How to redoing a horse mowing to a self -propelled gun. Drive unit

Horse braids: device, reviews. How to make a horse mowing with your own hands?

Hay cleaning, like any other work, has certain requirements. They include:

- Speed. Hammer’s workpiece should take place as fast as possible. During flowering, the grass accumulates the maximum amount of nutrients. Therefore, you need to have time to collect it at this moment.

- Quality. The grass should roll as low as possible. The better the work of the Cossets, the more hay will be prepared.

- Accuracy. When harvesting hay, a braid for grass should not touch the ground. The presence of dirt and a slice in the mowed grass is unacceptable.

Design

Horse mitch. a device designed for cleaning grass. The principle of its work is quite simple. With the progressive movement of the horse, the grass falls under the blade and is cut off. The mowed grass remains at the cut site. Then it remains only to dry the grass and collect.

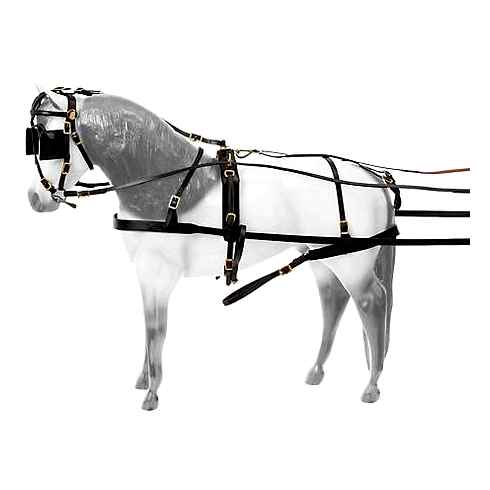

Rama in a mower made of cast cast iron. She relies on two chassis and drawbar. The cutting device is located on the right side of the frame. It is attached using a hinge. The seat is located on top. There are levers for controlling a horse mowing near it. In addition, the mower consists of the following spare parts:

- Cutting device.

- The drawbar.

- Lever regulating the slope of the cutting apparatus.

- The running wheel.

- Seat.

- Lifting lever.

- Rhistry coupling.

- Cylindrical and conical gears.

- Field divisor.

- Outrigger.

The cutting device is the main part of the mower. It is he who cuts the grass stem. Its design includes:

The purpose of the rotary mowing

If the farmer is interested in how a mower mower can be made with your own hands, you must first familiarize yourself with its purpose and the principle of operation. Such a device is designed to mow unnecessary vegetation in the meadows, fields and other territories, which allows you to maintain them in optimal condition. Rotor.type mowerpowers are a functional device that can be used for beating weeds, as well as for removing bushes and other plants along the roadway.

Since the effectiveness of such units is much higher than trimmers and other devices, they are universally used in the rural and utilities. Rotor braids are indispensable when performing work on hay harvesting, which makes them an extremely popular type of equipment.

Mowers help to carry out fast mowing grass

Varieties

When planning to assemble this equipment with your own hands, it must be remembered that the seno.sized for the tractor can be two main types. The first group of devices includes segmented products providing for the use of metal plates and knife. The main feature of this category of products is an affordable cost that made them extremely popular among consumers.

However, segmental products are low in the processing of impressive thickets of grass, weeds, shrubs, as well as some agricultural crops. In this regard, rotary devices that have increased performance are much more common for such tasks. The second.type devices have a universal purpose, can be used to work with various types of plants, hay harvesting for livestock.

Be sure to read: Segment mower for the tractor

Mount to the tractor

Finding out how to make a rotary mower for a tractor with your own hands, you will need to decide on the type of attachment to tractor technique. The functionality of the devices, as well as the working characteristics, depend on this.

- Semi.wow units. Provide for the presence of pneumatic fires, which allows more to distribute the load more uniformly. They are attached as a rear mounting equipment using a bracket, and hydraulic mechanisms are used for lifting/descent;

- hinged devices. The equipment is attached according to the standard scheme, located on the front of the tractor, suitable for operation in a complex landscape;

- Practicing equipment. Mounted to the hydraulic system of the tractor, equipped with rotors in an amount of at least 3 pcs, which are installed behind the equipment.

At the stage of studying the drawings, it is advisable to familiarize yourself with the methods of installing the mowing and, if necessary, make changes to the design of the selected model of the device. It should be noted that trailed models are the most easy to manufacture.

Rotor mowing diagram

How to make a rotary mower for a tractor with your own hands

The following materials and tools will be needed for the manufacture of rotary hayfields:

- wheels with a diameter of 450 mm;

- wheel axis;

- metal pipes and corners (thickness and diameter for choice);

- sheet metal;

- pulleys, knives, bearings;

- rubber belt;

- welding machine;

- drill;

- Bolts and nuts.

We will figure out how a rotary mower is made for a tractor with your own hands.

For rotary lawn mower, you can use scrap metal. You must definitely know what type of connection a mini.tractor has. There are 3 types of home.made connection to the tractor:

this breaks your joy cons! ��

First you need to cook the frame, attach discs on it, and on them. knives. Close all this with a protective casing. It will be good if you have old knives from a tractor rotary lawn mower. They just need to be seized from rust, if any, sharpen and weld to the disks. The discs themselves can be made from a barrel or sheet metal 4 mm thick.

Now we make axial shafts from a pipe with a diameter of 3 cm. We fasten one bearing on the pipe. It remains only to attach discs with knives to the axial shaft, weld the pulleys to the pipe, having previously fixed the second bearing on them, and the lawn mower can be considered ready. In order for a homemade rotary mower to the tractor completed, you need to attach a protective metal casing to the entire structure. the shield.

Such a mower mowel for grass copes with grass with a height of 5-7 cm. She can mow grass for the preparation of hay, as well as remove unnecessary harmful plants. Such a haymaking is considered the most profitable and cheap. You can, of course, buy a factory haymaking for a mini.tractor if you do not want to load yourself with independent manufacture and search for material, but homemade rotary mowers for a mini.tractor will last much longer.

The second type of lawn mower. segment. Such equipment is much more difficult to manufacture with your own hands, because its action is given by a crooked-shaped mechanism. One of the cro.shirts is connected to the crankshaft of the power unit. Knives are attached on the side of the krivoship. Knives are similar to 2 saws interconnected, and they work on the principle of scissors. they simply cut grass.

In order to make a segment model for a minister with your own hands, you need to take into account the stages of the sequence of its creation.

Neighbours Called Him Crazy, But He Had the Last Laugh

The optimal width of segments is considered 72 mm. It is necessary to install a gearbox on a metal base. It has a shaft on which the hub is attached. You need to install a pulley on the shaft, a wheel on the frame, which will not let the mower burst into the ground, and also set up the desired mowing height. The segment mower for the mini.tractor is driven as the rotary. through the power shaft. The most important thing in the work and use of the rotary or segment model is to observe safety precautions.

MB 90 alteration of the rotary mower, 2 parts

Good day! Continuation of the alteration of the braid.The first part here is www.Drive2.ru/c/566926888888052720364/Alteration was crowned with success, there is little left, and test in the field.

I bought a 19.pipe key for 19, it sits well on the slotted shaft, it remains to grow it with the shaft of the squirrel drive

The roller of the braid drive cut off in the same way as the key, hid the chamfer on the shaft and tightly filled the tubular key, after brewing

The mockery went well, launched- everything is spinning. Initially, I thought that the launch of the braid would sit the engine speed, but it turned out not, the engine on idle twists the rotors jokingly.

Instead of soil.spaced, I will put the wheel from the car.I hope this will correct the horizontal position. Or you have to shorten the shaft with the body that vertical on a mower.

It’s good to make out the mitch to stretch all the nuts that the gear of the gearbox holds, and at the same time fill it with a lithol, dismantled it and realized that every year they would not be engaged in this garbage (disassembly) for lubrication, it would be just laziness I decided to put it in every gearbox according to each gearbox Maslenka.

Now once a year or maybe more often. each gearbox will be discouraged depending on operation, and there are 4 of them.

On plates of mowers, he welded the bends so that the mowed grass was not stuck between them formed in the roll. This is needed where the grass is a very thick or strongly overgrown area. well, as in my case, I bought a house with a faster where the grass is above 1.5 meters.

I sharpened knives, although I heard that they were specially dulled so that the grass with knives is not just cut off, but how to tear and tighten between the milling

So far, in his thoughts, it is much better to rearrange the fuel tank decided not to walk around but strengthen the design of the mowing, threw the whine in order to remove the load from the design of the mower, because to mow well where you know that there is no log or stone under the grass, in my case you need to prepare for everything and think a step forward))

It remains to throw the steering wheel 180 ° and for this you need to come up with a new place for the tank or just throw off the tank and come up with a temporary thread in the form of a bottle. Although. Good luck, maybe where I missed, I will be glad to listen.

Today in the evening I turned the steering wheel, the fuel tank removed and in the replacement of it I put an extensor tank from Kia Pikanto, I fixed the whole thing with an elastic band for attaching barrels from the Lada.

Modernization or refinement

The main disadvantages of any braid that can be bought at the store are:

- insufficient strength of the structure;

- insufficiently rigid fixation to the walk.behind tractor;

- ineffective sharpening of knives;

- ineffective lubrication of rubbing parts;

- insufficient ski length;

- lack of defense of the operator;

- the impossibility of comfortable movement.

To increase the rigidity of the structure, pipe and other elements are welded to the braids on the bolts that remove excessive mobility of the frame. If the standard mount does not provide enough rigid fixation of the attachment equipment to the chassis, then it is redone, eliminating all the backlash. The method of alteration and refinement depends on the design of both devices.

The standard knives have no notes, so instead of them are used by homemade dampers, sliced from old sickles or knives of various agricultural machines, and then balanced so that vibration does not appear after installing them.

Reducers are often supplied with gearboxes without sufficient lubrication, especially often this happens with Chinese and devices.

In order not to disassemble the gearbox each time, a tawnnik is cut into its side or upper wall from a car, for example, gas 2410, then once a month or season through it is served a suitable lubricant.

Facial devices equipped with standard skiing are well suited for even areas, however, where there are pits of various sizes, their lengths are not enough, so the braid can fail, which will lead to a damage to the knife and possible breakdown of the shaft. Therefore, those who are forced to mow grass in uneven areas welcome extension cords to standard skis, so that the mowing passes without incident.

Almost all braids are deprived of the operator’s protection, so a stick or stone that came under a knife can injure you.

To avoid this, stretch behind the plates under the engine of a target from a tarpaulin or durable linoleum.

Parts of the owners of such devices do not like to walk for a long time, so in addition to the hitch, the mowing is attached to the walk.behind tractor, turning the device into a self.propelled machine. After such an alteration, even the mowing of huge areas is not difficult, because the operator does not have to follow the mower on foot, because he controls her while in the cart’s seat.

How to adjust?

Devices operating from a power selection shaft are unregulated, therefore, to change some parameter, they have to be seriously remade. The exception is mowers similar to mobiles to KM-0.5, in them you can adjust the height of the mowing, lowering or raising the wheels with the help of screws.

Most of the parameters of the devices operating from the shom are also unchanged, so only the belt tension mechanism has to be adjusted. Sometimes, after a collision with a stone, one of the disks turns on the shaft, which is why his knives collide with the knives of the second disk.

If this happened, do the following:

Principle of operation

Horse braids are ideal for harvesting grass in large areas. It will not be difficult to use this device even to a beginner. First you need to harness a horse into it. A seat is provided for an employee on a mower, while on which the mowing directs the horse and controls the device with the help of levers.

Knives in the cutting apparatus should be well sharpened. If you notice that the mower began not to cut, but to tear grass, this means that it is time to sharpen the blade. To do this, resort to the help of a special sharpener.

How to decide on constructive features

Homemade haymaking can be rotary or segmented. The first variety is most popular and convenient in terms of operational characteristics. The working part of the equipment is a disk with floating rotating knives. Such installations are effective for the case when you have to mow high grass.

Mobile knives cope with weed plants. If you want to make a device from a chainsaw, then you should not doubt it, because the unit is perfect for re.equipment, in addition, you can transform it back. A gasoline haying carp will have knives, as a material for which wood canvases act. You can use metal sharpened teeth.

What is included in a home.made mower

For assembling lawnmands at home, it is recommended to use an electric motor. The power of the lifting element should be more than 1 kW. As for the number of revolutions, their number should be at least 1500 per minute.

The size of the capture on average should be at least 5 cm. A power unit in the form of a motor can be taken from any old household appliances. For example, a vacuum cleaner, a washing machine and a chainsaw. The main requirement is the performance of the part.

In addition, the lawn mower is equipped with the following set of elements:

- Electric cord providing power;

- Maneuverable handle that allows you to control the entire installation;

- Knife. It will be used as a cutting part;

- Several wheels for installation mobility.

Experts recommend purchasing a protective casing that helps protect the user at the time of operation of the device.

As a cutting part, it is recommended to use metal knives that can be made of tool steel.

The width of such parts should be at least 5 cm, and their thickness is 3 mm. The photo contains an option to create a saw disk. As for the shape of the knife, it can be absolutely any.

The device of the mowing handle

You can use a metal profile as a handle for a home.made mowing, the length and width of which should be calculated taking into account the growth of the user.

In the process of moving the installation, a person should not bend and experience any discomfort. For the mobility of the installation, small wheels are used, which can be taken from furniture or baby stroller.

Do not use too large details that can disrupt the function of the lawn mower.

How to make a mower for a walk.behind tractor with your own hands?

It often happens that for some reason the manufacturer does not have a special mower on sale, specifically for this model, or that it does not suit her characteristics. In this case, it is easy to work on a homemade option. Full production on the basis of its economy will be demonstrated by the example of segment variation.

From spare parts, first of all, you need to take a rectangular pipe 5×1.5 120 cm long. An ordinary piece of old braids for grass is also suitable. About 12 holes are drilled on the pipe along the same distances, as drawings are shown.

You should prepare a frame from cooked corners and pipes, the frame can be covered with plywood and attached wheels to it. The tape is made by rubber ring.shaped. It is convenient to fix it with duralumin plates. Shrings are also welded on the frame to install the cutting strip. For the latter, a strip with metal blades is attached to a pipe prepared in advance with holes in advance.

Poster-platform

This drawing shows the option of a mowing platform, which is effectively used in the summer for mowing grass and weeds, and in the winter-as a snowpliter. For cleaning snow masses, special nozzles in the form of stars are mounted on equipment, and in the summer. knives. This modification is similar to a rotary mower, however, it is difficult to execute. This equipment allows you to cut hard grass and remove snowy sediments with ice.

The design of this equipment created by yourself is two cylinders connected by hooks with a frame and conveyor tape. The chassis is created from the corner or any other metal that is found in the workshop. Wheels are installed on the chassis that can be taken from an unnecessary stroller, and a thick plywood sheet, although ideally it is better to use metal. The dimensions of the frame can be different, but it will be optimal 800×400 mm.

The main node consists of two cylinders (5), belt (3), frames (10, 16, 17, 18.20), brackets (19), corners of hooks (4).

Working cylinders can be made of large tin cans, in which it is necessary to cut the bottom and cover, and in their place to install two rounds of wood. Instead of cans, you can use a thin metal sheet and make 4 disks with an external diameter of 200 mm and 4 with an internal diameter. 170 mm from it. Using the bolts, connect small disks with large. Attach four knives to these discs from discs.

DIY frame. The equipment consists of the upper crossbar (10) and a metal strip with corners and backy bushes (16). For the crossbar, you can take a metal corner of 35×35 mm. The cylinders are interconnected by a belt, for the installation of which grooves 13 mm wide are drilled in the corners. For this, the lower sleeve of the leading drum is mobile fastened on the bar (15), and stretch corners (20) are installed on the upper axes of the cylinders. Tighting corners (20) is carried out to the ends of the transverse beam using the M5x65 mm screws. The drum belt is easier to make from the rubber strip, the ends of which are connected using a duralumin plate 2 mm thick.

Next, knit a mower with a power block selection shaft. The work of the pitch-brey can be viewed on the presented video.

Mowers for different tractors

When developing a mower for a specific tractor model, consider:

- The power of the engine. the vehicle will have to not only twist the shaft of the cutting tool, but also move the tractor along not too flat land;

- Type effort. the higher this parameter, the more heavily the tractor can drag the tractor behind him;

- The speed of rotation of VOM. most tractors of 3 mode of operation of the REDUTOR VOM, which differ in the speed of rotation of the shaft, which must be taken into account in order to ensure the optimal rotation of the shaft of the cutting tool;

- the place of installation of the mowing. it can be put in front, back or side, and each of the installation options requires a special design of the frame and drive.

Next, we will talk about the features of braids of various types for the most popular tractors models.

This self.propelled chassis was born in the sixties of the twentieth century, but in the nineties its production stopped. Nevertheless, this chassis is still popular due to its versatility and maintainability. Engines with a capacity of 16 liters were installed on this technique. With. (T-16) and 25 l. With. (T-16MG), and the number and location of the VOM depends on the modification.

Here are the main technical characteristics of the tractor:

Due to small weight and power, you can use only relatively small mowers of any type, for example, segmented or multi-generated with a capture width of 1.5–2.2 m, which must be taken into account when making the device with your own hands.

Chain or saber with a capture width 40-60 cm are also suitable, if a wider mowing strip is needed, it is better to install a couple of such mowers with a capture width of 25–45 cm.

Remember, the thicker and tougher the grass, the less the capture width should be, otherwise the tractor engine will operate in overload mode and quickly fail.

This tractor also comes from the sixties of the last century, but, unlike the self.propelled platform, is precisely the tractor. It is equipped with engines with a capacity of 20–40 liters. With., as well as rear.wheel drive, although modern modifications are leading wheels.

Despite the fact that the initial model, which was developed at the Kharkov Tractor Plant in 1966, has already been discontinued, the total number of cars produced exceeds 800 thousand.

Here are the characteristics of the T-25:

Due to the fact that the T-25 is harder and more powerful than the T-16, it can be installed on it larger equipment, for example, a two-scale segment mower with a total capture width of 4 m.

However, installing rotary hinged devices with more than four disks is undesirable, especially on high.power motors with low.power motors.

On T-25 with a 40 l engine. With. Even six.rope mowers are suitable, however, you can use such a combination only for low young grass, but if you need to mow coarse green, it is better to use two.rope devices.

The T-40 tractor also comes from the middle of the last century, however, they developed and produced it at the Lipetsk Tractor Plant. This model is one of the most popular, because for the entire time the original T-40 (1961–1995) was produced more than a million cars.

The T-40 is noticeably harder and more powerful than previous models, therefore, it belongs to the traction class 0.9, which allows you to add even very heavy three.bide braids weighing two tons.

Here are its main characteristics:

Due to the increased power of the power unit, it can use mowers designed both for small tractors (some of the manufacturers attribute cars similar to T-16 and T-25 to the class of mini-tractors), and medium tractors, such as MTZ 80/82.

Therefore, as a sample and technical specifications for the manufacture of a home-made mower, you can use any hinged or trailer device of this type, designed for MTZ-80/82 or mini-tractors of a mini-minute.

MTZ-80/82

This legendary tractor has become a symbol of the era of the seventies, and today its modern modifications can be found in any farm or public household.

The reason for his popularity is that he was the first full.size universal tractor suitable for working in the field or on city streets.

It is equipped with an 80 liter engine. With., And its traction class 1.4 allows you to transport trailed devices weighing several tons.

Thanks to a more powerful engine, several braids can be installed on this tractor, for example, the front hinged and rear trailer, which sharply increases its performance, and a fairly large weight allows you to hang equipment weighing in a ton.

Here are the characteristics of MTZ-80/82:

- mass 3.6 t;

- engine power 80 liters. With.;

- traction class 1.4;

- rear drive (MTZ-80) or full (MTZ-82);

- The hydraulic system is separately agent;

- Installation of attaching equipment is possible in front, back, side.

This tractor can work with mowers of any reasonable size, so the maximum capture width is limited only by the cross.country ability and maneuverability of such a technique.

Therefore, choose the type and configuration of hinged/trailer equipment, which:

The design of the horse mowing KT 1 production Gomselmash

It is used in small areas, with continuous relief, in garden partnerships and forest areas. Can be used as a trailer equipment. The principle of operation of the equipment is elementary, while the device of a horse mowing designed for cutting plants is the following. while the traction of the equipment occurs, grass falls under the blades, and the mowed grass remains in the same place. It will need to be assembled.

The specifics of the field of activity determined the use of high.strength materials. The frame of the mowing is usually made of cast cast iron or special alloys, it rests on the wheels of a chassis and drawn up. Usually the cutting device is located from the right side and is attached using a hinge. In the upper part, the equestrian mowing on the one.axine tractor has a seat for the operator. There are also control levers, among the capabilities of which the slope of the cutting element.

Design features

The main working part is the cutting device. With it, the stems are cut off. It consists of:

Thanks to effective horse.drawn horse riders, even extensive territories can be easily processed, while even a beginner who had never encountered such equipment will quickly deal with the control and cope with the control. After you have done all the preparatory work, management is carried out using levers. It is worth noting that the knives should be well sharpened. If the unit does not cut off, but tears grass, it is time to bring the blades to proper condition.