How to put the piston on the trimmer correctly

Replacing the piston group in a chainsaw or trimmer

Repair of this level should always be balanced. In such small engines operating at high speeds, replacing one piston that is burned out or jammed does not give a long result and, if necessary, the entire piston group must be changed. Therefore, you need to consider whether to continue using this saw or purchase a new saw.

If this is a professional model, then such a repair is worth doing, but if it is an old household model like the Husqvarna 40 and it has worked for more than ten or twelve years, it is not profitable to repair it. Because its repair will cost so much. the same as the purchase of a new saw, albeit not from Husqvarna, but for PARTNER P350XT CHROME, the cost of 165 is definitely enough. over, such saws are sold by Husqvarna, since PARTNER is its subsidiary.

But if you nevertheless decide to repair a chainsaw or a trimmer, then you need original spare parts that are not cheap. With proper operation of the engine, the first repair may not come soon and only the piston ring or rings will have to be replaced, depending on the model. But if the saw is jammed, then it is necessary to change the entire piston group. the cylinder, piston and rings.

It should be noted that the Husqvarna 136/141 chainsaws have approximately a service life of 500-600 hours, the Husqvarna 340/350. 1000-1200 operating hours, professional chainsaws at least 2000-2500 operating hours, subject to strict observance of the operating instructions. In fact, it is impossible to rely on these figures, since the real resource can differ significantly, both up and down. But roughly we can say that semi-professional saws work 3-4 times longer than amateur saws, and professional ones up to 10 times or more.

Of course, nothing is eternal, but it’s one thing if you change the piston group, after many years of operation, and after working out its engine hours, it fully paid for itself, but another thing is that this saw was refueled, for example, with gasoline alone, without oil, and it jammed. Such a saw has to be repaired, since all other parts are normal.

Many firms deliberately inflate the cost of spare parts in order to buy new models. For chainsaws and trimmers, for example, from Stihl, spare parts are available in a larger range than on Husqvarna. Therefore, when choosing a certain model, find out how things are with spare parts.

PBT

How to wind the line on the trimmer correctly

A garden trimmer is a useful tool that makes life much easier for any gardener or private home owner. The grass just rushes in the summer, especially after the rains, so you can’t go anywhere without it. But over time, sooner or later, the line in it will end, and it will be necessary to insert a replaceable skein of new line. Some summer residents get stumped. how to do it yourself? So our article will help them.

Changing the line on the trimmer

This article will tell you how to change the line on the trimmer. For some people, this job may not be easy. But the step-by-step instructions that are available here will help you in this matter.

So the first thing to do is remove the gear cover. We combine the hole on the side of the curly lower washer and the axial recess, insert a screwdriver to fix the shaft from scrolling. Now unscrew the nozzle. The thread on the shaft, as a rule, has a reverse thread, take this into account when unscrewing.

Next, the disassembly of the nozzle follows. There, the lid is secured with latches through the holes. So you just have to push these clips into the holes and the cover will come off. If the attachment has automatic / semi-automatic line feeding modes, it means that there is a spring inside, which can simply fly out when the lid is opened, be prepared for this. We lay out all the removed parts neatly in order.

Now it’s time to take the fishing line and unwind 5 meters from it, cut off this piece. Pay attention to its thickness, do not wind a line of greater thickness on the unit than specified in the manual for the tool. Otherwise, there will be an increased load on the engine and higher fuel consumption during operation. We bend the measured line in half to find the middle and get a loop.

There are a couple of notches in the middle of the coil, sometimes these are not notches, but holes located opposite each other. With a loop we cling to one of the grooves and wind the fishing line counterclockwise. If the reel has 2 compartments, then we wind each end of the fishing line on them separately. Leave the last 15-20 cm free and clamp them while in the recesses of the coil.

We assemble the device again, pull the free ends of the fishing line into the holes on the body. We put on the cover, snapping the latches into their grooves. Now you can pull out these loose ends of the line.

It remains only to attach the working node in place, as in the first paragraph. Do not forget about reverse rotation on screwing.

Now you can learn how to wind the line around the trimmer. Actually, the whole process was detailed above. No time-consuming operations requiring the presence of specialists. Your lawn mower is ready for use again.

Trimmer preparation

When starting to use the device, study the manufacturer’s instructions to find out the type of oil for lubricating the blades (if necessary, for the model you have chosen), how to remove the knives and other nuances. Next, prepare the device for operation:

- Lubricate its head with oil so that it gets on the blades.

- Turn on the device for 20-30 seconds. Thus, you can check the efficiency of the device, and the lubricant is more evenly distributed over the knives.

- After checking, turn off the trimmer and wipe the blades to prevent trimmed hairs from sticking to them while shaving.

Choice of attachments

The trimmer without attachment can be used when trimming the beard and mustache. As for cutting, for this purpose, various accessories are used, which are selected depending on the desired length. To shave your beard with a trimmer, you usually choose 1-10 mm attachments, as they allow you to precisely trim the stubble and cut long hairs. In some models, you can use only one attachment, which is adjusted using a special wheel and a lock.

Using a beard trimmer

The question of how to shave correctly with a trimmer is asked by many men who have never cut their hair with this device. In reality, there is nothing complicated here. If you learn how to use a typewriter, you can always stay in trend and forget about visiting a barbershop.

Choosing a beard grooming device

One of the main points in beard care is choosing a quality device that will effectively cut hair and keep the battery charged throughout the entire shaving procedure. When buying, consider the following recommendations:

- Choose a beard trimmer with stainless steel blades. They have a long service life and allow you to shave vegetation without pulling.

- It’s good if your device has a durable waterproof case, which will allow you to clean it under running water.

- Pay attention to the handle. it should lie comfortably in your hand and have rubberized inserts that will prevent slipping.

- The more attachments are included, the more convenient it is to use the device when caring for a beard.

For more information on how to choose a beard trimmer, follow the link to our article with tips for choosing a device.

How to use the trimmer: shaving steps

Before starting a haircut, decide on the desired length of the beard. With a long beard, three device settings for different lengths are sufficient. If you like a short beard, you can only cut your hair with blades. no attachments are needed. Shaping a particular style, such as a goatee, requires a variety of features, including the ability to swap out standard blades for a head with smaller blades for high precision shaving.

After that, you can start shaving:

- Start shaving your beard with long hair and then work your way down to short hair. To give your beard a well-groomed look, you need to use the long attachments. Shave your chin against hair growth. Since the hairs grow downward, cut from the bottom up to shorten them.

- Change the attachment to a shorter one and start shaving your neck. Start at the Adam’s apple and work your way up. If the original length of beard hair is more than 5 cm, then for their initial haircut, you must remove the attachment and use only the trimmer blades.

- Move on to shaping the contours. To do this, treat the neck with a zero nozzle. Trimming the beard on the cheeks can be done with a trimmer without attachments. Draw the lateral outlines towards the ears, pulling gently on the skin with your hand while shaving in hard-to-reach areas. To achieve a more thorough shave of vegetation, you can use a razor or electric shaver.

When shaving, the flat part of the brush head should be applied to your face for the best results. All movements must be smooth and slow, otherwise the device will not have time to cut vegetation. It is advisable to keep the device at an angle to the skin. in this case, the hair length will be even throughout the beard.

To trim the antennae, move the device in any convenient direction, giving the hair the desired shape. If you want to shave off your mustache completely, you can use the trimmer without attachments. To do this, close your mouth, smile and remove hairs all over the mowing line above the upper lip.

To avoid clutter while shaving, it is best to place a waste basket under your feet. When clipping, a lot of cut hair will fall off the blades, especially when cutting a long beard, so you should take care in advance that they do not scatter around the bathroom.

How to use a beard trimmer: stylist tips

The electric trimmer is a relatively new “technical trend” designed for effective styling and removal of facial hair. Since the device has appeared on the market recently, not every man knows how to use a beard trimmer correctly. Meanwhile, it is an excellent solution for the stronger sex who want to always look well-groomed and neat. Learning how to use the trimmer can save you a lot of time and keep your beard in top condition.

Cleaning and maintaining the trimmer

Manufacturers recommend using the beard trimmer with care, because the quality of the care of the device largely depends on its performance and period of operation. Follow the guidelines below to keep your helper clean:

- Wash the attachments after you are finished using the device. You can use warm soapy water for washing. Do not wash the device under running water if its body is not protected from moisture. This can cause corrosion on the blades or breakage of the trimmer.

- Clean hairs from the trimmer regularly. To do this, you can use the brush that comes with the kit. Use a regular cotton swab to clean the grooves of the blades.

- Remember to lubricate the trimmer with oil (if specified in the instructions for your particular model). This will allow the blades and motor to maintain their performance for a long time.

- Charge the battery if it signals a low charge. If the battery is low, the trimmer can pull out hairs, resulting in discomfort and skin irritation.

Using the trimmer correctly will allow you to create your own style with a minimum of time. You can always control the formation of your image and perform stylish haircuts for your beard and mustache. no worse than that of a professional barber.

MOTORZONA

03 Information on the piston

When boring the block and installing pistons in the cylinder block, it is required to follow the piston manufacturer’s recommendations for cylinder processing, assembly and installation of parts of the cylinder-piston group. Basic information is printed on the top of the piston. If any information is not indicated by the piston manufacturer, neither on the packaging nor on the piston itself, then the recommendations of the car manufacturer must be followed. The explanation of symbols and meanings is given below.

Information on the top.

| The direction of installation of the pistons for the engine installed in front of the car |

The direction of installation of the pistons for the engine installed in back of the car |

Casting number on the inside of the piston.

Experienced mechanics often encounter difficulties in their work when a very old car comes in for repair, and there is no way to accurately identify the type of its engine. Often there is simply not correct information in the documents, for the car, for example, an error (typo) in the VIN code or in the column “TYPE OF ENGINE”. But it is necessary to repair, and it is necessary to choose the right repair pistons.

Then information about the number of the casting on the inside of the piston comes to the rescue. Remove the piston from the cylinder block, clean the inner cavity of carbon deposits and read the cast numbers and letters. This method is not suitable for all pistons, but the main suppliers of conveyors of European cars MAHLE, Kolbenschmidt, AE, Nural can decipher this data.

What is the “casting number”? Pistons with the same basic parameters are manufactured on the same technological equipment (in particular, in one injection mold), then they are subjected to subsequent machining depending on the required overhaul size and modification. That is, for pistons with STD and repair dimensions, the casting numbers are the same. As a rule, several pistons for one engine correspond to one casting number; this is a standard piston and its subsequent repairs. But there are exceptions (when the casting number coincides with several piston modifications), then it is necessary to measure the controlled geometric parameters.

How to decrypt? We recommend checking your casting numbers through the paper catalogs of the respective manufacturers. In addition, you can decrypt this data using the on-line catalogs of our suppliers.

Echo Trimmer Repair – How to replace the Piston Ring

The manufacturer of the old piston should be identified by the trade mark, and then, using its catalog (paper or electronic), enter the found number. The value of the casting number must be entered directly into the search field by part number (Artikel #) or search by replacement number (Reference No :). Do not forget to check the obtained results for the main geometrical dimensions with old parts.

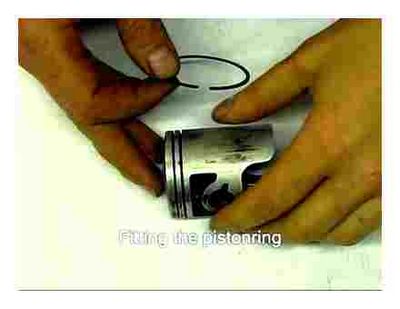

How to fit the piston correctly

The attachment shows and tells how to correctly install the piston into the cylinder on a scooter and motorcycle

Now about the third ring in the kit. Its purpose is to spring the lower compression ring. It installs it under it itself, and usually does not carry any benefit during operation. You can throw this ring away, or you can put it, there is no difference. How to properly install the piston on a chainsaw. Many piston manufacturers do not have one at all.

It’s time to put everything in place. Depending on the scooter model, the compression rings may be the same or differ in thickness and cross-section. Most pistons for Honda scooters, for example, have different rings, where the upper is thinner than the lower one and has a different cross-section.

It is imperative to pay attention to this when installing, the top is thinner and sharpened at an angle.

Also pay attention to the inscription on the ring (usually the letter T or the size of the repair), the inscription should always be on top, that is, opposite from the finger. First you need to put on the bottom, then the top. In this case, you do not need to stretch and bend them. These manipulations must be carried out carefully.

There are locks in the grooves for the rings that prevent the rings from turning during operation, therefore the ring gap must be exactly in these locks, otherwise you will not stick the piston into the cylinder.

And the last important point is the arrow (1) on the bottom of the piston or the inscription EX. Both the arrow and the inscription must be directed towards the exhaust (2). In this case, the ring locks will be on the side of the petal valve. How to put the piston on a chainsaw correctly. How right. If the locks are put in the direction of the exhaust, the piston will not last long, the rings will be pulled into the exhaust window and gradually grind it off.

With all the manipulations with the piston, it is imperative to shove a rag into the crankcase window so that something does not accidentally get there, we still need a crankshaft with bearings.

When installing the piston pin, pay attention to the condition of the cage (bearing), it may need to be replaced. Before installing the gudgeon pin, install the circlip on one side prior to installing the piston (usually the side where you will not be comfortable with the pin and second circlip). Then put the pin with the bearing and the second circlip, when it is fixed in the groove, it will emit a certain click.

That’s all, now put on the cylinder, not the piston (remembering to check the condition of the gaskets and lubricating the piston and cylinder walls with engine oil), the cylinder head and tighten the bolts alternately in a crosswise order.

How to change the piston on the trimmer.

In this video I will show you how to quickly change the piston trimmer on your own. I will change on the trimmer.

How To Fit The Piston On The Trimmer Correctly

Replacing the piston group in a chainsaw or trimmer

Repair of this level should always be weighed. In such small engines operating at high speeds, replacing the 1st piston, which is burned out or jammed, does not give a long result and the entire piston group needs to be changed as needed. »How to set correctly in a chainsaw or trimmer. Fitting the piston to sit on. Therefore, you need to think about whether to use this saw further or buy the latest saw.

If this is a professional model, then such repairs should be carried out, but if this is an ancient household model such as Husqvarna 40 and it has worked for more than 10 or 12 years, it is unprofitable to repair it. Therefore, how much will it cost to repair it. the same as the purchase of the newest saw, albeit not from Husqvarna, but for a PARTNER P350XT CHROME, the price of 165 will definitely be enough. over, such saws are sold by Husqvarna, since PARTNER is its subsidiary.

But if you nevertheless decide to repair a chainsaw or a trimmer, then you need unique spare parts that are not cheap. With proper operation of the motor, the first repair may not come soon and only the piston ring or rings will have to be changed, depending on the model. But if the saw is jammed, then you need to change the entire piston group. the cylinder, piston and rings.

It should be seen that the Husqvarna 136/141 chainsaws have approximately a service life of 500-600 hours, the Husqvarna 340/350. 1000-1200 hours, professional chainsaw more than 2000-2500 hours, subject to serious observance of the operation annotation. In fact, it is impossible to rely on these numbers, because the real resource can differ significantly, both in huge and in the smallest direction. But approximately we can say that semi-professional saws work 3-4 times longer than amateur ones, and professional up to 10 times or more.

Naturally, nothing is endless, but it’s one thing if you change the piston group, after long years of operation and it has worked out its engine hours, it paid for itself, and another thing is that this saw was refueled, for example, with gasoline, without oil, and it jammed. This saw has to be repaired because all other parts are normal.

Many companies deliberately inflate the price of spare parts to buy new models. For chainsaws and trimmers, for example, Stihl offices, spare parts are available in a larger assortment than for Husqvarna. Therefore, choosing a certain model, find out how things are with spare parts.

PBT

How to correctly install the rings on the piston of a two-stroke scooter

There is nothing difficult in installing rings on the piston of a two-stroke scooter, in general, like a four-stroke scooter, and many people understand this. But most of the scooters, who only recently acquired a similar technique, do not even have an idea of how to change the piston on a scooter, how to correctly install the rings on the piston, where the arrow on the piston should look, and almost everything else. In this lesson, I will tell you how to correctly put the rings on the piston and assemble the piston into place. Because we already talked about four-stroke engines earlier, here we will only talk about two-stroke engines. So, our piston engine is worn out and needs to be replaced. The attachment shows and tells how to correctly install the piston into the cylinder on a scooter and motorcycle. How to put a piston on a lawn mower in this lesson, I will tell you how to correctly put the rings on the piston and assemble the piston into place. The rings wear out first. The rings and the piston are the first to wear out, and usually only need to be replaced. With severe piston wear, the cylinder must be bored. It also loosens when the piston wedges in the cylinder, forming deep scratches on the walls of the latter. There is nothing wrong with that, and if your new cylinder has gone through the correct bore (for which you will need to pay only about 10), it will need a repair kit of rings with a new piston. Such rings are marked with a 0.25 mark. The second bore is 0.5, respectively, etc. to one.

After purchasing the piston, you need to assemble it. In the kit, as a rule, you will find the piston itself, two compression rings, a third thin corrugated ring (more on its purpose), a piston pin and two piston pin retaining rings

Trimmer repair tip MTD-600.

Good time of the day, dear friends!

Today I want to share useful information about trimmer repair, which was kindly provided to me by our reader Yuri. With his consent, I publish this, in my opinion, very useful information.

I will share how I repaired the MTD-600 trimmer (ignition problems), maybe someone will come in handy.

At first, nothing is clear, the trimmer simply does not start, does not even sneeze.

The Correct Way to Point Piston Arrow On A 2 Cycle engine

I checked the compression (to exclude a breakdown of the mechanics in the cylinder, rings, connecting rod, etc.). the compressor shows 10 bar after a couple of jerks. this is quite enough, the cylinder-piston-rings are in order.

Gasoline is supplied through the carburetor. the plug is wet and the top of the piston is wet.

The candle is clean, the gap is 0.6 mm. When scrolling, there is a spark. the twisted candle (its threaded skirt) is temporarily connected with a wire to the cylinder and we turn the starter. everything is in order.

There is compression, there is gasoline, there is a spark, but it does not start, which means there are problems with the ignition (ignition timing). But the ignition timing on trimmers / chainsaws, on such two-strokes is not regulated! Therefore, we disassemble the trimmer. we take the engine away from the shaft with the starter. Magneto opens. a coil with two pins-contacts and with two “cheeks” of the core, which at some point are closed by a magnet built into the flywheel, which the starter clings to when scrolling. It was found that this closure (it can be seen. this is the alignment of both ends of the magneto core with such well-defined areas of the magnet in the flywheel, the gap there is a fraction of a millimeter, while in other positions of the flywheel above the magneto there are several millimeters left) does not coincide with the TDC ( top dead center) of the piston (this point is easy to find by turning the shaft, observing the piston into the hole in which the candle is turned out).

Here comes the breakdown! Magneto should close somewhere near the “VMT”, and it closes when the piston went down somewhere! We unscrew the nut that presses the flywheel to the tapered shaft. It is found: the pin is cut off, which enters the grooves on the shaft cone on the outside and on the inner cone of the flywheel and which rigidly mates them in one position. How to replace how to correctly put the line on the trimmer. Then install the coil. The flywheel “cranked”. Most likely, someone with too much foolishness jerked the starter, so he tore off the flywheel, knocking down the ignition (the American trimmer should be easy to start by a child, no power is needed, but there are tractor drivers with experience in starting a diesel engine launcher, for them this technique will be rather tender).

If there is no standard pin, then you need to make it yourself: a small plate bent with the letter “U” so that with its “horns” it fits into two grooves in the flywheel, and with its curved part into a wide groove on the tapered shaft. How to put the coil on the trimmer correctly. How right. Empirically, its size is selected so that the flywheel lowers on the shaft and is securely fixed.

We check the coincidence of the closure of the magneto and “VMT”, tighten the flywheel nut, assemble the trimmer, start according to the instructions.

Many thanks to Yuri for such useful information!

Materials:

- metal perforated plate (100 mm x 240 mm)

- 2 hacksaw blades for metal

- 4 screws and 4 nuts M5

- 4 washers and 4 oversized washers

From a safety point of view, hacksaw blades should not be completely hardened.

Everything you need to make a nozzle

The most difficult thing in making a nozzle is to symmetrically mark and make holes for the knives and the trimmer shaft. That is why a finished perforated plate is chosen.

DIY trimmer attachment

For many summer residents, the trimmer has long become a familiar and almost irreplaceable technique. But it is not always possible to purchase a model that meets all needs. It happens that the trimmer copes with fresh young vegetation easily, but there is a desire to clear a place behind the fence or along the access road, and the tall ripened grass turns out to be too tough for the technique.

DIY trimmer attachment

We offer the option of self-production of the trimmer head from simple (almost improvised) tools.

Progress:

First you need to make the base of the nozzle. To do this, cut a square with a side of 100 mm from a metal plate of an angle grinder. You need to mark it in such a way that there is a hole exactly in the center (at the intersection of the diagonals). To do this, measure a distance of 50 mm from the center of the selected hole perpendicular to the short side of the plate and outline the cutting line for cutting.

We mark the base of the nozzle

Cut off the excess and get a square of 100 mm x 100 mm. Now you need to round off the corners a little and drill out the central hole for the trimmer shaft.

Round off the corners and drill the center hole for the trimmer shaft

We cut the canvases for metal, measuring 8 cm from each end.We get 4 blanks with ready-made holes.

We cut canvases for metal

These blanks need to be shaped like knives. To do this, we outline the cut line by eye (special accuracy is not required), fasten all 4 blanks together and grind off the excess.

Cut out knives from blanks

As a result, we get knives of the same weight and size, they can be sharpened a little on one side. Now all parts of the homemade trimmer attachment are prepared, you can start assembling.

Everything is ready for assembly

Put a small washer on the screw and insert it into the corner hole. We put on the knife from above, placing the sharpened side in the direction of rotation of the trimmer shaft. This is followed by a large washer and a nut that is not tightened so that the knife rotates freely. We attach the other 3 knives in the same way.

Fixing the knives

The end of the screw must be riveted so that the nut does not fly off.

The end of the screw must be riveted

The attachment is ready. It is installed with nuts to the ground and fixed in the same way as the three-blade knife that comes with the trimmer. When colliding with a stone, the knives fold and go inside a little.

This idea was suggested by our regular video author Tatiana (Tula region). You can see in more detail the whole process of making such a trimmer attachment and find out some of the nuances by watching the video that she prepared.

When working with a trimmer, it is important not to forget about safety, using any attachments, especially homemade ones.

We suggest discussing this idea in the comments to the publication. Share your thoughts with us, and also tell us about your good solutions.

Without accepting any of the sides of this sharp (literally and figuratively) discussion, let me show you one of the latest models of lawn mowers from the German company Robert Bosch. It provides for both a deflecting knife and an arcuate bracket, which excludes the knife “striking” on objects not intended by mowing. I show the general view of the lawn mowers and the knife itself, in two positions. General view of lawn mowers

Knife in a deflected state

Folded knife

Good evening everyone!

Exactly three years have passed since the discussion of the “acute” problem for the trimmer. Over the past 1000 days, a clear picture has emerged: “Glory to the author, the craftsman, who conducts an experiment on himself to reach the yield point of the metal from which these knives are made. He has every right to risk his own health. ” Nowadays in stunt films you can often see a frvza. “Do not try to repeat the movie stunts that were performed by professional stuntmen.” The very first article was supposed to end with approximately the same phrase: “Dear summer residents. This is my personal experiment. If you are not confident in your locksmith’s abilities, please do not repeat it. AND MOST IMPORTANT. I am not responsible for the operation of the tool, made in the footsteps of my articles.”

And the last thing. Do I see errors, judging by the photographs, of the execution of this tool. Yes, I see, and a rude one. Look closely at the plate, which is the carrier for the four knives. Look closely at the FAR RIGHT HOLE in the photo.

Alas, the author of this device does not even suspect how the hole for the shaft should be made.

I inform you that the distance from the point of the hole closest to the edge of the plate to the very edge should be NOT LESS than the diameter of the hole itself. Students of mechanics will learn this truth no later than the second year of the institute. What do we see here? A thin isthmus resembling a narrow PEREKOP, making a peninsula out of the Crimea. This is a priori the place that is weak in this design. it experiences the same loads as other knives, but the “digging” there is very thin.

Where it is thin, there and.

I would like to hope, and quite sincerely, that over these three years this isthmus has not undergone loads comparable to the yield point of this metal, but rather the alloy from which the perforated plate is stamped.

See the trimmer instructions for the continuous running time of the lawn mower. On average, we mow for 15-20 minutes, after which we turn off the trimmer and let it cool for 3-5 minutes. Weather conditions also affect the duration of continuous operation. In hot weather, when mowing tall grass, thickets of weeds, under heavy load, the trimmer overheats faster.

Many lawnmower problems arise from improperly prepared fuel mixtures. In two-stroke engines, lubrication is carried out with a special oil (not ordinary engine oil!), Mixed with gasoline. If the oil is not mixed with gasoline, the lawn mower will quickly fail. Mix the oil / gasoline in the proportion indicated in the trimmer instructions. Usually it is 1:40 or 1:50.

The question often arises: the proportion of 1:50 is how much oil and gasoline?

gas trimmer loves cleanliness. It is necessary to monitor the cleanliness of the air filter and fuel. Gasoline bought at a gas station is better to stand for 2 days and pass through the simplest filter. a piece of bike cloth.

We check the electrical equipment as follows:

We unscrew the candle, inspect the gap between the electrodes. We can set the correct gap between the electrodes in the “old-fashioned” way. We take the razor blade, break it in half and insert a homemade probe between the electrodes. If the blades fit tightly, then the gap is perfect.

We put the cap of the high-voltage wire on the candle and lean the candle against the metal surface of the engine. We pull the starter several times. If the spark hits one point well, then the gap is adjusted correctly. If not, the spark is weak or “wandering”, then it is necessary to re-adjust the gap between the electrodes.

Useful material from which you will learn how to start a naughty gasoline trimmer that does not want to work!

The summer time has come, and lawn-mowers clatter as usual on the personal plots. Great tool, powerful and mobile. With the help of a gasoline trimmer, you can cut the grass and get rid of the dried weeds. However, there are times when the lawn mower will not start, work intermittently or not at full capacity. There is certainly no time for work! And as they say, you pull the starter handle more than you mow.

Launching difficulties arise not only for seasoned lawn mowers, but also for new ones. How to be in this situation? There is only one way out. to heed the advice of experts and take advantage of their practical experience.!

Trimmer Repair. Replacing the Piston & Rod Assembly (Ryobi Part # 753-04367)

If you put a cable instead of a fishing line, without the possibility of releasing it, securely fixing the two ends of the cable and cutting them off by welding (a drop of melted metal keeps the cable from unraveling). Such a tool “knocks down” the grass at a time. Cuts off shoots up to about a finger thick. Not as afraid of stones as a disc. There is, however, a problem: when worn, pieces of cable thread break off, and these twisted wires remain in place of the mowing. Stepping on them can cause injury.

But the pieces of the cable left on the field are half the trouble. The fishing line, breaking off, weakens the dynamic shocks on the transmission and the engine, the cable does not give such an opportunity. The result is rapid wear on lawn mowers.

You bought yourself a new petrol trimmer and immediately got into trouble with it. It starts very badly. If you mow a little, and then turn it off, then turning it on “hot” is an even bigger problem than “cold”. What to do with it, I don’t know how to get it right?

The instruction for the lawn mowers plant sounds like this:

Switch on ignition.

Pump up fuel with a silicone button (primer) located on the bottom of the carburetor. Pressing must be done as much (or a little more) as written in the instructions, usually about 8-10.

Close air damper.

Lock the throttle lever with a stop button at high rpm.

Pull the starter handle 2-3 times. The engine should “grab”.

If the engine “grabs” and stalled, then you need to move the choke to the 1/2 position and try to start again. If the engine starts, then we release the gas and move the air damper to the “open” position. Getting started.

When performing fuel pumping manipulations, one should not be afraid to pour it over. If this happened, and, as they say, “filled the candle”, then you do not need to unscrew it, it is enough to move the air damper to the “open” position and, while holding full throttle, simultaneously turn the engine with the starter 2-4 times. After that, you can start the engine and get to work.

The numbers mean the following: one part of the oil takes fifty parts of gasoline. Hence: 1000 ml (1 liter of gasoline) is divided by 50, we get 20 ml, that is, 1:50.

Thus, you can calculate the composition of the fuel mixture (gasoline / oil) in any proportions. To add oil to gasoline not “by eye”, you can advise to take a 20 ml medical syringe, draw oil into it and “inject” into a container for preparing a fuel mixture.

Scooters Service and Repair

How to properly install the rings on the piston of a two-stroke scooter

There is nothing difficult in installing rings on the piston of a two-stroke scooter, however, like a four-stroke scooter, and many people know this. But most of the scooters who have just recently acquired such a technique do not even have an idea of how to replace the piston on a scooter, how to properly install the rings on the piston, where the arrow on the piston should look, and much more.

In this lesson, I will tell you how to properly put the rings on the piston and assemble the piston into place. Since we have already spoken about four-stroke engines before, we will only talk about two-stroke engines. So, our piston engine is worn out and needs to be replaced.

The rings and the piston are the first to wear out, and usually only need to be replaced. With severe piston wear, the cylinder must be bored. It also loosens when the piston wedges in the cylinder, forming deep scratches on the walls of the latter. There is nothing wrong with that, and if your new cylinder has gone through the correct bore (for which you will need to pay only about 10), it will need a repair kit of rings with a new piston. Such rings are marked with a 0.25 mark. The second bore is 0.5, respectively, etc. to one.

After purchasing the piston, you need to assemble it. In the kit, as a rule, you will find the piston itself, two compression rings, a third thin corrugated ring (more on its purpose), a piston pin and two piston pin retaining rings.

Now about the third ring in the kit. Its purpose is to spring the lower compression ring. It installs it under it itself, and usually does not carry any benefit during operation. You can throw this ring away, or you can put it, there is no difference. Many piston manufacturers do not have one at all.

It’s time to put everything in place. Depending on the scooter model, the compression rings may be the same or differ in thickness and cross-section. Most pistons for Honda scooters, for example, have different rings, where the upper is thinner than the lower one and has a different cross-section.

It is imperative to pay attention to this when installing, the top is thinner and sharpened at an angle.

Also pay attention to the inscription on the ring (usually the letter T or the size of the repair), the inscription should always be on top, that is, opposite from the finger. First you need to put on the bottom, then the top. In this case, you do not need to stretch and bend them. These manipulations must be carried out carefully.

There are locks in the grooves for the rings that prevent the rings from turning during operation, therefore the ring gap must be exactly in these locks, otherwise you will not stick the piston into the cylinder.

And the last important point is the arrow (1) on the bottom of the piston or the inscription EX. Both the arrow and the inscription must be directed towards the exhaust (2). In this case, the ring locks will be on the side of the petal valve. If the locks are put in the direction of the exhaust, the piston will not last long, the rings will be pulled into the exhaust window and gradually grind it off.

With all the manipulations with the piston, it is imperative to shove a rag into the crankcase window so that something does not accidentally get there, we still need a crankshaft with bearings.

When installing the piston pin, pay attention to the condition of the cage (bearing), it may need to be replaced. Before installing the gudgeon pin, install the circlip on one side prior to installing the piston (usually the side where you will not be comfortable with the pin and second circlip). Then put the pin with the bearing and the second circlip, when it is fixed in the groove, it will emit a certain click.

That’s all, now put on the cylinder, not the piston (remembering to check the condition of the gaskets and lubricating the piston and cylinder walls with engine oil), the cylinder head and tighten the bolts alternately in a crosswise order.

If you have any questions in the process of replacing the piston, you can ask them in the comments field or on the forum of our website. Good luck with the repair.

You can also check out other articles on the topic:

Situation:

The thermal clearances of some new piston compression rings are subject to a complaint. Unlike conventional sizes ranging from approx. 0.3 to 0.6 mm, the thermal clearances of these piston rings are 1 to 2 mm and are therefore considered too large. This is especially the case for the second piston ring compression, which is often suspected of incorrect delivery or manufacturing defect.

Technical reason:

Up to 90% of the total pressing force of the compression piston rings is generated during the expansion stroke by the combustion pressure (fig. 1). Exhaust gases enter the annular grooves and thus enter the underside of the piston rings. There, under the action of the combustion pressure, the force of pressing the piston rings against the cylinder wall increases, which affects the first compression piston ring and, to a lesser extent, the second compression piston ring.

Disadvantage:

At idle speed and at partial load, the combustion pressure is lower than at full load. Because of this, the compression piston rings are pressed against the wall with less force.

cylinder, which is reflected primarily in the function of removing oil from the second compression piston ring. This leads to increased oil consumption on certain engines.

Erroneous estimates of the thermal clearances of the piston rings

Large piston ring thermal clearance and high oil consumption: is the thermal clearance OK or the product is defective?

We will help you solve this problem.

Piston ring clearance and oil consumption

Remedy:

For the reasons stated above, engine manufacturers carry out a structural adjustment (increase) of the thermal clearances of the piston rings. Due to the increased clearance, gases under pressure-

by combustion, they penetrate more quickly into the annular groove and thus onto the reverse side of the piston ring. Due to this measure, the oil scraper and sealing functions are improved, and at the same time, oil consumption is reduced when idling and at partial load.

Indication:

All piston rings supplied by Motorservice comply with the engine manufacturers’ specifications. This ensures full compliance with all functional parameters.

Additional Information:

It is widely believed that large piston ring clearances cause increased oil consumption. However, this assumption is wrong. The increased thermal clearances of the piston rings cause a slight increase in gas breakthrough, but not an increase in oil consumption. The following is correct: as the piston rings wear, their thermal clearances increase. The performance of a reduced piston ring will deteriorate and no longer provide a proper seal. Increased thermal clearance and increased oil consumption are the consequences of radial wear of the piston ring.