How to Remove a Flywheel from a Chainsaw Without a Puller

How to remove the clutch on a chainsaw

- Chainsaw device

- Chainsaw engine device

- Carburetor and fuel system

- Ignition system and starter for chainsaw powerplant

- Chainsaw Clutch

Often people using chainsaws in the process of servicing raises the question of how to remove the clutch on a chainsaw. The fact is that this node of the chainsaw mechanism requires constant monitoring of operability, which, in turn, requires periodic disassembly for preventive maintenance and repair.

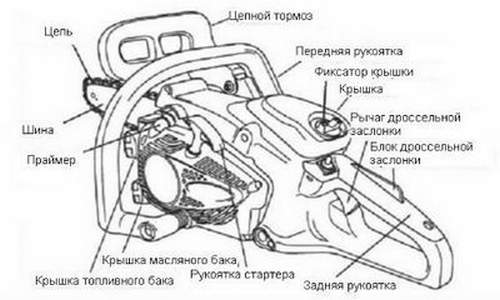

Chainsaw device diagram.

Chainsaw device

It is worth noting that all chainsaws are classic devices driven by gasoline ICE.

Chainsaw electronic ignition circuit.

Single-cylinder engines operating on high-octane gasoline have found application in the device of chainsaws. The power unit does not have a reducer. It acts as a single-stage transmission, which drives the chain. The simplicity of the design is the key to the reliability and reliability of the tool even in the presence of severe operating conditions.

In addition to these nodes, the design of the chainsaw includes an air purification system, which is supplied to the engine to prepare the combustible mixture, a tire with a saw chain installed on it, a starter that starts the chainsaw power plant, a chain tension mechanism, an ignition system, and an exhaust silencing system. In addition, the design of the chainsaw includes the so-called emergency brake, the operation of which allows you to instantly disconnect the power unit of the chainsaw from the drive sprocket in an emergency to prevent injury to the person operating the device.

Back to the table of contents

Chainsaw engine device

Types of spark plugs for chainsaws.

In modern chainsaws, a two-stroke single-cylinder power plant of a carburetor type is installed.

The engine consists of several systems and components that make up a single whole. In the design of the engine, there are several elements that ensure its functioning:

- flywheel

- clutch

- ignition module

- muffler

- special sleeve for mounting a carburetor.

Engines mounted on chainsaws are high speed. The maximum number of revolutions of the power plant is 13,500 revolutions per minute. This requires the use of high-quality oil when lubricating the engine, which is added to the fuel mixture.

Since the operation of chainsaws is carried out, as a rule, in difficult conditions, the power plants of the device require good cooling. The engines used to install the chainsaw are power plants equipped with a forced cooling system. For this purpose, an impeller is installed in one of the semi-axes of the crankshaft in a closed housing. Due to the rotation of the impeller, air is supplied to cool the cylinder of the power plant through the corresponding duct.

Back to the table of contents

Carburetor and fuel system

Chainsaw fuel system: 1. fuel filter, 2. carburetor, 3. manual pre-pump.

The carburetor in the power unit is designed to prepare and supply a combustible mixture to the cylinder. Most often, carburetors manufactured by manufacturers such as Walbro, Zama and some others are used in the device of chainsaws. A special filter is mounted on top of the carburetor to carry out the purification supplied to the air carburetor. The fuel system in the simplest version consists of a tank, a filter element, a hose for supplying fuel. As a rule, a fuel tank is enough to work for 30-40 minutes.

To fill the tank during operation of the device with air, its lid has a breather that lets air into the tank and prevents the flow of fuel. If the breather is clogged with debris, the engine stops working. A fuel filter is installed at the end of the freely dangling hose. Fuel injection occurs due to the operation of the pump located inside the carburetor.

When the power plant is operating, atmospheric air must be supplied to it to prepare a combustible mixture in the carburetor. The incoming air is cleaned with a special air filter. As a rule, two filters are installed in the chainsaw design: a coarse filter and a fine filter. The pre-filter has several elements and prevents large contaminants from entering the engine. The fine filter purifies the air from dust particles. In some models, a flywheel impeller is used as a cleaning element, which cleans the air stream from large impurities due to centrifugal forces. In the manufacture of fine filters, diffuse foam rubber, nylon mesh or some other materials are used as a filter element. The chainsaw filter requires regular cleaning.

Back to the table of contents

Ignition system and starter for chainsaw powerplant

Scheme of a two-stroke engine of a chainsaw.

To date, saws with a gasoline power plant are equipped with electronic ignition units, which does not require adjustment and cleaning. The ignition system includes a flywheel with magnets, a module having an electronic system, a spark plug and a high-voltage wire.

The starter installed on the device serves to start the saw engine by cranking the crankshaft. The starter mechanism includes the following elements:

- drum

- cable with handle

- body

- return spring.

When carrying out a sharp pulling of the cable, the starter ratchet engages with the crankshaft teeth, which leads to its turning. The return spring is designed to return the cable to its original position. To start the power plant you need to apply a certain force, since the engine starts only at a certain speed of rotation of the crankshaft.

Back to the table of contents

Chainsaw Clutch

The design of chainsaws is equipped with a centrifugal clutch, which is activated automatically, in full dependence on the speed of rotation of the engine crankshaft.

At low revs, the elements installed in the clutch basket and having special pads are attracted to the center of the shaft by springs. This position of the elements prevents the transmission of rotational motion from the crankshaft to the sprocket. Upon reaching a certain number of revolutions of the power plant, elements with special overlays diverge and are pressed to the clutch drum, transmitting rotation to the chain. The main feature of such a clutch is that when the saw chain stops, it starts to slip, which avoids damage to the power plant and mechanisms that transmit movement to the chain. Quite often, clutch as a result of intensive use is required to be prevented and repaired. For this purpose, the clutch is disassembled.

How to remove the clutch chainsaw?

The clutch drum is simultaneously the drive sprocket.

This structural element is consumable, and this, in turn, requires regular replacement or repair.

File position when sharpening the chainsaw chain.

The main reason for the failure of this unit is the wear of the sprocket teeth. If the drum is monolithic, then in the process the chain cuts an asterisk. Such a drum must be replaced. On some drum devices there is a replaceable crown and during repair it is replaced, and the drum, while maintaining its normal state, is operated on.

If it is necessary to repair the chainsaw, the question arises of how to disassemble the clutch. If there is a service center, it is better to contact specialists, but in the absence of the latter, the disassembly and repair procedure can be done with your own hands. This operation is simple and with the availability of appropriate tools it can be carried out by almost everyone. Almost every model of this tool has its own nuances in dismantling the clutch, however, the general sequence of actions is the same for any models.

The first step is to remove the chain brake cover. For this purpose, pull the handle towards you. This is done so that the tape does not come into contact with the clutch cup. After that, the nuts for securing the cover and the chain tensioner are loosened.

Loosening the tensioner loosens the chain and the bar. After that, the nuts for fastening the brake cover are unscrewed, after which the cover is completely dismantled.

At the second stage, the guide bar and chain are dismantled, and contaminants are removed.

The next stage of disassembly is the inversion of the cylinder head candles. Then the piston is fixed in the cylinder. For this purpose, the crankshaft is rotated and after the outlet is closed, a piece of rope is lowered into the cylinder, which prevents further movement of the piston. After the repair, the rope is pulled out at the other end.

The fourth stage of disassembly is the direct dismantling of the clutch. First you need to unscrew the nut on the clutch. It should be remembered that this one has a left-hand thread, when unscrewing it, you need to turn the key clockwise. For work, a key is used, which is included in the set of accessories for the chainsaw.

After unscrewing the nut, disengage the clutch and inspect the drum with the drive sprocket for wear. Then, after inspecting the drum and sprocket, the condition of the needle bearing is inspected. If necessary, worn items must be replaced.

The assembly of the tool is carried out in the reverse order.

There are several nuances that you need to know when repairing a clutch:

- On some modifications and models of chainsaws, a washer is placed between the clutch and the cup of the drive sprocket. In the case of disassembling this element, it is necessary to install the washer in the position in which it was previously. This washer can sometimes be installed between the engine and the cup.

- Some models of oil pump drives have a special spring. It transfers the rotation from the sprocket to the oil pump drive. The correct installation of this spring when assembling the device is very important. If installed incorrectly, the oil pump stops the oil supply to lubricate the chain. Which can lead to costly repairs.

After carrying out repair work, before starting the use of the chainsaw for its intended purpose, it is necessary to check the operation of the oil pump and its oil supply to lubricate the saw chain and guide rail mechanisms.

Chainsaw clutch repair

Added 3 years ago. Channel: Rostinmir

1.Chainsaw repair. Replacing the clutch. (Rem.

Added 2 years ago. Channel: Popular

Repair of the Chinese Stihl ms 660 chainsaw.

Chainsaw sprocket replacement.

The Chinese chainsaw will not start. The diagnosis.

Replacing the sprocket on a Chinese chainsaw

Chinese chainsaw. Part II

Clutch cams for the Ural chainsaw (co.

Tribune of your news

Chainsaw device. Chainsaw clutch.

Chainsaw device

The chain includes three types of links: cutting, driving and connecting. Links are connected by rivets. The cutting link is the most difficult part of the saw chain. It consists of two parts: a cutter depth limiter and the cutting element itself. The cutting teeth are divided into 2 types that are right and left-handed, they are attached in turn. Chains with a smaller gap between the teeth are low profile, and with a large gap they are high profile. Safer chains are low profile, but they are less effective. Such chains are usually used in household chainsaws, and professionals are highly specialized. Chains still vary in link length and liner thickness. The larger the chain pitch, the higher its performance. Chains with a small pitch have more teeth providing a smooth movement in the cut and, accordingly, reduced vibration. And the cut itself is cleaner. A chainsaw tire is a chain guide. A groove goes along the entire end, and shanks of links (groove) pass along it. Most often in the front of the tire is a driven sprocket. For different tasks, different tires are used, but in everyday life you can use a universal bus. The tire and chain, removable parts of the chainsaw, so they are called a headset. Chainsaw lubrication system. The headset (chain and tire) requires constant lubrication during operation. The lubricant supply must be continuous, because the oil leaves the groove of the tire and is immediately absorbed by sawdust. But when the engine is idling, the chain does not move, and lubrication is not needed. Therefore, chain saws have an automatic lubrication system.

Chainsaw chain brake.

You yourself probably understand that a light touch of a moving chain of a chainsaw is enough to get a serious wound. To protect a person from such damage, there is a chain brake. The time it takes for the circuit to stop completely depends on two factors. This is directly the moment the brake is applied and the braking speed. Check it out is not difficult.

Most modern chainsaws have a single-cylinder, 2-stroke, air-cooled carburetor engine. Due to the fact that the fuel is constantly washing the crankcase, oil must be added directly to gasoline. In the ratio from 1 to 20 to 1 to 50. (Although there are “top models” equipped with separate oil barrels and mixing the oil in automatic mode) In order to reduce the weight of the engine, plastic crankcases are installed in chainsaws (which are not designed for long-term operation).

Chainsaw air filter.

The air that enters the engine should not contain dust, this accelerates the wear of the piston group. The chainsaw air filter works under special conditions. If the filter passes less air, this will lead to a drop in speed and lower power, as well as to overheating of the engine. In this regard, the filter needs regular cleaning.

Most often, it is a rope with a handle wound on a pulley. It is activated by pulling the rope, the dogs catch on the ratchet and the flywheel is untwisted. The difficulty lies in the fact that the larger the engine capacity, the more efforts are made to pull the starter cable. Therefore, many modern saws are equipped with various mechanisms that facilitate starting. Some models have a more convenient feature. Just press the button and the engine will start. Chainsaw carburetor is one of the most important components. The stability of the engine and its performance depends on how the carburetor prepares the air-fuel mixture. If the carburetor is adjusted correctly, the engine starts with one jerk of the starter.

All modern chainsaws are equipped with an automatic clutch.

Anti-vibration system of a chainsaw.

The work of the chainsaw creates vibrations that, when exposed for a long time, have a bad effect on health. For example, joints suffer. Therefore, damping systems is a necessity.

After finishing work, it is imperative to prepare it for storage. To do this, drain the remaining oil and fuel from all tanks. The fuel remaining in the tank and carburetor must be burned at idle. The chain is stored in an oil bath. The tire is wrapped in oiled paper.

How to remove the clutch chainsaw?

Видео: How to Remove a Flywheel from a Chainsaw Without a Puller

What tools are needed to disassemble a chainsaw? How to remove the clutch of a chainsaw, share your experience, who came across?

It is necessary to remove the brake, after making the piston fixation a special device for fixing the piston, then unscrew the clutch. Usually you need to turn it clockwise with an open-end wrench.

First, you need to remove the clutch cover, unscrew the candle, lock the piston with a stopper through the hole for the candle and with the help of a puller and a hammer, gently unscrew the clutch, use a hammer to beat with weak blows so that there is nothing to beat off.

The saw brand is not visible, unfortunately, oh well, the principle is basically the same for saws of this type. Use a hex wrench on 6 or a star of the same diameter. Remove the air filter cover, clutch cover. We unscrew the spark plug with a candle key, bring the piston to the bottom dead center. We take the rope and push it into the candle hole, I try to keep the piston in the BDC, thereby jamming the piston in this position. With the supplied chainsaw key, unscrew the clutch clockwise. On the clutch there is a nut 13. unscrew it. We unscrew the clutch, remove the basket with the drive sprocket. Change the clutch. do not forget to put the washers in place. We tighten the clutch by hand counterclockwise until it stops. The rest of the assembly is in reverse order. Next, we move the brake lever forward, start the engine and remove it from the brake. the clutch is tightened with the help of the motor.

I tried to unclutch

and everything turned out very easy for me

how to adjust a chainsaw carburetor

No idle. What to do.

All about chainsaws.

Gardening equipment for the most part has a rather narrow specialization and is not used except in a garden, garden or lawn. Another thing is a chainsaw, this is a universal tool needed by people of various professions:

for lumberjacks a chainsaw is the main tool of labor

special saws for the care of tree crowns are produced for employees of urban landscaping and park services. They can be operated with one hand, and the second hold on to branches or stairs

special saws capable of gnawing steel and concrete are produced for rescuers

finally, a chainsaw may be in the hands of a sculptor. recently, wooden or ice sculptures have been very popular.

And, of course, it’s hard to do without a saw to the owner of a country house or cottage.

About twenty years ago, chainsaws were a powerful, but heavy and expensive professional equipment intended primarily for sawing. Now the situation has changed radically. the market is dominated by light and medium models of the household or semi-professional class. They are understandable. the demand among non-professional users, for example, summer residents, has increased many times. And for them, affordable price, ease of operation and maintenance are important. By the way, to the greatest extent these criteria are met not by gasoline, but by electric chain saws. After all, a summer resident doesn’t need to cut down trees (except occasionally), but to prepare firewood near the house. There are no problems with electricity, just an extension cord. But the maintenance of the saw is much simpler and also much cheaper. They can also be used in a closed, unventilated area. On the other hand, attachment to the outlet does not allow you to go far. Yes, and within reach, a long clinging “tail” does not contribute to the convenience of work (I once had to cut branches on a tall tree with a saw, disgusting memories).

The market offers equipment for every taste and budget. Sometimes “weak” saws are much more expensive than more powerful ones. To make it easier to understand, we sorted them out "into shelves", dividing them into five tables. The first is electric, the second is gasoline, "one-handed", the rest are gasoline-powered household, semi-professional and professional.

Professional chainsaws. Designed for those who work with a saw often and for a long time. primarily lumberjacks. They are distinguished by great performance, maximum resource, as well as vibration protection of the highest level and a perfectly balanced case with convenient handles. after all, such a saw has to be worked every day and for a long time. In addition, professional ones are simple and convenient to maintain and repair. there is no place to look for a service in the forest and there is no time to find it, it is easier to deal with minor problems yourself. Obviously, such a technique cannot be cheap, but it costs its money.

Household chainsaws. A completely different situation when a summer resident needs a saw. The need for it arises occasionally, the volume of work is small. Such chainsaws are notable for their low price. who wants to pay big money for an instrument that is needed only occasionally? Cost is reduced by reducing power and simplifying the design. After all, in order to cut a tree in the garden once a year or to cut firewood for the weekend, a huge resource, like that of professional chainsaws, is not needed. So they can be sacrificed using cheaper materials and simpler technologies. But what exactly can’t be saved is safety, because an inexperienced user often makes mistakes.

Semi-professional chainsaws. They are also called farm-oriented work of medium intensity. The characteristics are closer to professional, but have a shorter resource and sometimes a relatively simple anti-vibration system. For the price they also occupy the "middle row".

They buy such saws for both household and professional use (for example, for urban landscaping services). Another important niche is construction: in this field of activity, the power and resource of household saws are usually not enough, and professional, even small, power is not always profitable.

The first mechanical saws, first driven by a water mill, and then by motors, repeated the principle of a hand saw. the reciprocating movement of a wide blade with teeth. At the beginning of the 20th century they were replaced by circular saws. At the same time, with the advent of light gasoline engines, attempts were made to construct a portable chainsaw. The disk is not suitable for this, since to cut a tree with a diameter of more than 20 cm, you need a half-meter diameter disk, and this is unacceptable for portable equipment. The solution was closed, like a bicycle chain with teeth fixed on it. At first, the teeth were flat and straight, like hand saws. But they turned out to be ineffective, quickly dull and required very laborious maintenance. Attempts to modernize the chains were made repeatedly, but only in 1947 the development of Joseph Cox was successful. He gave the sawing teeth a curved L-shape and bent the even ones in one direction, and the odd ones in the opposite.

Such teeth did not “scratch” the tree, like hand saws, but cut out a square straw, which immediately crumbled into smaller pieces.

As the name implies, “gasoline chain saws,” the actuator is a chain enclosed in a ring that fits on a guide rail. The tire and chain are removable, so they are called the "headset."

The chain consists of three types of links: cutting, driving (shanks) and connecting. The links are interconnected by rivets. The cutting link. perhaps the most complex part of the saw chain, consists in fact of two parts: a cutter depth limiter and a L-shaped cutting element. The upper cutting edge of the link is always wider than the chain itself and the tire, so that the cut is wide enough so that the chain does not pinch in the cut. The cutting teeth are right-handed and left-handed, and they are strengthened alternately on the chain. The tooth works according to the planer principle: the further the knife is extended (upper cutting edge) above the plane of the plane (cutter depth limiter), the thicker the shavings. Chains in which this gap is small are called low profile, in which it is large. high profile. Low profile chains are less efficient but safer. They are less prone to back impact when the saw bounces back and can break out of hands. Therefore, only low-profile chains are allowed to be used on household saws, while professionals prefer “evil” high-profile chains.

Leading links equipped with shanks provide chain movement, transmitting rotation from the engine through the drive sprocket, and also fix the position of the chain on the saw bar. In this case, the shanks move along a special groove in the guide rail. The second function of the drive link is to distribute the lubricant from the drive sprocket (where the oil pump feeds it) throughout the tire and chain. It should be noted that the number of shanks plays the main role in the designation of the chain length for a saw bar of a given length, which facilitates the correct choice in accordance with the size.

Connecting links, corresponding to its name, combine cutting and leading parts into a single whole.

On some chains, links with cutting teeth alternate with links with shock absorbers. At the moment when the cutter hits the wood with the working edge, it stops for a fraction of a second, being sandwiched between the tree and the guide rail. If part of the cutting links is replaced by smooth shock absorbers with a beveled front edge, then the vibration will noticeably decrease. Such chains are less efficient, but more secure. They are also less prone to a “back strike."

In addition to the shape of the links, the chains also vary in pitch (link length) and shank thickness. Chain pitch is the distance between three consecutive rivets divided by two. This is a defining parameter, and depending on its value, all existing circuits are divided into five groups in increments of 1/4 ″, 0.325 ″, 3/8 ″, 0.404 ″ and 3/4 ″. A 1/4 ″ pitch (6.35 mm) is inherent in miniature chains mounted on low-power one-handed saws. True, they are practically not used. Chains with steps of 0.325 ″ (8.25 mm) and 3/8 ″ ”(9.3 mm) are the most common options. than 80% of saws produced worldwide are equipped with them. Steps 0.404 ″ (10.26 mm) and 3/4 ″ (19.05 mm) are distinguished by chains with larger links and increased performance. For several decades, they were equipped with domestic “Friendships” and “Urals”, but now they are installed only on powerful felling saws and harvester equipment.

The larger the pitch of the chain, the larger its component links and the higher its performance. But, on the other hand, the wider the cut, and to overcome resistance to cutting, a more powerful saw is required. Chains with small steps have other advantages. a larger number of teeth per unit length, a smooth movement in the cut and, accordingly, reduced vibration. Yes, and they get a cleaner cut.

The thickness of the leading link (shank) is the second most important parameter. During operation, the chain slides into the groove of the tire, and this slip should be smooth, without hooks and at the same time without unnecessary "bumpy". In a word, the thickness of the shank and the thickness of the groove must strictly correspond to each other, increasing the reliability of the chain landing and eliminating the likelihood of its "jump". There are five standard sizes: 1.1 mm (0.043 ″), 1.3 mm (0.050 ″), 1.5 mm (0.058 ″), 1.6 mm (0.063 ″) and 2.0 mm (0.080 ″). 1.1 mm. such thin drive links are characteristic of the smallest chains and saws of the corresponding size. 1.3 mm is perhaps the most demanded size inherent in household and semi-professional chains, in second place in demand is 1.5 mm, the value is typical for more powerful and productive saws. 1.6 and 2.0 mm. such thick shanks are found only on chains for highly professional saws.

Serves to guide the chain. Along the entire end there is a groove along which the shanks of the leading links — the groove — pass. A front sprocket is usually located in front of the tire. In some professional models, it is possible to replace it.

Different tires are optimal for different tasks: for felling and bucking of thick trees. long (0.5-1.0 m), for trimming branches. shorter (25-35 cm). However, a replaceable headset is for professionals, in “everyday life” it will fit “universal”, 35-45 cm long. The shape of the end part of the tire plays an important role. it is elliptical in many modern models, this reduces the likelihood of a back strike when meeting a “risk zone” (upper front tire sector) with an obstacle. On individual models of the household class, a special casing is installed that covers the hazardous sector. True, a thick tree cannot be cut with such a saw.

The chain and the tire need constant lubrication during operation. The supply of lubricant (engine or specialty oil) must be continuous, as the oil is squeezed out of the groove of the tire and immediately absorbed by sawdust. The faster the chain rotates, the more it should be lubricated. On the other hand, when the engine is idling and the chain is stationary, lubrication is not necessary. Therefore, chain saws (both gasoline and electric) are equipped with an automatic lubrication system. On some saws, usually professional or farmer class, its feed rate is adjustable. Note that for outdated cheap models there is a hand pump with a “drive” from a button on the handle.

Chainsaw chain brake. Those who happened to play DOOM probably remember that the chainsaw there is almost the worst weapon. In life, everything is about the same: a light touch by a moving chain is enough to cause serious injury. In this regard, the most dangerous back strike.

To protect the operator, a chain brake was invented: he must react and stop the saw before the tire reaches a person. The time of a complete stop of the circuit is determined by two factors. the moment of inclusion and the braking speed. There are two ways to enable: contact and inertial. The first one is when, with a quick “jump” of the saw, the hand rests on the shield, which is connected by a lever to the brake mechanism. In an inertial brake, the lever is displaced without contact with the hand, by inertia (the contact method in this case is still present. as a backup). It is clear that the inertial brake is better. it is faster and more sensitive and works even with improper grip. But it is structurally more complex, and a really reliable inertial brake is not so common. over, sometimes declared as an “inertial” mechanism, in fact, it works only as a “contact” one. Checking it is not so difficult, the corresponding technique is described below. The method is suitable for gasoline and electric cars.

Almost all chainsaws currently manufactured are equipped with single-cylinder, two-stroke carbureted air-cooled engines. Unlike the four-stroke engines used in automobiles, in which all cycles (exhaust stroke, filling the cylinder with a working medium and compression) are clearly separated and replaced when the piston is at the upper or lower point, some processes occur simultaneously in two-stroke ones. When the cylinder is compressed, the air-fuel mixture from the carburetor is sucked into the crankcase. When the piston is at the top, the spark ignites the mixture in the cylinder and the piston goes down. At this time, the mixture in the crankcase is compressed, at the end of the stroke the purge windows open where the exhaust gases (but not all, some) remain, then a new mixture is injected from the crankcase under pressure (part of the mixture flies into the purge windows ) It is clear that two-stroke engines for the most part are not very economical.

Since the fuel is constantly washing the crankcase, the oil has to be added directly to gasoline (in a ratio of 1:20 to 1:50 for different models of saws and different grades of oil). Therefore, it burns down along with gasoline, complicating the “bouquet” of exhaust gases. But you have to put up with all this for the main advantage. twice as much power with the same weight. Indeed, for four-stroke engines, the working stroke occurs once in two turns, and for two-stroke engines. on each. By the way, to reduce the weight of the engine on some chainsaws that are not designed for too long work, they put plastic crankcases (made of aluminum or a magnesium alloy heavier, but stronger and more reliable).

Some models have recently appeared engines, which are a hybrid of two- and four-stroke. In them, the cylinder is not blown by the mixture, but by air, there is an inlet valve. After purging, when the piston has already closed the outlet windows, a valve opens, through which the air-fuel mixture is injected under pressure. Such engines are much more economical and environmentally friendly than their predecessors and comparable in fuel consumption with four-stroke ones.

The air entering the engine must not contain dust, this is fraught with accelerated wear of the piston group. On a chainsaw, the air filter works in particularly difficult conditions. sawdust and strive to get into the air intake. A clogged filter allows much less air to pass through, which leads to a drop in speed and a decrease in power, as well as over-enrichment of the mixture and, consequently, increased fuel consumption and engine overheating. Therefore, the filter needs regular cleaning. It is convenient when its cover is fastened with hand-catching latches. in this case it is easy to reach it, a screwdriver or wrench is not needed. But only in Europe (in particular, in Sweden) such "delights" are forbidden, latches are permissible only on professional equipment.

To make the filter less likely to clog, various air pre-treatment mechanisms are used. either a mesh (additional coarse filter) or they direct the air intake channels so that the flow goes down first, then turns up, and the sawdust remains below at the bottom of the “pit”. But the centrifugal cleaning system gives the best effect when a rapidly rotating impeller (the starter flywheel blades) swirls the air flow, throwing large debris away from the "entrance".

Chainsaw starter. Usually this is a rope wound around a pulley with a handle. When you pull the rope, the dogs catch on the ratchet and untwist the flywheel.

The larger the engine capacity, the more difficult it is to overcome the resistance of compressible air by pulling the starter cable. If we take into account that at the first revolutions the fuel does not enter the cylinder, but is first sucked into the carburetor, then into the crankcase, then by the time the engine could start, there is no more power to twist the engine sharply. Therefore, many modern saws, including even low-power ones, are equipped with various mechanisms that facilitate starting. Here they are:

primer. fuel pre-pump, reduces the number of "empty" turns

decompression valve. connects the cylinder to the atmosphere, reducing the pressure in it and allowing the engine to spin up without much effort. After starting, the valve closes under the pressure of the exhaust gases.

spring starter. makes it possible to pull the cable slowly, since the engine does not spin, but only a special spring is cocked. At a certain point, she overpowers the compression in the cylinder and sharply cranks the crankshaft.

Some models have a different idea. The flywheel locks, the spring extends and locks in the cocked position. Now it is enough to press the button so that the engine spins up and starts up.

One of the most critical nodes. Manufacturers of saws prefer not to "fence" their own designs, using instead successful models of third-party companies (as a rule, they put either Japanese Walbro or Chinese Zama). The stability of the engine and its performance in general depends on how the carburetor prepares the air-fuel mixture. A properly adjusted and warmed up engine must start from one jerk of the starter. So that vibration does not interfere with the carburetor, it is sometimes placed on a vibration-isolating gasket. The air temperature is important (ideally, from 10 to 20 degrees Celsius). At low temperatures, gasoline does not evaporate well, so many models provide for the possibility of air intake from the cooling fins of the cylinder or exhaust pipe, where it is heated by the heat of a running engine. But in the summer, it is imperative to switch to the "cold" mode, with "overheating" the density of the fuel mixture will be low.

Chainsaws are equipped with an automatic clutch at low engine speeds (at idle) the chain does not move. With their increase, the clutch is turned on under the action of centrifugal force, and turns off when the gas is released. With increasing resistance of the material or jamming of the chain, it slips and prevents the motor from stalling and prevents breakdowns of mechanisms due to increased load.

The operation of the chainsaw is associated with significant vibrations, which, if exposed for a long time, are harmful to health. First of all, this is the so-called Raynaud’s syndrome: a violation of the blood supply to the fingers, leading to a loss of sensitivity, which in the cold season is fraught with frostbite. Joints also suffer. Therefore, vibration damping systems are not a luxury, but a necessity. To do this, the handles are connected to the engine with damping elements. steel springs or rubber gaskets. The latter are cheaper and easier, but short-lived in professional saws usually use springs, although there are also combined options. The “two masses” system gives the greatest effect when the handles are combined in one unit with a fuel tank. As a result, the “sprung” mass is larger and, therefore, less susceptible to shaking.

In order for the chainsaw to work well and last for a long time, at the end of the work, it must be prepared for storage. Drain the remaining oil (on some models, the grease slowly flows by gravity and with the engine stopped) and fuel from the tanks. The mixture remaining in the tank, carburetor and fuel hose must be burned. start the engine and wait until it dies.

It is advisable to store the chains in an oil bath, tires. wrapped in oiled paper, or at least treat them with aerosol grease, for example, the well-known WD-40 or its analogues.

It is not recommended to store the prepared fuel-oil mixture for more than a month. In any case, the mixture, even after lying just a couple of days, must be shaken well before pouring into the tank.

For the convenience of moving the chainsaw, we recommend purchasing special bags.