How to remove a chain from a chainsaw. A stepbystep installation algorithm

How to remove clutch on a chainsaw partner

STIHL MS 180. The tool is reliable and unpretentious, but sometimes requiring repair, like any equipment. In this article, we consider how disassembling the chainsaw of Stil MS 180, which is necessary in case of overhaul of the engine.

Preparatory stage

Repair of any equipment should begin with the stage of preparatory work, and drank a calm 180, no exception.

At the preparatory stage, before disassembling the chainsaw of the calm 180, it is necessary to remove the side cover, chain and tire from the chainsaw.

Further, using a compressor and brushes, you need to clean the chainsaw of dirt, sawdust, oil drones and other things.

Particular attention when cleaning the saw should be given to the place where the leading star of the chainsaw is located, t. To. This is the most polluted site.

In places of large accumulation of oil, you can rinse with clean gasoline.

Removing the handle

Direct disassembly of the calm 180, begins with the removal of the handle, which is attached to the chainsaw housing using three rubber shock absorbers.

To remove, it is necessary to remove the plastic plugs from the inner cavity of shock absorbers, after which with the help of a powerful screwdriver, squeeze the upper shock absorber first, then the one which is closer to the posterior handle.

When the handle remains on one shock absorber, it is necessary to turn the chainsaw housing from the inside of the handle and breaking to the side, remove the case from the last elastic Band.

Removing the starter

At the next stage, the upper cover of the case is removed and 4 screws fastening screws are promoted, after which it is necessary to remove the lids of the oil tank and the fuel barrel. The starter is removed quite simply and there should not be problems.

After removing the starter, the opening of the inner cavity of the chainsaw must be cleaned, t. To. Typically, on the case under the starter there is a large number of compressed small sawdust.

Removing the flywheel

The flywheel of the chainsaw of Shtil 180 is twisted with great effort, so to remove it, you will need a head with a metal gate. The nut holding the flywheel is unscrewed by the head by 13.

To block the crankshaft from turning, you need to unscrew the candle and install the piston lock through the candle hole, if not, you can use the old lace from the starter, with nodes imposed on it and immersed in the cylinder through the candle hole.

It is strictly forbidden to hold the flywheel from turning by installing between its ribs and the body of the power screwdriver and other tools, with this method of blocking from turning, the flywheel blades are not able to withstand the loads and break off.

After the piston in the cylinder is blocked, you can unscrew the nut of the flywheel. The thread in the nut is common, so you need to twist to the left side.

Having loosened the nut, it is not necessary to remove it to the end, it is enough to twist it until the moment when its upper edge is equal to the tip of the shaft, after which the gap made of soft metal is installed on the nut and a sharp blow is made on it.

Thus, the flywheel from a sharp blow jumps off the shaft and can easily be removed without the help of additional tools.

Dismantling of the clutch and drive of the oil pump

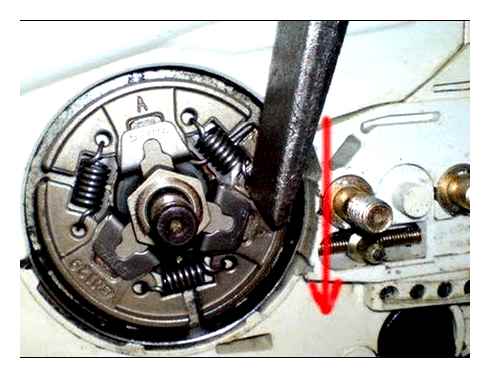

Before making a clutch, it is necessary to dismantle the leading star. To do this, carefully take out the lock washer from the grooves on the shaft and remove the star and the needle bearing.

High head at 19, it is necessary to unscrew the clutch. The thread on it is the left, so it is unscrewed towards the tire, and not the back of the saw of the Shtil 180.

Having promoted and removing the clutch, you need to immediately remove the reflecting plate and drive of the pump oil, it is easy to do it, t. To. They are worn on the shaft without any fastening.

Carburetor, muffler and ignition coil

To remove the carburetor, you must have a 8.Head and extension cord, with which it is convenient to spin the nuts of the carburetor and air filter mounting.

Before dismantling the carburetor, it is necessary to disconnect the ignition wire and the craving of the air damper from the engine control lever and remove the lever, only after that the air filter and the carburetor are removed.

The muffler of the Shtil 180 is attached with two nuts, promoting which you need to pull it over, it will easily withdraw.

The coil is attached to two screws, you just need to spin them to remove.

Removing and disassembling the engine

The engine hold 4 screws installed on the bottom of the chainsaw of the calm 180. To remove them, it is necessary to spin them, and then carefully remove the engine from the seat and the rubber pipe of the carburetor.

For disassembling the engine, 4 screws of the crankcase are spinning, and it is removed, then you can remove the crankshaft assembly with seals, bearings and piston rings.

Removing bearings and oil seals usually does not require additional tools, but if the bearings have been tuned to the shaft with an effort, then a special puller is needed to dismantle.

To remove the piston from the connecting rod, you need to remove the locking ring from the planting nest, using a thin screwdriver, then the piston finger is squeezed out from the opposite side, after which the piston is removed to the side.

Assembly of a chainsaw Shtil 180

Collect the STIHL MS 180 saw back, quite simple, the main thing is to adhere to the next algorithm:

- Install the piston on the connecting rod, the arrow on the piston should look along the ruptric of the rodpie 180, and the side of the crankshaft, which is designed to install the flywheel;

- Gently insert the piston back into the cylinder, the place for mounting the coil should be on the side where the flywheel is installed on the crankshaft;

- Install bearings, seals, a stop ring on the shaft and lower everything assembled to the seat in the cylinder;

- Next, degrease the place of installation of the crankcase and the crankcase itself, then smear with sealant and installing in place to tighten 4 screws of fastening;

The direction of the chain and which side to wear

Chain of the chainsaw, if you carefully examine, has saw teeth directed in one direction. Therefore, the correct direction of saw teeth on the guide tire is very simple to determine: if you place the chainsaw itself in the plane, which it is in the process of operation, then a number of teeth located on top of the guide tire should be directed by sharp edges to the end of the tire. While a number of teeth, which is located below the chainsaw, should look in the opposite direction, towards the leading star.

How to unscrew the clutch on a chainsaw

The operation to extract the coupling and the drum is quite simple and with a full hand requires about 1 minute of time. If you find out the nuances and prepare in advance, there will be no problems, but with a spontaneous approach, the procedure is significantly delayed if it does not break at all. The next instruction submitted, clearly and by steps, demonstrates how to disassemble the clutch on the chainsaw in different ways using an affordable tool.

How To Fit Tighten A New Bar Chain On A Chainsaw

One. The first and easiest step is to remove the tire cover by unscrewing 2 fasteners, a hexagonal key from a set of a chainsaw. The saw tire and the chain are also removed (if installed).

If the drum is located on the outer side, it is enough to remove the stop ring to remove it to remove it. This operation is more convenient to carry out a slotted screwdriver.

Since the overall coupling is fixed to the shaft, the unscrewing attempt will only lead to the rotation of the details. It is necessary to fix the position of the crankshaft by installing the stop for the piston, through the candle hole. As a stopper, you can use special devices, the cost of which starts from 200 rubles. If there is no way and desire to spend time searching for such a stop, you can always place a regular cable with a node in the combustion chamber.

After fixing the position of the shaft, you can proceed to unscrewing the coupling. Typically, it does not have a convenient nut for a uniform key, and disassembly involves the use of a special puller. The cost of such devices starts from several hundred and often exceeds the cost of the coupling itself.

As an alternative, you can use the key to the grinder or tear off the neat beats of the hammer, resting the chisel. As an option, you can use the tire of the chainsaw, passing 2 short bolts into its holes and tightening them with nuts from the reverse side. You can make a home.Made clutch pulp, noting and drilling in a sheet of metal (from 4 mm), corresponding to the grooves, into which the screws will pass and tighten. In general, there are many sophisticated ways to “hook” the coupling without unnecessary costs. Some are unscrewed with a simple wrench or pliers.

It should be clarified that for the reliability of fastening the coupling, a latch is applied to the shaft thread, which extremely tightly connects these elements. To disrupt such a clutch is quite difficult, even if there is a convenient stop. To facilitate the analysis process and protect the piston and the rest of the mechanism from damage, the thread should be heated by a gas burner or a building hairdryer. From high temperature, the adhesive properties of the latch will disappear, and it will become much easier to disconnect the details.

Having broken the fixation of the overtaking coupling, we continue to unscrew the clockwise (left thread).

Under the coupling, a large metal washer can be located on the shaft, separating the components (not on all models). We take it out, and after her a drum with a needle bearing. The clutch is removed.

If the management above, it did not fully convey the essence, consolidate the acquired knowledge by a visual demonstration of the entire process. The next short video instruction, with the author’s useful Комментарии и мнения владельцев, will explain in detail how to remove and repair the clutch of a chainsaw with your own hands, with minimal time costs.

Description of the adhesion removal process can be called universal, applicable for all modern saw models. As mentioned above, the main constructive difference can manifest itself in the location of the star, which is usually inside (between the coupling and the crankcase), but it is also installed on the outside (this is much easier to change). Otherwise, if you want to figure out how to remove the clutch from the chainsaw partner or Khuskvarna, it is enough to familiarize yourself with the above instructions reflecting all the stages of the process. Small nuances characteristic of certain models (fastening of the duct cover, chain tensioner) are usually not difficult and easily resolved on their own, or using technical documentation.

Tools necessary for work

Starting to the rivet, the first thing you need to remove the link from the chain, for this you need to plug the rivets. To rivet, you will need an anvil, a hammer, thin beards, a vice, a grinder with a grinding circle or a sandpaper. These tools do not allow you to work efficiently, but they will find them for everyone. A more cultural and careful way to remove rivets using a special punch.

There are several designs of the breakdowns, we will talk about the most popular.

Rubber for rivets

Punch. A machine used to remove rivets.

It is mechanical, works on the principle of the press. The kit has a special anvil in which grooves are selected for installing a headset with a different step. There are also interchangeable tips, which are squeezed out of the rivets.

Important: the size of rivets in different types of chains differs, so when buying a breakdown machine, make sure that there are several tips that are used for different types of headset.

We suggest watching a video that shows how to flan out a saw chain using a mechanical punch.

After the chain is flared up, it is necessary to remove the old link, install a new one and stuck. For this, the machine is used to rivet. It is electric, so it costs much more than a breakdown machine.

The rivet-probe machine

A gearbox with a high torque is installed on the machine.

See also: Articles is a punch is designed to carry out drilling work on concrete, brick and stone. Accordingly, the main field of its use is construction sites and work on the installation of different

It is used for riveting and rolling the headset in steps from 1/4 ″ to 0.404 ″. The depth of cut chains that can be stuck with this machine from 1.1 mm, to 2 mm (0.043 ″. 0.080 ″). Together with the machine, special rotating inserts and anvils for different types are delivered. Inserts and anvils are marked. Marking “a” means that the inserts are designed for a headset with a 3/8 ″ and 0.404 ″ step. “B”. For 1/4 ″ and 0.325 ″.

The machine works as follows. The saw chain with a new link and rivets is installed in the guide inserts. The repair link with rivets installed in it is pressed by a working roller to the anvil, after which the engine turns on and the roller begins to rotate, gradually crushing the rivet, at this moment, the machine operator slightly increases the force of the roller, tightening the adjusting screw. For clarity, we suggest watching a video about the work of a riveted-rolling machine.

Use such a machine in order to rivet at home is not profitable, t. To. It is expensive. If you need to block not regularly, then you can do without it. Consider how to shorten the chain of chainships with your own hands without using expensive machines. You need to start with riveting and lifting the link.

The advantages of the machine are that the rivets stained with its help are practically no different in quality from those that riveted in the factory.

Install the chain step by step

The procedure for installing consumables on a gasoline saw is not related to any difficulties. You just need to unscrew the main screw and place the cloves on the asterisk correctly. Before starting to saw the wood, be sure to inspect the working surfaces. Various pollution (dirt, sand, small shavings) can accumulate here, which leads to a deterioration in the tool.

- Unscrew the screws that are responsible for fixing the cover that protects the asterisk. This element is twisted, as a rule, a lamb nut.

- Scroll the stretch asterisk to the right side until it stops.

- Put the links of the chain headset on the tire, starting from above. Make sure that all the cloves fall into the grooves.

- Fix the asterisk.

- Turn off the chain brake, check the tension of the circuit.

After installation, check the condition of the installation wheel. If the chain headset is set correctly, this part will freely scroll. The final stage is the lubrication of the working parts of the tool in order to slow down and protect the unit from breakdowns.

Note! The chain of chainsaws is acute. With inaccurate handling of her, there is a risk of injury, cut a hand during the installation process. To protect yourself from such troubles, use dense gloves.

The chain is stretched

With improper or prolonged operation of the chain, it can be very stretched. This is due to the fact that the metal can be deformed over time. Too strong wear becomes the reason why you have to acquire a new version of execution, but there is an opportunity to use the old during a short period. You can avoid quick stretching solely in compliance with the recommendation for operation. For work, it is required:

It is not difficult to wear a stretched version of the execution, but with the restoration there are quite a lot of problems, since the metal is characterized by increased strength. In this case, the main elements are attached with rivets. The work is carried out as follows:

- The product is attached to Teski.

- If the work is carried out when using a grinder, then there is a chance that the surface will be damaged, since this tool is difficult to control.

- After grinding, rivets are knocked out. No need to throw it out due to the possibility of re.Use.

- Chain manufacturers do not produce spare elements that are required when servicing.

- You can make a rivet with your own hands, but the work is quite complicated.

- The product is divided into two parts. It should be borne in mind that the number of guides and the distance between them should remain unchanged.

When solving a problem with a large length, do not forget that you can’t pull too short a chain anymore. In addition, it is not recommended to apply oil to the electric saw circuit.

The principle of design of the clutch drum at the unit

A chainsaw is an unit that is equipped with a leading asterisk, and is a single complex that has a clutch basket. Clutches with a centrifugal type are installed on such units, which are automatically triggered, based on how many revolutions the engine has.

Drums that are the basis of such clutch on the mechanism of the unit are considered integral parts of chain drive systems. Such details are similar in shape to the star, as a result of which they received such a name. Based on which chainsaws are considered, these details are divided into professional and household. Since professional chainsaws are more often used, the replacement of the leading star in the tool should occur more often. Considering domestic tools, it is worth noting that the volumes of work and loads that affect the aggregate chain affect the frequency of replacement of parts.

But in any situation, the main reason for replacing the asterisk is worn teeth on which the chain affects. If there is a monolithic drum in the device, the chain cuts it out in fact through and therefore it needs to be completely replaced. If drums are installed in the units that have interchangeable crowns, then it is enough to replace the crown itself.

As a rule, if it is necessary to remove the star from the chainsaw, many tool owners use the services of specialized service centers, but to save the family budget, such a replacement can be performed independently. The implementation of this task is not difficult, but for its implementation it is necessary to have the necessary details and tools. Replacement of a sprocket for each model of a chainsaw is carried out in a similar way.

The design and principle of action of the leading stars

The quality of maintenance of the tool largely depends on the understanding of the device of its nodes, therefore, for the completeness of the picture, we will conduct a brief educational program by the types and features of the existing gear ratings. The lead gear of the chainsaw is located on the clutch plate and is set in motion with an increase in engine speed. These elements can have an all.Metal or collapsible structure. The first option implies a complete replacement for wear, and in the case of the latter, it is enough to replace a removable crown.

The sizes of the stars limit their use for all types of chains. 2 Standards widespread: in step 0.325 mm and 3/8 inch (the most important parameter when choosing for replacement). Similar standardization is due to the powerful capabilities of the chainsaw engine. In addition to the step of the star, the choice should be based on the number of teeth (6 or 7) and on the inner diameter of the bowl, but it is best to push away from the specific model of your tool.

How to replace it with your own hands

Experienced craftsmen recommend the following sequence of operations when replacing an asterisk:

- Remove the case and air filter (if necessary).

- Dill out a candle and insert a fixer instead to lock the piston.

- Remove the clutch of the chainsaw.

- Remove the gear with a pull.Up or an open key.

Removable crown should be unscrewed clockwise. If when disassembling it turns out that the details of the centrifugal mechanism are worn out or broken, it should also be removed and replaced. If the parts and nodes are not visually damaged, then the assembly of the mechanism is carried out in the reverse order.

How to remove a star from a chainsaw with your own hands

In order to correctly and accurately fix the clutch mechanism on the leading shaft, you should remove the piston lock, smoothly pull the launch cord and release it.

How to remove a chain from a STIHL chainsaw

There are not many of them and depend on how many links need to be removed, and in what conditions the repair will be carried out.

It is important to know: the chain of chainsaws consists of incisors and binding links, which are connected by pwarler in the factory. Connect a shortened circuit in the same way, but using homemade rivets

Each link (cutter and links connecting them) have two such rivets. In case of damage to nearby “relatives” of the connecting links, you can use the elements from any other similar chain of any, even automobile, equipment. It is only necessary to fit the profile with a file, especially from below, where it has a small gutter.

The easiest way is to take a long chain in which several segments can be removed without problems. So, at least, it becomes possible to use native links. They are removed with a hacksaw for metal, but it is better to use the sandpaper.

Initially, unnecessary rivets must be stuck, and then cut off the extra area. To do this, you need to put with a knife and knock out with a home.Made groove riveting from unnecessary links.

By connecting a new circuit, you have to make a home.Made link of links. The rivets themselves can be bought in the store, but in the absence of those, use a steel wire, or better a short bolt with a flat hat. The riveting is made on a rigid base (metal workbench or vise). Alternately extending through the elements of future rivets, with a hammer, collapse them from the back.

Perhaps you will also be interested in the article Sharpening of the chain of the chain with your own hands. You can read about the types and characteristics of modern chainsaws here.

And in this article you can find out how to repair the rupture “Shtil 180”.

What gasoline to fill in a chainsaw?

Manufacturers strongly recommend the use of only high.Quality gasoline for a chainsaw, with an octane number of at least 92 and the ethanol content of not more than 10%. It is not recommended to use opaque gasoline, having impurities. They will quickly clog the fuel system and engine.

Important: it is not necessary to prepare a gasoline mixture for a chainsaw immediately before pouring into a tank. This can be done in advance. Over, many manufacturers produce ready.Made containers with several departments, for example, for gasoline and oil or gasoline, oil and finished mixture, and also complete such a container with a special measuring syringe

With it, oil is typed in a chainsaw in a proportion that is required. But if the mixture is prepared in advance, then the maximum period of its storage should not exceed 10 days-over time, the octane number of gasoline is reduced, and due to the fact that part of the gasoline from the mixture disappears, the proportion of oil and gasoline for the chainsaw is changed.

Do.It.Yourself saw repair

With the advent of a light and comfortable chainsaw, Shtil MS 180 in the household, it will completely replace two.Handed, beam and even hacksaw. Over time, chains are dull, sprockets are brought up, an oil supply system is damaged. Some problems can be eliminated independently. Others require repairs in special service centers.

You can repair the saw yourself only by understanding the installation of nodes and the sequence of operations for the removal and restoration or replacement of the assembly. Operating instructions for the chainsaw of the Stil 180 will become a reliable assistant. It is in it that you can find installation techniques and the sequence of repair operations:

In addition, a home master can shorten a stretched chain and sharpen it.

If the saw chain during operation remains dry or the oil proceeds, then it is required to eliminate the malfunction and repair of the lubrication system of the chainsaw of the rod of the rod 180. In this case, the oil pipelines and the density of the connection with the fittings are examined. Be sure to clean the filter for oil supply. If there are small mechanical damage on the hoses, tightness can be restored using a sealant.

The carburetor makes itself felt by the difficulty when starting a saw, a neglected tool does not gain momentum, stalls during throttling. The cause may be wear of the cuff on the piston, as a result, the air sucks when discharge. For repair, the carburetor is removed and reached the cuff on the accelerator, disassemble the knot in the sequence:

- Remove the lid with the membrane, twisting the screw;

- Remove the locking ring;

- Disconnect the air damper, remove the throttle;

- Pull the accelerator with the spring;

- Replace a tiny piston with a cuff and assemble a carburetor in a reverse sequence.

Problems may be associated with the ignition system. After checking the operability of candles and cutting a carriage, the carburetor is adjusted, the supply system and the injection is cleaned. The carburetor is a complex node and the work of the chassis depends on its configuration. If there is no confidence and skill, it is better to use the services of a specialist. Often, work on poor.Quality gasoline, with not recommended oil, is the root cause of all problems.

Read also what frozen flowers dream of

To help the master on the resources there is information on how to repair the chainsaw of the rosopile 180 with your own hands, for example, the video will show the sequence of disassembly.

You can see about the diagnosis of the lubricant system here:

Replacing a leading star on a chainsaw according to the instructions. When to perform and what to put

The operation of any tool contributes to the wear of the parts. Basil is no exception, and often the owners of this tool are faced with the need to replace the leading star. It is a device for transmitting torque from the crankshaft for ICE to the chain. Before replacing the sprocket on the chainsaw, which each owner of the tool can handle it, you need to competently approach the issue of choice.

What you need to know about the design of the leading gear on the chainsaw

The operation of the chainsaw can last long enough until there is a need to replace the failed parts. Leading star or gear, through which torque transmission from the crankshaft to the chain has a large operational resource. However, it ends, which leads to the need to replace the part. Before you do this, it will be useful to find out about what chainsaw stars are.

Leading gears are produced by two types. Whole or whole.Littered with the drum and prefabricated. The difference between these details is not only in the external structure, but also in operational features, which will definitely be interesting to know the owners of the chainsaws.

How to remove and install a chainsaw chain

- Solid. They consist of a drum with a hub and a tuned gear crown. The part is made by casting. The disadvantage of this type of stars is that if necessary, they must be completely changed. There are advantages of such options for drive mechanisms, the main of which is a long operational resource. The teeth of such devices are cut off extremely rarely, and only in those exceptional cases when marriage is appropriate. The second advantage is the lack of a problem with the search for details, as they are in all specialized stores. If there is a need to replace a whole gear on a chainsaw, then you need to know that such devices are more expensive than prefabricated.

- Prefabricated. Few people know about their advantages. They are called prefabricated due to the fact that a random crown acts as an asterisk. He sits on the hub leash of the drum with slots, and sets the chain in motion. The advantage of such stars is that the crown wears out, which is inexpensive. With its wear, it is not necessary to change the entire drum completely, which saves to eliminate the breakdown. The disadvantage is that finding such crowns is problematic. This is due to the fact that the detail has a low cost, but at the same time requires large costs for the manufacture.

If there is a need to replace the leading star on the chainsaw, then the first thing you need to clarify what type of part is installed on the tool. Manufacturers of different models of chainsaws equip them with leading gears of both prefabricated and solid type. How they differ among themselves is already known. It is only worth adding the following:

- Both types of parts are interchangeable, only replacement is carried out in conjunction with a drive drum;

- By reliability, prefabricated devices win, through which an effective connection with the tool chain is ensured;

- In addition to reliability, the prefabricated types differ in the smoothness of the chain, which is achieved due to the presence of a backlash between the protrusion with the slots on the drum and the crown;

- Due to the presence of a backlash, the operational resource of protrusions on the drum increases, but the entire load falls on the replaced crown.

Prefabricated devices are noisiness compared to solid, but at the same time they are more effective. It often happens that it is not possible to find a replaced crown for the chainsaw star, which leads to the need to install a whole drum.

Interesting to know! The drum on the chainsaw practically does not wear out, so the use of whole stars for the drive of the chain into motion is irrational.

How to determine the need to replace the gas station sprocket

The consumables of the chainsaws include not only chains and tires, but also leading gears. Their resource corresponds to the service life of the chain, that is, it is recommended to make them change after wear of the cutting headset. However, this should not be oriented, since it all depends on the features of the operation of the tool. If you saw a chainsaw with dull teeth, then after a couple of hours not only the wear of the tire will occur, but also the tools of the tool.

The need to replace the leading star on the chainsaw is determined visually. If the instrument has a gear team, then you can work with it up to its destruction. Wear of the grooves on the crown occurs very slowly, due to the presence of backlash. If an integral star is installed on the unit, then you can determine the need for its replacement by a number of the following signs:

- The presence of noticeable radii in places between teeth.

- The tops of the teeth have obvious signs of metal chips.

- Uneven width of the teeth.

- The presence of bullying and chips inside the wheel hole, which is a sign of poor lubrication of the mechanism.

If you are always striving to support the tool in proper form, it is recommended to change the stars with the chain.

Interesting to know! If the leading sprocket is replaced with the tool, then you must first make sure that the needle bearing is not required to change. If the bearing is serviceable and has small wear, it is necessary to lubricate it with special lubricant with high.Temperature mixtures.

An algorithm for independent replacement of a sprocket on a chainsaw

The process of changing the chain drive mechanism to the tool is not difficult, and even a beginner will cope with the task. At the same time, it is important to take into account some features that you will learn about from this section. Due to the fact that the stars on the units are whole and prefabricated, then the procedure for replacing them will be different.

How to replace a star with a replaceable crown

If your chainsaw is equipped with a leading gear of a prefabricated type, then only the crown is subject to replacement. It is inexpensive, and before buying it, you need to clarify the step of the chain. The process of installing a new part is performed in the following sequence:

- Remove the casing, unscrewing two nuts.

- Dismantle the tire with the chain, after weakening the tension of the headset.

- Remove the plastic cover followed by the dismantling of the air filter.

- To unscrew the spark plug, which is performed in order to stop the piston.

- In the cylinder hole, put a dense and durable rope, having previously moved the piston to the VMT. With the help of the rope, the crankshaft is stopped, which is performed to unscrew the coupling on the chainsaw.

- Next, we proceed to the unscrewing of the coupling, for which a special key will be needed. If such a key is not attached in the configuration to the chainsaw, then the usual lacture is suitable. However, it is best to use the key for the UShM, which is ideal for unscrewing the coupling.

- To unscrew the coupling, it is necessary to rotate it in the direction clockwise.

- After disinfecting the coupling, it remains to dismantle the drum along with the crown.

- Inspect the integrity of the bearing, which is planted on the shaft. If necessary, it is also recommended to replace and lubricate it.

- Replace a shift crown, and assemble the mechanism in the sequence of reverse removal.

Typical errors and their consequences

If you have not previously encountered such operations, you have no idea how a gasoline saw is arranged, how to stuck a saw chain, it is better not to take up shortening with your own hands. Riveting chains for chainsaws. Only at first glance it seems that it is easier. In fact, the task is quite difficult. The consequences of unprofessional renovation with errors can be very deplorable: a chain on a chainsaw or electric saw was torn, the torn element injured the operator, etc. What to do? If the saw chain extends, buy a new consumable or contact the workshop where the specialist will shorten and switch the product.

Not only newcomers, but also experienced workers who are accepted for shortening the chain with their own hands are not safe from errors. Consider the most common.

- The step does not match. If the installed link does not fit the key parameters, the circuit will not work. Over, if you install it on the tire and try to complete the cut, you will have to change both the leading star and the working surface.

- Incorrect installation of a working tooth. If the clove is installed in the opposite direction, the tire and the leading star can also break.

- Chain headset longer than tire. A dangling chain, which is not regulated even by a tensioner, accelerates the wear of the leading star and leads to a premature failure of this element.

- The chain is shorter than the tire. In this case, it is simply not possible to put a chain headset on the working surface of the chainsaw. You have to flan out the chain and lengthen or use a new.

- Exceeded the length of the connecting link. This error leads to a change in the step, again provokes the failure of the leading star.

Do not try to repair the saw chain using a welding machine. The welding method is used, but only to restore the integrity of gearbox chains, and not the headset that is used to equip the chainsaws. Transporters, heavy machines that are operated in agriculture are equipped with gearboxes. The elements are designed to transmit a rotational moment from one star to another.

Shortening the chain of gasoline saw will help increase the service life of the consumable element. If the work is done efficiently, you can continue the operation of the chain headset. Incorrect repairs can lead not only to the breakdown of the tool, but also to the inflorescence of serious injuries to the operator. To protect yourself from various troubles during the operation of a chain headset, do not save on its quality, buy expensive consumables.

How to shorten the chain of chainsaws with your own hands. The procedure for action

Often during the operation of the chainsaw, the saw chain is stretched, which makes it impossible to further use the tool. To date, there are specialized workshops providing services for shortening chains of a chainsaw, but it is possible to shorten the chain of a chain of a chainship with your own hands at home or right at the workplace.

How to remove clutch on the chainsaw Husqvarna 365

Despite the availability of services for maintenance and repair of gasoline tools, many chainsaw owners prefer to repair them on their own. At the beginning of self.Healing, you need to know what a chainsaw consists of, how to diagnose malfunctions, and have a set of tools that you may need to repair.

In this article, we will consider how to make a self.Healing Huskvarn chainsaw and what needs to be.

What you need to repair Husqvarna with your own hands

- Stop the piston. It is necessary to limit the stroke of the piston through the spark plug hole. Used to unscrew the nut and clutch the nut (if necessary, it can be replaced with a cord from the starter with the nodes imposed on it);

Tip: When repairing any gasoline tool, it is convenient to use a medical clamp and tweezers. You will also need a headset, a slotted screwdriver and a set of Torx keys.

Husqvarna pollen disassembly algorithm

The process of dismantling the chainsaw Huskvarna is quite simple. In order to do everything correctly and not violate the details of the case or CNG, you need to disassemble in the following order:

- Upper cover.

- Chain brake cover and a set drank.

- Starter.

- Flywheel and clutch.

- Front handle

- Carburetor.

- Oil pump.

- Engine.

Depending on the Husqvarna model, the dismantling procedure may vary slightly.

Important: Before proceeding with the disassembly of the chainsaw, it must be cleaned. When working with a saw, a lot of shavings and wood dust forms, which, when disassembled, can get inside the chausopila Husqvarna.

Removing the side cover and a set of pollen

The side cover, or it is also called the brake chain cover, is held by two thirteen nuts.

Remote nuts, the lid is removed from the guide pins, after which the tire and chain can be removed from the chainsaw. In some models, the Husqvarn saw have a special mechanism that allows you to remove the cover and a set of saws without using special tools.

Starter

The starter is located on the right side of Husqvarna and has several screws. By unscrewing it, you can easily remove the starter and gain access to the flywheel and ignition coil.

Removing a flywheel and clutch

To unscrew the flywheel nut, unscrew the spark plug and replace the fixing piston.

If you do not have a special fork, instead you can use the old starting cord of the chainsaw. It is necessary to put the nodes on the lace at a distance of 2-3 cm, then use a screwdriver insert it through the hole for the candle into the cylinder. The lace will limit the piston stroke, thereby preventing the rotation of the crankshaft and protecting the piston from damage.

How to Sharpen a Chainsaw | Ask This Old House

After installing the emphasis of the piston in the cylinder, the flywheel nut can be loosened. The field, how the nut is spinning, requires a hammer and a drift made of soft material to deliver one sharp blow by installing a drift on the installation shaft of the flywheel. This is necessary to remove the flywheel from the shaft, since the design involves the installation and tightening of this element with great effort.

To learn more about how to remove the flywheel from the Huskvarn chainsaw, as well as how to completely disassemble the saw, you can watch the video. The master explains the whole process step by step and demonstrates all the necessary tools:

You need a special key to unlock the clutch. If there is no key, you can do this from the old head to twenty.Two, turning it in a certain way with sandpaper.

The sleeve has a left thread and clockwise.

Do not try to unscrew the clutch with a hammer and chisel, as some masters advise. Using these tools, you risk breaking the clutch body and increase the cost of repairs. It can also damage the crankshaft bearings.

Front handle

Removing the front handle of Huskvarna is quite easy, as it is attached to the shock absorbers with screws.

Air filter and carburetor

To remove the carburetor, it is necessary to disconnect it from the fuel hose and traction shutters, it is convenient to do this after removing the air filter, which is installed immediately after the carburetor and retained by two nuts for 10. After removing the air filter and the fuel hose and the rods are disconnected, just pull the carburetor over yourself and remove it from the hairpins.

How to remove a chainsaw clutch.

One. In order to remove the clutch on the chainsaw, you must first remove the cutting headset, then the air filter lid and clutch cover.

Then you need to lock the crankshaft so that it does not rotate when the clutch will be unscrewed. To stall the crankshaft, for example, with a large screw, it is necessary to remove the lid of the manual starter and screw two bolts into the rotor of the ignition system. Or unscrew the spark plug, lower the piston in the NMT and stall it there, pushing the rope into the candle hole.

Next, unscrew the clutch itself. The key from the set of the chainsaw, or the key for the disks of the grinder, or with a home.Made key (for example, from the old tire with two bolts), the clutch (there is left thread) to disrupt a significant force clockwise.

Then remove the drum with a leading asterisk from the chainsaw. Replacing the clutch drum of a chainsaw is carried out according to the rule: replaced two tires. Replaced one drum.

Then put a new clutch and twist it with your hands until it stops (twists counterclockwise). In this case, you must again lock the crankshaft so that the wrapping clutch does not break the starter located at the other end of the crankshaft of the chainsaw.

Then everything is going in the order of the reverse disassembly.

To tighten the clutch on the chainsaw finally, you need to serve the cutting brake of the quapi, start a chainsaw and then remove from the brake.