How To Put A Spring On A Chainsaw

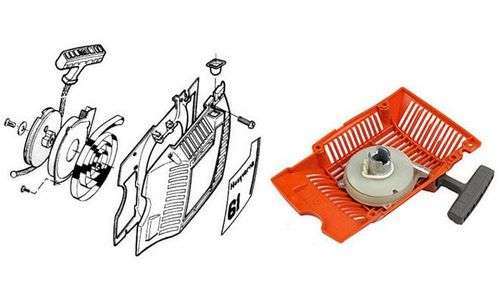

How to Replace Chainsaw Spring Husqvarna Chainsaw starter. Learning to self-repair To quickly start any chainsaw you need a starter. With accelerated scrolling of the crankshaft of the tool, the fuel-air mixture supplied to the engine is compressed, not its subsequent ignition. How to replace the spring; details of replacing the dogs

Replacing the cord

When pulling it out, there is a constant friction of the cable against the starter housing. To replace, disassemble the body of the unit, and carefully raise the ratchet drum so as to prevent the return spring from jumping off its seats. It is better to do this work together: the assistant fixes the spring, while the cable is being replaced.

The installation process shows the springs and starter assemblies Husqvarna Chainsaw (Husqvarna). Spring, coil and starter.

Do-it-yourself chainsaw repair Replacing the recoil starter spring.

When pulling it out, there is a constant friction of the cable against the starter housing. My carburetor mounting studs on the Partner chainsaw are loose. How to remove the drive. To replace, disassemble the body of the unit, and carefully raise the ratchet drum so as to prevent the return spring from jumping off its seats.

How to put a spring on a chainsaw starter?

Fitting the starter spring into the correct groove is not easy, even for an experienced user. How to wind a spring and how How to make a starter on a chainsaw yourself? How to bend. First, the spring should be twisted to the previous diameter and installed in the cavity of the drum hub. The outer end of the spring is fixed by the stopping lug, and the outer end with a screwdriver should be positioned opposite the hole in the lock.

After installing the spring, it is necessary to adjust its tension. To do this, a cable is inserted into the groove on the circumference, and a return spring is twisted around it. First on the chainsaw Adjusting the carburetor of the Stihl chainsaw how to adjust. After removing the slack, it is better to wind the spring a few extra turns to ensure the required tension on the part.

After installing the spring, the tension must be adjusted. To do this, a cable is inserted into the groove around the perimeter, and a return spring is wound around it. After removing the slack, it is best to screw the spring a few more turns to ensure the required tightness of the part.

Chainsaw starter repair. With your own hands.

How to make a starter on a chainsaw yourself? How to bend the spring on the chainsaw starter? How to wind a spring.

With an increase in engine volume, the required amount of the fuel-air mixture necessary for its subsequent ignition also increases, so the number of jerks for the starting cable for high-power saws increases. Therefore, in order to accelerate the return of the drum, unwanted return springs made of steels with high elastic properties are used.

- By preliminary enrichment of the working mixture, for which there is a special damper in the carburetor design.

- Installation of an automatic decompression valve, which reduces the working pressure in the chainsaw cylinder.

- Installing an additional spring, which, during the movement of the cable, facilitates the unwinding of the crankshaft.

- The presence in the design of some chainsaws (for example, Partner S series, Maxcut, etc.) a primer for the pump that provides preliminary fuel pumping.

The principle of operation of a starter for a chainsaw is as follows. Holding the cord and the mechanism, let us wind the cord on How to draw on a tablet. A handle is installed in the groove of the body, through which a cable is passed. If the handle is lifted sharply, the cable is pulled out, and engages the drum of the ratchet mechanism, which transfers the movement to the drum with splines provided on the shaft.

With an increase in the volume of the engine, the required amount of fuel-air consistency, required for its next ignition, also increases, therefore the number of jerks for the starting cable for high-power saws increases. Therefore, in order to accelerate the return of the drum, unwanted returnable springs are used, made of steels with the highest elastic qualities.

Chainsaw starter repair (broken spring)

Simple chainsaw starter repair with your own hands.

Read:

The principle of operation of a starter for a chainsaw is as follows. A handle is installed in the groove of the body through which a cable is passed. The principle of operation of a starter for a chainsaw is how to put a spring on the starter. If the handle is lifted sharply, the cable is pulled out, and engages the drum of the ratchet mechanism, which transfers the movement to the drum with splines provided on the shaft.

With an increase in engine volume, the unnecessary amount of fuel-air mixture necessary for its subsequent ignition increases, therefore the number of jerks for the starting cable for high-power saws increases. Therefore, with the intention of accelerating the return of the drum, unwanted return springs made of steels with high elastic properties are used.

Facilitation of starting the chainsaw is implemented in the following ways:

- By preliminary enrichment of the working mixture, for what purpose there is a special damper in the carburetor design.

- Installation of an automatic decompression valve, which reduces the working pressure in the chainsaw cylinder.

- Installing an additional spring, which, during the movement of the cable, facilitates the unwinding of the crankshaft.

- The presence in the design of some chainsaws (nettle, Partner S series, Maxcut, etc.) a primer for the pump, which provides preliminary fuel pumping.

After installing the spring, it is necessary to adjust its tension. How to wind the starter spring tension the spring. Starter handle like. To do this, a cable is inserted into the groove on the circumference, and a return spring is twisted around it. After removing the slack, it is better to wind the spring a few extra turns to ensure the required tension on the part.

Device

The chainsaw starter device includes the following elements:

- Ignition system screw;

- Return spring;

- Starting system coil;

- Deflector;

- Cap;

- Magneto;

- Drum;

- Spark plug;

- The electronic unit;

- Wiring;

- Power button;

- Handle and cable.

The main parameters of the chainsaw start system:

- Power from 2000 to 2500 W;

- The maximum number of revolutions per minute 3000;

- Weight 0.5 kg.

An electromotive force appears in the system. The resulting current is converted into electrical signals using the electronic unit, which are transmitted to the driving elements. A spark is formed and ignites the fuel-air mixture.

Replacing the cord

In order to replace the cord, the following tools are required:

- Screwdriwer set;

- Rope.

Replacing the starting cord is performed as follows:

- It is necessary to unscrew the fastening screws that hold the side cover with a screwdriver.

- Then remove the starter from the tool body.

- After that, you need to turn the lid and conduct an inspection.

- Then remove the clamp and spring.

- Untie the knot on the rope.

- It is necessary to pull out the pulley on which the cord is wound. Remove the cord and replace it with a new one.

- Then put the pulley in place and tie the rope to a knot. Install the clamp and spring.

- Then screw on the cover with the fixing screws.

- Finally, put the starter back in place and tighten the fixing screws.

Diagnostics

Diagnostics of the tool triggering system is carried out as follows:

- Unscrew the fastening screws and remove the cover.

- Remove the screw that attaches the mechanism to the protective cover.

- The starter is smoothly started by removing the spring and clamps from it.

- For inspection for wear and defects, dismantle the cable reel.

- Check the fuel system for water. If there is water inside the system, the fuel fluid must be replaced.

- Inspect the power unit for overflow with fuel fluid. In this case, unscrew and dry the spark plug, pull the starter, dismantling the air damper.

- Check the spark plug for spark.

Spring repair

Procedure for repairing the starting system spring:

- Remove the starter from the tool body.

- Remove the protective cover.

- Wind the cord around the end of the pulley to avoid twisting the mechanism.

- Pass the other end of the cord through the hole in the protective cover.

- Pull the cord 17-20 cm to check the rotation of the spring mechanism pulley.

- Check the operation of the spring after pulling and releasing the mechanism.

- Unscrew the pulley circle from the side of the generator by removing the 3 mounting bolts.

- Remove the pulley and cord.

- Check the condition of the parts for wear and damage or breakage. If the spring break is small, then the defect can be eliminated by welding.

How to put the spring

In order to install a new spring, follow these steps:

- Carefully remove the mechanism holder.

- Inspect the inside of the cage, where the spring mechanism is located near the C-shaped element.

- Secure and tighten the top of the spring with your finger and pull the starter handle aside.

- Remove the worn mechanism and wind up a new spring. Bends and twists of the element should be avoided.

- Assemble a new spring mechanism. It is recommended to do this slowly so that the mechanism does not unwind.

- Fill the spring and insert it into the starter mechanism.

- Secure the clip carefully.

How to fix a starter on a chainsaw

The cause of a malfunction of the chainsaw starting system can be:

- Drive pulley. This part is subject to high axial and radial loads, therefore it is recommended to inspect the pulley for damage and cracks on the back of the housing before starting work. If necessary, repair the part or replace it with a new one.

- Spring mechanism. If it has lost its properties or has cracks or breaks on it, it is necessary to replace this element. It is also recommended to inspect the attachment points for defects.

- Rope launch system. The rope should be inspected for wear and damage. If necessary, replace the part and install it on the pulley.

The device and principle of operation of the chainsaw starter

Most of the well-known chainsaw manufacturers equip their products with starters that work on almost the same principle. Its essence is as follows: in the groove of the saw body there is a handle through which the cord is passed. When the handle is suddenly lifted, the cord is pulled out, which engages the drum, which is in the ratchet mechanism. This drives the spitz drum, which is located on the shaft. During this, the crankshaft makes a couple of revolutions, which leads to compression of the fuel mixture, which at this moment is located between the cylinder head and the piston. On the contrary, when the handle is lowered, the ratchet and pins lose their contact, which leads to a stop of the shaft.

With an increase in the power of the chainsaw, the amount of the fuel mixture increases, which should ignite when the chainsaw is started. In such a case, increase the number of jerks of the starter cord to start the engine. To speed up the return of the drum mechanism, manufacturers use a special steel starter return spring, which has excellent elasticity. Leading brands use other methods to make it easier to start a chainsaw:

- Pre-enrichment of the fuel mixture using a separate flap;

- Installation of an automatic decompression valve, which reduces the pressure inside the cylinder of the chainsaw;

- Installing a primer designed to pump fuel before starting the engine.

The use of one of these technologies greatly facilitates starting and extends the life of the starter, which is especially noticeable at low temperatures.

Typical breakdowns and repairs of the chainsaw starter

The appearance of various malfunctions of the starter leads to the inability to start the chainsaw. The most common starter breakdowns include:

- The starter pulley is completely burst or cracked;

- The spring has burst;

- Starter rope broke.

To fix each of these faults with your own hands, you will need certain tools. You must have a set of screwdrivers and a spare cable with you. You need to remove and inspect the starter for a chainsaw in the following order:

- To find the cause of the breakdown, the starter will need to be removed from the chainsaw. To do this, unscrew the screws with a screwdriver, with the help of which the protective cover with the starter attached to it is held;

- After removing the cover, you must carefully unscrew the screw by means of which the starter is attached to the protective cover;

- Then you need to try to smoothly start the starter to do this, remove the spring and clamps from it;

- Further, a coil with a cable is removed from the starter for inspection.

As a result of inspection, you can find a number of typical faults. These include:

- Various damage to the pulley in the form of ruptures or cracks, mainly in the rear part of the part, they interfere with the normal operation of the entire starter;

- Damage to the starter spring of the lightweight start-up in such cases, not only the spring itself can be faulty, but also the place of its fixation is the most vulnerable part of the spring;

- Damaged starter flywheel pawl.

In any case, any defective part must be completely replaced with a new part.

Chainsaw starter: device, damage and DIY repair

In the design of the chainsaw, the starter is responsible for the proper starting of the engine of the tool. Over time, owners of chainsaws are faced with the need to repair this important unit. And, the sooner it is possible to eliminate the malfunction, the less other important parts and mechanisms of the tool will succumb to wear.

How to replace the chainsaw starter spring?

In order to replace the old spring in the disassembled starter, you must proceed in the following order:

Starter device, principle of operation

Almost all manufacturers use a standard design starter when assembling chainsaws, which works according to a simple principle.

- There is a handle in a small groove in the tool body, where a special cord is located.

- When the operator lifts the handle and the cord, it affects the drum (engagement occurs) located in the ratchet system (a simple mechanism that is the same in almost all models of chainsaws).

- After the drum engages, the latter begins to interact with the pins that are attached to the shaft.

- At the same time, the crankshaft rotates, which causes compression of the oil-fuel mix passing in the gap between the piston mechanism and the cylinder (its head).

When the operator lowers the handle, the pins and ratchet stop contacting and the shaft stops.

When the power of the fuel mixture is improved (using a premium or pre-tuning the fuel system), this has a positive effect on the power of the chainsaw. Then the tool can be started with several jerks of the starter lanyard. To achieve maximum drum acceleration (return mechanism), manufacturers use a specialized return spring made of high quality metal with good elasticity.

To make starting the unit easier, home appliance leaders use:

- A separate flap, due to which the fuel mixture is enriched;

- Integration of a decompression valve (automatic system), which reduces the pressure in the tool cylinder;

- Installation of a primer that pumps fuel before starting the engine;

- Preliminary enrichment of the fuel mixture with a separate flap.

All these technologies simplify the easy start of the starter system, and also prolong the operation of this part, even if the chainsaw is actively used by the operator at low temperatures.

How to repair a starter?

As soon as you diagnosed the cause of the chainsaw breakdown, found a damaged starter part that could not cope with the intense and dynamic load, you can start repairing.

Chainsaw starter device

Not sure how to put a starter on your chainsaw? Start small and consider the design features of this functional part. What is its main goal? She is responsible for the easy start of the engine of the unit, the start of the device. It doesn’t matter what the quality of the chainsaw is, sooner or later you will have to adjust the starter, and possibly carry out repairs.

In some cases, this important unit must be replaced. This can happen even when the operator is using a professional chainsaw, following the manufacturer’s recommendations for use and maintenance of the equipment. Remember that the better you know the chainsaw starter device, the more chances that you will notice a minor malfunction in time and return the tool to working condition as soon as possible.

Why does the starter break down: breakdowns and methods of their elimination

If the starter fails, starting the chainsaw becomes impossible. Often the problem is as follows:

- The pulley of the starter system is damaged (it can crack or burst completely);

- The spring has deteriorated (sometimes the steel spring bursts);

- The system cable is torn.

To quickly fix the problem, you need to have a few screwdrivers and a starter in reserve.

Before you figure out how to put the spring on the chainsaw starter, replace the cable, eliminate other problems, you need to remove the starter system in order to study it more closely. To do this, we rely on the standard instructions.

- We start with the protective shield that needs to be dismantled. To do this, unscrew the screws. This will make it possible to get rid of the part covering the starter (it is attached to the screen).

- As soon as we dismantled the cover, we begin to unscrew the screw that fixes the position of the starter.

- Slowly and carefully start the starter by removing the spring clips.

- Remove the torso and coil to inspect.

During inspection, you will likely notice common faults.

- The pulley is damaged (you can see not only cracks, but also tears that are concentrated at the back). This prevents the starter from working fully.

- The spring is damaged (and not necessarily only it, so carefully inspect its vulnerable attachment point), which leads to a malfunction of the tool.

- Broken flywheel or flywheel.

Sometimes it is difficult to repair a damaged part, so they replace the element with a new one that suits your model.

Repair of the cable

If the cable bursts, the ratchet teeth (not necessarily all) will crumble. This slows down the speed of rotation of the crankshaft. But why does the cable break? Do not forget about its friction, about the body of the starter system, over time this leads to damage to the cable.

- We disassemble the case, that is, remove the cover;

- We carefully lift the drum of the ratchet system, make sure that the return spring does not jump off the socket (ask someone to help you, the assistant will hold the spring until you change the cable);

- We fix a new cable inside the handle, do not forget to wind it on a roller located in the drum grooves;

- Putting the body together.

Spring repair

Not all manufacturers make the spring from high quality steel, but even if it is high quality, it will eventually need to be replaced or repaired due to damage at the spring / drum connection. A loop forms at this point.

If it is the junction of the drums and springs that is damaged, it is not necessary to replace the spring. Just:

- Sand the place of damage (remove dust, dirt, traces of oil);

- Heat the spring (up to about 650C, so that it becomes crimson);

- Cool gradually;

- We wrap it at about 150 degrees Celsius (focusing on the restrictive protrusion next to the inside of the drum, wrapping the end of the spring exactly in the shape of the stop).

- Insert the spring in its place.

It is not worth worrying that the elasticity of the spring will suffer.

But what if you need to replace the spring (if this particular part is damaged)?

Then we change the old one to a new one, focusing on the algorithm of actions:

- Remove the mechanism (dismantle the clip), make sure that no part is damaged at this stage;

- Inspect the inner side of the mechanism, where the spring is located, repeating the shape of the C-shaped functional element;

- Remove the spring, fixing its top with your fingers, slightly pulling the handle of the starter system;

- As soon as you take out the damaged spring, we install a new one, winding it like the old one, avoiding twisting and bending of the material (we act slowly so that in the future there are no problems with unwinding this part).

If you managed to disassemble the starter and remove the spring, you will quickly and intuitively understand how to assemble the chainsaw starter. The main thing is to securely fix the mechanism clip.

Once you are done assembling the starter and making sure all fasteners are in place, screwed tight, try starting the unit.

As you can see, having dealt with the structural features of the starter system, the types of breakdowns and their causes, you can independently repair the parts of this functional unit, replace them without resorting to the services of service center masters. They would have to pay decent money for work that you can do yourself.