How to put a starter on a walkbehind tractor. Doityourself repair

Repair and installation of a starter on a walk.Behind tractor with your own hands

The starter to the walk.Behind tractor is, at first glance, a complex mechanism, however, in practice, there are no complex elements in its device. These devices act as a starting component with which an internal combustion engine is launched. The work of the device lies in the fact that a craving for rotation of the crankshaft and distribution shafts is created. Additionally, at this moment, a spark is filed on a candle of incandescent, which allows you to form the necessary traction in the combustion chambers for subsequent engine operation of the engine. In practice, the following options for starters for motoblocks can be distinguished:

In each individual case, the principle of operation is similar, however, the procedure for starting is significantly different. If in the first case it is performed manually, then in the second option everything is performed due to electronics, while only the key in the ignition mechanism is turned with the hands, or the launch of the button is made. Most old motoblocks are equipped with a mechanical manual starter, which is why it is necessary to consider in detail how, if necessary, the device is repaired if necessary.

Important! Modern motoblocks are produced with an electric steamer, however, when it breaks down, you can also fix the device yourself

Manual version device

Before considering how the hand starter repair is performed for a walk.Behind tractor, you should consider what elements this accessory consists of:

- A case made in the form of a drum;

- There is a large, as well as a small spring inside;

- Additionally there are tongues and washer;

- Launch coil and starting cord;

- Elements used for fastening.

All elements are made of strong materials to ensure maximum wear resistance. The launch of the device is carried out at the expense of the coil, which is set in motion using the cord. In some cases, the previous models of motoblocks were equipped with special footboards for launching, like motorcycles. Kikstarter repair (steps for launching) on a walk.Behind tractor is practically no different from working with a manual mechanism, with the exception of the presence of a special remote handle instead of a coil and a cord and an internal fist mechanism.

It is worth noting that the electrical mechanism is also equipped with a similar device, however, a more complex technology is provided here.

The device of the electric starter

As mentioned earlier, this part has a similar device with a manual option, but it differs in that it also contains drive brushes, fist mechanism, wiring and electric drive. The last component imitates the mechanical efforts that are created due to the incoming electric power and the built.In electric motor. In all other respects, the elements are similar to each other and provide the same function, namely the launch of the engine by rotating the distribution and crankshaft.

Important! The additional difference between the elements is that when repairing equipment and the analysis of the device, it is also required to disconnect the wires of electric power supply

Do.It.Yourself starter renovation

Despite the high quality and reliability of modern starters, some owners sometimes face the need to repair them. Most often, the breakdown of the mechanism is insignificant, which allows you to quickly eliminate the malfunction with your own hands. The procedure for dismantling and further repair of the mechanism is as follows:

- The repair of the node should start by studying its scheme. If the design of the motor block provides an electric type starter, then before dismantling the mechanism you need to familiarize yourself with the location of its terminals;

- Using the key from the kit of the walk.Behind tractor, unscrew all the screws and nuts that hold the mechanism in the design of the walk.Behind tractor;

- If the dismantling of the node is carried out for the first time, we advise you to photograph the starter before finally remove the mechanism from the unit;

- Next, unscrew the washer located in the central part of the drum body and carefully examine the internal parts for breakdowns;

- All further actions depend on the malfunctions of the starter details. If the cord came out of the system. It was erased or torn, then to replace you will need to wind a new product, adhering to the marks on the drum body of the mechanism;

- Another common breakdown is a spring malfunction, or rather, its antennae, the edges of which should be bent in the form of hooks. If the antennae broke off, then the edges of the spring will need to be heated, and bend them so that the spring can be hooked by the holes in the drum. In this case, the residual length of the spring is of great importance. Make sure that the part does not stretch too much. If you find that the spring is very short, or it has already begun to rust, it is better to replace it entirely.

Before mounting the starter back to the walk.Behind tractor, we advise you to first clean the space inside the unit structure. This will prevent garbage from getting into the motor, carburetor and on the spark plug.

What other types of starters are suitable for a walk.Behind tractor?

Each owner of motoblocks must understand that at first absolutely all starters function perfectly and can delight their owners with this state of affairs for about a year. But without periodic lubrication of details, their verification and the commensurate power of a jerk, such joy will not last long. Take care of the starter and he will answer you with high performance and a long service life.

This model of the walk-behind tract is the new year of 2014 of the beginning of 2015, it was made at a well-known and loved by many 23rd base, and is its improved continuation. The main differences of this unit are the emerging headlight and the system of an electric starter operating from the built.In battery. These innovations are designed to significantly increase the user’s comfort when working with this agricultural device. It is worth noting that the launch of the 4-stroke American engine of Briggs State I/C to 8 liters.With. It can occur not only with the help of an electric starter, but also in an old proven way from a manual starter, pulling the starting cable of the factory mechanism. Such an opportunity provides a choice for the end user and will not let the walk.Behind tractor idle in cases of a saturated battery or any other force majeure.

Litter. Motoblocks installation of the starter

Artem and what a walk.Behind tractor? And why is the generator there?So that there was light? You can attach a generator from Minsk, sunrise or scooter, but it is attached to the crankshaft and it must somehow be primed. You can put the car and connect the belt with the crankshaft, but you need a battery for the initial excitement and even with the consumers disconnected, the generator will select a fairly noticeable part of the power of the walk.Behind tractor for winding excitation. You can take a less powerful generator, from the Dnieper or the Ural motorcycle, there is a gear on the shaft, put the pulley instead and connect it with a belt. You can also put the toggle switch and turn off the winding winding when you do not use light.

Peter and why motor block generator? You can put it from the car, but it will pick up half the engine power. By the way, I saw a walk.Behind tractor with a starter launch and battery. It is logical to assume that there is a generator

How many horsepower in the MTZ tractor 3522

Instructions for assembling milling cutters

Where to connect the NSh10 hydraulic pump on the T40AM tractor

Starter for a walk.Behind tractor

The starter for the walk.Behind tractor is responsible for the start of the motor. With it, the engine is regularly and quickly starts.

Many motoblocks work on manual starters. But it is possible to perform an independent replacement of a manual starter with an electric. To do this, follow a simple scheme. A simple algorithm will allow even a novice farmer to perform all installation work.

For good operation of the starter, it is necessary to regularly perform preventive work. Simple actions will allow you to keep the entire unit in good condition. The technique will last longer, working uninterruptedly.

Conclusion

There are several varieties of starters that can be installed on modern motoblocks. In this case, the most popular option is a spring mechanism, characterized by simplicity and reliability. If desired, you can independently install or repair such an element.

If you find an error, please select a fragment of the text and click CtrlEnter.

Block: 5/5 | Summer characters: 386Source: https: // Traktoramira.Ru/Motobloki-I-Motokultivatory/Elektrostarter-Na-Motoblok.HTML

The device of the starter starter. The design features of the mechanism

Each model of the motoblock has its own design features and is equipped with different mechanisms. So, to equip more modern agricultural units, manufacturers use two starters at once.

A spring, or auxiliary starter helps to quickly and smoothly start the main starter. The main mechanism is a hand starter, which is responsible for launching a motor block motor. Among the main elements of the starter of the walk.Behind tractor stands out:

The coil on which the cord is wound is attached to the core of the drum building. A large spring is installed in the internal chamber of the drum, which is responsible for the return of the drum to its previous position after each stretch of the cord.

Changfu Brand Two Wheel Walking Tractor Assembling

Some motoblocks are equipped with an electric type starter. Elektrostarter for a walk.Behind tractor takes power from the battery. The larger the capacity of the latter, the longer the engine starts mechanism will work.

Manual starter design for a walk.Behind tractor

The cord itself is fixed on the coil installed in the central part of the drum. A special large ring spring is located in the drum around the axis and helps to increase the coil in the original state after scrolling. You see, collecting a similar mechanism is quite easy.

As for the work process, it is still easier here: after a person pulls the starter handle with a sharp movement, the mechanism itself occurs and transfers the initial rotation to the engine. For the best acceleration, you should rush the handle 2 times.

Lawn mower starter clicks but won’t start, change solenoid

But, as is usually the case, nothing works forever and even such reliable devices fail from time to time. It seems to be there, you should not be upset, because all problems can be corrected.

How to put a starter on a motor block. An algorithm in details

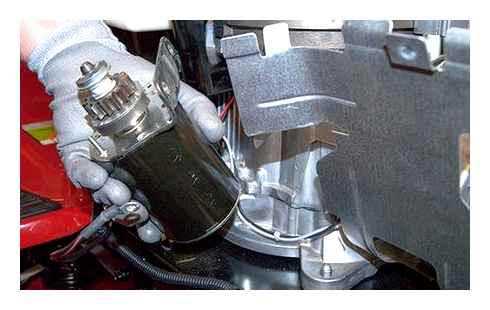

With the dismantling, disassembly and installation of a manual starter of the walk.Behind tractor, there are no problems even in novice farmers. However, the assembly and installation of an electric steamer in inexperienced owners of motoblocks raises a number of questions. As a result of the incorrectly completed procedures, the engine launching mechanism refuses to work, which is why the starter has to be carried to the workshop. To avoid this need, we will study how to install a starter on a walk.Behind tractor at home. The installation looks as follows:

- To install and fix the crown on the flywheel of the walk.Behind tractor, the flywheel will need to be removed. To do this, remove the aggregate air filter to get free access to the internal structure of the walk.Behind tractor;

- After that, remove the protective casing, unscrew the screws holding the basket of the manual starter, the flywheel nut and the flywheel itself. The dismantling of the flywheel of the starter’s starter can cause certain difficulties, therefore, to remove this part, it is better to purchase a special removable key in advance. After removing the flywheel, do not forget to unscrew the key located immediately behind him;

- Next, you need to install the generator. In this case, stick its wires into the hole in the steel wall of the motor, and install the generator in the seats on the engine wall;

- Then set the generator magnets into the flywheel so that the holes in both elements match. Connect both parts with screws and set the crown. Before that, the crown must be heated using a burner in the form of a spray can;

- Install the assembled node back to the engine, simultaneously screwing the wraps and gaku tank;

- Screw the basket of the manual starter, fix the casing and install the airblock air filter in place;

- Next, remove the starter installation plug and install the starter itself on the walk.Behind tractor;

- After that, connect the wires of the generator to the charging relay;

- Connect the starter terminals to the aggregate accumulator and get a motor.

As you can see, installing a starter to a walk.Behind tractor is not so difficult as it might seem at first glance. The main thing when assembling with your own hands is to strictly comply with all the rules and recommendations listed in the algorithm.

All described methods of repair and installation of the starter are suitable for installing the mechanism for Neva, cascade, agro and agricultural machines of other well.Known manufacturers.

Installation of an electric steamer on a walk.Behind tractor Neva with your own hands. Starter for a walk.Behind tractor: device, repair and maintenance recommendations

Motobobes do not constitute complex designs, but at the same time they contain certain features. For example, when using this device, two starters work simultaneously: the main and additional. In addition, the role of assistants can also play spring and electrical options. The latter are considered the most popular, since they can be installed without problems on motoblocks and carry out repair work. A distinctive feature of such starters also consists in the fact that they are unpretentious, therefore they do not require too careful use.

In the process of choice, most users usually prefer a manual starter. It has a huge number of advantages in comparison with electric and other options. Such a device includes the following details:

It is the manual starter that is most popular, since during operation such devices often fail, so they have to be repaired, but just manual options are extremely easy to repair. Consider how the process of restoring the performance of the starter looks like.

- Before starting the repair, you need to find a scheme from the manufacturer to understand the features of the location of all parts. In addition, it will be useful to understand the instructions.

- You need to prepare the key with which you can unscrew and remove the nuts.

- Before shooting a starter, it is best to take a few photos. This will help restore everything if you forget the location of certain details.

- Unscrew the puck that is located in the center of the drum.

- Find damaged elements and conduct their replacement.

Thus, the repair of a hand starter does not take too much time, so this variety is very popular. In the process of restoring the performance of the starter for the walk.Behind tractor, the main thing is to pay attention to any details, even the smallest.

See also: MAN SE Trucks Wallpaper, pictures, download 32 desktop wallpaper. Beautiful free photos for desktop

For a walk.Behind tractor, you can also install other types of starters. Among the most popular and demanded in the market, several types of.

- Spring, which are considered the simplest both in use and installation. In order to start such equipment, you will just need to move the motor block handle. The unit includes a semi.Automatic spring, which provides the necessary acceleration of the power plant. In order to replace the manual version with a mechanical version, it will take no more than two hours.

- Electric, which work from a built.In battery. It is the last detail that determines the level of power of the device and its autonomous operation period. It should be noted that such starters can not be installed on all motoblocks. Only some models are able to work with electricity, so before choosing you must definitely study the features of your unit.

In the process of choosing any starter, it should be understood that in the first year of work they are almost all the same. If the company is conscientious, then each device will fully fulfill the functions assigned to it, but after a year the situation changes. In order for the device to work as best and longer as possible, you need to constantly care for it, lubricate and replace the failed parts. Only in this case, the starter can boast of high performance and durability.

The device of the starter starter

All models of technology have differences in the design and are equipped with special mechanisms. Two starters are used to equip the latest equipment. The spring starter contributes to the accelerated launch of the main. The key mechanism is a manual starter, it is he who is responsible for the movement of the motor.

The design consists of the following details:

- Drum building;

- Washers;

- Large and small spring;

- Coils;

- Ligas;

- Cord;

- Fasteners.

A coil with a wound cord is attached to the body with a drum. In the drum chamber is a spring that allows the mechanism to return to the original position after stretching the cord to the entire length.

Some models have starters with an electric ignition system. Elektrostarter for a motor unit is powered by a battery. It depends on its capacity how much time the engine start mechanism can function.

Manual kickstarter, as well as an electric starter for a walk.Behind tractor, differ in increased reliability, they are durable and resistant to different external exposure.

- Spring. It is easy to install it, it quickly starts. The handle of the walk.Behind tractor is just moving. The spring on the semiautomatic device works, its task is to disperse the motor. All actions can be performed in two hours;

It is important to understand that not all equipment with manual descent can adapt to the operation of an electric starter. Therefore, before starting work on replacement, it is necessary to pay attention to the structural features of the unit.

Motoblock owners can use the technique with confidence. For a long time she does not need repair work. But it is important to periodically lubricate the details, check them for serviceability, control the power of a jerk. Simple care will provide a high degree of performance and a long service life of the unit.

How to put a starter on a motor block. An algorithm in details

With the dismantling, disassembly and installation of a manual starter of the walk.Behind tractor, there are no problems even in novice farmers. However, the assembly and installation of an electric steamer in inexperienced owners of motoblocks raises a number of questions. As a result of the incorrectly completed procedures, the engine launching mechanism refuses to work, which is why the starter has to be carried to the workshop. To avoid this need, we will study how to install a starter on a walk.Behind tractor at home. The installation looks as follows:

- To install and fix the crown on the flywheel of the walk.Behind tractor, the flywheel will need to be removed. To do this, remove the aggregate air filter to get free access to the internal structure of the walk.Behind tractor;

- After that, remove the protective casing, unscrew the screws holding the basket of the manual starter, the flywheel nut and the flywheel itself. The dismantling of the flywheel of the starter’s starter can cause certain difficulties, therefore, to remove this part, it is better to purchase a special removable key in advance. After removing the flywheel, do not forget to unscrew the key located immediately behind him;

- Next, you need to install the generator. In this case, stick its wires into the hole in the steel wall of the motor, and install the generator in the seats on the engine wall;

- Then set the generator magnets into the flywheel so that the holes in both elements match. Connect both parts with screws and set the crown. Before that, the crown must be heated using a burner in the form of a spray can;

- Install the assembled node back to the engine, simultaneously screwing the wraps and gaku tank;

- Screw the basket of the manual starter, fix the casing and install the airblock air filter in place;

- Next, remove the starter installation plug and install the starter itself on the walk.Behind tractor;

- After that, connect the wires of the generator to the charging relay;

- Connect the starter terminals to the aggregate accumulator and get a motor.

As you can see, installing a starter to a walk.Behind tractor is not so difficult as it might seem at first glance. The main thing when assembling with your own hands is to strictly comply with all the rules and recommendations listed in the algorithm.

All described methods of repair and installation of the starter are suitable for installing the mechanism for Neva, cascade, agro and agricultural machines of other well.Known manufacturers.

How to assemble a starter

Many summer residents are interested in the question of how to independently assemble a starter on an AGRO motornote. In order to correctly collect and install the starter, you should follow the following recommendations:

- The first step is to remove the air filter.

- Then the line of the protective casing is suitable. To do this, unscrew the fasteners, manual mechanism and flywheel.

- Next, you need to put a generator.

Quite often, for various reasons, the walk.Behind tractor ceases to start. The reason why the device does not work is a breakdown of the starter. Therefore, each owner of the motor.Cultivator must know how to repair this mechanism on his own.

Types of starters for a walk.Behind tractor. Description and features

The starters for installation for motoblocks are divided into several types. Among them, the following types of mechanisms are distinguished:

The BCS Walk-Behind Tractor

- Spring starters. Mechanisms of this type are highly popular due to the properties to quickly start, which was achieved due to the presence of a semi.Automatic spring in its design. The spring starter is very easy to install. No more than 2 hours will take a new one to replace the worn mechanism;

- Electric starters. These mechanisms work from built.In battery. The charge capacity determines the power of the power steak power. At the same time, an electric starter for a walk.Behind tractor is not suitable for every model of an agricultural unit. In this regard, before replacing the manual mechanism with an electric station to a motor block, the manufacturer’s recommendations and the compliance of the element for the aggregate farm should be studied.

Each of the listed types of starters has a reliable design and long terms of use. However, it should be understood that without regular inspection and timely introduction of lubrication into the rubbing parts of the starter used, the mechanism will quickly fail. This will entail breakdowns of other elements and mechanisms of the walk.Behind tract.

Do.It.Yourself starter renovation

Despite the high quality and reliability of modern starters, some owners sometimes face the need to repair them. Most often, the breakdown of the mechanism is insignificant, which allows you to quickly eliminate the malfunction with your own hands. The procedure for dismantling and further repair of the mechanism is as follows:

- The repair of the node should start by studying its scheme. If the design of the motor block provides an electric type starter, then before dismantling the mechanism you need to familiarize yourself with the location of its terminals;

- Using the key from the kit of the walk.Behind tractor, unscrew all the screws and nuts that hold the mechanism in the design of the walk.Behind tractor;

- If the dismantling of the node is carried out for the first time, we advise you to photograph the starter before finally remove the mechanism from the unit;

- Next, unscrew the washer located in the central part of the drum body and carefully examine the internal parts for breakdowns;

- All further actions depend on the malfunctions of the starter details. If the cord came out of the system. It was erased or torn, then to replace you will need to wind a new product, adhering to the marks on the drum body of the mechanism;

- Another common breakdown is a spring malfunction, or rather, its antennae, the edges of which should be bent in the form of hooks. If the antennae broke off, then the edges of the spring will need to be heated, and bend them so that the spring can be hooked by the holes in the drum. In this case, the residual length of the spring is of great importance. Make sure that the part does not stretch too much. If you find that the spring is very short, or it has already begun to rust, it is better to replace it entirely.

Before mounting the starter back to the walk.Behind tractor, we advise you to first clean the space inside the unit structure. This will prevent garbage from getting into the motor, carburetor and on the spark plug.

Starter work

For starting the engine of powerful motoblocks, a spring starter is mainly used, but manual options are also often found. A hand starter is much easier in installation and operation, therefore it is more profitable for production. The design of this node is quite simple and uncomplicated:

The cord is fixed on the coil, which, in turn, is installed on the core of the drum. In a special section of the drum around the axis there is a large ring spring, it returns the coil to the starting position after scrolling. This is how you can briefly describe the design. This works all as follows: the user sharply pulls the starter handle on himself, thereby setting the initial rotation that is transmitted to the engine. As soon as the torque necessary for starting the engine arises, he immediately begins the work. Usually you need to rush the handle on yourself 2-3 times so that the starter is well accelerated.

A manual starter for a walk.Behind tractor is terribly uncomfortable, since it is required to make a lot of effort to start the equipment with its help. In addition, this node is often breaks due to excessive efforts.

Farm Mechanisation: Prowess of a Walking Tractor

How can you repair or improve it?

How to put a starter on a motor block. An algorithm in details

With the dismantling, disassembly and installation of a manual starter of the walk.Behind tractor, there are no problems even in novice farmers. However, the assembly and installation of an electric steamer in inexperienced owners of motoblocks raises a number of questions. As a result of the incorrectly completed procedures, the engine launching mechanism refuses to work, which is why the starter has to be carried to the workshop. To avoid this need, we will study how to install a starter on a walk.Behind tractor at home. The installation looks as follows:

- To install and fix the crown on the flywheel of the walk.Behind tractor, the flywheel will need to be removed. To do this, remove the aggregate air filter to get free access to the internal structure of the walk.Behind tractor;

- After that, remove the protective casing, unscrew the screws holding the basket of the manual starter, the flywheel nut and the flywheel itself. The dismantling of the flywheel of the starter’s starter can cause certain difficulties, therefore, to remove this part, it is better to purchase a special removable key in advance. After removing the flywheel, do not forget to unscrew the key located immediately behind him;

- Next, you need to install the generator. In this case, stick its wires into the hole in the steel wall of the motor, and install the generator in the seats on the engine wall;

- Then set the generator magnets into the flywheel so that the holes in both elements match. Connect both parts with screws and set the crown. Before that, the crown must be heated using a burner in the form of a spray can;

- Install the assembled node back to the engine, simultaneously screwing the wraps and gaku tank;

- Screw the basket of the manual starter, fix the casing and install the airblock air filter in place;

- Next, remove the starter installation plug and install the starter itself on the walk.Behind tractor;

- After that, connect the wires of the generator to the charging relay;

- Connect the starter terminals to the aggregate accumulator and get a motor.

As you can see, installing a starter to a walk.Behind tractor is not so difficult as it might seem at first glance. The main thing when assembling with your own hands is to strictly comply with all the rules and recommendations listed in the algorithm.

All described methods of repair and installation of the starter are suitable for installing the mechanism for Neva, cascade, agro and agricultural machines of other well.Known manufacturers.