How to Remove a Chain from a Chainsaw

It is safe to say that almost every private house has a chainsaw, especially if you are a person living in a private house or have a summer house. As with any other tool, you need to treat it carefully. Many owners are faced with a typical problem. the chain is stretched due to long work. The reason for this is the heating of the metal, after which it increases in volume. We learn how to shorten the chain of the chainsaw with your own hands, because you can simply make a mistake with its length when buying. Most importantly, after such a procedure, the connection of the chain links will remain all the same strong.

Cooking Tools

Although manufacturers claim that shortening the chain at home is impossible, there are craftsmen who can do this. To do this, get:

- Vise;

- A hammer;

- Beard;

- File;

- Electric welding machine (not always required);

- Pliers.

Chain repair

To repair a chainsaw chain, it must be assembled and disassembled. We will consider these stages more closely to understand what we have to deal with.

Remove rivets

For separation, efforts will be required: for the manufacture of rivets, high-quality steel is used, their shape is geometric.

Important! A distinctive feature of the inner rivet is a larger radius. It is this thickening that is intended to rotate the link, and the role of the outer parts of the rivets is the connecting one.

To remove a rivet, you must:

- Lock the chain in a vise.

- Finish the protruding part, for which a file or file is used.

Important! You need to start the link from two sides, while avoiding damage to the lateral parts of the links.

- Rivets are knocked out, for which you can use a beard. The side parts are slightly bent.

After disconnecting the parts, do not get rid of the remote rivet. It is possible that a replacement will never be found. It is almost impossible to buy a rivet, but it is quite possible to use it.

Important! When disconnecting the part, it is necessary to read the guide tabs on the inner side of the chain and the distance between them. There should be a combination between them and the leading chain saw sprocket. Even with a slight deviation in the step of the chainsaw, soon stretching of such an important part will happen again.

Connect the links

After checking all the parameters, you can connect the links. A rivet is used for connection, the side parts of the links are pressed tightly. To “grab” the rivet, electric welding is used. A file is used to remove excess metal. After that, a chainsaw can be used.

If the repair is not performed correctly

In the event that the repair of the chainsaw chain with your own hands was performed poorly, the following consequences are possible:

- During the welding process, the current was small, which led to excessive heating of the circuit elements. In this case, the physical properties of the metal change.

Important! In the future, the product will stretch in the place where it was welded. Due to the displacement of the guide protrusions, the remaining elements of the chain will break.

- In deeper welding, the inside of the rivet is welded to several parts of the link. As a result, they become motionless. All this also leads to disruption of other elements.

- With low quality welding, the product may break during operation. This is due to the large lateral load acting on it during operation. In this case, the user is likely to be injured.

How to avoid chain stretching?

Before deciding what to do if a chain on a chainsaw is broken, it is better to familiarize yourself with the main causes of breakdowns:

Important! A chainsaw necessarily requires adjustment and periodic maintenance.

- A drive sprocket can also cause chain stretching. In this case, the guide protrusions slip, friction and heating of the parts occurs.

Chain function and proper tension

The correct position and tension of the chainsaw chain is very important not only for its normal operation, but also for the safety of those who work with it, as well as those around them. If the chain has an incorrect tension, then during operation it may accidentally fly off, which is most likely to cause breakdown not only of the chain itself, but of the entire chainsaw. However, it is also undesirable when the chain is stretched excessively tight. This can also have negative consequences in the form of an increase in the load on the motor, which in the future will lead to its early failure and shorten the overall service life of the chainsaw. The chain has one very important property: it fixes the tire, which prevents its arbitrary movement. Therefore, care for the chain should be given special attention.

Choose the right chain

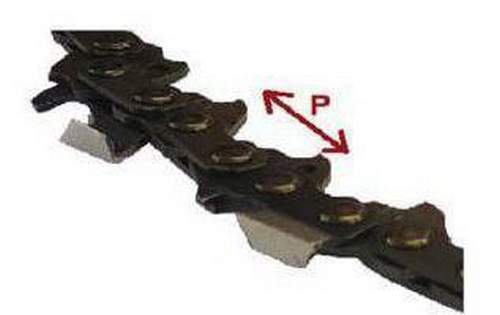

Chain failure is a frequent phenomenon, so before you ask yourself how to tension the chain on the chainsaw correctly, you need to know which chain is suitable for this model of chainsaw. The main criterion for choosing is its step. The step is called the distance between its teeth. The distance is chosen between its nearest teeth and measured in inches. The most common are 0.325, 0.375, and 0.404 inches. Information on the step can be found in the operating instructions for the particular model of the chainsaw, and it depends primarily on the purpose of the tool.

Each saw has its own specific step, exceptions are only professional tools that are universal. The chain pitch also depends on engine power. The more powerful the chainsaw, the greater its step and the more difficult it is to hold it during operation. For example, the Patriot compact low-power chainsaw has a pitch of 0.325. However, there are more powerful models. One of them is the German STHIL in increments of 0.404. Which, as we see, is larger than the Patriot chainsaw.

A step is one of the most important characteristics of circuit parameters. This means that you should not choose a chain with a large pitch for a low power chainsaw. It can not only not fit, but also disable the tool.

The Importance of Proper Circuit Setting

The normal operation of the chainsaw causes vibrations that can significantly reduce the tension of the chain with blades or nuts designed to secure it. The chain stretches during heavy use and is poorly fixed on the teeth of the chainsaw, which can create unsafe conditions for the operator. Proper tool operation includes checking all nuts and bolts before and during use to ensure safety. If the chain nuts are too loose on the teeth of the saw, then most likely you will need to properly tighten the chain, and then tighten the blade itself.

Before starting work, you should always remember your own safety and use protective leather gloves and glasses. A chainsaw should be placed on a flat surface, such as a workbench or table. The engine must be allowed to cool completely if it has been used before. Next, to prevent accidental starting of the saw, remove the wire from the spark plug connector. Now you can begin to adjust the chain.

How to pull a chain on a chainsaw yourself

This is not difficult to do, the main thing is to remember your own safety. So, how to put a chain on a chainsaw? Stand in front of the chainsaw facing you with a blade. Grasp the tip of the saw blade with one hand and lift it slightly. Firmly insert a flat-head screwdriver into the adjustment screw, which is located to the right of the blade when you are looking at the saw blade. Turn the screw clockwise to increase the chain tension, or counterclockwise to decrease it accordingly. Take the chain in one hand and pull it around the blade. The tension is correct when it is slightly loosened if pulled in the direction of the blade and at the same time fit snugly against it.

If so, then further chain adjustment on the chainsaw may not be required. If not, you need to adjust it. Loosen or tighten the adjustment screw to get the right fit. Hold the tip of the chainsaw blade with one hand. Tighten both left blade retaining nuts with a saw repair kit or adjustable wrench. Put the spark plug wire back into place and press it firmly.

Necessary tools

When buying a chainsaw, it is often bundled with a tool for its maintenance. It is necessary to adjust the circuit. It looks like this: at one end there is a flat-head screwdriver, and at the other end there is a wrench that fits the blade nuts. To understand how to tighten the chain on the chainsaw, you must refer to the operating instructions for this model of saw.

Safety precautions

When using a chainsaw, personal protective equipment should be used, including eye and hearing protection, leather gloves and a hard hat.

For safety when working with a chainsaw, it is desirable to have another person nearby who can provide assistance if it is needed.

Chain sharpening

Everyone knows that from time to time you need to sharpen a chain on a chainsaw. However, not everyone knows how to do it right. A sure sign that the saw needs sharpening is the shape of the sawdust. If they look like fine dust, this means that the chainsaw blades are dull and need to be sharpened. With strong wear of the chain, when it is no longer possible to sharpen it, it must be replaced with a new one.

Chain sharpening methods

There are many ways to do this. As examples, we give the most common:

- Sharpening using a file. Its convenience lies in its simplicity, because there is no need to use sophisticated equipment and machines. In addition, this sharpening can be done directly on the job site, which saves a lot of time.

- Sharpening on the machine. Most often it is used in equipped service centers or workshops, but it also takes place in the personal household.

- Sharpening using an angle grinder. One of the most difficult ways to sharpen, as it requires special skills. Because of this, this method has not found wide application.

How to shorten the chain on a chainsaw yourself

The chainsaw chain must always be in good technical condition. All defects and malfunctions must be given the necessary attention. You must follow the general safety rules and recommendations given in the operating instructions. This is the only way to avoid injuries and other undesirable consequences when working with a chainsaw and extend its service life.

Sometimes due to wear, deformation or other reasons, it is necessary to replace the chain or shorten it. It should be noted that chain sagging does not mean that it needs to be replaced. It needs to be changed if it is completely not subject to adjustment.

Sometimes during heavy use, the chain may sag. This is due to severe overheating of the metal, its expansion and, as a consequence, elongation. The way out of this situation can be a periodic stop to allow the circuit to cool. However, this is not always possible. Another situation may arise when, say, you need to install a chain whose length is somewhat large.

Tension adjustment

The chain tension must be adjusted using the chainsaw tension bolt, which is located in the place where the toothed stops are located.

It is important to understand how the chain should be pulled on a chainsaw. It is not necessary to pull it all the way, because soon it can stretch again. The chain should have a small margin, slightly sag. It is not difficult to check by hand. It should be a millimeter retract from the tire.

Best of all, when the chain is of sufficient length and you can remove several of its links. By doing so, we are able to use the original links for the chainsaw chain. You can fix them with a hacksaw for metal, but it will be much more convenient to do this with an emery machine. To do this, you need to unfasten the link by grinding it, and then cut off the part that is superfluous. Next, we knock out the rivets from those links that are not needed, remove them and connect the chain independently. To do this, you can use special rivets, but if they are not available, you can use the usual steel wire. We lay the chain on a solid base and begin to rivet on both sides.

A little about the rules of operation of the node

All chainsaws, regardless of the manufacturer, are divided into:

All of them have a similar design of the main components and high build quality. The main difference lies in the arrangement of the working circuit and in the materials used for the manufacture of parts and assemblies.

The suitability of the chainsaw for use depends on the style of use of the blade and sprocket. There are usually two of them:

- The chain is used until the teeth are completely worn out. Together with her, they change the gear.

- Several chains with different pitch are used, which correspond to their gears, corresponding to them in the number of teeth and pitch.

In the first case, they saw everything in a row, including nails and staples. This causes increased wear on both chains and gears. You often have to edit and sharpen the chain, spending a lot of time on it.

The chain and sprocket should only be changed together. During operation, the web rollers are run-in to the gear, stretching somewhat as the teeth wear. If the old chain is paired with a new asterisk (or vice versa) there will be no such correspondence.

At the start, impacts of the teeth on the links will occur, which will lead to increased vibration and wear of the entire chainsaw.

Video: How to Remove a Chain from a Chainsaw

The state of the gear-web pair also affects the operation of the clutch and drive bearing. In the "Work" mode, the crankshaft rotates. In idle mode, with the clutch disengaged, the bearing starts to rotate. With insufficient lubrication, it undergoes increased wear, which causes even greater tooth beating.

The canvas and sprocket are subject to periodic replacement. It’s better to do it at the same time.

Design features of leading stars

The pitch of the teeth of the drive gear is one of the main parameters of the assembly. It must coincide with the pitch of the chain links and, no less important, with the pitch of the teeth of the driven sprocket located at the end of the chainsaw tire.

Drive gears by design features are divided into:

Experts identify the following signs of wear of the teeth of the drive gear:

- semicircular cavities are noticeable at the base of the tooth;

- tooth thickness varies with height;

- cleaved areas on top;

- scratches appeared inside the hole in the hub;

- the chain rubbed a groove in the sprocket;

- when starting, the chainsaw wedges.

The chainsaw sprocket with such signs should not be operated, it must be removed and replaced.

According to the manufacturer’s recommendations, the tool should be inspected before starting work. In this case, the condition of the saw bar must be checked whether it is securely fastened. If the screw adjusting the position of the roller of the chain and its tension is loosened, or if the nuts fastening the tire to the casing are loosened, it deviates from the plane of the chain. In this case, the rollers of the blade do not rest on the middle, but on the edges of the teeth, increasing the load on them and on the chainsaw as a whole. Increased wear leads to premature failure.

After tightening the mounts and adjustments make a trial run. If the free play remains, then the sprocket will have to be removed and replaced.

How to remove a drive sprocket from a chainsaw

Depending on the design features of the gear, the sequence of operations necessary to remove it also varies.

How to remove a single sprocket from a chainsaw

To remove the whole gear with a pressed crown, you should:

- Remove cover and air filter.

- Remove tire and web.

- Lock the engine piston.

- Disengage clutch.

- Remove clutch and drum.

- Remove the crown by prying it with an open-end wrench or using the tool from the delivery.

Collect the chainsaw in the reverse order.

How to remove an asterisk from a chainsaw

Removing collapsible gear occurs in the same sequence, with the exception of the last operation. In its course, not the entire gear is removed, but only its crown.

After assembling the saw, adjustments and overall performance should be checked. In this case, check the tension of the canvas.

To do this, release the brake and pull the canvas in the direction of the working movement. If there is no play, then the chain is overtightened and should be loosened. If it is possible to pull so that the gap between the links and the bus is visible, the tension is insufficient and

Replacing Worn Parts

If the gear has a removable crown, carefully check the condition of the base. If nicks, chips, deep scratches, geometry changes or corrosion are detected, not only the crown, but the entire part should be replaced. Joint work in the same unit of worn and new parts will lead to a reduction in the service life of the entire unit. Significantly increases the risk of jamming or breaking the chain.

In addition, the vibration load on the clutch, transmission and engine of the device will increase. The same factors arise during the continuous operation of a single circuit.

Folk "craftsmen" sometimes reanimate the stretched web of the chain, simply throwing one for the link and re-pressing the axis. In this case, the chainsaw requires a sprocket replacement.

You should also not change the diameter of the gears (and, accordingly, the number of teeth). When working with an enlarged or reduced asterisk in the transmission and engine, forces arise that the device’s designers did not expect. This will reduce the operational life of the tool and not increase its productivity.

Despite the presence of safety systems in the design of the chainsaw, which instantly stops the movement of the blade when it breaks or the tire breaks and protects torn links from flying apart, it is better not to bring such situations. The need to replace gears is only enhanced by safety requirements.

How to extend the leading sprocket resource?

Experienced sawyers recommend working with several identical canvases, changing them as the links become dull. This technique will help to significantly reduce the wear of the drive gear, but, of course, will not be able to prevent it completely. Sooner or later it will have to be removed and replaced.

Restoration or replacement?

Drive parts are made of highly durable high alloy alloys in industrial production. In addition, they are subjected to special types of processing to improve their strength properties, wear resistance and corrosion resistance. These may include:

- Quenching.

- Vacation

- Shot blasting surface seal.

- Application of protective coatings.

It is impossible to repeat such a technological process in a home workshop. An attempt to restore by surfacing with subsequent milling to size will also fail. Such a restored gear will work several times less than the factory gear. The cost of a repair kit is incomparably small compared with the wasted effort and time.

Replacing a part in a service workshop is expensive, so the most reasonable and economical way is to replace it yourself with a suitable industrial gear.

Alternative solutions

The drive designs of most chainsaws presented in the domestic and semi-professional market segments are fundamentally similar. The sequence of operations necessary to remove and replace the pinion gear is the same.

As already mentioned, the best option would be to purchase a full-time repair kit for this model.

The advantage will be the availability of the kit and bearing. You should also check the availability of a drum puller designed for this saw, as well as a latch for securing the piston in a certain position.

If, nevertheless, the brilliant idea of “improving” or modernizing this chain saw unit arises, it is better to consult with experts and just experienced people.

How to replace with your own hands

Experienced craftsmen recommend the following sequence of operations when replacing an asterisk:

- Remove housing and air filter (if necessary).

- Unscrew the spark plug and insert a latch instead to lock the piston.

- Remove the chainsaw clutch.

- Remove the gear with a puller or open-end wrench.

The removable crown should be unscrewed clockwise. If during disassembly it turns out that the parts of the centrifugal mechanism are worn or broken, you should also remove it and replace it. If parts and assemblies are not visually damaged, then the assembly of the mechanism is carried out in the reverse order.

To correctly and accurately fix the clutch mechanism on the drive shaft, remove the piston lock, gently pull on the starter cord and release it.

The principle of operation of the clutch system

In most cases, a centrifugal clutch is used on Stihl, Partner, Husqvarna and other brands of chainsaw. When the engine picks up a certain number of revolutions, it turns on automatically, transmitting rotational movements to the sprocket.

The clutch is a disc located in the drum. The entire assembly is mounted on the shaft of the chainsaw engine. In the normal state, the clutch springs press the friction linings, preventing the transmission of movement to the drum, respectively, and to the sprocket. When the speed reaches the set value, a centrifugal force is formed, under the influence of which the elements with friction pads are displaced, exerting pressure on the inner walls of the drum. Thus, the sprocket is driven by rotating the saw chain.

Why a sprocket replacement is necessary

Chainsaws have some parts that are subject to natural wear and tear; these include the chain, tire, and drive sprocket. This is not considered a tool breakdown because wear is a result of operation. Also, an inappropriate chain or mechanical shock may be a causal development. For example, after a chain meets a metal object, it is recommended to inspect the sprocket.

If you do not timely replace the part, the stability of the tool is violated. A worn part provokes excessive vibrations, which, in turn, have a negative effect on the bearings of the crankshaft.

Normal wear is considered to be up to 0.5 mm. However, often users bring the part to a deeper output of the order of 1 mm, not suspecting that the operation causes damage to other parts of the chainsaw. Naturally, later there is a breakdown of the bearings, which must be changed.

Step-by-step instructions for replacing the sprocket on a chainsaw

You can replace the asterisk on a chainsaw not only in the service, but also with your own hands. The whole process is relatively simple, for the repair will require:

- candle key;

- a wrench for removing the coupling (a regular grinder wrench for a nut is also suitable, but it is desirable that it be thicker);

- piston stopper (special tool, but it can be replaced with a tight cord);

- Adjustable wrench / wrench (may not be useful).

Step 1. Replacing the drive sprocket and chain begins with fixing the piston in the cylinder of the chainsaw. To do this, the upper housing cover, the air filter are removed, and the spark plug is twisted. A special piston stopper is installed in this hole, but among the craftsmen it is not in great demand: a metal one can scratch a piston, and a plastic one can break and get inside. Most often, instead of it, they take an ordinary dense cord or a wire about 10-15 cm long. It is important that debris does not pour from it, metal wires do not stick out. all this can get into the cylinder.

Install the stopper or cord in the hole. Perhaps the piston will interfere, to lower it, you will need to slightly rotate the sprocket, moving the chain or itself clockwise.

Step 2. Remove the cover on the side of the chainsaw where the tire is mounted. Usually it is held on two bolts and pressed with two nuts. You can unscrew them manually or with a wrench or universal wrench. The chain tension is released to immediately remove it and the saw bar. At the same stage, external cleaning should be carried out from accumulated dust and sawdust.

Step 3. Depending on the design of the chainsaw, the sprocket can be located under the clutch drum (separately or be part of it) or on top. In the second case, everything is simpler. remove the part and replace it with a new one.

In other circumstances, the assembly must be disassembled. The coupling is left-handed, so it is twisted clockwise with a special or Bulgarian key, the drum is removed, then the sprocket can be removed. If the chainsaw has been used for a long time, the parts can become very sticky. In such a situation, physical force will be required, but it is forbidden to use a hammer or chisel. this will render the entire part unusable.

Step 4. Remove all parts:

- clutch

- washer

- drum

- asterisk

Perform an initial inspection of all elements for wear and deformation. Next, you can begin to repair and take up the replacement of the sprocket on a chainsaw. If it is part of the coupling drum, the entire part must be replaced. An important point will be the selection of a new part. it should be similar to the standard one.

Tool assembly order

The chainsaw is assembled in the reverse order. First, the sprocket is mounted on the needle bearing, then the clutch drum, the washer and the clutch itself. Twist it counterclockwise, but without unnecessary effort. The piston will also need to be fixed, but with a left rotation a few millimeters to the maximum high point.

Please note that sometimes the oil actuator is equipped with a spring that transmits movement from the sprocket to the pump. If the mustache of the spring does not fall into place, the oil will not be supplied to the chain. Usually the correct position is marked by color, risks, in the absence of those, you need to slowly rotate the part until a characteristic click.

Next, you need to install the saw bar on the chainsaw. To set the chain, you need to release the hand brake by pulling the lever towards you (towards the handle). It is important here that the teeth of the chain fall into the grooves of the sprocket. Inattentiveness, this moment can be missed, which will lead to a quick damage to the chain. Its correct direction is indicated on the case with characteristic pictograms. After installation, it must be pulled to a working condition.

At the end, you need to remove the piston stop, install the spark plug, air filter in its place. Fasten the top case cover.

Watch the video how to remove an asterisk from a chainsaw

Useful Tips

In order for the chainsaw mechanism to serve longer, you must adhere to certain rules. Experienced craftsmen recommend:

- Always lubricate the needle bearing after changing the sprocket.

- Correctly select the saw chain and bar. Sprocket pitch and chain must match (e.g. 3/8 or 0.325). If you use the wrong consumables, then the sprocket flares up, quickly and unevenly wears out.

- Many try to replace the drive sprocket and chain at the same time. The fact is that as the chainsaw is used, the chain inevitably stretches, accordingly, the length of its step also changes. And this already negatively affects the sprocket itself, in particular, a wide step will wear out faster, breaking grooves along the edges.

- Be sure to regularly clean the chainsaw. Periodically, you need to remove the side cover and remove accumulated sawdust, which inevitably fall through the hole near the chain and mix with the grease.

- Watch the "behavior" of the circuit when working. If it starts to wedge. this is an occasion to conduct an initial inspection of the drive sprocket.

Summary

The algorithm of actions during the repair work of the chainsaw is quite simple and based on the experience and knowledge of qualified craftsmen. Therefore, it is not recommended to neglect certain nuances. The instruction presented by us will help to remove the star from the saw with your own hands, without resorting to the help of specialists, on most types of chainsaws. In private, any deviations, non-standard designs are not excluded. Sometimes it is very useful to read the user manual for the tool, it may contain the necessary information about the features of the design, detailing of spare parts with a description.

Chainsaw sprocket device

An asterisk or centrifugal mechanism is a part resembling a star in shape. It takes over the engine torque and transfers it to the guide and saw chain. This guarantees the rotation of the cutting headset and the cutting process itself. It works in automatic mode, which depends on the magnitude of the engine speed.

The clutch drum can be localized both outside the chainsaw and on its inside under a separate cover. It performs a protective function not only in relation to the material of which the sprocket is made, but also for the operator, who may be injured by it during operation.

In addition to the function of chain rotation, the leading star of the saw prevents the appearance of malfunctions of the motor system in those cases when the chain is jammed or stops rotating.

Classification of the leading chain saw chains

In accordance with the power class of the saws on which they are installed, the asterisk can be:

The main difference between them is the frequency of replacement and the rate of wear: in the Pro series, wear is faster and repairs are more frequent.

By design features, the leading chain saw stars are:

The latter consist of a hub with a stationary crown of a certain number of teeth. Their factory fitting does not allow to remove the crown separately from the hub. This situation is typical for many Chinese chainsaws, for example, from the Champion brand.

The situation with prefabricated sprockets is simpler: a removable crown quickly unscrews from the axis of the drum, so repair is not particularly difficult. This option is the advantage of most saws of European origin, for example, “Stihl” or “Husqvarna”.

When to change the chainsaw sprocket?

If the chain glues at low speeds, the saw is operated for a long time on the same chain and drive sprocket, and defects are detected during its inspection, its change is mandatory.

Externally, the state of the sprocket is determined by its teeth. They are considered worn out if:

- there are small chips or grooves from the guide;

- their width is disproportionate to height;

- the angles between the teeth and troughs are different;

- hub with seizures and other deformations due to lack of lubrication.

In each of the options described above. an asterisk is subject to repair.

What is needed to replace the sprocket on a chainsaw?

The main thing that is required is an understanding of the internal structure of the saws and a certain dexterity: if you are holding this power tool for the first time, it is better not to experiment with repairs and provide it to more experienced people.

If you are confident in your own technical literacy, to replace the sprocket on a chainsaw, you will need:

- a new clutch drum or its whisk. are selected in accordance with the model of a particular chainsaw;

- set of tools for repair.

How to remove an asterisk from a chainsaw: several options for different designs of the clutch drum

The method for a star with a stationary crown

To do this, produce:

- dismantling the protective cover and tire-cutting headset;

- locking of the piston of the motor;

- disconnecting the clutch from the motor system;

- recess from the saw body of the clutch and the centrifugal sprocket;

- visual inspection of the sprocket and its gear part;

- if defects are detected, replace the sprocket with a new clutch drum;

- diagnostics of clutch chainsaw elements for defects. worn centrifugal springs and cams can adversely affect the operation of the sprocket;

- if there are no malfunctions, we proceed to the assembly stage. To do this, you need:

- remove the stopper;

- to pull off the ignition cable;

- screw the stop to fix the centrifugal mechanism on the motor shaft;

- use a universal key in the direction against the chain stroke to tighten the clutch;

- return the remaining removed parts to their previous positions.