How to refuel a trimmer with a fishing line. Two working antennae

How to refuel a trimmer line in a trimmer calm

It should be noted that the coils in mowers can be different:

- For functioning with one osik;

- For functioning with two antennae;

- The trimmer line should be extended through the through hole, which is located inside the element.

And you should not confuse this part with an extension cord for a lawn mower on a coil, because despite the similar name these are two completely different elements.

This article will tell you how much the ZIL 130 dump truck weighs and what this transport is capable of.

Read here // MachinSpec.COM/Leszagotovitelnaya/Benzopila/Stanok-Dlya-Zatochki.Html, how to assemble a machine for sharpening chains of a chainsaw with your own hands quickly and simply.

In the first version, wound the cutting element is very simple:

- On the inside of the coil element there is a fixing ear.

- One mustache is inserted into it.

- Refuel the nylon thread in the direction of the reverse rotation of the coil element.

- You will need only 2 to 4 meters of trimmer line. When the winding process is completed, the small end of this cutting element is put out and fixed in the groove that is necessary to fix the trimmer line so that it does not spin during the functioning of the mower.

- If there is no special groove, then the end should be held with a hand so that the cutting element does not spin during the further collection of the element.

- At the last stage, it is necessary to pass the outer end of the thread into a special hole located on the outer part of the element. After that, the coil can be inserted into a mower.

When the video works with two ends of the polyethylene thread, then you need to take the following steps to tie the fishing line into the lawn mower:

- Inside, the coil will see how many recesses for winding are available (two or one). If one deepening, then both ends of the threads will be laid on this recess. If there are two of them, then the antennae are laid out separately. Each by its own seizure.

- It is necessary to rewind from 2 to 4 meters of polyethylene thread and pass two ends into the hole.

- Wind both threads in one direction, reverse the drum.

- When the entire trimmer line is wound, the ends should be fixed in grooves or held with a hand.

- Both ends are threaded in the ear from the outside of the clip body.

- After that, the drum is assembled and inserted into a mower.

To insert the trimmer line into the lawn mower in which the coil contains two grooves, you must use the previous option for refueling this polyethylene thread. In this case, each of the ends of the trimmer line will be wrapped in a groove. All other actions similar to the previous process.

Coil element or video can have a completely different design, different from the previous two options. The trimmer line can last through the ear, which is through and is located inside the coil. In this case, you do not need to disassemble the roller drum and manually wrap the plastic thread.

The polyethylene thread is threaded through the hole and rotates by pressing a special button. This button is located on the case and is intended for the operation of the equipment so that it is possible to produce a fishing line as it is worn out.

Do not worry that the polyethylene thread is wound in the wrong direction, since it can spin in this design only in one direction.

How to remove a trimmer line from the coils of different types

In the instructions for the operation of each trimmer, there is a detailed description of the standard replacement of the fishing line, which involves the removal of the old cord. If you have a regular trimmer head or other model of the same type, then Follow the instructions set forth in the operating instructions.

If you have a coil of a different type or a trimmer line to cut off inside the trimmer head, then you can’t do without disassembling or removing this part (depending on the type of coil), so we will share the recommendations that will help you pull the trimmer line from the reel of any type.

Mechanical non.Devastated

In such coils, the fixation of the trimmer line occurs due to its wiring through curved channels of various shapes, that is, the cord, due to its rigidity, holds itself. The only problem is that The cutting string is located on both sides of the head, Therefore, it is impossible to comfortably remove it without dismantling the details from the trimmer.

To unwind it, remove the coil from the trimmer, using the full.Time key and any suitable latch, for example, a nail or hairpin, and getting access to both sides of the part, pull out the cord.

Mechanical collapsible

To extract the remaining cord from a collapsible mechanical coil, the key that is delivered with it, unscrew the clamping bolt, then pull the material out of the holes.

If the bolt hat is clogged with scraps of grass and dirt (this happens with mowing after rain or watering) and it does not work to insert a hexagonal key into the hat, bring the device home, where or wash your head right on the trimmer, or remove it from it using a gas key, and then wash it separately. When the coil is washed, you easily unscrew the bolt and remove the remaining strings.

Automatic and semi.Automatic

Combines these trimmer heads system for feeding trimmer line. When clicking on the button, just pull a piece of cord sticking out of the case And he will come out for some length. By pressing the button and gradually pulling the string, you can completely unwind the coil.

If a simple way does not help, then squeeze your fingers a couple of latches on the sides of the case next to the lid and remove the latter to get access to the spool. Then pull out the spool with the remains of the trimmer line and not only remove the string, but also look for the reason why the standard feed did not work.

If you can’t remove the lid, do not have enough fingers or for some other reasons, then twist the coil from the trimmer as a whole. If you have a motorcycle or electric cos with a straight bar, then twist the coil clockwise, if the bar is curved, then against the sentry.

The electric cos with the lower motor location of this method does not work, Because there is no thread on the shaft. Instead of it, the slots, and the trimmer head is planted “on hot”, that is, if you couldn’t disassemble the head on the spot, you will have to carry the device in the workshop or come up with something at home.

If jammed because of too thick trimmer line

Trimmer owners often neglect the information indicated in the manual about the maximum thickness of the trimmer line and put a larger cord, because this increases the efficiency of the mowing.

The result of this attitude is the jamming of the string inside the coil, which is why Automatic feed stops working, After all, the cord stucks in the holes of the case and is too tense inside the spray.

The most unpleasant thing in this situation is the inability to pull the squelpile normally, because the trimmer line stuck in the body blocks it. In the field, you can (if there is a suitable tool at hand) cut the string along the edge of the case, and then press the crushing with a cross.Plate, which is included in the supply of most trimmers.

Когда такой способ не дал нужного результата, поставьте на место крышку и скрутите катушку в сборе, как описано выше, затем разберите ее на столе.

If you want to use it with a thicker trimmer line, which is allowed for your electric ships or benzo.Coats, then Install new plates with the corresponding calibration holes (not available on all trimmer heads).

If the cord is twisted inside the coil

This happens if the cutting string is wound incorrectly or it is stained with something sticky, in this case, remove the lid and pull the coil out.

Then soak the fishing line and either rewind it correctly, or wrap a new, not smeared with a sticky substance.

The process of winding the trimmer line on the reel

-

After all the preparatory actions, we need to correctly decide how exactly the trimmer line will be washed on your device, by turning the cover or in the opposite direction.

- We measure approximately 7 mm cutting material and at one end we insert it into the opening hole. It is worth noting that the trimmer line is wound precisely on the model of mowers style from two side. The direction of winding of the trimmer line in such models is indicated on the bastard itself.

- The trimmer line is exposed to about 17 cm freely so that weeds can be cut off with the ends. Add that you should not wrap the trimmer line on the coil of a huge length. About 5 mm leave the distance from the trimmer line to the edge.

- The two ends of the trimmer line are inserted into the holes. Both of these ends should be reliably fixed on the device case.

- The springs extracted from the coil (if any) insert the same as they were extracted, t.E. In the backlog and the body of the head itself.

- To determine whether you put the trimmer line into a trimmer correctly, you need the element itself (bobbin) itself can easily be inserted into the body of the head of your device. If necessary, remove the free ends of the trimmer line to the outside. To achieve this, you need to pull the trimmer line through the holes in the squire with a sharp movement.

So, let’s say, you figured out how quickly, and most importantly, to correctly wrap the trimmer line on the coil of the trimmer calm. All that you have left is to insert everything into the grooves and fix the main cover on the device. Then you can press the bobbin itself and make movements counterclockwise until you feel the emphasis. If you do not feel the emphasis, then most likely you set the trimmer line not correctly and you will have to start everything from scratch.

Coil with one working osik

The easiest option and a simple sequence of actions:

- The dimensions of the bobbin and the length of the original factory winding determine the length of the trimmer line recommended for winding. 2 5 m.

- One end of the trimmer line is inserted into the fixing technological hole located inside the spool.

- The trimmer line is wound on the drum in the reverse rotation of the spilles in the trimmer product direction. As a rule, on the inside of the bobin, the arrow indicates which direction the winding is carried out.

- A small section of the trimmer line is left free to output it. It is fixed in a specialized border on the inside of the bobbin, designed to keep the winding when assembling a spool in working condition.

- The left end of the trimmer line is passed through the hole of the outer part of the bobbin.

- Half of the bobbin are collected and put on the bar of the trimmer device.

Preliminary preparation

First of all, to wind the trimmer line, it is required to remove the coil (bobbin, spool) from the trimmer. Specific actions will depend on the complexity of the configuration and the type of product itself:

- Small electric trimmers with a working location of the engine and coils in the lower part, as a rule, have side keys on both sides of the bobbin. With the simultaneous press on them, the upper part of the coil, along with the internal contents for winding the fishing line, is disconnected, while the lower remains on the trimmer. It is advisable to analyze the bobbing in an even smooth place, so that the spring does not jump out and not be lost;

- Electric and gasoline trimmers with a curved rod without the ability to install a knife, as a rule, have coils with a special lamb: in such structures, you should hold the spool in a motionless position with one hand, and rotate the fixing bobbin on the bar with a barack’s bar with one hand. After disconnecting the nut, the whole bobin is removed.

- Electric and gasoline trimmers with the ability to install a knife on a straight rod (for example, trimmers of calm) under the bobbin have a hole. For the immobility of the bar, a screwdriver or another suitable object is inserted into this hole and, with slow rotation, such a mutual arrangement is achieved when the screwdriver enters the hole and the bob is fixed. After that, the coil body is scrolled clockwise (with the left thread) and removed from the trimmer.

Three Essential Fishing Knots for Beginners

For the second and third cases, the coil, depending on the design, are versed in various ways. In the bobbins with a lamb, lamb is twisted, in the reels with latches, latches-fixers are pressed and one part of the coil is freed from the other. If the halves of the spool are connected by thread, then it is enough to turn them with your hands in the opposite directions until they are completely developed.

Trimcut braid head

Such models are considered two.String and designed for mowing and clearing space. The main difference between this design is the presence of a cutting string coil and manual length adjustment. Such a settings should be carried out with a drowned engine.

Trammer’s line refueling with Trimcut head begins with the fact that it is necessary to prepare two strings of the maximum length (8 m, 6 m or 5 m). It depends on the type indicated on the packaging.

- Take a trimmer drum in your hand with a wide part down: warning inscriptions on the body will be turned upside down. A fixing screw will be in the deepening of. Unscrew it with the second hand with movements clockwise until the nut is freed and it will not be able to take it out. If necessary, you can use a large hexagon.

- Remove the coil itself from the head of the head. Its winding part is divided into two compartments with a partition. Start with the bottom department. Each of them has a small recess. It is in this ear that you need to season the end of the trimmer line until it stops. Having pushed the string by almost 360 °, begin to evenly and tightly wrap it on the coil of the circle behind the circle. The arrows on the case will show you the direction of this action. Try to wrap the cord around the bobbin a row behind a row, avoiding the overflow of cross-subsequently this can weaken the tension. At the end, hook the last 7-10 cm strings for the notch on the extreme ring of the drum.

- Now you know how to wind the cord on the coil of the trimmer. In the same sequence, repeat the actions for the second part of the spool and, accordingly, the second string. Do not forget to FOCUS on the hint with the arrow. Pass the end of this cord first through the notch in the ring separating the compartment, and then through the extreme ring so that both cutting segments protrude from the coil in opposite directions.

- Now hold the coil right above the body and gradually insert. At the same time, both fishing lines need to be carefully drawn and through the main holes of the head available on its sides. Pull both trimmer cords outward. Then insert the bobbin to the end and wrap back the screw counterclockwise.

- If necessary, shorten the seconds of strings to the secateur so that they protrude about 12 centimeters.

Preparation of a trimmer coil for winding

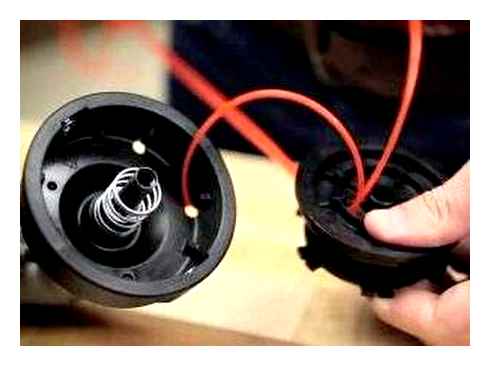

Initially, as a rule, the coil is installed to the head of the device itself. The coil consists of two parts. This is a lid and a spring.

You can buy the highest quality electric ships, trimmers and additional components here in the online store “Garden mechanisms” at the lowest from 1200 rubles for the selected goods from the category. The directory of the link presents the most popular, demanded electric mowers from world brands such as Bosch, Makita, Patriot, Gardena, Hyundai and others.

- Whatever company you have a trimmer to prepare the same for all types. Disassemble the device, or rather, remove the coil from the trimmer head. To do this, we click on the fixers located on the sides of the head of the head, and turn the head clockwise.

- In order to open the mowing head without problems, click on the side latches, if you do not succeed with your hands, use a flat screwdriver to help you help. We take out the coil from the head.

- To choose the right trimmer line for your equipment, digital designations must be applied from the inside of the coil, which indicate the thickness and type of permissible trimmer line. All designations are indicated, as a rule, in millimeters.

- If you have not found any numbers, then the maximum permissible diameter of the trimmer line can be determined by a through hole for lingering the trimmer line. The trimmer line must go forward and backward.

Replacing trimmer line in trimmer: 2 simple ways

In this instruction, we will analyze the entire replacement process step by step. Looking ahead, there are two ways to refill a fishing rod with a fishing rod. There is no fundamental difference. The difference is that in the first case, one trimmer line folded in half will be refueling, and in the second such forests will be two segments.

Trimmer head “Black Decker

Before you start changing the trimmer line in a trimmer head of the Black Decker type, first turn off the trimmer and remove the battery.

Click on latches on the sides of the trimmer head and remove the lid.

Remove the remaining trimmer line from the coil

And clean the lid and body of the trimmer head from soil and grass.

To replace the trimmer line, you can use one of two options:-buy a new coil with an already wound trimmer line in a branded Black Decker company store and replace it with a coil in a trimmer head;. Buy a trimmer line, for example, in the service center of your dealer, in a specialized store or in the market and replace only trimmer line in a trimmer head. The diameter of the trimmer line, the shape of its cross section and the recommended brand see. In the guide of the Trimmer user and the price level.

The end of the trimmer line from the bay must be inserted into one of the holes, it is better to start from the outside, where the arrows are drawn. Then bend the end of the trimmer line with a hook under 90 degrees with the length of the bent part of about 2 cm. Insert this hook into the hole in the drum (coil) of the trimmer head.

In the direction of the indicated arrows. No need to wrap it very tightly or very much and do not cross the turns of each other, since during the work the trimmer line heats up and can count and cease to move out of the trimmer head. Cut a trimmer line from a bay. End the end into the hole to fix it. Wind the second half of the drum in the same way.

Insert the wound up into the case

Eight. Put the ends of the trimmer line in the holes in the case

Nine. Lightly press the coil so that she sat in her place.

Make sure that the trimmer line inside the trimmer head is not confused and is advanced.

Ten. Close the lid without distortions and so as to hear two distinct clicks

, Thus collecting a trimmer head. At the first high speeds, the trimmer line will move out of the trimmer head, stretch out into the string and led to the desired length on the cutting knife located on the plastic protection of the trimmer.

Before you buy a trimmer trimmer line, you need to look at the user’s management in order to know the fishing diameters permissible for this trimmer. Also, the type of vegetation, which must be sown with this trimmer line (the thicker the weeds, the thicker and rude to be the trimmer line within the limits permissible by the leadership).

A gasoline or electric trimmer is an excellent assistant in the processing of a garden plot. But, like another technique, requires attention and a certain care. Unfortunately, equipment developers do not give complete instructions on how to wind the trimmer line on the coil of the trimmer. In this connection, the owners of motor vehicles have many questions. In this article, we will examine in detail various examples and methods of winding trimmer line on the reel.

Fishing Knots: How to Tie a Surgeon’s Knot

Trimmer gasoline calm how to season a trimmer line. Change the trimmer line in the trimmer (lawn mower)

When spring comes, people often spend their free time in a summer cottage. They try to save their site from such a problem as weeds and grass with the onset of warm days. It is difficult to do this manually, especially if the territory is very large, so the lawn mower will help. Thanks to this technique, you can trim the grass and remove weeds. This is a suitable device to mow unnecessary plants near the fence, at home, between rows in the garden on a flower bed and so on. About how to choose a lawn mower, which is suitable for your needs, read here. The cutting element in this device is a fishing line (strong polyethylene thread), which is wound on a special element. A reel. But over time, the trimmer line wears out and there is a need to replace it. The article will talk about how to refuel a trimmer line in a lawn mower.

The thickness of the polyethylene thread depends on the model of the technique and varies from 1.2 to 4 mm. She may be:

- With a round section. This is the most durable material for mowing herbaceous plants;

- With curly section. Used to mow soft plants;

- Twisted. Used for thin grass;

- Professional type, is not suitable for all models of technology.

To change the trimmer line on the lawn mower, you need to purchase a cutting thread, which will be ideal for a particular type of mower.

You can soak the thread in a basin of water for several minutes to increase elasticity and strength.

Communities Make yourself Blog Motokos Shtil FS55

Welcome all. This problem has arisen today: as soon as the braid is gaining momentum, strong vibration appears in the engine area. After the set of working revolutions, the vibration ceases. If you “wash” the braid forward-back, a metallic ringing is heard, as if something metal hangs inside the case. It appeared today, the braid regularly worked out two seasons, this year. The third will be. Tell the master what it is?

Комментарии и мнения владельцев 77

About the clutch here correctly wrote (a) Madolf such a design feature of 55ki 11 years we are engaged in the repair of the Shtile, do not worry an extremely reliable braid.

Suggested, how often you need a lubricant to fill it into a gearbox and what you yourself advise?

This is normal, unless of course, mow a metal knife or disk, try with a spool with a trimmer line if it’s quiet, then everything is fine. The mass of the knife here is the vibration of the drive.

I have been working for this for years7.Wonderful.

This is a feature of the clutch of FS 55, the clutch drum on the crankshaft shaft is installed through a bronze sleeve and screwed in a screw in the end, through the square hole of the flexible shaft of the drive. The drum has a constructively long.Term backlash, it is the cause of vibration when recruiting. This is not a malfunction, but a feature of the work of this braid. No need to disassemble and do anything, with this it will work for a hundred years. Information 100% is reliable.

Sort it out and look what is in the nurseries, and there are many reasons

The same was the problem. I went to the free official then replaced the shaft everything was gone

SW Antenna made from a 12 Foot collapsible fishing pole

Watch the clutch. An extremely reliable braid, for many years, there was no breakdown, not a single. A lot of porridge, knives. The service is simple. Lubricant in a gearbox, every 50 hours, replacement of a candle, every 100 hours, replacement in. Filter every 100 hours. Only STIHL oil is red, it was possible green, but for some reason I chose red. Mixture 1 to 50, gasoline only 92, a mixture of no more than three months of storage. The tank worked, I give a rest for 20-30 minutes.

We carry out the winding of the trimmer line

Sentlessly completed disassembly of a spray coil without losing its spare parts allows you to go to the main task-winding into a trimmer line coil. Technological features of the design of the spool and the number of working antennae determine the sequence of actions.

Coil with one working osik

The easiest option and a simple sequence of actions:

- The dimensions of the bobbin and the length of the original factory winding determine the length of the trimmer line recommended for winding. 2 5 m.

- One end of the trimmer line is inserted into the fixing technological hole located inside the spool.

- The trimmer line is wound on the drum in the reverse rotation of the spilles in the trimmer product direction. As a rule, on the inside of the bobin, the arrow indicates which direction the winding is carried out.

- A small section of the trimmer line is left free to output it. It is fixed in a specialized border on the inside of the bobbin, designed to keep the winding when assembling a spool in working condition.

- The left end of the trimmer line is passed through the hole of the outer part of the bobbin.

- Half of the bobbin are collected and put on the bar of the trimmer device.

Two working antennae

In this type of spools, the number of grooves for winding the trimmer line lying on the inside of the coil should be determined:

For both cases, a trimmer line 2-3 m long is taken. In a single.Capanal coils, the trimmer line stretches into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the back of the rotation of the bobbin on the bar the side. Inside the arrow is usually indicated the correct direction of the winding. In the presence of fixing grooves, the ends of the trimmer line are threaded in them or hold their free arm fingers, spread into the through hole of the outer half of the bobin, the spool is closed and attached to the bar of the trimmer product.

The difference between the winding of the trimmer line in the two-to-dancing coils is that initially a line of trimmer line 2-5 m long is folded in half (to determine the middle fold), and the bend loop is inserted into a special groove between the grooves. Both strains of the trimmer line are wound each in its own groove, fixing the antennae and assembly of the coil is similar to the option considered above with one groove.

The first implementation of this procedure may seem long and quite time.Consuming, but over time and experience, this task will be solved much faster and easier.

The video below will clearly show how to tuck a trimmer line into the coil of the trimmer and correct it correctly. This operation is not a complicated one and, with some patience, will necessarily be crowned with success:

After the cutting thread as a result of the work is worn out, turn off the braid and remove the lid on the mowing head. Pull out from the slot of the forest, stretching it to the desired length, and insert it again in the slot. The amount of material wound on the coil is enough for 5-10 cycles of work depending on the model of the device. When you install the lid in place, carefully look at whether the grooves were clogged where the latches are inserted, if they are clogged, then carefully clean them.

When the trimmer line is worn out, you need to disassemble the braid head again, pull out the coil and wind up the work trimmer line on it again.

Trimmer is the most common unit used to cut grass and cut small shrubs. This device is distinguished by its simplicity in maintenance, simple management during operation, and even women cope with it even a small weight. It is no secret that for the high.Quality performance of herbal mowing work, the correct selection of a cutting tool is required. As the latter in trimmers, special cutting nozzles (wheels, knives) or trimmer heads with trimmer line inside are used. Nozzles and trimmer line are a consumable tool, but if the knives can be sharpened, then when spending the trimmer line, it requires its replacement. In this article, we will tell the most detail how to replace the trimmer line correctly.

How to wind a trimmer line on a trimmer reel

The refueling of the trimmer line in the coil of the tool, at first glance, is not easy. But to carefully study this process carefully-and in the future all the necessary actions will be carried out without any difficulties.

To find out how to tie a trimmer line in a trimmer, you should read this guide. The step.By.Step instruction below takes into account the features of coils of different types of trimmers, so applicable to any tool.

- The reel with a trimmer line is the lower edge of the trimmer. First, of course, it is necessary to remove this head from the device. To do this, fix the rod (or, in other words, the shaft) on which the coil is attached. Fix it in such a way that it does not scroll at. It is easiest to do this by placing a peculiar stupor between the thread of the shaft through a special hole (best metallic). When the shaft is fixed, you can unscrew the coil.

- At this stage, it will be necessary to extract a bobbin from the head, on which the trimmer line is attached. To do this, you need to disassemble the head to the elements. To do this, you must first find a fixer on its case. It is located on the circumference of the product and is the likeness of the buttons. When the lock is found, you need to press it with an effort. Holding the latch pressed, you need to turn the head cover clockwise. Then you need to remove the lid and remove the bobbin.

- A tight spring is placed between the bobbin and the head. It must be set aside for a while so that it does not interfere with the winding process. Before proceeding to the winding of the trimmer line, it is necessary to inspect the bobbin. If it has the remains of an old trimmer line, they must be removed. When the bobbin is cleaned, you can start preparing a new skein.

- From a pre.Prepared skein of a new trimmer line, it is necessary to measure and cut off six (maximum. Seven) meters. Spulk should be at hand.

At this moment, the key stage actually begins, which is devoted to this article.

The first method of winding fishing

The required amount of fishing line is cut off. Now you need to carefully examine the bobbin to understand what type it belongs to. It depends on this how to wrap the trimmer line on it.

Spulks are of two types. In general, they are slightly different from each other. Regardless of the species, the coil is divided into two compartments. The upper and lower. In the first type, the dividing line does not close into the ring and has a deepening.

The second type is solid, but near it on the sides on both sides there are small through holes. The method of winding the thread must be studied depending on which of the above species the coil belongs.

- The previously prepared six.Meter segment must be bent in half. Best not exactly in the middle, but so that one half turned out to be about fifteen centimeters longer.

- Then the bending place must be inserted into the recess in the dividing line. One half of the trimmer line should be in the upper part of the coil, the other half in the lower part.

- Now you can proceed directly to the winding. You need to wind up in the direction in which the arrow on the bobbin indicates. When winding, you need to keep the threads so that they are not intertwined and the upper half is wound into the upper part of the coil, and the lower half into the lower part. Each half should remain free about fifteen centimeters from the end.

- There are small recesses (or, in other words, grooves) in the upper edge of the bobbin to fix the consumable. The ends of the threads need to be inserted into these recesses so that they are fixed one opposite the other.

- The final stage of refueling the consumable in the tool. The ends fixed on the bobbin must be put into the corresponding holes in the head of the trimmer.

- That’s all. The winding process is completed. Now it remains only to collect the head into a single whole. The spring is neatly placed back between the bobbin and the head. Then you need to insert the bobbin into the head and press them to each other.

- Free ends of threads are recommended to pull out more tightly. To do this, take turns pulling the ends of the consumables so as to extract them from the grooves of the bobbin. You can make sure that the cutting element is extracted from the holding grooves, having tried to pull the threads a little. They must freely go through the holes in the head.

- Clutching a bobbin downward, you need to put on a lid over it. The lid must be screwed to the head so that all the grooves on their buildings are compatible and the bobbin remains between them.

- And finally, the very last action. The head is screwed back to its place in the lower part of the tool.

The process is completed. Flakes are tucked in a reel. Trimmer is ready for further work.

The second method of winding

- The previously prepared segment is six meters long, you need to bend exactly in the middle and cut. Thus, two segments of the same length are obtained.

- At one end of each segment, you need to make a small “hook”. To do this, bend a couple of centimeters from the edge and briefly fix it so that the “hook” does not extend.

- Then one segment is taken. The “hook” is inserted into the through hole in the upper part of the bobbin.

- Now you can start the key stage. Winding. The direction in which you need to wind up indicates the arrow on the bobbin. It is important to ensure that the trimmer line is wound strictly within the upper part of the coil. It is not necessary to wind the thread to the tip. From the end should remain free about fifteen centimeters.

- There are small recesses (the so.Called grooves) in the upper edge of the coil to fix the consumable. Free “tail” of the thread must be inserted into one of these recesses.

- The upper part of the coil is filled. Now you need to do the same procedure with the lower part. The second section of the thread is taken. “Hook” is spreading into the through hole in the lower part of the bobbin.

- After that, you can start wrapping a trimmer line (within the lower compartment). And this segment also needs to be left with free ones about fifteen centimeters from the end. This remaining “tail” must be inserted into a recess opposite to the one in which the end of the first segment is inserted.

How to tie a trimmer line in a lawn mower: how to change and charge a reel, how to change and how much to wind it into a trimmer

When spring comes, people often spend their free time in a summer cottage. They try to save their site from such a problem as weeds and grass with the onset of warm days. It is difficult to do this manually, especially if the territory is very large, so the lawn mower will help. Thanks to this technique, you can trim the grass and remove weeds. This is a suitable device to mow unnecessary plants near the fence, at home, between rows in the garden on a flower bed and so on. About how to choose a lawn mower, which is suitable for your needs, read here. The cutting element in this device is Field (strong plastic thread), which is wound on a special element. A coil. But with time Field wears out and there is a need to replace it. The article will talk about how to refuel a trimmer line in a lawn mower.

If there is a country plot or large land near your individual house or cottage, then for the convenience of cleaning grass and weeds, you must use the lawn mower. If you think to choose an electric lawn mower or gasoline, then click here and you will find comparative characteristics of different models.

With time Field On a mower wears out and it requires its replacement. This can be done independently. Choosing this polyethylene thread is necessary depending on the model of the mowing. It is also worth monitoring the rest of the unit details, for example, you will find information about knives for the Craftsman lawn mower, which also wear out and can lead to irreversible consequences.

The device of the coil, into which the trimmer line is inserted, is very simple. But it differs depending on whether a coil with one or two antennae works works

It is important to observe safety precautions while replacing the fishing line in the reel

Large cord consumption

Basically, the cord quickly ends if you often knock on the ground with a semi.Automatic head or press it hard. The coil unlock occurs, and Field, lengthening, cut off with a knife. Another reason that the cord quickly ends is the improper operation of the device with an automatic head: the user during kosbe often drops engine speed. But as we recall, the automatic head is arranged so that it is with each reduction in the revolution that a new portion of trimmer line is supplied, so it is quickly consumed.

The first way

The prepared segment (in this case, it is 4 meters) is bent approximately in half-one segment should be 15-20 cm longer, and inserted into a special gap located on the dividing partition.

A trimmer line is wound in a particular direction. This is done in an interference, the trimmer line is neatly distributed. In this case, you need to wind the segment, which is longer into the section, which is closer to the button.

There are designs in which there is no division of the coil into two sections. It does not change anything, the trimmer line is wound in a similar way. It is only necessary to ensure that the segments do not overlap among themselves.

The first should end the segment that is located at the bottom of the coil, t.E. Closer to the fixing holes.

This tip is placed in the corresponding diameter hole. The trimmer line is reliably fixed.

A long segment wraps another half turn. There it is similarly fixed. At the same time, the segment crosses another coil section.

A long segment wraps another half turn

The fixed ends of the wound trimmer line are inserted into the holes of the trimmer spool body.

The fixed ends of the wound trimmer line are inserted into the holes of the trimmer spool body

The coil is attached to the body. The ends of the trimmer line are pulled with force so that the trimmer line previously recorded in the holes of the coil of the fishing. This is easily determined by the characteristic sound (click).

The coil with the button is plugged in the trimmer’s bobbin housing.

The coil with the button is plugged in the trimmer’s bobbin housing

The replacement of the trimmer line was successfully made. In this case, you need to install it back on a trimmer and you can proceed to the mowing of the grass.

How to refill the trimmer line on your HYTR250E trimmer

It should be repeated, you do not need to remove the spool from the trimmer. This was done to clarify the process of replacing the trimmer line. You can disassemble the rogue in place, wind it up and put it back.

Tips so that they do not beat the trimmer casing can and should be cut.

Types of coils

There are 3 types of the most popular trimmer heads:

Mechanical

A mechanical coil is a plastic or metal disk in which one or more small cuts of the trimmer line are fixed in various ways, which is why it is necessary to manually change the trimmer line.

Here are the most popular models of such heads:

Semi.Automatic (collapsible)

Despite the variety of models and differences in appearance, the coils of this type are arranged and work according to one principle.

The base connects the remaining elements of the trimmer head with a motorcycle or electric shock through the threaded sleeve paid in it, so each coil is only approached that trimmer, The diameter of the shaft of the gearbox or lower engine corresponds to the diameter of the sleeve.

A spring is installed inside the base, which supports the spool, squeezing the pressing part outward through the removable case.

Holes for the string are made in the removable case, and they are located so that the output of the trimmer line from the spray is noticeably higher, this provides reliable fixation of the trimmer line in working condition.

When the operator beats the pressure on the ground, the spool enters the case and all the holes through which the trimmer line passes are combined. Then centrifugal force pulls part of the wound string outside, And when the pressure on the pressure disappears, the spool leaves the body and again occupies the working position.

Automatic (indifferent)

Regardless of the model and manufacturer, all automatic coils are arranged and work according to one principle.

They consist of the following details:

A threaded sleeve is soldered into the foundation of the base, and a ratchet clamp is installed on the inner surface, which allows the spool to rotate in only one direction. There is a through canal inside the spool, fishing. The cap is rigidly put on the spool, and the curly faces facilitate its rotation to wind the fishing line.

How to tuck a trimmer line in a trimmer calm

Trimmer This is one of the most common tools with which you can quickly and easily cut the grass, cut off small shrubs, lawn grass and other weeds. It’s no secret for anyone in order for the mowing of the grass successfully, it is necessary to use the tool correctly and correctly handle individual cutting elements.

It doesn’t matter in trimmers what kind of fuel they work, special cutting nozzles (knives, discs) are used and some trimmers are delivered to the market in the heads of which, such a cutting element as a trimmer line is installed, and therefore many are wondering, and how to fill the trimmer line in the coil of the trimmer calm if there are no skills as such at all.

- Cutting nozzles in the form of knives can be sharpened, but the trimmer line (also the cutting elements) but has the ability to spend. Below we will talk about how to properly tie the cutting element #8212 into the coil of the trimmer; trimmer line.

- Preparation of a trimmer coil for winding.

- The process of winding the trimmer line on the reel.

- A couple of tips.

- What can be used instead of trimmer line.

Preparation of a trimmer coil for winding

Initially, as a rule, the coil is installed to the head of the device itself. The coil consists of two parts This is a lid and spring.

You can buy the highest quality electric ships, trimmers and additional components here in the online store “Garden mechanisms” at the lowest from 1200 rubles for the selected goods from the category. The directory of the link presents the most popular, demanded electric mowers from world brands such as Bosch, Makita, Patriot, Gardena, Hyundai and others.

- Whatever company you have a trimmer to prepare the same for all types. Disassemble the device, or rather, remove the coil from the trimmer head. To do this, we click on the fixers located on the sides of the head of the head, and turn the head clockwise.

- In order to open the mowing head without problems, click on the side latches, if you do not succeed with your hands, use a flat screwdriver to help you help. We take out the coil from the head.

- To choose the right trimmer line for your equipment, digital designations must be applied from the inside of the coil, which indicate the thickness and type of permissible trimmer line. All designations are indicated, as a rule, in millimeters.

- If you have not found any numbers, then the maximum permissible diameter of the trimmer line can be determined by a through hole for lingering the trimmer line. The trimmer line must go forward and backward.

The process of winding the fishing line on the reel

- After all the preparatory actions, we need to correctly decide how exactly the trimmer line will be washed on your device, by turning the cover or in the opposite direction.

- We measure approximately 7 mm cutting material and at one end we insert it into the hole. It is worth noting that the trimmer line is wound precisely on the model of mowers style from two side. The direction of winding of the trimmer line in such models is indicated on the bastard itself.

- The trimmer line is exposed to about 17 cm freely so that weeds can be cut off with the ends. Add that you should not wrap the fishing line on the coil of a huge length. About 5 mm leave the distance from the trimmer line to the edge.

- The two ends of the trimmer line are inserted into the holes. Both of these ends should be reliably fixed on the device case.

- The springs extracted from the coil (if any) insert the same as they were extracted, t.E. In the backlog and the body of the head itself.

- To determine whether you put the trimmer line into a trimmer correctly, you need the element itself (bobbin) itself can easily be inserted into the body of the head of your device. If necessary, remove the free ends of the trimmer line to the outside. To achieve this, you need to pull the trimmer line through the holes in the squire with a sharp movement.

So, let’s say, you figured out how quickly, and most importantly, to correctly wrap the trimmer line on the coil of the trimmer calm. All that you have left is to insert everything into the grooves and fix the main cover on the device. Then you can press the bobbin itself and make movements counterclockwise until you feel the emphasis. If you do not feel the emphasis, then most likely you set the trimmer line not correctly and you will have to start everything from scratch.

A couple of tips

If you were wound the trimmer line correctly, then when pressing the button button should automatically stretch the cutting element. A trimmer line for your mowing device is one of the most important elements, without which a trimmer can lose all its functional abilities. We can say that the trimmer line (cutting element) is the heart of your braid. Therefore, when buying a trimmer line, primarily devote to its quality. When purchasing a trimmer line of a particular company, be sure to compare it with the quality of the old trimmer line.

What can be used instead of trimmer line

Most mowers are interested in others or sellers in specialized stores about what can still be used (replaced) except for the trimmer line. Many of them begin to experiment and use unsafe methods, installing different cutting elements on their trimmer, including Copper wire, metal, some manage to use strings from guitars and even cables, and someone is completely trimmer line from fishing nets.

- If instead of a special cutting element, say trimmer line, install a metal cable, then your trimmer can “turn” into a real dangerous weapon not only for you and your eyes, but also for all people around you nearby. This is due to the fact that during the work of the trimmer, the steel cable will constantly work, which will lead to confusion, and its small pieces can fly to all sides with a huge speed.

- The same can happen if a copper wire is used instead of a steel cable, but in this case, the pieces of separation from copper wire will be slightly larger and may give you an even greater injury. And if God forbid, accidentally catch such a cutting element by the leg, then after that 100% is guaranteed a deep cut of soft tissues, and in some cases, all this can lead to amputation of small limbs (fingers) of the legs and even hands. Therefore, our advice to you, do not use any other cutting elements, except for trimmer line, for your own safety and others.