulky things through the opening, which is fraught with damage to the corners, and you can simply accidentally touch the outer corner and damage it. There can be a lot of situations, most importantly, the result is the same. a damaged surface and, accordingly, a view. In addition, as practice shows, most often the wallpaper begins to flake off precisely in these places. So it is best to protect the outer corner of the slope with a decorative element that will also transform the interior.

Corners are not only protection, but also a neat aesthetic appearance

Installation of plastic corners

The work on installing plastic corners on slopes is as follows:

- Regardless of where you need to glue the plastic corners. on the door, if a casing or window is not provided, outside or inside, you need to make measurements and cut the material to length correctly.

- Prepare the surface where gluing will take place. remove unnecessary elements, clean the base.

- Install and glue the strips correctly.

How to properly glue plastic corners to any slopes:

- Degrease the surface well before attaching the corner piece.

- Polyurethane foam is not used in the design process.

- Excess protruding plaster is smoothed out to a noticeable smoothness.

How to glue plastic corners correctly

- The sticker provides for marking with a pencil.

- Before you glue all the details, you should use the advice: it is better to measure the corners for the slopes of doors and plastic windows locally. Place the top horizontal element first, and then use the cutting tool to mark the vertical stripes.

Important! Using photos and videos, each beginner will cope with the gluing process on their own. The metal element is also fixed with self-tapping screws.

Sheathing with corners also implies additional fastening of the strips using narrow masking tape. Fix the strip with it in several places and leave it for about 24 hours. This time is enough to reliably glue the corners to the surface.

If the corner is used as a finishing finish, then the place of its gluing should be cleaned of finishing materials. Thus, the grip quality is increased. When fixing on an area decorated with trellises, a strip should be cut a couple of millimeters wide than the plastic corners. Adhering to simple design rules, fixing decorative elements will be simple and quick, and in the end they will delight you with an aesthetic and relaxed look.

Installation of corners on the slopes of a window or door

Having figured out what such products are made of, what are their features and having decided on the choice, you should study how to install the corners on the slopes. Detailed instructions are given below.

Scope of use and additional information

The framing corner is made by hot folding the PVC sheet. The decorative element makes it possible to choose colors that suit any interior. Application area:

- Window slope inside a house or apartment.

- As an external material to protect external or internal corners.

- Door or arched opening.

- To protect the corner of the wall when wallpapering.

- Corner protection for plastic finishing in the bathroom.

- Draping of the joint when decorating the external cladding with siding.

A plastic element is a good protector against mechanical stress, but, like any material, it has advantages and disadvantages:

- The installed corner is used as a finishing of the seam at the junction of finishing materials.

- Long service life. up to 25 years.

- Installation is carried out independently, you can glue the corner without preliminary preparation.

- The plastic element is easy to cut and comes in a variety of colors.

- Acceptable price.

Why do we need plastic corners on slopes

Among the shortcomings, the following were significant:

- Plastic is a fragile material, so it must be cut with special tools. cracks may appear.

- Flammable finishing element does not tolerate high temperatures.

How to glue corners on windows

What material to use depends on the quality of the surface finish of the window slopes. Check them with a level. If the curvature is strong, bendable plastic corners are used. Installation technology does not depend on the type of slopes. The main thing is to choose an adhesive suitable for each of the surfaces.

The sequence of mounting a plastic corner:

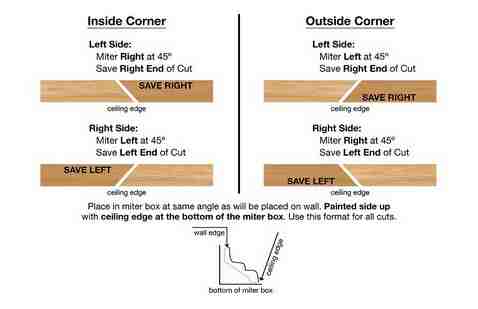

- Measure the height of the slope, the upper part of the segment is done with a margin. Mark an angle of 90 degrees from the seamy side, front 45 degrees. Make cuts with scissors or a knife.

- Apply glue, set the part in place, wait until it sets.

- Measure the width of the opening, cut a strip of the required length, providing a margin that will be used to mate with vertical parts.

- The blank from the front side is cut at an angle of 45 degrees on both sides (bottom and top).

- After trying on vertical elements with side slopes, the excess is cut off.

- Adhesive is applied to the top bar, applied in place.

- All details are fixed using masking tape.

- After a day, the glue will harden, and the tape can be removed.

An example of securing corners with tape

Characteristics of PVC corners

Finishing is carried out with rigid PVC corners, made by forming under the influence of high temperatures. This process is necessary to give them strength, long service life.

- when laying tiles;

- for framing arches, doors, windows;

- around windows, doors when framing slopes;

- for leveling and protection at the corners of wall surfaces when plastering.

A variety of shapes, colors makes it possible to choose the right material to give a finished look to any interior. They do not fade, so they can be used for a long time.

In addition to aesthetic purposes, they have a lot of other advantages:

- close gaps, hide irregularities in finishing areas with 90 ° angles;

- lightweight. they weigh a little, this makes installation easier;

- do not need processing;

- long service life, without loss of basic qualities (up to 25 years);

- easy to install, attached with glue;

- plastic, well pruned;

- reliably protects corners from scratches and chips;

- unpretentious in care;

- have little cost.

The corner on the window has drawbacks that do not affect the demand:

- fragility, you need to carefully cut;

- with strong heating, toxic substances are released;

- scratches may remain on the surface;

- fades after expiration.

How to choose corners for window slopes

The quality of the final result is influenced by the correct choice of material that will be used during its direct installation. There are a large number of products in various colors with pictures. Plain and imitating metal, marble, wood materials.

How To Build a Retaining Wall (Step-by-Step)

Depending on the scope of application, several types are produced:

- standard. U-shaped, used for finishing openings on windows and doors at the beginning of installation;

- versatile. have the shape of the letter L, flexible, angle 90 degrees, used for curly, arched openings;

- T.-like. are fixed on different surfaces, form an even border of joints, used when laying tiles;

- F-shaped. used for fastening to the ends of the panels using a special jumper, which can be removed if necessary. Acts as a platband, framing window or doorways;

- removable. plastic, with a latch, the edges are easily folded back;

- self-adhesive. flexible, easy to install, available in rolls.

Designed not only for internal but also external corners (90 and 105 degrees). An angle of 90 degrees is fixed so that one strip is on the outside as an edging, and 105 degrees. with shelves up. Length of one strip of material 2.6. 3.0 meters.

The dimensions of the raw material for finishing plastic windows can be 10×10 mm or 15×15 mm. For corner surfaces, in order to strengthen them, material is used in size from 20×20 mm to 50×50 mm. Before purchasing, you can see a photo with samples of plastic corners.

How to glue a plastic corner to the wall and to the PVC window slope

Before mounting the profile, you need to choose an adhesive, study the instructions, characteristics.

The quality of the material determines which tool to use, how to glue:

- silicone-based sealants. designed to work with tiles, ceramics, wallpaper;

- liquid plastic. only for plastic surfaces;

- polyurethane glue. quickly sets;

- “Liquid” nails. easy to apply, do not corrode, adhere well.

The adhesive is applied to the inner surface of the profile with dotted lines 1 cm long.

Mounting options

To design a window opening, the following installation methods can be used:

- Gluing the corner on the wallpaper. suitable only for simple wallpapers with a smooth relief, with deep embossing, the adhesion to the wall will be weak.

- The profile is attached to the wall, free of wallpaper. To do this, you need to put it to the installation site, align it, press it against the wall. Use a sharp knife to cut off the strips of wallpaper under the overlay. You can mark it up with a pencil, and then cut it off. Smear the inner surfaces of the corner with “liquid” nails or other glue, and push it to the slope. Secure with tape, leave to dry for a day.

Preparation for work

Before attaching the plastic corner to the work areas, they are freed from dust particles and building contaminants. If there are protruding parts, remove and level the surface, otherwise the profile will lie crooked.

For work, you need to prepare the following devices and tools:

- glue gun;

- roulette;

- construction knife;

- masking tape;

- square, preferably made of metal;

- miter box (it is possible without it).

Clean and dry glued surfaces can be degreased with any solvent.

It is important to correctly measure the window slopes, prepare the finishing material. The base should be one of the sides of the corner, which, from the outside, is cut off with a margin of 20 mm, this applies to the vertical, upper parts, taking into account both sides. All parts must consist of one whole segment, connections are not allowed.

The outer corners are joined in the following ways:

- overlapping each other, then leveled with putty to match the color of the plastic;

- trimming at an angle of 45 °;

- trimming to the base of one of the allowances (the upper one remains with a margin, and the vertical ones are trimmed flush).

It is advisable to check the accuracy of the cut elements by joining the parts. Cut with a special knife, otherwise you can spoil the material.

How to glue corners to window slopes

Windows Professional Windows info How to glue corners on window slopes: how to glue a plastic corner

After completing the main repair work: installing windows, doors, painting or wallpapering the walls, the turn of finishing comes. Skirting boards and corners on the slopes create an aesthetically finished look of the room, close the corner joints, and protect against mechanical stress. Before starting finishing work, it is necessary to choose the right material. You can watch videos of professionals with detailed instructions on the Internet, study the sequence of work, and as a result, the work will delight you for more than one year.

Specialist recommendations

Beginners can self-glue plastic corners around window openings.

The recommendations of experts will help you do this with confidence:

- So that there are no gaps between the joints, it is advised to increase the size of the workpieces (1 mm), to observe accuracy when marking. Thanks to the elasticity of the material, everything will fall into place.

- It is advisable not to use silicone for sealing joints. The connection will darken over time, this will ruin the appearance of the slope.

- In order not to make mistakes when preparing parts, the profile can be attached with tape, then measured.

- When gluing a profile to arched slopes, a construction hairdryer is used to heat the corner.

- Openings with non-standard angles (more or less than 90 degrees). measure by applying workpieces to the wall.

- To avoid cracks when cutting blanks, you need to use tools designed for this type of work.

- Purchase a profile for finishing only after thorough measurements, taking into account the parameters of the slopes. If there are corners with significant deviations, use flexible corners, for the correct 90 degrees. more rigid ones.

- Taking into account the type of room, it is necessary to choose the material. Strong corner pieces with a larger width are used for rooms with increased wear resistance. Small corners are suitable for the interior, which will be in harmony with the design of the room.

- When choosing a material, pay attention to whether the corner holds its shape. Otherwise, it is better not to buy it.

- If you need to install a corner on slopes after repair, for better adhesion of parts, clean the strip around the window opening.

- Corner elements, glued to a plastic surface with glue, it is recommended to use “liquid” nails for plastering drywall.

- When buying a profile, you need to make sure that the finishing material is not bent, the sides are the same size and are not deformed.

Compliance with all the rules to ensure stability when installing a plastic PVC corner is a guarantee of long-term operation, practicality and aesthetic condition of window openings.