How to reduce the course of the walkbehind tractor with a pulley. Pulley: characteristics and properties

How to reduce the speed of a walk.Behind tractor using pulleys

Maize corn harvest for walking tractor

Motobobes with a minimum number of components are sold. However, cutters and a standard plow to perform all agricultural work are not enough. How to improve a motor.Cultivator using improvised materials? With the help of tools that are in every house, you can expand the capabilities of the walk.Behind tractor. Equipment that can be manufactured independently:

- Installation on a walk.Behind tractor for harvesting garbage, leaves, hay. Such a simple device will accelerate autumn-field work, will allow you to clean large areas from garbage in a matter of minutes. For the manufacture of rakes, it will be necessary: several meters of reinforcement with a cross section of 8-12 mm and a strip of sheet metal. Reinforcement, cut into segments of 10 cm long and welded to the plate in several rows with an interval of 3-5 cm. To increase the maneuverability, the rake can be equipped with roller wheels.

- Trailer and cart, help to transport the overall goods. The cart can be made from improvised materials. A channel and old wheels from a car, a metal profile and boards. Clutch is done standard as for tractors and cars.

- If desired, you can make a potato.Cutter, a cupboard and harrows, which will not be inferior in quality to purchased.

Plugs for motor blocks

Another device for processing the soil using a walk.Behind tractor is a plow.

- The easiest way to use is single.Pointing, as known as Zykov’s plow.

- Reverse plow for a walk.Behind tractor: rotary or revolving. The upper part with a bent feather, which in the process of plowing turns the earth. Universal device that easily copes with plowing heavy soils. Quickly copes with the processing of areas with clay and marshy soil.

- Rotor plow for a walk.Behind tractor has a complex structure. Depending on the number of plunders, there are two.Building and three.Body models. Active strains drop the earth only in one direction, and passive compare the beds and lift them. Earth cultivation with such a plow has a number of advantages: the soil is as saturated with oxygen; the wear of the tires and fuel consumption decreases; After cultivation, there are no large lumps of the Earth.

- Rotation plow for a walk.Behind tractor gives unlimited possibilities. During operation, the axis turns, and with it the soil layers. Even very hard soil at a depth of about 30 centimeters plows easily. Lobed, drum, spatulas and screw plows differ. The first types of devices are equipped with a rigid pusher, can consist of a spring plate or be combined. The second.Type units are equipped with a disk with blades rotating during operation. A plow with a disk knife for a walk.Behind tractor is suitable for work in early spring, it copes well with wet soil.

Any of the above plows can be made independently, given the design features and following the instructions and schemes. You can also improve the already purchased plow.

Thanks to the expansion of the capabilities of the motorcycle block, it becomes universal. You can use it to solve a variety of problems from field work to snow cleaning in the winter.

The purpose of the lowering gearbox

The driver is a conventional lowering gearbox, which increases the rotational moment due to a decrease in the speed of the motor. The operation of the driver is rational: when cultivating fertile or uncomfortable lands, a large depth of plowing, transportation of heavy cargoes, or the use of heavy mounted equipment. When everyday work in such conditions, it is necessary to most carefully monitor the work procedure.

The correct solution would be to slow down the engine speed and work at the least speed. However, in such a situation, the power is lost, which is unacceptable. Here, the revenue of the motorbone reducer reducers come to the rescue. They make it possible, without reducing the engine speed, and, therefore, without losing power, get optimal control over the processing procedure, and even increase the power.

This is interesting: Motoblocks virgin: device, models, characteristics, video

Increase in the power of the walk.Behind tractor will allow the most efficient use of the unit

Motoblock is an indispensable thing for farmers. Increase in the power of the walk.Behind tractor allows you to increase the productivity of technology and accelerate the execution of agricultural work. You can improve the technique with both your own hands and by buying the necessary devices.

Increase in the power of the walk.Behind tractor

You can increase the speed of the walk.Behind tractor in ways:

1962 Simplicity Tractor Model W Back to Life

An increase in speed in the first way is a rather complicated process. Therefore, without the presence of knowledge and skills in this area, it is better not to do this on your own and will contact a special service center. If there are necessary skills, you can make a replacement yourself.

Just like any other technique, the motorcycle block has several speed modes controlled with the help of gears. Motoblock moves at a speed of 2 to 15 km/h. There is usually 61 tooths for a larger gear, and 12 on a small one. To increase the power of the walk.Behind tractor, the gear pairs of the gearbox is replaced.

The maximum speed can be achieved by increasing the number of teeth on the gear.

When replacing the gear, it is imperative to choose the right pulley. With improper selection of pulley pullers, it may stop working.

To increase the speed, you can set up tires with a diameter of 70.4 cm, such a replacement will help to speed up the motorcycle block by several times. If the arches in which the tires are placed will allow you to put wheels with a large diameter, you can try to increase another few centimeters.

Increased patency and improvement of the walk.Behind tractor

As you can improve the motor cultivator with the help of weighting. They can be bought or manufactured and installed independently. Weighting agents are installed on the frame and wheels. Cargo for wheels is made of full profile and steel disks. The case is weighted using special removable frames and corner. Cargoes with different weights and configuration are attached to the frame.

As you need to weight a motor.Cultivator sometimes quite strongly, reinforced concrete products can be used.

Such goods can be able to load a motorcycle block quite well. With the help of such non.Cunning devices, the range of technology expands significantly.

It is possible to understand a home.Made snowmobile with a sled to transport property or animal feed, fishing or hunting.

How to increase the power of the walk.Behind tractor using the rear speed

Installing the rear speed on the motor.Cultivator is another way to improve the motorcycle block. The presence of a reverse depends on the size and models. It can work on any type of equipment, it all depends on the tasks set before the technique, whether it be a light or heavy motoblock, or a motor.Cultivator. For equipment weighing up to 30 kg, there is no need in the rear speed, on a weighted unit without it, it is more difficult to get the work.

Gear gearbox is a transmitter that works between the wheels and the motor. The reverse tutor consists of a coupling located between the gears and are on the main roller. The corner is responsible for the operation of the transmission with the engine, which affects the power.

The reducing gearbox is responsible for reducing the number of revolutions, which helps to increase power. The main task of this system is to ensure reverse.To make this mechanism at home, you first need to make a case. Then choose the necessary details.

Additional devices

Motobobes with a minimum number of components are sold. However, cutters and a standard plow to perform all agricultural work are not enough. How to improve a motor.Cultivator using improvised materials? With the help of tools that are in every house, you can expand the capabilities of the walk.Behind tractor.Equipment that can be manufactured independently:

- Installation on a walk.Behind tractor for harvesting garbage, leaves, hay. Such a simple device will accelerate autumn-field work, will allow you to clean large areas from garbage in a matter of minutes. For the manufacture of rakes, it will be necessary: several meters of reinforcement with a cross section of 8-12 mm and a strip of sheet metal. Reinforcement, cut into segments of 10 cm long and welded to the plate in several rows with an interval of 3-5 cm. To increase the maneuverability, the rake can be equipped with roller wheels.

- Trailer and cart, help to transport the overall goods. The cart can be made from improvised materials. A channel and old wheels from a car, a metal profile and boards. Clutch is done standard as for tractors and cars.

- If desired, you can make a potato.Cutter, a cupboard and harrows, which will not be inferior in quality to purchased.

Plugs for motor blocks

Another device for processing the soil using a walk.Behind tractor is a plow.

- The easiest way to use is single.Pointing, as known as Zykov’s plow.

- Reverse plow for a walk.Behind tractor: rotary or revolving. The upper part with a bent feather, which in the process of plowing turns the earth. Universal device that easily copes with plowing heavy soils. Quickly copes with the processing of areas with clay and marshy soil.

- Rotor plow for a walk.Behind tractor has a complex structure. Depending on the number of plunders, there are two.Building and three.Body models. Active strains drop the earth only in one direction, and passive compare the beds and lift them. Earth cultivation with such a plow has a number of advantages: the soil is as saturated with oxygen; the wear of the tires and fuel consumption decreases; After cultivation, there are no large lumps of the Earth.

- Rotation plow for a walk.Behind tractor gives unlimited possibilities. During operation, the axis turns, and with it the soil layers. Even very hard soil plows at a depth of about 30 centimeters easily. Lobed, drum, spatulas and screw plows differ. The first types of devices are equipped with a rigid pusher, can consist of a spring plate or be combined. The second.Type units are equipped with a disk with blades rotating during operation. A plow with a disk knife for a walk.Behind tractor is suitable for work in early spring, it copes well with wet soil.

Reduce the speed of the Neva MK80R motor.Cultivator

So it’s time to engage in a motor.Cultivator.

In the last publication, I already wrote that the speed of the Neva MK80R motor.Cultivator at the average engine speed with wheels with a diameter of 400. 410 mm is about 6 km/h, agree this is a bit too much and you have to jump over this unit.

The network has a lot of information on the manufacture of howling, but these are all complex designs and in the country barn this is problematic to do this. There is an easier option to increase the driven pulley or a decrease in the lead.

There is another plus of an increase in the driven pulley. With a decrease in speed, the load on the engine decreases.

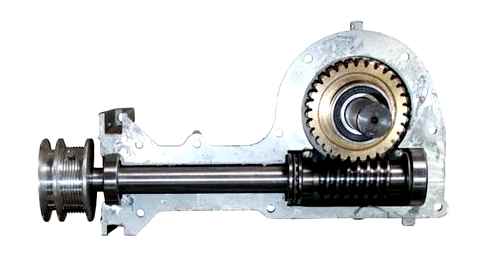

There is only one way out. Change the pulleys. Let’s start with the manager. Native plastic pulley diameter 170 mm, a landing hole for a shaft of a reducer of 15 mm with a groove for the veneer, belt profile “a”- length 960 mm. It is clear that the finished pulley with an outer diameter of 220-230 mm and I can’t find 15 mm landing, I go to the car shop and buy the “pulley of the ZIL-130 compressor”

External diameter 240 mm, belt profile “B”, conical landing hole 20 mm.Cost 640 rubles. Pulley weight 2950 g. There is no choice, we buy and redo.

We cut out the whole middle with the knitting needles, so it will be easier to make a new filling.

I don’t have a turning machine, so I will do everything on my knee. Found the pipe wall 2 mm inner diameter 14 mm. We cut a piece with a small margin with a small margin, cut it along, plant it on the gear shaft, criminalize, gently drag the landing under the venerable. Then we take a piece of water pipe 0.5 inch, also cut it along and attach it to the already made workpiece under the veneer. Clearly combine, adjust that there are no backlash and weld our details together.

Everything is simple with the knitting needles, we take a steel strip of 25×4 mm, clearly mark the center of the pulley and weld the knitting room. We cut out the middle of the knitting needles under our sleeve, clearly reconcile and weld it strictly in the center between the knitting needles. We check our pulley for a vertical beating, weld the transverse knitting needles on the deviation from the central axis, again check for the beating and deviation, if everything is OK, we welcome our design.

The case remains small, to adjust the outer size. Gently cut out the outer sides by 5 mm and as a result we get a diameter of 230 mm, which we need. A gap of 3-4 mm is obtained to the wing of the motor-cultivator

Putting a new pulley of the old belt will no longer work. We go to the store and take the belt all that one. The same profile “a” but already 1090 mm. By the way, in a specialized store, it costs five times cheaper than the native, which is offered by Neva. We put on a motor.Cultivator and enjoy the smoothness after our improvement. The belt with profile “A” clearly approached the groove of the cut pulley. Compared to a plastic pulley, the release became smooth, without jerking, the speed, as I suggested at the average engine speed of about 4.5 km/h, which was required for me.

It remains to make a protective casing and you can comfortably cling to any mounting equipment, even a cart. By the way about the cart, we will try and attach it.

If necessary, your native pulley can be rearranged in a couple of minutes.

How to regulate the speed?

Sometimes it turns out that I want to change the speed of the movement of your walk.Behind device: increase or, what happens quite rarely, reduce it.

To increase the speed of motion units, one of two methods below is usually used:

BCS walk behind 2 wheels tractor buying used? What to look for

The usual diameter of the wheels of almost all motoblocks is 570 mm. Most often, when replacing, tires with a diameter are selected, which is more than 1.25 times more, 704 mm. Although the difference in size is relatively small (only 13.4 cm), the speed of movement increases significantly. Of course, if the design allows you to put larger tires, you can try to increase the speed of speed.

The gears installed in a wheel gearbox usually consists of two gears with the number of cloves 12 in small and 61 in large. You can change this indicator by 18 and 55, respectively (only among specialists in agricultural service centers), then the winnings in speed will be approximately 1.7 times. Do not try to independently conduct an operation to replace the gears: it is very important to choose not only high.Quality parts with minimal errors, but also the corresponding pulley. An important role is played by the latch of the gearbox shaft.

Logically reasoning, reducing the speed of the motoblock movement can be achieved by the performance of diametrically opposite actions. To reduce the diameter of the tires or the number of cloves on a gear pair.

A possible solution to the speed of speed consists in adjusting the gas switch: When the device turns on, rearrange it from the first position to the second. To reduce the speed of movement, return to the starting position. Of course, to change speeds in the shorter direction, special reducers are not needed. It is enough not to switch to high gears.

First of all, the stars of the primary shaft are mounted. If the design is massive, flange or key mounts is fixed by means of point welding. At the next stage, they choose the method of attaching the driven shaft and a pair of half.Skinned axes.

When installing, it should be taken into account the possibility of shifting a star in one of two directions. The case is made independently or with the help of specialists. If the first option is selected, take into account the features of the seals, the corresponding seals and bearings.

The device of the driver

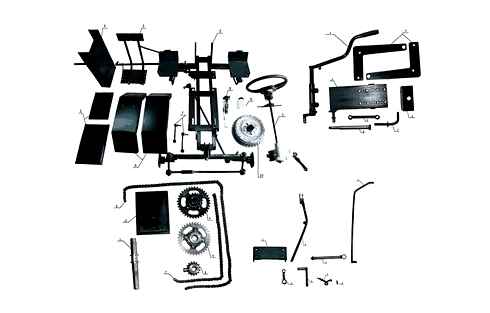

The design of the mechanism is quite simple from a technical point of view and includes:

You can choose a driver for a walk.Behind tractor at any specialized point of sales of agricultural machinery. In the case of independent manufacture, you can save and leave a considerable amount of money for anything else necessary in the garden. Before making the structure, it is better to prepare drawings of all nodes with sizes.

In this video, consider the installation of the driver:

Description

In motoblocks, designers use belt gear, which consists of two pulleys, belt and stretch device.

- High speed of work;

- Protection of the drive units from overheating;

- Simplicity;

- Reliability;

- Low cost;

- Lack of noise.

Pulley. The main part of the gearbox, which is located on the central shaft of the engine. The appearance of the part resembles the shape of the wheel, interacts with other elements through a special belt.

In specialized stores, you can purchase these devices of different sizes. Most of the details are made of aluminum, steel, cast iron and duralumin, has high strength and reliability. To reduce the cost of goods, some manufacturers use plastic, plywood and textolite for production.

The main criterion when choosing a part is the size of the belt. The size of the pulley depends on it.