How to properly saw chipboard with a jigsaw

What is a jigsaw for?

Most often, an electric jigsaw is used to make wood products. This tool has found wide application in the furniture industry, where elements and parts of various shapes are made with its help.

If, when working with an electric jigsaw, you choose the right consumable and cutting mode, then you can:

- make straight and curved cuts;

- sawing circles without damaging the sheet;

- cut thin metal;

- to make products from wood up to 10 cm thick (the Dnipro-M LE-110R electric jigsaw model cuts 11 cm bars);

- cut plastic;

- sawing ceramic and porcelain tiles.

Whether a power tool can work with a particular material will depend on the power and type of the tool (household, semi-professional, professional). Not all electric jigsaws have additional functions, such as an angled cut or the ability to connect additional elements and tools. To find the right tool, read the article “How to choose a jigsaw”.

In this case, you also need to correctly select the saw blades. The pitch of the teeth, their length, material are taken into account.

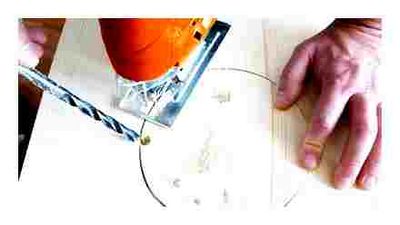

How to cut circles

Cutting a circle in a workpiece is one of the most difficult tasks for a beginner. But there is nothing incredible in it, since you can quickly learn how to work correctly with a jigsaw.

- Disable the pendulum stroke.

- Make the markup.

- Drill a hole for the saw blade.

- Install the compass and get to work.

You can make a compass with your own hands. To do this, you need a flat plate and a self-tapping screw. The jigsaw is securely fixed on the bar. Next, the required segment is measured (equal to the radius of the circle), and a self-tapping screw is screwed into the center, which will serve as the axis of rotation.

How to cut metal with a jigsaw

An electric jigsaw can serve as an alternative to an angle grinder in cases where you need to work with profiles, pipes, sheet metal. It is this material that gives the highest load on tools and files. Be prepared to take breaks from work and frequently change consumables.

The maximum thickness of metal that household and semi-professional jigsaws can work with is 10 mm.

Before cutting metal with a jigsaw, you need to select special saw blades.

Set of metal saws Dnipro-M T 118 A are made of solid steel and are perfect for straight cuts. Use the pendulum function to reduce wear and prevent melting of the working part.

How to cut plastic

Soft artificial materials, such as plastic, plexiglass, foam, are perfectly cut with an electric jigsaw. In terms of properties, they are very close to wood, and therefore the same consumables are used for sawing. The only remark: they cut plastic at low speeds, since at a high speed of movement of the blade, the edges can melt.

How to cut thin and thick wood

The electric jigsaw was created for working with wood, and therefore it is not at all strange that most of the work is carried out with this material. over, you can cut with equal success:

- solid wood;

- lumber;

- pressed wood.

Different webs are used depending on the thickness of the material. over, they will differ not only in length, but in the frequency and size of the teeth. The thinner the material. the smaller and denser the teeth should be.

To obtain a clean cut on thick wood, use saws with progressive teeth, which are gradually reduced.

How to make a curved cut

A curved cut, like a straight cut, begins with a marking. You should definitely connect a vacuum cleaner or turn on the purge to remove debris from the marking.

Sawing of figured products with a jigsaw is carried out without a pendulum motion. A narrow blade with fine teeth is used, which makes it easy to change the direction of travel.

7 uses of the jigsaw. instruction from Dnipro-M

The electric jigsaw is widely used for working with sheet materials. It will come in handy in repairs, carpentry or furniture workshop. With a jigsaw, you can cut soft wood, plastic, drywall, as well as complex materials such as ceramic tiles and metal. Depending on the hardness and brittleness of the material, as well as the type of cut you want to get, the technique of working with a jigsaw will have some peculiarities. In this article, we will talk about how to cut the most popular building materials.

Additional accessories

The jigsaw with an electric drive is a hand tool, however, if necessary, it can be secured using a stop bar and a parallel stop.

Sometimes you need to saw off a part covered with a layer of paint or varnish, and I really don’t want to scratch it. For this case, a plastic shoe or self-adhesive felt is provided.

In addition to files, rasp and grinding attachments can be installed on the tool. Thanks to the first, the corners are rounded, and with the help of the second they clean the finished product.

Some models provide for the use of a pendulum mechanism, due to which the sawing process is accelerated. This function is good for making rough cuts, as the quality and accuracy of the cut line will be reduced. When working with plastic and metal, the use of the pendulum mechanism is unacceptable.

When working with a jigsaw, a lot of fine dust is formed, which harms the respiratory system. You can get rid of it by connecting a construction vacuum cleaner to the nozzle of the device, which will suck in all the dust generated during the operation of the electric jigsaw.

If the purchase of two tools is not affordable, a jigsaw with the function of blowing the working area will be enough for work.

How to use a jigsaw correctly

Every man, being a real owner, should not only have repair tools in his arsenal, but also be able to apply them in practice. It will be about one of the modern tools, namely the jigsaw. Let’s figure out what kind of device it is and how to work with it.

How to prepare the instrument

It will be useful for beginners in this business to learn how to work with a jigsaw correctly, but first we will talk about preparing the tool for use:

- The first step is to carefully study the operating instructions for the electrical appliance.

- Visually assess the appearance of the device for damage: cracks, chips, cable integrity.

- Choose a saw in accordance with the quality of the material with which you have to work.

- Select the appropriate mode. Here are some examples: to work with soft tree species, it is necessary to set the maximum speed and apply a pendulum mechanism. If you need to cut a chipboard sheet, then leave the high speed of the cutting blade, but the pendulum mechanism will be superfluous here because it will contribute to the appearance of chips.

To avoid injury, you need to adhere to safety precautions when working with a jigsaw: wear protective goggles and gloves.

Device device

The electric jigsaw is designed for cutting various sheet materials. Depending on the purpose, jigsaws are:

- professional;

- semi-professional:

- household.

The differences lie in the technical characteristics and functionality of the tools.

Before you learn how to use a jigsaw, you need to familiarize yourself with its device. The tool consists of:

- Aluminum body.

- Electric motor. A powerful tool will be able to cut thicker and stronger material.

- Gearbox covers.

- Pendulum stroke control buttons. The pendulum mechanism allows you to make an accurate cut of materials with a low density (soft woods, plywood, foam).

- Covers and brackets for safe work.

- Support roller for sawing.

- Chip blowing regulator.

- Regulator of the number of strokes of the saw, on which the speed of its movement depends.

- Slab tilt adjuster. It allows you to cut wood at an angle of 15, 30, 45 and 90 degrees.

- Laser guide. Allows you to adhere to the drawn mowing line for cutting.

- Keyless chuck, which acts as a saw.

- Battery, thanks to which you can cut with a jigsaw for some time without being connected to the mains.

Choosing saws for a jigsaw

Saws are purchased separately and are selected depending on the material of the cutting blade and whether you need a straight or curly cut. The packaging indicates the purpose of the saws, what material they are made of, as well as the direction and size of the teeth.

What can you saw with a jigsaw?

- wood, plywood;

- drywall;

- metal;

- aluminum;

- Styrofoam;

- glass;

- ceramics;

- rubber;

- skin;

- carpets.

One or another type of saw is selected depending on what you need to saw off.

Consider the types of jigsaw saws and determine what each of them can do.

- With a wide canvas. Designed for cutting saw blades along a straight mowing line. With a saw like this, you don’t have to put in a lot of effort, just make a little directional adjustments. For a more accurate cutting line, you need to turn on the “Soft start” function, in which the motor gradually picks up speed.

- Narrow saw. Needed for cutting material along a curved mowing line. To cut with maximum precision, use a tilting tool. The head turn radius depends on the selected jigsaw model.

- With coarse teeth. Their purpose is to cut quickly, while the quality is poor.

- Saws with fine teeth and a thin blade can cut the most complex shapes.

The quality of the jigsaw depends on the method of fastening the saw. When processing thick sheets with a high density of material, it is necessary to use equipment with a rigid mount.

Working with blunt saws can lead to tool breakage due to the increased load on the jigsaw motor. And also the quality of the cut will decrease.

Markup

Marking is an important detail, because you need to avoid chipping on the front side of the part. Please note that chips are often formed on the side of the sheet towards the person working. Most often this applies to chipboard and fiberboard sheets. Based on this, the markings must be applied on the back side, and the canvas must be placed with the front side away from you.

For an accurate cut, you need to mark without allowances, and guide the saw near the mowing line of the marking. For the convenience of work, the workpiece must be secured using a bench clamp or a saw table.

Jigsaw tips

To find out how to properly saw with an electric jigsaw, our tips will help:

- Stronger is not better. This concerns the force of pressure on the device during operation. This style of sawing will break the tool. The correct use of the jigsaw is to firmly fix the device in the hand and direct the saw in the right direction.

- Vibration occurs when processing thin metal sheets. To eliminate it, you need to reduce the speed of the saw and put a sheet of plywood under the metal. When cutting such material, there is a large load on the jigsaw motor, so you should periodically turn off the device to cool the motor.

- For a high-quality and accurate cut, you need to fix the workpiece.

- To avoid chipping from the bottom or top side, for example, laminated chipboard, you must choose the right saw or turn the board the right side. But if there is a need to get a cut without chips on both sides, then on top of the chipboard you need to put a small piece of the same plate and start sawing. The chip will remain on the additional material, and the desired plate will be with a clean cut.

- To prevent chips from appearing, you can resort to this trick: glue adhesive tape according to the marking.

- When sawing brittle material such as plastic, we recommend installing a saw with medium-toothed teeth, turning off the pendulum mechanism and setting the saw speed to the lowest.

- In the event that it is necessary to cut out a part with a closed contour, and it is impossible to start sawing from the edge, then a hole is drilled in a convenient place, an electric jigsaw is inserted into it and work continues.

- To cut plexiglass or non-ferrous metals, the saw must be treated with machine oil.

We hope that our tips will help you, and if you have additional questions about how to use an electric jigsaw correctly, you can always watch the training video.

As it turned out, the jigsaw is an indispensable tool in everyday life that even a beginner can handle. And with the right approach and work experience, you can not only make straight cuts, but also cut out various curly details for decoration.

What tools can be used

Jigsaw

A jigsaw is the most popular solution at home, since the tool itself does not cost fabulous money, which means it is available for the average consumer.

Saw blades for cutting tabletops using a jigsaw should be selected in a small length (not exceeding 75 cm) with teeth of classes A or B, suitable specifically for chipboard.

In the process of cutting with a jigsaw, you need to make smooth movements with the tool without pressure at a speed slightly above average. Chips are most likely to appear on the opposite side of the slab from the one that includes the jigsaw teeth.

Chips in the process appear on the back of the plate and spoil the appearance of the part. It will be possible to remove them only with a milling cutter, and this is an additional amount of work and wasted material. Therefore, this tool does not suit us either.

- Than categorically it is impossible to saw chipboard

- What tools can be used

- Hacksaw

- Jigsaw

- A circular saw

- Fraser

- Panel saw

- Rules to follow during the sawing process

Hacksaw

This tool is used for the good old scratch method. I must say that it is difficult to achieve good quality sawing with a hacksaw.

The algorithm of actions in this case is as follows:

- First, we scratch or cut the measuring line on the material with some kind of piercing-cutting tool (for example, a knife) and glue adhesive tape over it. It is needed in order not to damage the laminated coating.

- We direct the hacksaw to the material at an angle of 30 degrees and smoothly move it back and forth. Chips from it in this case will definitely remain.

- If damage from a hacksaw remains, then we go through them with a file (from edge to center).

- The final stage is to process the slices of chipboard with sandpaper so that there are no rough edges.

The main advantage of a hacksaw is its availability and ease of use, but at the same time it does not perform the function we need to prevent chips, so we do not recommend using it.

Fraser

Another option for sawing laminated chipboard is the power tool for manual woodworking. It is used in tandem with a jigsaw. The process looks like this: first, cut the chipboard with a jigsaw, slightly moving away from the markings, and then with a milling cutter with a bearing that deepens the cut to the desired level.

The main disadvantages of this tool are that it is not as common as, for example, an angle grinder, and not everyone has it in the house. Well, its use is a rather laborious process, which only qualified specialists can handle, and beginners should not even approach it.

Panel saw

The most correct sawing and a guarantee of the absence of chips can be provided by only one tool. a panel saw, which belongs to professional equipment. Since the machine is very expensive and is mainly used in production, amateurs usually cannot afford it. The only optimal solution in this case is to turn to professionals. Companies specializing in cutting furniture parts usually use these machines in their work.

The panel saws have the following settings, which are set depending on the length and width of the board for cutting:

- position of the workpiece;

- the depth of the cut;

- cutting angle.

The machines themselves are divided into the following types:

- lungs (can work 5 hours);

- medium (can work from 8 to 10 hours);

- heavy (can work from 16 to 20 hours).

Components of the panel saw, which allow to ensure the accuracy and absence of chips in the manufacture of parts:

- the bed is the fixed base of the machine on which all other mechanisms are attached. The heavier it is, the better for cutting, since this eliminates vibrations and vibrations that can interfere with the process;

- undercutting unit. an element that pre-saws the workpiece of the part and serves so that there are no chips from below;

- the main saw serves for the final sawing of the slab and is responsible for a clean cut without chips from above;

- desktops. there are only three of them. The first is stationary and serves as the basis for the scoring unit, the second is movable, and on it the plate is fed to the disk, the third serves to support the parts that are sawn off from the plate;

- carriage. part of the machine that provides the formatting table with the ability to move;

- stops and rulers are components, the main function of which is to fix the slab in the desired position.

The design of panel saws allows them to provide such precision in cutting laminated chipboard parts for furniture that no other tool can guarantee. In addition, this is the only way that allows you to completely avoid chips.

How to cut chipboard without chips: correct sawing

And one of the most important stages of home furniture production is sawing. What affects the quality of the cut, how can it be done and under what conditions? And is it possible to do without chips, without resorting to professionals, but taking the whole process upon yourself? Let’s take a look at all the issues related to cutting in order in our instructions. And since laminated chipboard is one of the most popular and budget solutions for home-made furniture, we will focus on this material.

We saw with a jigsaw evenly and without chips

The electric jigsaw is the most convenient and versatile tool for demanding woodworking. It can be used to produce artistic carving, preparation of various parts for joinery and other tasks.

Cutting instructions

Before starting work, you need to drill a hole in the plywood for the jigsaw blade.

You don’t need to be an expert in this area to cut straight circles with a jigsaw quickly and beautifully, but for a beginner it can be a very difficult task. In this case, the main thing is patience and, of course, the availability of the necessary accompanying tools, such as the jigsaw itself, a file, a compass, a simple pencil and tools for polishing the surface.

The first thing to do is draw a circle on the surface of the material you will be working with. It would be best to use a compass or find a suitable circle and circle. It is necessary to trace with a pencil so that traces from it can be erased in the future.

If it is necessary to cut a circle inside the surface, then a through starting hole should be made. Next, you need to insert a jigsaw blade or a file into this hole and fix the free end of the file with a clamp. It is recommended to saw out while sitting. First of all, you need to fix the file in the jigsaw with a key, while keeping in mind that the teeth of the file should be directed downward.

Smooth cut with a jigsaw. how?

Accuracy problems

Consider how to cut with a jigsaw exactly:

- The processing object must be securely fastened. over, in such a way that it was convenient to make a cut.

- In case of extreme uncertainty or for greater assurance of accuracy, it makes sense to use guides. For straight sawing, you can use a block of wood fixed along the line as a guide. If the shape of the cut is complex, then the situation becomes more complicated. In this case, you can use patterns, if any, or you will have to reduce the speed of work due to more accurate guidance of the jigsaw.

- One of the options why the jigsaw cuts crookedly is a problem with the saw. It may be dull or has chipped teeth. Noticing that the jigsaw literally turns itself wherever he likes, inspect the saw.

- Jigsaw breakage. For example, if the motor is jerky, the likelihood of a crooked cut increases dramatically. Likewise, other failures of the mechanism can lead to a drop in accuracy. Such problems are difficult to fix on the spot, as diagnostics and possibly repairs are required.

- Finally, the skill of the performer greatly affects the accuracy of the work. If you are an aspiring carpenter, do not be upset with periodic failures: precision comes with experience.

How to cut smoothly with a jigsaw: recommendations

If this is the case, then it is better to make the cut with a circular saw.

How to make a device with your own hands

The cut-off device is made for a specific model of power tool. Measure the distance from the motor to the bottom of the sole on your circular saw and subtract 5 mm. The result is the height of the guide fence.

Removing the desired dimensions of the circular saw.

Prepare right-angled plywood base and parallel-edged wooden battens to measure.

Blanks for assembling a cross-cut device with a circular saw.

Measure the distance from the blade to the edge of the sole.

Add a 6-10 mm allowance and install a guide rail at this distance from the right end of the plywood. Fix the bar with countersunk screws, controlling its strictly perpendicular position.

Screw the stop block on the back and fix the fixture on the workbench.

Cut the plywood with a circular saw to the final width, creating a reference end for precise positioning of the fixture along the lines.

Draw the eccentric cam pattern on the paper.

Eccentric clamp drawing.

Mark the part on 10mm plywood and mark the center of the bolt hole with an awl.

Saw the workpiece with a jigsaw.

Make a 50 mm washer out of the same plywood using a ballerina wood drill.

Grind the blanks and pick up an M6 or M8 furniture bolt with a mustache (or with a square headrest), a handwheel nut, washer and bushing. The latter can be made from a tube of a suitable diameter. Sleeve length is the total thickness of the base, arm, and plywood washer.

Ready-made eccentric from plywood.

Make holes in the base with a drill according to the diameter of the sleeve, which serve to rearrange the eccentric clamp according to the width of the board to be cut.

Hole drilling pattern.

Assemble the eccentric mechanism: insert the bolt with the sleeve from above, and from the bottom insert the wooden washer, the cam itself and the steel washer. Tighten the parts with a nut.

Glue a strip of sandpaper on the inside of the stop to prevent slippage when the eccentric gets locked, which can occur when the fixture is attached to a smoothly cut workpiece.

The clamping system of this device has a stroke that ensures fastening on the boards with a take-off in width of about 10 mm. If you need to cut or trim different size workpieces, just place a wooden backing in front of the stop bar.

An example of using a device for a cross-cut with a hand-held circular saw of a board of smaller width.

If desired, the potential of the considered device can be expanded by adding a cutting angle of 45 °. To do this, you will need to slightly increase the dimensions of the support platform and install a second thrust bar at this angle.

Smooth cutting of material with a jigsaw

For example this. But they, too, do not always provide a cut without chips. And what to do?

Let’s see why chips occur. Watch how the chip appears. When the fine file goes down, the teeth come out of the material, practically without sawing it or forming any chips. On the contrary, they saw up and the teeth at the exit catch the material and break it out. Adjacent fibers cling to a tree, chips with chipboard on chipboard.

Now try to cut two layers of chipboard at once. You will find that the bottom layer has been cut cleanly on both sides. If you think a little, it is not difficult to understand why this happened.

This happened because the top layer of chipboard did not allow chips to form.

With these small observations and experiments, you can fairly easily solve the problem of cutting with a jigsaw without chips. So what needs to be done?

I want to draw your attention to the fact that when drilling holes, the same picture is observed: at the exit of the drill, chips are also easily formed, so you need to press some unnecessary part from the exit side of the drill when drilling through holes.

Carpentry Tricks Jan 21, 2014

Straight cutting technique: nuances you need to know

Any device has additional accessories. They allow the entire process to be made more precise and simplified. It is believed that cutting plywood with a jigsaw is the easiest process, since the material is not very thick. Sometimes it is necessary to saw small parts. How to cut plywood straight with a jigsaw?

The use of a clamp is always necessary. The same applies to the table. it is fixed using such an installation. But the cutting process takes place in the opposite direction. But the movement is not produced by electrical equipment, but by a part. Experts believe that this is how the mowing line is accurate and correct.

Many beginners may be faced with the problem of clamping the saw. But how do you deal with it? Many people often use a replaceable insert. This applies to additional tools. In this case, the material for creating such a component is taken from the most varied. And it is fixed to the sole of the electrical installation. And already with the use of components such as a guide bar and an adapter, a precise line is obtained.

Sometimes, when sawing, the material starts to heat up, and the process will simply slow down. In such a situation, it will be necessary to cool the material. For this, simple cold water is used. It is fixed to the support sole. Often people have a question about how to cut laminate flooring smoothly with a jigsaw. Everyone knows that this is a tree, for this reason the same principle applies to it. In the process of laying a laminate board, just such a tool helps to make the process easier.

It is better to cut from the back, and the smallest saw is taken for this. This helps to avoid deformation along the mowing line of the cut. It is with metal parts that heating occurs. Here you need a cold liquid, and for a tool. machine oil. The thinnest saw is taken to create a mowing line of any shape. Another addition is a circular cutter. Before installing it, make a hole in the center.

Why the jigsaw saws crooked

You can achieve a straight cut with a conventional jigsaw. To do this, use the ruler that should come with the kit. To control the sawing process was easier, you need to reduce the speed.

Novice craftsmen often face a problem: when cutting, the jigsaw leads to the side, and the cut is obtained at an angle. To cope with this, you need to study in detail the process of correct and even cutting.

There are several reasons for an uneven saw:

- the saw is blunt;

- too much pressure is used;

- there is a slanting in the wood.

Material that is too thick can be one of the reasons for crooked cuts. As a rule, thin wood is easier and easier to cut. The jigsaw may have poor mechanics. in which case it needs to be replaced. You can check the quality of the jigsaw by moving it from side to side. If it dangles, then it is a cheap tool for rough work. To get an acceptable result, you should cut with a margin, and trim the edges with a hand cutter.

Another effective way to learn how to cut straight with a jigsaw is to draw not one line on the workpiece, but two parallel ones. This will make the cut smoother.

Features of the operation

- What you need to know about working with a jigsaw?

- How to make a high precision cut?

Many people ask: how to cut with a jigsaw exactly? A similar question arises for almost everyone who did not previously have the skills to work with such a tool. A few useful secrets will help you master the jigsaw and learn how to cut any material evenly.

Jigsaw device diagram.

With a jigsaw, you can cut materials such as wood, tiles, metal and even plastic. This tool is a conventional electric saw.

The device can have an ordinary vertical or pendulum stroke, in which the jigsaw, when raised, moves slightly forward, thereby increasing the speed of work. An electric jigsaw in the household is simply irreplaceable, especially for those who like to craft with their own hands.

Before you start sawing with a jigsaw, you need to familiarize yourself with the technology and prepare the workplace. The table on which the sawing will take place should not wobble, it should be stable, not move when pressed.

Diagram of cutting a circle with a jigsaw.

In order to cut an evenly wide surface, it is necessary to use a special carpenter’s table, which is attached to the main table with clamps. In this case, cutting is much easier, since the tool remains in place, and the material being cut moves towards it.

To make the cut on a wooden surface even, it is performed from the back side (necessarily across the fibers).

If, nevertheless, you need to cut wood along the grain, then use a special parallel stop, which is attached with one side to the tool, the other to the surface to be sawn. Do not let the tool overheat, take breaks from work, otherwise the service life of the jigsaw will be short. For the same reason, do not press down hard on the tool, as this will cause overheating.

When working with tiles or metal, machine oil is used to lubricate the saw blade. When cutting metal, the cutting line is cooled with cold water. Do not neglect personal protective equipment, use goggles and rubber gloves. You need to cut the plastic with a jigsaw from the back side, then the cut will be even.

To cut a round hole, use a special circular cutter.

- jigsaw;

- wood;

- clamps;

- guides;

- Ruler and pencil.

Jigsaw accessories.

Can you cut chipboard with an electric jigsaw? (13) #StayHome and make a kitchen cabinet #WithMe

In order to make a high-precision cut, it is not enough to know how to properly saw with a jigsaw. In addition, you need to secure the material to be cut well, and when working with a long blade, use a guide in the form of a flat rail. Prepare 2 clamps to fit the board to be cut and the guide.

The first step is to mark the board, measure the required distance on both sides with a ruler, make notes, then connect them in such a way that you get a cut line.

If you need to make a curved cut, then draw it first on paper, then transfer it with a carbon copy to the wood.

In order to transfer the drawing exactly, it is necessary to sand the surface before starting work.

Next, the board is laid on the work surface, it is well fixed along the edges of the table, after which the clamps are placed in front of the table. A guide is laid on the board, stepping back from the cutting line of the cut a distance equal to the width of the tool.

With the help of clamps, the board is clamped with the guide located on it, the fastening must be strong, but not too strong.

After the board is secured, you can start sawing. A special wide saw for cutting wood is installed on the jigsaw, the tool is set at maximum speed.

At the minimum speed, the tool overheats, so it is better not to use it. The pendulum stroke regulator must be set to number 1.

Next, they begin to cut, while pressing down the edge of the platform and the guide.

If you need to make a square or rectangle, then first cut out one side, reaching the corner, go around it with a smooth line, then the turn of the second side comes, etc. The corners are drawn up last.

By following these recommendations, you can do the jigsaw work yourself.

First you need to choose the right file

for a jigsaw. The variety of files allows you to choose the option that will correspond to both the material of the original workpiece and the final required result.

In general, a jigsaw can be with a pendulum and with a normal stroke. In the second option, for an even cut, the blade must be moved clearly vertically, cutting the material upward. Due to the high generated speed, the blade wears out more slowly.

When working with a pendulum stroke tool, the principle is essentially the same, only the preferred material for processing is soft wood or plastic, difficulties with steel can arise.

In order to make a straight cut, it is necessary to choose a wide blade, it is better if the jigsaw has the “Smooth start” function, which will avoid sharp movements at the initial stage.

If you need to cut a round hole, you first need to drill the original version, inside which the necessary file is inserted.

Sawing along the edge of the workpiece is allowed, but you must make sure of its initial evenness, without this the jigsaw cuts crookedly. If the edge is uneven, then only correct marking can fix it.

When working with thin wooden sheets, there is a risk of chipping. To prevent this, the sheet should be placed face down.

.

The names speak for themselves. In the first case, the panels are installed vertically, the beam, installed on the guides, acts as a bracket. The ability to rotate it to a right angle allows you to cut the material in any plane. The horizontal version assumes the presence of a sawing table, the mechanism itself and a carriage that ensures the movement of the saw along.

How to cut straight with a jigsaw? Before starting work, it is worth finding out the whole process, otherwise you will not be able to come to the desired result. Often, when working with any material, you need to create a cut with maximum accuracy. It is the electric jigsaw that will do the job.

Here’s what you need to do this:

- Material for work.

- Jigsaw.

- Guide tools.

- Clamps.

- Pencil.

- Construction tape.

Why do chips appear

Before cutting chipboard or laminate with a jigsaw, it is advisable to understand why chips are formed when cutting sheet material. And the answer is simple: everything lies in the construction of the jigsaw, or rather in the construction of the nail file.

So, in the process of cutting, the nail file receives return movements (up and down). And if when the file moves along the teeth (usually down), chips practically do not form, then when the tool moves in the opposite direction, the teeth seem to pull out the top layer of the material, thereby forming an impartial chip. That is why you can observe an almost perfect cut on the lower side of the chipboard and a cut with chips along its upper edge.

The subtleties of sawing chipboard at home

In large industries, special technologies are used to solve this problem, but it is not always possible to apply them at home. For example, if you need to cut about 20-30 sheets of chipboard, then it is very difficult to remove all the resulting construction waste.

The best solution that many people resort to today is sawing chipboard at the stage of purchasing sheets. But there are those who still prefer to cut with their own hands, that is, on their own.

But remember, in this case, you yourself will have to solve all the problems during the cut. To avoid them all the same, heed our advice.!

For the implementation of high-quality and accurate cutting, we suggest using several recommendations of specialists.

For example, it is advisable to cut at home using the most ordinary carpentry saw, with fine sharp teeth. When using such a tool, you can get an even, clear and high-quality cutting of the chipboard cut. To do this, the saw must work, leaning at an acute angle to the surface of the chipboard sheet.

For additional protection, you must use the following method: stick adhesive tape on the cutting line, this method is ideal in the case of cutting laminated chipboard.

During work, you must adhere to strict technology and be as careful with the material as possible, as well as be consistent in your actions and not rush anywhere. If you do everything very quickly, then chips may appear on the surface of the building material, which will worsen the appearance of the finished sheet.

If everything is done correctly, then after the completion of the work, a perfectly flat edge is formed, there will be no need for additional processing of the sheets. If everything was not done as accurately as possible, then in this case it is necessary to level the uneven edge with a planer, rasp or file.

How to Cut Chipboard Smoothly Angle Grinder?

When cutting on a curly mowing line, turn the plywood, not the jigsaw, while cutting. this will reduce the likelihood of breaking the saw.

When cutting sharp corners, move the file in place, gradually turning the plywood.

You should have free space. the hole in which the file will turn, now continue to cut in the desired direction.

Make free space for turning the file on that part of the plywood that will be thrown away and you will easily get sharp corners.

After the entire contour of the drawing has been cut out, the sawn out part can be freely removed from the plywood.

Now, in order not to break the file, insert it into the cut from which the part began to be cut and smoothly moving the jigsaw up and down, but only pull it out of the plywood with the back of the file.

Saw out the second piece of the Christmas tree in the same way.

Sand the resulting parts.

Now we have two parts of the herringbone ready for assembly.

Putting them together in one structure.

Now let’s paint the Christmas tree with watercolors or gouache.

All our Christmas tree is ready.

And at the end of the lesson, we will show you the sequence of cutting the inner holes in detail. Let’s say we need to cut out a part of the circle.

In the middle of the part to be removed, pierce a hole with an awl. Do not try to make a hole close to the drawn mowing line, this can cause the plywood to chip off, which will be rather ugly.

Having loosened the upper clamp of the jigsaw, and having released the file, we insert its upper end from the bottom into the punctured hole.

Clamp the file into the upper clamp of the jigsaw and cut out the part of the picture to be removed.

Then we release the file from the upper clamp again. And we repeat this operation with each inner hole of the picture.

The herringbone turned out to be stable and quite strong, for greater stability, the abutting parts of the parts can be coated with some kind of glue that does not leave marks on the tree. this is PVA glue, carpentry or casein.

In order to make a thrust platform for a jigsaw, it is enough from any dense material (for example, from a laminate) to cut out a rectangle in dimensions identical to the dimensions of the sole of the power tool.

Then, on the larger axial mowing line, a cut should be made and the resulting equipment should be fixed to the sole of the jigsaw using insulating tape or double-sided tape. All revision is ready and you can carry out finishing work in compliance with certain recommendations.

First, as mentioned above, you should use a file for a jigsaw with a straight cut.

Secondly, in order to better control the cutting process, it is justified to apply a marking line on both sides of the chipboard and check the processing accuracy from above and below.

And thirdly, take constant breaks from work to cool the cutting equipment.

Sometimes the solution to this issue can be a simple cutting of the leminated layer of material using an assembly knife, and subsequent work with a jigsaw will no longer cause large defects in the form of chips. However, this work requires a certain experience and accuracy from the performer.

Any craftsman should know how to work with a jigsaw. This is one of the most popular tools in the home workshop: it is convenient for them to cut wood, plywood, chipboard or fiberboard, metal sheet, and various types of plastic. With a jigsaw, you can cut out a part of almost any shape, if you approach the work correctly.

The jigsaw is an irreplaceable tool in construction and repair. It can be used to cut or cut holes in building materials.

Like any household power tool, a jigsaw does not work automatically, it requires skills, experience, dexterity, and a thoughtful approach. It all starts with the choice of tools and consumables. This is not a trivial task, considering that there are about a hundred models sold only by well-known manufacturers.

How to cut off chipboard at home evenly and without chips?

It is used in various sectors of construction, because all the technologies for working with this material are very clear and accessible. Everyone who has ever dealt with chipboard knows how to cut this material.

But the apparent simplicity of cutting this material requires knowledge of all the subtleties in order to avoid damage to the sheets. If the cutting technology is violated, irreparable difficulties may arise, so you need to know how to avoid them in the process.

How to cut with a jigsaw correctly and evenly?

In order to cut smoothly with a jigsaw, you must act as follows:

- Before starting work, it is necessary to strengthen the material with maximum strength. Cutting along the grain is strongly discouraged as it is very difficult to achieve evenness in this case. In this regard, it is best to use a circular saw; in the absence of such a tool, you can use a parallel stop. Such a parallel stop must be attached to the jigsaw with one end, and the other end must abut against the edge of the workpiece. This is how the most even cut is made.

- If it is necessary to make a cut inside the workpiece, then first a hole is made in the circumference. Then insert a jigsaw into the hole made and start moving in the direction of the marking. After the desired hole has been cut, the corners of the workpiece are easily corrected on both sides.

- In order to cut correctly with the jigsaw, you should not use force when pressing the tool. Otherwise, the blade will quickly heat up, which can lead to breakage. You should not use one file for a long time, as it becomes dull rather quickly. And such a file makes scuffs at the edges of the material, which significantly impairs the quality of work. When it comes to cutting materials of increased hardness, then the blade must be lubricated with a small amount of machine oil. Thus, it will be easier to work with a file, in addition, the service life of the file will significantly extend.

- When working with a jigsaw at low speeds, the jigsaw needs a break, since in this process, engine overheating often occurs. In this case, it is necessary to strictly observe safety precautions, the presence of protective glasses and gloves is simply necessary. After the work is completed, the tool must be cleaned and lubricated.

Diagram of a homemade jigsaw.

An electric jigsaw is available with a pendulum and normal motion. When the stroke is normal, then the blade must be moved vertically, while the material is cut when moving up. The working speed is quite high, the blade wears out much less.

As for working with a jigsaw with a pendulum stroke, the principle of operation is the same, but it must be borne in mind that it is best to work with soft wood and plastic, but it is better to refuse cutting steel sheets with such a tool.

If you need to cut a round hole, then an initial hole is drilled in the workpiece, then you need to insert a file there.

Then you should cut along the mark. If you want to make a hole in the form of a square or rectangle, then cut it along a straight line of the mowing line. Then the cut out area is removed and the remaining parts, which are in the shape of a triangle, are cut out.

If it is not possible to make a starting hole in the workpiece, plunge sawing is advisable. This tilts the electric jigsaw forward until the saw reaches the workpiece. Thus, the file makes a through-type hole in the workpiece. Using a jigsaw, you can cut bevels.

When working with a jigsaw, it is necessary that the table is stable, the material is securely fixed and the correct saw is selected.

Sawing with a jigsaw so that everything is smooth is not at all difficult. A guide is attached to the tool, which is then wound over the edge of the workpiece.

If everything is done this way, then the movements of the file are carried out smoothly and without much effort. In the event that the edge is curved, it is necessary to cut out according to the markings, which must be done before.

If it is necessary to saw a sheet of wood that has a small thickness, chips may appear.

In order to prevent this phenomenon, the workpiece must be placed face down.

To carry out the work with such a tool with maximum efficiency, there is no need to use anything else. Nevertheless, to increase the “working capacity” of the jigsaw, there are some additional devices.

When machining small workpieces, it is very important that the work is carried out with maximum precision. For this, it is recommended to have a special table that is designed for sawing.

In order for the jigsaw to easily process any surface, it is permissible to use another additional device. a replaceable plate (the materials used in its manufacture are very different). This removable plate neatly attaches to the support sole.

It should be borne in mind that there are materials that need to be pre-cooled and only then start to process. Therefore, it is necessary to have a tank filled with cold water. To work with such a tool was easy and convenient, you must regularly use a lubricant. It is used for cooling and lubrication, as a result of which the service life of such a tool will be significantly extended.

When You Only Have a Jigsaw to Make a Straight Cut

In this lesson, we will show you the basics of working with a conventional hand-held jigsaw. Of course, a jigsaw can also be electric, but it costs a lot of money, and working on it is already a pursuit of speed, and not a calm, moderate creation of beauty.

For work, we need: a hand jigsaw, a file, a table stand, a clamp for attaching the table stand, an awl, a pencil, two paper clips, a sheet of tracing paper, a sheet of carbon paper, sandpaper and, of course, a piece of plywood of the required size. We will cut out a Christmas tree, in this work, in addition to the cutting technique, we will also master the technique of assembling plywood parts into a three-dimensional shape of a Christmas tree and the easiest way to finish the finished product using ordinary watercolor paint.

The size of the plywood should correspond to the pattern you have chosen, try to arrange the cut parts more compactly, tighter to each other, since everything that remains after cutting out, as a rule, can no longer be used in further work due to its fragility. And so we clean the selected piece of plywood with sandpaper, trying to drive it along the fibers, since the transverse scratches will be strongly visible on the finished product and they are very difficult to remove later, and the processed plywood looks velvety and soft.

The sandpaper should be medium grit so that it will scratch less plywood.

Fasten the tracing paper sheet and the drawing with clamps, then copy the drawing onto the tracing paper with a pencil. This operation is necessary in order not to damage the original drawing when transferring it to plywood.

It should be noted right away that with the current level of distribution and availability of a copying machine, with large-scale and complex drawings, it is good to use a copier for cutting out and the necessary drawing just needs to be copied onto a blank sheet of paper and then transferred from it to plywood.

Having transferred the entire drawing to plywood, we carefully check whether all the mowing lines of the drawing are clearly visible on plywood.

At the next stage, it is very important to check the future nodes of the interconnection of the herringbone parts.

To do this, a piece of plywood of the same thickness that we are using needs to be attached to the drawn groove of the Christmas tree part and make sure that it fits exactly in the drawn borders. If the dimensions of the groove and the thickness of the plywood do not match, the width of the groove is adjusted. it is drawn equal to the thickness of the plywood used. Otherwise, when assembling finished parts, they will dangle or simply will not fit into each other. This is how all grooves in all drawings of parts are checked.

We take the stand and insert its clamp into the central hole.

We attach the stand with a clamp to the edge of the table, windowsill or workbench.

If your file is not inserted into the jigsaw, then we do it in the following sequence. We loosen the lamb of the lower clamp of the jigsaw (after turning the handle down to the working position). Insert the file into the lower clamp.

The direction of the saw teeth should be as in figure “b”. this is very important.

Then, having loosened the lamb of the upper clamp, insert the upper end of the saw into it and put the jigsaw on the stand, press it with effort and screw the lamb tightly. The file should be taut. But excessively strong tension can lead to breakage of the file during curly cutting, and a weak tension of the file will also lead to this. So everything should be in moderation.

The position of the body when cutting should be as shown.

When cutting with a jigsaw, you need to smoothly move your hand up and down, up and down, observing the position of the file so that it does not tilt from the vertical position.

In the process of self-production of furniture, the contractor may need to cut or trim laminated chipboard for subsequent use. Of course, it is best to perform this operation on sawing, however, if necessary, and to reduce the labor intensity, it is quite possible to cut the chipboard at home (using a jigsaw). over, it is very important to implement this procedure in such a way as to minimize the number of chips and thereby form an even cut.

When preparing a jigsaw for use, you must adhere to the rules for working with an electric tool. It is necessary to inspect the device for damage, check the condition of the power cable and the connection to the power supply network. Working without safety glasses and gloves is prohibited by safety regulations.

To work with different materials, it is necessary to select specially designed canvases for them and correctly configure the appropriate modes. For example, for soft woods, you can use the pendulum mechanism and the high speed of the saw. To cut laminated chipboard, to avoid chipping, the pendulum mechanism must be turned off, but the saw speed must be kept high.

High-quality markings of the material, thick, well-visible fishing line are the guarantee that the exact figure that is needed will be cut. It is good if the tool has a laser guide. It will help maintain the correct line. If not, you can navigate by the marks applied to the base plate.