How to pull the line out of the Stihl trimmer spool

How to thread the line into the Stihl trimmer spool

The trimmer is one of the most common tools that you can use to quickly and easily cut grass, small shrubs, lawn grass and other weeds. It’s not a secret for anyone that in order for the mowing of grass to be successful, it is necessary to use the tool correctly and correctly handle individual cutting elements.

In trimmers, it doesn’t matter what fuel they use, special cutting attachments (knives, discs) are used, and some trimmers are supplied to the market in the heads of which such a cutting element as a fishing line is installed, and therefore many are wondering how to fill the line into the Stihl trimmer coil if there are no skills as such.

- Cutting attachments in the form of knives can be sharpened, but the fishing line (also cutting elements), but tends to be consumed. Below we will talk about how to properly thread the cutting element into the Stihl trimmer spool. fishing line.

articles

The process of winding the line on a reel

- After all the preparatory steps, we need to correctly determine how exactly the fishing line will be washed on your device, by turning the lid or in the opposite direction.

- We measure out about 7 mm of cutting material and insert it into the hole of the bobbin with one end. It is worth noting that the line is wound exactly on the style mower model from both sides. The direction of winding the line in such models is indicated on the bobbin itself.

- The line is brought out to about 17 cm freely so that the ends can cut the weeds. We add that it is not worth winding the line on a reel of great length. Leave a distance of about 5 mm from the line to the edge of the bobbin.

- The two ends of the line are inserted into the holes in the bobbin. Both of these ends must be securely attached to the body of the device.

- The springs removed from the coil (if any) are inserted in the same way as they were removed, i.e. into the bobbin and the head body itself.

- To determine if you have correctly inserted the line into the trimmer, you need the element itself (bobbin) to be easily inserted into the head body of your device. If necessary, pull the free ends of the line outward. To achieve this, you need to pull the line out of the groove with a sharp movement through the holes in the bobbin.

So, let’s say you figured out how quickly, and most importantly, to correctly wind the line on the Stihl trimmer reel. All that remains for you is to insert everything correctly into the grooves and fix the main cover to the device. Then you can press on the bobbin itself and make counterclockwise movements until you feel the stop. If you do not feel the emphasis, then most likely you have not tucked the line correctly and you will have to start everything from scratch.

Preparing the trimmer spool for winding

Initially, as a rule, the coil is installed to the head of the device itself. The coil consists of two parts. a cover and a spring.

- Whichever company you have a trimmer, the preparation steps are the same for all types. Disassemble the device, or rather, remove the coil from the trimmer head. To do this, until it stops, press the latches located on the sides of the head body, and turn the head clockwise.

- To open the mowing head without any problems, press the side latches, if you cannot do this with your hands, use a flat screwdriver to help. We take out the coil from the head.

- In order to choose the right line for your equipment, on the inside of the reel, digital designations must be applied, which indicate the thickness and type of acceptable line. All designations are indicated, as a rule, in millimeters.

- If you did not find any numbers, then the maximum allowable diameter of the fishing line can be determined by the through hole for inserting the fishing line. The line should run smoothly back and forth.

A couple of tips

If the line was wound correctly by you, then when you press the bobbin button, the cutting element should be automatically pulled out. The line for your mowing device is one of the most important elements, without which the trimmer can lose all its functionality. You could say that the line (cutting element) is the heart of your mower. Therefore, when buying a fishing line, pay attention to its quality first. When purchasing a fishing line of a particular company, be sure to compare it with the quality of the old fishing line.

What can be used instead of fishing line

- If instead of a special cutting element, say a fishing line, you install a metal cable, then your trimmer can “turn” into a real dangerous weapon not only for you and your eyes, but for all the people around you nearby. This is due to the fact that while the trimmer is in operation, the steel cable will constantly work, which will lead to entanglement, and small pieces of it can scatter on all sides with great speed.

- The same can happen if you use copper wire instead of a steel cable, but in this case the pieces of separation from the copper wire will be slightly larger and can cause you even more injury. And if God forbid, you accidentally catch such a cutting element on the leg, then after that a deep cut in soft tissues is 100% guaranteed, and in some cases, all this can lead to amputation of small limbs (fingers) of the legs and even hands. Therefore, our advice to you, do not use any other cutting elements, except for the fishing line, for your own safety and those around you.

Automatic line winding on a spool

There is a type of reel in which the automatic mechanism winds without the help of others. from the user it is enough to just fill the line correctly. How do I load the line into the trimmer spool? Video instruction. How to remove the spool from the trimmer? How to wind the line in order to tuck the line. The fishing line is passed through a hole on the inside of the body, its antennae without winding are passed through the hole on the outer body, the reel is assembled, and when the winding button is rotated, the fishing line is wound from the inside without the help of others. In such a spool, it is unrealistic to make the winding wrong: the mechanism itself will determine the correct direction, since it can only rotate in one direction.

The warranty production of the factory trimmer refueling will inevitably require line replacement. Having a very rough idea of how to thread the line into the trimmer reel on their own, beginners are reluctant to take up this business. However, with some skills, mastering this simple science does not present any difficulties, and the similar instruction presented below will make this process as easy as possible.

How to correctly replace the line in the mowing head, reel of STIHL FS 55 lawn mowers

We carry out the winding of the fishing line

Sluggishly completed disassembly of the spool-spool without losing its spare parts allows you to proceed to the main task. winding the fishing line into the spool. Technological features of the spool design and the number of working antennae determine the sequence of actions.

We carry out the winding of the fishing line

Slowly completed disassembly of the spool-spool without losing its spare parts allows you to proceed to the main task. winding the fishing line into the reel. Technological features of the spool design and the number of working antennae determine the sequence of actions.

Coil with two working tendrils

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

- one groove. both antennae are wound together in one groove;

- two grooves. each antenna is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the rod side. inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the spool is closed and attached to the trimmer bar.

The difference between the line winding in two-groove spools is that initially a 2-5 m long line segment is folded in half (to determine the middle bend), and the bend loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The video below will clearly show how to thread the line into the trimmer spool and wind it correctly. this operation is not difficult and with some patience it will certainly be crowned with success:

How to thread the line into the Stihl trimmer spool

How do I load the line into the trimmer spool? Video instruction

The guaranteed output of the factory trimmer refueling will inevitably require a line change. Having a very rough idea of how to thread the line into the trimmer reel without the help of others, the newcomers are reluctant to take up this business. How to wind the line on the trimmer reel, how to thread the line into the trimmer reel. Autocut for stihl fs 55 trimmer line threading into the trimmer spool 2 part line winding on. But with some abilities, mastering this simple science does not present any difficulties, and the similar annotation presented below will greatly facilitate this process.

How to put line in the Stihl.FS-38 mower

took out the mower from the barn, but there was no line in it, I had to put the line and on the occasion took off a small

Coil with one working tendril

The most common option and easy sequence of actions:

- The dimensions of the reel and the length of the unique factory winding determine the recommended length of the line for winding. 2. 5 m.

- One end of the line is inserted into the fixing technological hole located on the inside of the spool.

- The fishing line is wound on the drum in the reverse rotation of the spool on the trimmer product direction. usually, on the inner side of the bobbin, an arrow indicates in which direction the winding is being carried out.

- A small section of the fishing line is left free to bring it out. it is fixed in a special groove on the inner side of the bobbin, created to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole on the outside of the bobbin.

- The bobbin halves are assembled and put on the trimmer bar.

How to properly wind the line on the trimmer spool?

Despite the fact that gardening equipment has been used for quite some time, it is still a novelty for some owners of private houses. That is why there are often questions about how to properly wind the line on an electric or gasoline trimmer.

This is essentially a simple operation, but all its stages must be performed correctly in order to achieve the desired result. over, in the operating instructions, only a few manufacturers provide an answer to this painful question. Explore the article and find out how the line winds on the trimmer reel.

The procedure for winding the line on the trimmer spool

First of all, you should know that trimmers have different working attachments. The reel can be designed for different lengths and thicknesses of the line. this point should be taken into account when purchasing consumables.

So how do you load the line into the trimmer reel? All work is divided into several stages:

- First you need to disassemble the trimmer head.

- Unscrew the nozzle by rotating the drum to the right.

- Press with your fingers on the two latches located on different sides of the entrance, and remove the top cover of the nozzle. You can pry off the cover with a screwdriver. This should be done carefully: reels with automatic line feed have a spring that can forcefully throw the cover along with all the contents of the reel.

- Remove scraps of old fishing line.

- Now you need to find the middle of the line. To do this, unwind it to the required length (for example, 10 m), cut and fold it in half.

- Hook the middle of the line into the existing groove or insert it into the hole specially designed for this. And start winding. The direction is indicated by an arrow, which is usually marked on the trimmer reel body (usually against the rotation of the drum). Some models have a double-sided spool: in this case, the line should be wound in different directions: one end in one direction, the other in the other, while the loop of the line must be inserted into the dividing slot located in the middle.

- Leave loose ends of the line about 20cm each. Later they will need to be fixed in the recesses.

- And finally, the last step will be the assembly of the drum. Reinstall the washers and spring. On the top ring of the reel there are two notches where you need to tuck the antennae of the fishing line. Thread them through the holes and place the spool in the drum, trying to tighten the line without displacing the spring.

- Place the drum cover on top and close it with your fingers. The latches will snap into place with a distinctive click.

When you turn on the trimmer, the excess line will be cut off by the trimmer blade.

As you can see, winding the line on the trimmer reel is not difficult: the main thing is to do everything right. And here are some more tips that will come in handy when choosing a fishing line, winding it and subsequent work:

- fishing line comes in different thicknesses and with different sections. The best option for winding is the “native” line for this model;

- never use fishing line or metal cables for the trimmer. Such a substitution may seem effective, but it is very dangerous. Jumping off a working trimmer, the cable can seriously injure not only the lawnmower himself, but also those around him;

- the line is cut when the trimmer is in contact with hard objects. Try not to allow this, otherwise you will have to stop each time, turn off the device and rewind the line on the reel;

- Use regular line for cutting lawn grass and pigtail line for coarse weeds. It is more durable and will not constantly cut.

Preparing for replacement

We disassemble the trimmer spool

For clarity, the mowing head (spool) was removed from the lawn mower. To replace the fishing line, you do not need to remove it, everything is done locally. It doesn’t take long.

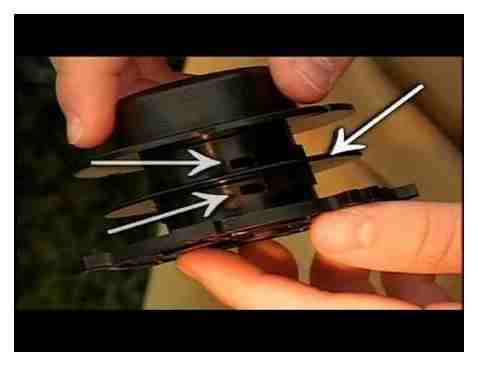

We disassemble the trimmer spool. it rests on the latches. Remove the cover by pressing on the latches. If you do not have enough effort to do this with your hands, then use a screwdriver.

The spool consists of the following:

- Spring case

- Cover with locking latches

- Button coil

The principle of operation is as follows. By pressing the button, the spool presses on the spring and comes out of the locking grooves in the spool cap. Holding in this state, the reel can be twisted, thereby adjusting the length of the line. When the button is released, the body spring returns the coil to its original fixed state.

Disassembled trimmer spool

On the bottom of the reel there are several holes for different diameters of the lines. They may differ from trimmer manufacturer. In some cases (like here) they are signed, in others they are not.

Holes for fixing the line

There are models without specifying the diameter of the consumable. Then, in order to find out what the maximum diameter of the scaffold can be used, it is tried on along the holes for removing the fishing line from the trimmer spool body (see figure below).

Fitting on the holes of the line output

The reel has two line sections separated by a baffle. They may not exist. They are needed only to delimit and facilitate the winding of the consumable.

Two sections for fishing line

How To Remove, Change Or Replace Trimmer Head For STIHL AutoCut® 25-2 String Weed Wacker Grass Eater

First, they are determined with the required length of the loess. The latter is wound into one of the sections of the coil so that it does not go beyond its limits. In this case, 3 mm was wound, the length turned out to be about 2 meters. Those. for two sections you need a 4-meter segment. this is for the 1st method. For the second method, you need two segments of 2 meters each.

Determining the required line length

Now you need to figure out which way you need to wind it. To do this, many trimmer manufacturers apply special designations to the spools, such as in the figure below.

Special designation on the reel

HOW-TO. Stihl String Trimmer Head Replacement

If no such designations were found, then you need to pay attention to the spool body. There is necessarily an arrow that indicates the movement of the mowing head. The line is wound in the opposite direction.

Bobbin case designation

My own master

Preparing the trimmer spool for winding

Initially, as a rule, the coil is installed to the head of the device itself. The coil consists of two parts. a cover and a spring.

- Whichever company you have a trimmer, the preparation steps are the same for all types. Disassemble the device, or rather, remove the coil from the trimmer head. To do this, until it stops, press the latches located on the sides of the head body, and turn the head clockwise.

- To open the mowing head without any problems, press the side latches, if you cannot do this with your hands, use a flat screwdriver to help. We take out the coil from the head.

- In order to choose the right line for your equipment, on the inside of the reel, digital designations must be applied, which indicate the thickness and type of acceptable line. All designations are indicated, as a rule, in millimeters.

- If you did not find any numbers, then the maximum allowable diameter of the fishing line can be determined by the through hole for inserting the fishing line. The line should run smoothly back and forth.

The first way

Line bent in half

The prepared segment (in this case, it is 4 meters) is bent approximately in half. one segment should be 15-20 cm longer, and inserted into a special slot located on the dividing partition.

The line is inserted into the slot

The line is wound in the direction determined earlier. This is done in an interference fit, the line is neatly distributed. In this case, you need to wind a segment that is longer in the section that is closer to the button.

There are designs that do not provide for dividing the coil into two sections. This does not change anything, the line is wound in a similar way. You just need to make sure that the segments do not overlap with each other.

The first should end that section, which is located at the bottom of the coil, i.e. the one closest to the fixing holes.

This tip fits into the corresponding hole in diameter. The line is securely fixed.

The line is securely fixed

A long segment is wound another half turn. There he is similarly fixed. In this case, the segment crosses another section of the coil.

A long segment is wound another half turn

The fixed ends of the coiled line are inserted into the holes in the trimmer spool body.

The fixed ends of the coiled line are inserted into the holes in the trimmer spool body

The coil is attached to the body. The ends of the fishing line are pulled with effort so that the fishing lines previously fixed in the holes of the reel jump out from there. It is easily identified by the characteristic sound (click).

The ends of the line pull up with effort

Button spool snaps into trimmer spool housing.

Button spool snaps into trimmer spool housing

The line was changed successfully. In this case, you need to put it back on the trimmer and you can start mowing the grass.

It should be repeated, there is no need to remove the spool from the trimmer. this was done for clarity of the process of replacing the fishing line. You can disassemble the spool in place, wind it on the spool and put it back.

Line replacement completed successfully

Tips so that they do not hit the trimmer cover can and should be trimmed.

Master class: weaving the “Tree of Life” pendant from wire

Spring has fully entered into its legal rights and we thought that today’s master class on weaving a wonderful “Tree of Life” pendant made of wire would be just right for the theme. After all, what is spring if not the rebirth of life after a long sleep? The ancients reasonably imagined the annual cycle of the seasons precisely as the sequential movement of nature from birth to death, and spring quite naturally symbolized precisely its birth.

The very same symbol “Tree of Life” is found in almost all world cultures.

Whatever it was, but the image of the Tree has a uniquely positive meaning, symbolizing the unity of nature and the eternal cycle of life.

In our master class, we will use the Celtic version of this symbol, which is most widespread in the modern world and is often used in the production of decorative products, jewelry and cult attributes.

We wish you pleasant and, most importantly, successful creativity.!

Sketches of the “Tree of Life”, they are easy enough to find on the Internet.

Changing the line in the trimmer: 2 easy ways

A trimmer is a necessary and useful tool for a summer cottage and a private house. Many people own and actively use it, but not everyone knows how to replace the line in the trimmer, especially at first.

In this manual, we’ll walk through the entire replacement process step by step. Looking ahead, there are two ways to line the trimmer spool. There is no fundamental difference. the difference lies in the fact that in the first case one line will be refueled, folded in half, and in the second there will be two such lines.

For work we need:

The first step is to give the shape of a circle to our future pendant. To do this, just wrap a thick wire around the jar and bite off excess material in the right places with wire cutters.

We form the pendant holder, as indicated in the photo.

Now you need to beat off the circle so that it becomes flat and bend the holder, thereby forming an eyelet through which you can pass a chain or lace.

We wind the wire, form the roots of the tree as indicated in the photo.

We form the crown of the tree as indicated in the photo, string the stone chips. We fix the branches along the edge of the round base very carefully so that the edges of our pendant look neat and there are no gaps between the winding rings.

Basically everything. our pendant is ready.

Another option for making a pendant. Here there are fewer branches, and instead of stone chips, beads are used, which are distributed closer to the rim of the pendant.

And for inspiration.

Did you like the article? Subscribe to the channel to keep abreast of the most interesting materials