How to properly dilute gasoline on a chainsaw

TEST # 2.Check the chain oil supply

With the engine sorted out. Now let’s evaluate the correct supply of chain oil.

To do this, after starting the engine, run the chain at medium speed to remove excess oil. If necessary, adjust the feed with a screwdriver. It is necessary to insert it from the underside of the coupling and set the desired oil flow.

In what proportions to mix oil and gasoline for chainsaws?

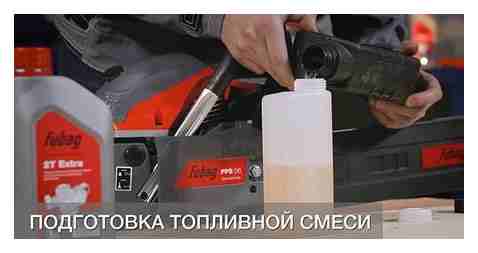

The chainsaw is equipped with a single-cylinder two-stroke engine that uses a fuel mixture for operation. To refuel, you will need 92nd gasoline and special oil for air-cooled two-stroke engines.

Prepare a mixture in the proportion of oil and gasoline. 1:40. In other words, we observe the ratio per 1 liter of gasoline. 25 grams of butter. Most often, such a volume is contained in a standard cap of a container with a technical liquid.

Mix the mixture well in a separate container. Owners of FUBAG FPS 56 are in luck, because it is already included in the kit. After completing the preparation of the fuel mixture, pour it into the gas tank.

Which chainsaw oil to choose? For our engines, we recommend Fubag 2T Extra semi-synthetic oil. optimally selected quality composition. Please note that oil for four-stroke engines or for outboard motors will not work in any way.

Chainsaw fuel mixture isn’t the only one that uses oil. The devices have one more technological tank, where the lubricant for the chain is poured. By the time the fuel runs out, the oil for the chain also runs out, so it will need to be refilled every time after refueling the tool.

How to choose chain oil? We recommend the special brand Fubag Super Chain oil.

Chainsaw. first start: assembly, proportions of oil and gasoline, care and storage

How to prepare your chainsaw for the first start? How to prepare the correct fuel mixture and quickly change the headset? In this article, we will answer these and many other questions, as well as give some tips for maintaining and storing your chainsaw.

Assembling a chainsaw using the example of Fubag FPS 56

Like most analogues, the chainsaw is supplied unassembled: a body, a separate tire and a saw headset. In addition to the main parts, the kit includes: a set of tools, a container for gasoline mixture, a tire cover, a bumper, a file for sharpening a chain and reliable safety goggles.

Everything is clear with the kit. let’s move on to the assembly:

Move the guard towards the front handle to make sure the chain brake is disengaged.

Loosen the nuts and remove the chain cover.

Install the cutting link (for the FUBAG FPS 56 chainsaw, it is included in the kit).

We turn the chain on the sprocket, and at the same time install the tire on the saw body.

Check if the direction of rotation of the saw chain is correctly set.

Install the chain cover on the main saw body and tighten the nuts by hand.

Adjust the chain tension by turning the tensioning screw until the connecting link touches the underside of the guide.

Raise the end of the tire and finally tighten the nuts.

Manually check the uniformity of rotation and the degree of saw tension.

If the chainsaw has a gas-powered tensioning system, as, for example, the FPS 37 saw model, then the assembly process will take no more than a minute. For this you need:

Place the bar and chain on the chainsaw pins in the correct way (the cutting teeth must be in the direction of travel).

2. Install the cover. For correct installation of the cover, adjust the position.

pins on it so that they go into the holes of the tire.

Pull out the screw stop and tighten a little until the bar and chain do not dangle, but there is some freedom to adjust the chain tension.

4. Adjust the chain tension by rotating the wheel.

Pull out the stop and tighten the cover, ensuring reliable fixation of the equipment.

It is not necessary to tighten the chain all the way, because it may soon stretch again. The chain should have a small margin, slightly sag. It’s not hard to check with your hand Ideal if it lends itself to bend off the tire by a millimeter.

Let’s start with the engine

Engine care includes blowing out the cylinder cooling fins, checking the spark plug, oil, fuel and air filters.

The air filter and cylinder cover must be removed to clean the cylinder fins. When refitting the cylinder cover, check that the wires of the switch and the sealing ring are in the correct position.

To clean the fuel and oil filters, you need to remove them and rinse them with gasoline for chainsaws, or replace with a new filter.

It does not hurt to check the spark plug periodically. In case of contamination, clean the electrodes with a wire brush and restore the gap to 0.65 mm.

To check the air filter, we take it out, remove dust from the surface. If it is heavily clogged, it is better to rinse it in gasoline.

If cleaning with compressed air, direct the jet towards the inner surface.

TEST No. 1. checking the supply of the fuel mixture

Our saw is fueled. Let’s start the engine and test the oil flow.

We check the caps of the gas tank and oil tank. They must be tightly closed.

2. This model has an easy start system and a primer. a fuel pumping button. Pull out the air damper handle and turn on the ignition switch.

Pull the recoil starter. Important! In this case, the saw should not be in hand, only on the ground! This is necessary to avoid injury when jerking.

Let the engine run for 30-40 seconds at idle, after which the air damper can be moved to its original position.

Chainsaw chain maintenance

During operation, the chain stretches and does not fit well on the saw teeth. If the chain nuts are too loose on the saw teeth, then tighten the chain and then tighten the blade itself. When the chain is worn out, you need to change it, but first you can try to sharpen it.

Learning about link wear is simple:

- Sawdust becomes powdery

- It takes more effort to work

- The saw vibrates strongly

- Fuel consumption increases

You will need a file to sharpen the chain (Fubag already has it in the kit). Having prepared the tool, you can get down to business:

Lock the chain in place

2. Take a round file of the appropriate size

3. Place the file on the bit and start sharpening, keeping it straight.

4. After sharpening each cutter, measure the depth and bring to the desired size.

5. To minimize the chance of kickback and link breakage, round off the leading edge.

Refueling your chainsaw

For beginners, the question of how to refuel a chainsaw is especially relevant. However, the refueling process itself is not difficult at all. The main task is to formulate the fuel / oil mixture in the correct proportions. They are indicated in the instructions for the tool. Before refueling, you should carefully study the information given by the manufacturer in order to exclude the possibility of errors in the preparation of the fuel mixture.

What fuel to use for a chainsaw?

Choosing the right fuel is an important and significant issue. The only correct approach to its solution is a careful study of the user manual, which indicates the type and brand of fuel, the proportions of mixing gasoline and oil, and also reflects all the features of this tool. Modern standards require the use of high-octane refined fuels and special types of engine oil.

How to properly mix the fuel mixture?

The mixing process is quite simple. you need to measure out a certain amount of oil and pour it into the appropriate volume of gasoline. Prepare a clean container for mixing. Usually, plastic canisters are used, which are quite suitable for this purpose. However, some species have a serious drawback. they accumulate static electricity, which can lead to the formation of a spark and ignite the fuel mixture.

The best option is to use a special canister with two necks, into which gasoline and oil are poured, but they are quite expensive. For accurate dosage of oil, many use medical syringes with marked divisions. The more carefully the amount of the mixture is measured, the longer the service life and the higher the quality of the tool.

Attention! Do not mix gasoline and oil directly in the fuel tank of the tool. on how to turn on your chainsaw.

Gasoline to oil ratio

The standard ratio of oil to gasoline, which is relevant for most chainsaws, is 1 to 50. This means that 20 ml of oil must be added to 1 liter of gasoline. However, each manufacturer has its own requirements for the composition of the fuel mixture, which are due to the design of the engine, the peculiarities of its parameters and other factors. It is impossible to determine on your own what proportions are best suited for a given instrument.

Complete and accurate information can only be obtained from the user manual. If it does not contain any instructions regarding the composition of the fuel mixture, then generally accepted practice should be followed and make it in a ratio of 1: 50. There are other options, from 1: 20 to 1: 50.

Figure 3. The ratio of oil and gasoline for the fuel mixture

Gasoline selection

Many are interested in what gasoline the chainsaw works best on. Most models require clean, high-quality fuel with an octane rating of no higher than 90. Sometimes there are recommendations on the network to mix 92 or 93 gasoline with 95 to increase its efficiency. In no case should this be done, since higher-octane grades are often faked, and no one will dilute the A92 or AI92 grades.

Therefore, when choosing which gasoline to pour into the chainsaw in the domestic market, it is recommended to use just such a fuel. It is necessary to ensure that the gasoline is sufficiently fresh, as during long-term storage it begins to release resins and other elements that deteriorate quality. Manufacturers recommend using:

- Chainsaw Stihl (Stihl) 180. it is better to refuel with gasoline A90 and higher;

- Stihl 250. runs on gasoline with an octane rating of at least 90. You should not use fuel with an ethanol content exceeding 10%;

- Partner. it is necessary to use only unleaded gasoline with an octane rating of at least 90;

- Husqvarna. Gasoline with an octane rating of at least 90, it is allowed to use clean fuel or with the addition of tetraethyl lead. Catalyzed engines require a fuel / oil mixture made from unleaded gasoline.

As a rule, the owners of such tools use AI92 gasoline, which fully meets the requirements of manufacturers. However, for most domestic chainsaws, A72 or A80 gasoline is quite suitable. It must also be borne in mind that the failure of the chainsaw due to the use of low-quality fuel is not a warranty case.

Chainsaw device features

The chainsaw is a chain hand tool, the cutting body of which is driven by a carburetor engine.

Typically, this is a single cylinder two-stroke engine.

This design is simple, economical, capable of working in any position.

The structure of the saw, in addition to the engine, includes:

- carburetor;

- tire;

- cutting body (chain);

- starter;

- centrifugal clutch;

- ignition, fuel supply system, air filters;

- chain lubrication system;

- muffler;

- handles.

The motor can be positioned vertically (heavy duty professional models) or horizontally (light household tools). Heavy-duty saws are used for felling and crosscutting trunks and have a large frame size. Lightweight saws are used for cutting branches or sawing wood and are usually purchased by private house owners, farmers, gardeners, etc.

The design of the tool is simple, which is a guarantee of high strength and reliability. The engine shaft drives the drive sprocket through the clutch, which moves the chain along the tire using the drive sprocket. The two-stroke engine does not need a camshaft, valve system and other elements, which also contributes to increased structural reliability.

The centrifugal clutch is equipped with two clutches, which are pressed against each other at low shaft speeds, and with an increase in rotation speed, under the action of centrifugal force, they are pressed against the outer part of the clutch and drive the drive sprocket. The power of the motor determines the type of chain. the more powerful the saw, the greater the chain pitch (the distance between the teeth, which determines the performance of the tool).

Important! Using a chain that is not compatible with the motor will result in a loss of tool performance.

Oil selection

The chainsaw uses two types of oil. motor oil and chain (adhesive) oil. They should not be confused because the tasks they perform are different from each other. Any gear oil can be used to lubricate the chain, although manufacturers always recommend using the same materials. Engine oil requirements are stricter. On this issue, all manufacturers are unanimous. you should use the oil of the same company that made the saw.

There is no lubrication system in two-stroke engines, which is replaced by the presence of some material in the fuel. The carburetor injects a fuel-oil mist, which simultaneously lubricates all parts. thereafter, the residues are burned in the cylinder. If there are no specific instructions in the instructions, any two-stroke oil can be used.

For different tool models, manufacturers recommend:

- for the Stihl 180 chainsaw. the best option is STIHL HP, HP SUPER or HP ULTRA oil;

- Stihl 250. use STIHL HP, HP SUPER or HP ULTRA correctly, STIHL HP ULTRA is the most effective;

- Partner. any two-stroke oil. Do not use automotive or marine oil, this will damage the engine;

- Husqvarna. Manufacturer recommends the use of HUSQVARNA two-stroke oil. Do not use oil for four-stroke engines, or for two-stroke water-cooled engines.

Important! Not all types of oil are commercially available in Russia, so sometimes you have to change them to other available types. The most successful option is the use of synthetic high quality materials.

Storage conditions for the finished mixture

Most users usually prepare the fuel mixture for future use. This is due to the saving of time. it is believed that it is more correct to mix a large volume once, and then simply add fuel to the tool tank. This point of view is valid, but with important limitations. The finished mixture should not be stored for too long, as irreversible changes occur in it.

Ideally, it should only be cooked for one day, but this is considered too irrational by many. The permissible shelf life depends on the ratio and grade of the components. Most experts recommend not storing the mixture for more than 3 months. It is recommended to use metal canisters and keep the mixture under a canopy, away from direct sunlight.

Fuel quality

If you want the tool to do its job perfectly and last for more than one year, you must provide it with fuel and lubricant of the proper quality.

Flushing The Fuel And Oil Tank Of A Husqvarna Chainsaw.

Proportions

There are several options for the ratio of fuel and lubricant. As a rule, this number ranges from 20 to 50 ml of oil per 1 liter of gasoline.

Again, you must follow the instructions for the product or the recommendations indicated on the oil label (priority of the instruction). In the absence of such, before diluting gasoline, you need to pay attention to the power indicator of the product, since the created proportion directly depends on it.

For chainsaws with power:

- Up to 1.5 kW, the recommended ratio is 25 ml of oil per 1 liter of gasoline;

- Above 1.5 kW 20ml / l.

In gasoline for a chainsaw, it is allowed to add oil a little more than the recommended proportions (up to 5 ml per 1 liter). In this case, you should be extremely careful, because non-observance of the proportions can lead to breakdown, and as a result, expensive repairs.

If gasoline is diluted with a large volume of oil, then during operation the number of shock loads on the cylinder-piston system will be increased, and carbon deposits may also form, as a result of which the CHP will fail.

Adding a small amount of oil to gasoline for a chainsaw can lead to insufficient lubrication of the surfaces of moving elements, which will lead to additional friction of the elements and their heating, followed by the destruction of the entire mechanism.

How to dilute gasoline with chainsaw oil

The surest solution is to follow the recommendations specified in the instructions for the product! In the absence of such an opportunity, you can use a special fuel preparation formula.

Butter

According to the international classification, oils of the following markings are used for chainsaws:

- API-TB;

- API-TS;

- JASO-FB;

- JASO-FD.

- Use oil for 2-stroke engines only;

- Do not use the material after the expiration date;

- It is strictly forbidden to add mining (it contains many unnecessary impurities. harmful to the central mechanism of the chainsaw);

- You can not use chain lubricant (for each device: chain and engine. it is its own);

- It is preferable to use synthetics or semi-synthetics (during development, it almost does not form combustion products, but the price of such material is higher than that of mineral oils).

Formula

- High quality fuels and lubricants;

- Correct proportions;

- Mixing tools and technology.

Petrol

According to experts, it is necessary to use unleaded fuel with an octane rating exceeding 90. Gasoline A92 and Ai92 is considered ideal. You can use the 95th, but there is an opinion that it is better to refrain from this kind of gasoline, since some of them are made on the basis of the 92nd with the addition of additives. The latter, in turn, are harmless for 4-stroke car engines, but they will be superfluous for the “sensitive” mechanisms of 2-stroke motors.

It is recommended to use fresh gasoline for chainsaws, since when stored in cans the fuel can lose its octane properties.

Technology

Not only the quality and proportion of fuels and lubricants is important (although it is dominant in this matter), but where and how (how) gasoline is diluted with oil for chainsaws.

The technology provides for the use of containers with graduated divisions, some brands (along with chainsaws and oil) produce containers for mixing and storing fuel. Made of special non-combustible material, they are produced in the form of a canister or bottle, often endowed with measuring lines, and some of them have two entrances (separate for each type of fuel and lubricants).

Often, improvised means are used for mixing:

- Plastic / glass bottles;

- Syringe (no needle);

- Measuring cups;

When using household products, be extremely careful, as during the mixing process, when combustible material interacts with the surface of non-specialized containers, static electricity can be generated. this is fraught with an explosion. When making a mixture, oil is added to gasoline, since it has a higher density.

Petrol

According to experts, it is necessary to use unleaded fuel with an octane rating exceeding 90. Gasoline A92 and Ai92 is considered ideal. You can use the 95th, but there is an opinion that it is better to refrain from this kind of gasoline, since some of them are made on the basis of the 92nd with the addition of additives. The latter, in turn, are harmless for 4-stroke car engines, but they will be superfluous for the “sensitive” mechanisms of 2-stroke motors.

It is recommended to use fresh gasoline for chainsaws, since when stored in cans the fuel can lose its octane properties.

Fuel quality

If you want the tool to do its job perfectly and last for more than one year, you must provide it with fuel and lubricant of the proper quality.

What oil to use?

The oil, as already mentioned, should be for two-stroke engines. over, it should be suitable specifically for chainsaws, as indicated on its packaging. It’s just that there are two-stroke oils, for example, purely for outboard motors or scooters. They should not be used, since the operating mode of such equipment is not so stressful, therefore, the requirements for oil are somewhat lower.

At the same time, there are oils where it is indicated that they are suitable for both chainsaws and boat motors and scooters. This oil can be used. But if it is only for boat motors or scooters, then it is impossible.

Mineral or synthetics?

Yes, just like for cars, there are both mineral and synthetic oils for chainsaws. Due to the lower price, in most cases, mineral oil is used. However, synthetic provides a longer service life of the chainsaw, since no carbon remains on the cylinder walls with it.

But don’t be afraid of mineral oil if you can’t get a synthetic one. Although there is carbon deposits with him, there is not much of it. However, the service life of the saw with such oil will be slightly lower (but not catastrophic).

What you just can’t do is start using synthetic oil after you have used mineral water on your chainsaw for a long time (more than 100 hours). This is due to the fact that synthetics will wash away the accumulated carbon deposits and it can get in pieces where it is not needed. Therefore, if you started using mineral oil initially, then use only it.

What gasoline to use?

It is better to use AI-92 gasoline for modern chainsaws. It is better not to use the 95th. Firstly, because the saws are set up to work with 92 gasoline. And, secondly, 95th gasoline is obtained by adding special additives to gasoline with a lower octane number. And as experts say, this is not good.

In general, fill in 92nd gasoline and you will be happy. Just do not stock up on it, as its octane number drops during long-term storage.

In general, they say (they say!) That our refineries can produce only 80 gasoline in pure form. But already it is brought to the 92nd and 95th due to additives. In 95, there are naturally more additives. So, during long-term storage, these additives “evaporate” and gasoline again becomes 80th. True or not. I don’t know, but I learned this information back in 2009 at one of the seminars on servicing gasoline equipment from the head of the service department in Russia of one of the manufacturers of gasoline equipment. If this was true, then maybe today (2018) the situation has improved.

In any case, it is better to buy gasoline at proven gas stations, where you have already refueled and everything was fine.

Technology

Not only the quality and proportion of fuels and lubricants is important (although it is dominant in this matter), but where and how (how) gasoline is diluted with oil for chainsaws.

The technology provides for the use of containers with graduated divisions, some brands (along with chainsaws and oil) produce containers for mixing and storing fuel. Made of special non-combustible material, they are produced in the form of a canister or bottle, often endowed with measuring lines, and some of them have two entrances (separate for each type of fuel and lubricants).

Often, improvised means are used for mixing:

- Plastic / glass bottles;

- Syringe (no needle);

- Measuring cups;

When using household products, be extremely careful, as during the mixing process, when combustible material interacts with the surface of non-specialized containers, static electricity can be generated. this is fraught with an explosion. When making a mixture, oil is added to gasoline, since it has a higher density.

Correct proportions

So, I will not beat around the bush for a long time, but I will go straight to the numbers. The most common dilution ratios are 1:50 and 1:40. That is, one part of oil is poured into 50 or 40 parts of gasoline. For those who did not understand, I will explain in more detail. We take one liter of gasoline and divide it by 50 or 40, respectively. As a result, we get the right amount of oil for one liter of gasoline. That is, one liter is 1000 ml. Divide 1000 ml by 50, we get 20 ml of oil. Divide by 40, we get 25 ml. This is exactly how much oil you need to add to one liter of gasoline.

But you will say that you do not know what the proportion should be on your chainsaw. Well, if you have lost the instruction or for some reason there is no information about the proportion in it, then you can use the following rules:

- if the chainsaw and oil are from the same brand (for example, Stihl chainsaw and Stihl oil), then dilute gasoline with oil in the proportion indicated on the oil (usually 1:50);

- if the chainsaw and oil are of different brands, then observe the ratio of 1:40;

- if the brand is the same, but there is no information on the oil, then dilute in a ratio of 1:40;

- if nothing is known at all. you do not know either the brand of the chainsaw or the oil., then you still dilute in a ratio of 1:40. The main thing is to know that the oil is exactly suitable for two-stroke engines of chainsaws.

If the saw is new and runs in, it is recommended to increase the amount of oil for the first three fuel tank fillings by about 20%. That is, the proportion of 1:50 turns into 1:42, and 1:40 into 1:33. Or 24 or 30 ml of oil per 1 liter of gasoline, respectively. Well, I note here that in addition to increasing the amount of oil in the fuel mixture, no more running-in measures with a chainsaw are needed, unless otherwise indicated in the instructions. That is, it is not necessary, for example, to leave it idling for a long time or to cut it not at full speed, as this will lead to its overheating and faster failure. Always cut only at maximum speed. And after running out of three tanks of fuel (meaning the tank of the chainsaw), go to the usual proportions of 1:50 or 1:40.

But sometimes it happens that the manufacturer indicates a different proportion, compared to those that I gave above. For example, 1:25 or 1:32. In this case, these proportions must be observed. Although if you know about them, then what did you forget in this article?

How to properly dilute gasoline with chainsaw oil

The correct ratio of oil to gasoline is not a guarantee of a good mixture. It is important to choose quality ingredients, and in relation to the latter, pay attention to the following requirements:

- ethanol in it (aka gasohol) is not recommended above a value of 10%, and MTBE (which is methyl butylether) is up to 15%;

- gasoline should be homogeneous, without inclusions and cloudy sediment;

- additives, alternative fuel. use is strictly prohibited;

- octane number, it is, the detonation resistance of the component. not less than 92.

If we talk about oil, then only a specially designed liquid should be used in the preparation of the mixture, otherwise, any device of the mechanism may fail, in most cases the needle bearing of the connecting rod. Using branded oil designed for a specific chainsaw (you can find out about this from the information on its label), you will ensure high-quality performance and durability of the mechanism.

So, the following rules on how to dilute gasoline with chainsaw oil:

- use measuring cups, clean dry containers and graduated bottles;

- mixing should take place in a separate container, but in no case in the tank of the chainsaw;

- pour gasoline into the container, and after it there is oil, stirring the total mixture. Otherwise, the oil sticks and lingers on the walls of the vessel and interacts poorly with gasoline;

- the lubricant label indicates in what ratio the product must be mixed with gasoline to refuel the chainsaw. Popular proportions: 1:33; 1:40; 1:50. The ratios 1:15, 1:20 are less common; 1:25; Feel free to use a twenty-cube syringe when measuring oil;

- adhere to the rules of how to dilute the main fuel with oil. it is necessary for full-fledged work and your benefit, since an excess of the latter will lead to unnecessary expenses, and its lack will provoke overheating of the system;

- waste fluids are categorically unacceptable for two-stroke engines. Their use leads to premature wear and breakdown of individual parts;

- it is important not only to properly dilute gasoline with oil, but also to mix a certain portion, supposed to be produced in one working day. Weigh that the fuel cannot stay in the chainsaw for a long time, and the octane number is also decreasing.

How to dilute gasoline for a chainsaw

The specifics of the functioning of a two-stroke engine, namely, this is located in a chainsaw, is distinguished by the need to include oil in the main fuel, gasoline, for the full operation of the entire system. Different units and the motors themselves, as well as the characteristics of liquids, suggest a different dosage, which is why we propose in this article to consider the procedure: how to dilute gasoline for a chainsaw.

In many ways, the proportions of lubricant relative to fuel depend on the manufacturer. Stihl, Makkaloch, Husqvarna or domestic brands, but also on the running-in of the mechanism, its operating power. We will tell you about all the nuances related to the question: in what proportion to correctly form the fuel mixture, and if you do it correctly, you will be able to avoid many troubles in the operation of the chainsaw.

We dilute gasoline on our own together with the specialists of “Kosi Kosa

So, you already know how to dilute gasoline for a chainsaw, but in order to do everything perfectly, you need to allocate a secluded place for this procedure, clean containers and appropriate liquids: oil for two-stroke engines, clean high-quality gasoline. What kind of oil to dilute is a private matter for everyone, it is important that it be just motor, not chain. You also need to take into account that this fluid should be designed specifically for two-stroke engines.

Do you own a Stihl, Partner chainsaw or a sample of a domestic brand. remember the break-in moment if you use a new unit. Correctly diluted fuel will be one of the main criteria for long-term successful operation. And even if you have forgotten, or have doubts about the components, it is necessary to dilute gasoline with oil in a timely manner and competently, not forgetting to read the instructions once again. How much each ingredient is needed. you can always find out from the labels of the fuel products purchased from us. The shop of gasoline-powered tools “Kosi Kosa” is always glad to offer a quality product, services and advice on the competent operation of lawn mowers.

Petrol

The main component of the fuel mixture for chainsaw engines is gasoline with an octane number of at least 92. Consumables with expired storage, made on the basis of gas condensate, having water and mechanical impurities in their volume are not suitable for fuel preparation.

- The opinions of experts on the use of gasoline of different brands are ambiguous. On the one hand, the incomplete compliance of domestic A-92 gasoline with European standards is recognized.

- On the other hand, the quality of A-95 gasoline is questioned due to the high content of anti-knock additives. It is possible to use this fuel for the preparation of fuel for a chainsaw only with full confidence in its quality.

- The difficulty lies in the presence of various improving additives, with the help of which unscrupulous manufacturers and distributors increase the performance properties of motor gasoline with a lower octane index.

Also, irreversible changes in the working properties of the fuel occur when it is stored for a sufficiently long time in a plastic container, regardless of the level of its petrol and oil resistance.

Working proportions of the fuel mixture

The standard gasoline to oil mixture ratio for carburetor chainsaw engines of various models is 40: 1 and 50: 1. This proportion provides full lubrication of the rubbing parts of the crank mechanism and piston group, and also does not prevent the complete combustion of the gasoline-air mixture.

Taking into account external factors, the fuel mixture can be adjusted in the direction of increasing the amount of oil. Such a need arises at the stage of running in a new tool, as well as at high air temperatures. In this case, the standard oil dosage is increased by 20%.

In practice, an increase in the percentage of oil in the fuel mixture is used if its characteristics do not fully meet the stated requirements. How much oil per liter of gasoline is needed in each case is determined by the sawman himself.

Caution. fake!

Small private companies from China and other Asian countries specialize in the production of motor oils, which are sold at a lower cost in the markets under the trademarks of leading manufacturers.

- The characteristics of counterfeit products are an order of magnitude lower than those of the branded originals. The constant use of counterfeit products adversely affects the operation of the chainsaw and the durability of its operation.

- Only an experienced specialist can determine the status and quality of oil, therefore, you can avoid possible risks by buying consumable components in a network of branded and licensed retail outlets.

- The use of substandard lubricants for service specialists is a legal basis for depriving the owner of a faulty saw of warranty repair and restoration obligations.

Lubricants

Stricter criteria for the selection of the oil component. In the best variant, it is a mineral or semi-synthetic engine oil recommended by the manufacturer, intended for operation in high-speed, air-cooled two-stroke internal combustion engines.

The advantage of mineral oils is their lower cost. Their more expensive semi-synthetic and synthetic counterparts are distinguished by improved performance and compliance with environmental standards.

Synthetics:

- maintain working properties in a wide range of operating temperatures;

- do not form carbon deposits;

- contain detergents, antioxidants, preservatives and other additives useful for the operation of the power unit.

Benefits of branded oils

Many domestic and foreign manufacturers specialize in the production of special motor oils, but the highest rating indicators are for branded products Stihl, Husqvarna and Makita.

Only in certain parameters are the domestic motor oils of the Lukoil trademark inferior to the branded assortment.

The list of advantages of branded motor oils includes:

- economical consumption;

- stability of performance under difficult operating conditions and during long-term storage;

- minimum amount of toxic compounds in exhaust gases;

- almost complete absence of carbon deposits.

According to the American classification, API-TB oils can be used for work in household and professional models. The Japanese counterpart is JASO-FB and JASO FD. Preparation of a combustible mixture using oil for 4-stroke engines is strictly excluded.

Red, green or any other color of oil determines the product’s belonging to the assortment of a certain manufacturer, therefore, when determining the characteristics of the material, it is not taken into account. Be extremely careful when choosing a motor oil of unknown composition and origin.

Until you receive additional information about the quality and operational parameters, it is better to temporarily refuse to use such material.

It is allowed to mix motor oils of the same type in composition and purpose, produced by brands known for the quality of their assortment. Under no circumstances is it permitted to mix mineral and synthetic oils.

Dosage of oil in the Chinese version

Many chainsaws of the Chinese assembly are simplified copies of popular models of European design. The lack of special materials and proprietary technologies contributes to the preservation of the outdated proportion of gasoline and oil in a ratio of 25: 1.

The doubled consumption of engine oil is compensated by its lower cost. According to the developers, original components are introduced into the composition of Chinese oils, contributing to the increase in the durability of power units and the real extension of their assigned resource.

According to independent experts, the quality of the best brands of Chinese motor lubricants corresponds to those of European manufacturers in the middle price range. This is the level of branded motor oils of the Standard group and partially. Super.

Storage advice

It is better to prepare the mixture in an amount that should be enough to perform one-time work. The problem lies in the irreversible deterioration of the working properties of the mixture during storage. The finished composition is recommended to be used over the next few days.

A mixture of gasoline with a month-old oil impairs the traction capabilities of the engine. There is also the formation of resinous compounds in the fuel system and intense carbon formation in the combustion chamber, loss of mobility of the piston rings.

- With minimal damage to quality, it is advisable to store gasoline with oil for no more than 2 weeks. At an ambient temperature of 25 degrees Celsius or more, this period is reduced to 8-10 days.

- In order to save money, the expired mixture can be gradually consumed by mixing it into the fresh composition in an amount of no more than 10% of the total volume.

In order to avoid problems associated with the failure of the fuel system, it is recommended to filter the prepared mixture through a non-fiber material such as suede, or a fine-mesh twill weave, a metal mesh.