How To Remove The Line From The Trimmer

Installing new line on the trimmer reel

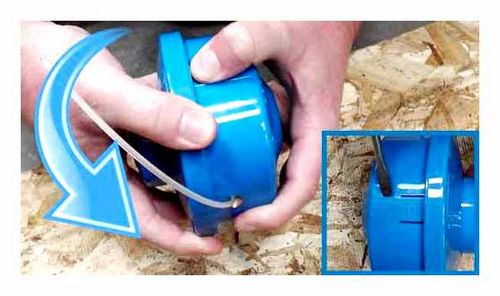

Equipping the reel with a new line is carried out in the reverse order. The procedure looks something like the following, regardless of the lawnmower model:

Removing the trimmer head cover

At the first stage of disassembly, the trimmer head cover is removed. On the example of Black and Decker trimmer models and others, to remove the cover, it is usually enough to apply some pressure in order to squeeze the locking latches, which are located on the side of the head body.

On some mower models, the trimmer head is initially dismantled using the Allen key supplied with the tool. The head is usually held in place by two to three screws, which are accessed through the side holes of the rear bezel.

The head cover, where the line spool is installed, is usually held by a latch-tongue. It is enough to squeeze the latch tab with some effort and turn the cover slightly, after which the cover can be easily removed

At the moment of pressing the locking tab, you need to slightly return and lift the trimmer head cover to remove the winding drum.

Step three: complete the head assembly

Pull the ends of the line through a pair of oval slotted spool. Replace both washers and the spring (if any in the structure) supplied with new elements. Bend both ends of the line at right angles.

The final technical touch of the process of replacing the line with a trimmer is the imposition of the cap on the head, followed by fixation by means of pushing force and slight twisting.

Pass each end into the hole in the base of the winding drum. Install the coil in the inner area of the head, resting on the spring. Place the lid on, align with the base and lightly push down with a small counterclockwise rotation, fit the lid on the tabs of the latches. This completes the replacement procedure.

How to replace the line with a trimmer?

Replacing the trimmer line Step-by-step instructions will allow even an inexperienced lawn mower owner to perform a rather difficult job.

However, before starting work on replacing the line with a trimmer, it is necessary to ensure the safety of the work. In particular, measures should be taken to prevent unintentional or unintentional starting of the lawnmower:

- Eliminate Spontaneous Startup,

- Remove battery (if applicable),

- Place the tool on a platform convenient for work.

It is convenient to work on replacing the trimmer line when the mower is lying on the table, and the foreman, who replaces the trimmer line, has the opportunity to approach the tool from either side.

Instruction: replacing the trimmer line

The above explains (using the example of the design of an electric and gasoline lawn mower) how to replace the line in the trimmer. The use of different types of cutting material for cutting grass is noted. The complete process of changing the cutting material in each section of the winding drum is clearly demonstrated.

Step one: securing and laying

Fold the end of the line in half. Place a blank over the spool on each side of each half of the winding zone. Draw both halves all the way around the winding drum. Pull the line through the loop.

The procedure for preparing the line engagement in the area of both winding sections of the drum. The loops are placed in specially made cutouts, after which the line is wound in each zone

Pull the line tight enough to fit the knot into the groove made on each side of the winding drum.

Step two: winding the cutting material along the section

The next step is to wrap the line around the reel, being careful. It is necessary that each half be filled with “own” winding, exactly, without Peresechen. Usually, arrows can be seen on the body of the winding reel indicating the direction of winding. This point should be borne in mind, Fill the spool with fishing line.

Step two: remove the winding drum (spool) with line

The next step in the process is the removal of the winding drum with line from the inside of the head. You need to return the head with the open side to see the line and spool. On the side of the head, find two recesses (eyes) through which the fishing line is brought out.

It is necessary to free the fishing line from the holes turned the drum. Then carefully remove the coil from the head area. Winding drum Some models are spring-mounted. This point must be taken into account when performing the extraction operation.

The procedure for removing the trimmer spool with line from the inside of the head: 1. head assembly with spool; 2. extraction carefully with small axial rotation; 3. extracted parts

The old line is completely removed from the reel. To remove the old trimmer line, you need to remove the forest from the locking loops and pull the free end. This method removes all the old winding. The same process is repeated on the second section of the drum. The master is recommended to use gloves when performing work.

Changing the trimmer line: Step-by-step instructions for replacing the line with a trimmer

Trimmers (they are also lawn mowers) are actively used by modern society to care for lawns and other similar objects of horticultural farms. The tool is noted for high efficiency, despite the questionable quality of cutting grass (in comparison with the usual peasant scythe. earth and sky). The main advantage of trimmers (lawn mowers) is high productivity with low expenditure of physical forces of the operator. However, over time, the trimmer’s cutting element (nylon scaffold) wears out or gets damaged, making the trimmer a useless tool as a result. Hence, the task becomes urgent. how to replace the trimmer head and how to replace the trimmer head line? Let’s consider this process using the example of lawn mowers manufactured by “Black and Decker” and others.

Line problems

Users of trimmers, both gasoline and electric, sometimes have problems with the cord. “Advanced” Owners of mowers easily cope with difficulties in automotive products, understanding why this happens, and for beginners, these are problems that have no rational explanation. But in fact, everything is solved quite simply. The most common problems that happen with the line are as follows.

The first way

To correctly determine how many meters of line is required for a particular reel, it is necessary to screw it onto the bobbin so that the skein does NOT exceed the diameter of the sides. If the line sticks out over the edges of the spool, you will NOT be able to insert it into the casing. After you have decided on the length of the material, it must be threaded into the bobbin, so do the following.

- It is necessary to fold the fishing line in half, so that one end of it is 10-15 cm longer from the second.

- Please note that the bobbin is divided into 2 parts by the central edge, from which charging begins. Find a groove on it and insert a cord into it, bent in half, put a little effort.

- It is very important to determine in which direction the line is wound onto the reel. If you look closely, you can find an arrow on the bobbin or an inscription with an arrow indicating in which direction the winding should be carried out. There are times when there is no arrow on the coil. In such a situation, you can look at the arrow drawn on the mowing head and wind the cord in the opposite direction.

- Winding should be done carefully, turn by turn, with maximum thread tension.

- After the laying of the cord is completed, you will first need to fix the short end of the fishing line, insert it into a groove of a suitable diameter on the side of the reel.

- The second end, the one that is longer, is attached in a groove on the opposite side of the bobbin.

- After fixing the fishing line, cut off its ends, leaving about 10 cm allowances.

- Next, you need to install the loaded bobbin into the mowing head. To do this, alternately insert and pull the thread into the outlet holes of the head, place the bobbin in the casing, then, applying the required force, Pull the fishing line out of the fixing grooves and tighten it.

- Now you can put on the cover and fix it with the latches.

Second way

Some reels have a second method of securing the cord: you can charge 2 pieces of yarn instead of one folded in half. The line is replaced according to the following algorithm.

- Before you change or load a new thread into the spool, determine how many meters it will take using the method described above.

- One end of the cord Fold into a hook.

- Find the hole at the bottom of the bobbin for fixing the line, and insert the end of the thread bent in a loop into it.

- It is required to wind the cord according to the direction of the arrow to the required level, and not exceeding the coil diameter.

- Do the same for the second bobbin compartment.

- The assembly of the head does not differ in any way from the method that was given when it was considered threading the bobbin with a piece of line folded in half.

For Shtil lawn mowers, there is a very simple and quick way to change the line without disassembling the mowing head, which you can get acquainted with by looking at this.

The ends of the cord protruding from the holes in the casing can be cut to the desired length when the part is installed in the trimmer. This can be done in two ways:

- Turned on the trimmer (when rotating, the ends of the line will be cut into a knife, fixed for THESE purposes on the protective casing)

- Cutting off the excess ends with scissors so that they DO NOT touch the casing body.

The second method is used if a large diameter cord had to be supplied, and the edging knife cannot shorten it.

If a charge was made to whine into the mowing head, but the length of the protruding ends of the cord is insufficient, then they must be lengthened before starting the machine. this applies to the head with manual adjustment. However, there are cases when using a semi-automatic mowing head, when, due to the insufficient length of the protruding ends of the cord, they do NOT automatically lengthen. In this case, it is necessary to turn off the unit (on electrical apparatus, it is imperative to unplug the plug from the socket), manually press the button located at the bottom of the part, and pull out a little line. After this procedure, the cord can again be extended due to centrifugal force, if you set the maximum spindle speed.

The thread does NOT hold

It happens that the thread is unwound if the spring in the semi-automatic head has weakened. The line is constantly extended and cut with a knife installed on the cover, which increases its consumption. To check this, remove the cover and turn on the unit. If the line “climbed”, spring replacement is required.

No cord feed, coil does NOT spin

An automatic or semi-automatic head should feed the line without stopping the machine. But if She does not come out, then the reasons may be as follows:

- The line in the reel is not wound correctly, because of which the latter does NOT spin;

- The cord is not wound evenly, and the thread can get stuck between the turns (the thread should be wound neatly, turn to turn, without distortion)

- Too short ends of the thread come out of the holes, as a result of which there is not enough centrifugal force to extract them, and the line is NOT fed (it is recommended to always adjust the length of the cord by pulling it slightly before starting the unit)

- The line is stuck together (will be discussed later).

High cord consumption

Basically, the cord runs out quickly if you hit the ground frequently with the semi-automatic head or press it down hard. The spool is unlocked, and the line, lengthening, is cut with a knife. Another reason that the cord runs out quickly is improper operation of the machine with an automatic head: the user often cuts the engine speed when mowing. But as we remember, the automatic head is designed in such a way that it is with each decrease in revolutions that a new portion of the line is supplied, so it is quickly consumed.

Cord breaks

If the line breaks frequently, this may be due to the following reasons:

- Stones, small branches and other solid obstacles come across in the grass;

- Users are mowing the grass right next to the fence, and if it is mesh, it cuts off even faster “antennae”;

- Poor cord quality (it is recommended to purchase a quality one)

- The outlet holes in the mowing head are worn out, which causes the line to be erased on the sharp edges of the bushings and break off (a complete replacement of the part will be required).

Option

In this embodiment, the head is screwed onto the gearbox shaft. To remove it, you need to fix this shaft. To do this, in such trimmers, for example, in the Huter and Champion devices, a hole is provided through which you can insert either a thin screwdriver or a metal rod.

So, to remove the bobbin, follow 2 easy steps.

- Insert a screwdriver into the hole and lock the shaft.

- Grasp the head body and start turning it clockwise. Torque in this direction follows because the thread cut on the shaft is left.

What can be used instead of fishing line

Many users of trimmers ask themselves the question: what can be used to replace the default cord used in this kind of machines? Begin unsafe experiments by installing metal or copper wires, metal ropes or strings, and ordinary fishing line in the mowing head.

If you install a metal cable instead of a fishing line, the trimmer turns into a dangerous device Not only for the user, but also for those around. This fact is explained by the fact that during the operation of the unit, the steel cable will gradually be triggered, its ends will unravel, and small pieces of wire will scatter in different directions at high speed.

And if you accidentally hook your or someone else’s leg while working with a steel cable (wire), then a strong and deep tissue incision, and in some cases amputation of your toes, is guaranteed. The manufacturer does NOT use nylon for THESE purposes in vain, since it is light and strong enough, and when it comes off it does not fly far away and cannot cause injury.

Of course, you can use fishing line in the trimmer instead of the standard one, but this will add extra trouble to you, since it wears out quickly, tears, mows slowly and is NOT suitable for cutting tough grass. In addition, when carrying out work, a lot of time is lost to replace the broken tool more than once.

In practice, the installation of a conventional line is justified if the user is going to mow the grass near the fence, especially if he is from the netting. In this case, in order to protect the standard, and sometimes expensive, line from wear and tear, it is changed to a fishing line, which is not a complaint. Usually, in order to change the line to the line, it must be selected The greatest thickness. 2-3 mm.

How to wind the line on the detachable reel trimmer with two tendrils

You can see before work. And also take into account the following recommendations.

- If there is only one track, both threads are wound parallel.

- If there are two tracks, each piece is wound in a separate groove.

- Wind the threads in the opposite direction to the rotation of the head.

- The length of the risers does not have to exceed fifteen centimeters.

- Thread the ends into the outlet holes.

- Assemble the head and check the trimmer performance.

By size

Before threading the thread onto the trimmer spool, pay attention to its size. Most often used fishing line with a cross section of 2 mm.

You can choose a suitable diameter in the following ways:

- See recommendations in the manufacturer’s instructions for trimmers.

- Manufacturers often apply cross-sectional information to the bobbin.

- The cross-section of the cord must match the diameter of the reel hole.

What are the trimmers and features of their use

The trimmer is useful for mowing small or difficult areas, such as near hedges, between beds and along paths. Today manufacturers produce a wide variety of gasoline, electric and battery models, which can be selected for any owner’s request.

A fishing line is used as a cutting element of the trimmer. In the process of work, sooner or later, its length will end, and then the owner will have a question of how to correctly replace and fix the thread tucked into a removable coil.

By quality

Before you put the line on the trimmer, you need to Pay attention to the section of the cord:

- Whining with a circular cross-section is the most common option. They cut the grass perfectly even in difficult areas;

- Spiral line is suitable for thin grass. It is not very durable and is NOT suitable for old thickets;

- A cord with notches and sharp edges is chosen for mowing weeds;

- A fishing line with a variety of geometric sections will help mow the lawn more evenly, but the strength of the consumables is low.

The owner of the lawn mower should know that it is absolutely forbidden to use metal wire, fishing thread and various strings.

Auto feed trimmer: how to wind the line into the removable spool

Some models of trimmers have a reel, the threading of which is automatic. It is enough for the owner to fix the ends in the head, after turning on the equipment, the mechanism will perform all the winding manipulations on its own.

How to wind the line correctly on the spool of the trimmer with one tendril

Most often, a thread up to five meters long is used. The procedure consists of the following steps:

- Bent the cord with a loop and insert into the groove of the head.

- Wind the thread in the direction opposite to the marks on the body. They indicate the direction of movement of the head.

- Leave the end of the thread up to fifteen centimeters long to increase the centrifugal force.

- Thread the free end through the spool outlet.

- Assemble the trimmer head.

How to quickly and easily remove the coil with your own hands

Before replacing the old line with a new one in the detachable trimmer spool, you must remove the head.

The process is completely simple, even beginners can do the job:

- Remove the upper fixing cover.

- Remove the removable spool.

- Get the spring out, if any.

- Screwdriver Unscrew the bolt.

- Remove the housing from the shaft.

How to properly wind the line around the trimmer: Step-by-step guide and instructions

A beautiful lawn will only look truly well-groomed if you regularly mow the grass. A trimmer is best for tackling difficult areas. Any owner of the unit will sooner or later face a solution to the problem of how to wind the line on a reel, because wrong actions can not only worsen the quality of the mowing, but also disable the equipment. Today in the Homius review we will tell you about all the methods and nuances of replacing the fishing line and the features of choosing consumables.

Things to consider when choosing a line

It is important to choose the right material before inserting and locking the line into the detachable trimmer spool.

Rating of the best petrol trimmer models. An overview of manufacturers and models, as well as useful tips from experts, considered in this review, will help in a difficult choice among many device models.

The line does NOT extend automatically

If the line is NOT lengthened by lightly hitting the trimmer button into the ground, the reasons for this may be the following.

Option 1. a bite has occurred, i.e. Clamping of the cord between turns. This problem usually appears if the user has been winding the line on the reel unevenly, with the intersection of turns, or winding it with insufficient tension. In the latter case, when the mowing head rotates at high speeds under the influence of centrifugal force, the cord begins to tighten, as a result of which inter-turn clamping of the fishing line is possible. To fix the problem, you will have to disassemble the coil into trimmers and rewind the cord correctly, that is, in even turns with good tension.

Option 2. too short ends protrude from the head. The fishing line may not come out when it hits the ground if its ends sticking out of the head are not long enough (short). In this case, the centrifugal force is not enough to stretch the line. Therefore, it is required to stop the unit (turn off the engine or disconnect the trimmer from the mains) and pull the line manually, after pressing the button.

Option 3. the line is soldered inside the mowing head. This causes the coil to lock and NOT spin when the button is pressed. Basically, this happens for several reasons: poor quality of the cord, overheating of the coil during prolonged operation of the unit, line hitting hard objects.

- In the first case, third-party cord can be made of low-quality and low-melting materials, which DO NOT withstand mechanical and temperature stress. Therefore, preference should be given “branded” line.

- But, if you nevertheless purchased a fishing line of unknown quality, and it is often soldered during operation, then you can follow the example of some users who, after filling the cord into the reel, moisten it with either silicone grease (from a can) or mineral oil. This procedure greatly reduces the likelihood of the coils of the fishing line being soldered together.

- Also, the line may become soldered if it strikes a hard object (stone, fence, dry branch, etc.) during mowing. As a result, it stretches slightly and is pulled back into the head at high speed. Here the friction of the cord heats up, and its turns stick together. The only thing that can be done to eliminate this malfunction is to open the trimmer spool and rewind the line.

How to remove the spool and replace the line

Trimmer owners, mostly beginners, find themselves in confusion, bordering on panic, when they need to change the cutting tool or line in the reel. Very often, when trying to unscrew the mowing head, users simply render it unusable, and not suspecting that it is unscrewed in the opposite direction. To prevent this from happening, if you need to change the tool, it is recommended to Read the Step-by-step instructions given below.

- Stop the mowers engine or power off the trimmer before threading the line into the spool to avoid personal injury that could result from accidentally starting the cutting tool.

- Unscrew the nozzle attached to the gearbox shaft. To do this, the shaft must be fixed by aligning the holes on the washer and on the axle, and inserted a metal rod or screwdriver into them.

- Unscrew the nozzle. You should know that the thread on the shaft is left-hand. Therefore, it turns the trimmer coil to the right, that is, clockwise.

- Let’s disassemble the mowing head. Most often, the head cover is attached to a latch. To remove it, you need to sink these clips into the case, squeeze the edges of the cover. If your trimmer has a Semi-automatic mowing head with a button on the bottom, then the disassembly of the nozzle should be done carefully, since you can lose the spring, which sometimes flies out when the cover is removed.

- Cut off the required amount of line. Usually its length is 5 meters. Use a cord of the same diameter as indicated in the instructions for the tool. It is not recommended to exceed the maximum line diameter as this will result in increased engine stress and higher gas mileage.

- Find the midpoint of the line by folding it in half. You will have a loop.

- Special grooves are cut inside the coil (there may be holes). Insert a loop of line into this groove.

- Wind the line around the spool by turning it counterclockwise. The cord should be tucked in as evenly as possible, the turns should lie down without overlap and with good tension. When the winding is finished, leave the free ends of the line about 20 cm long and fix them in the grooves on the sides of the reel.

- Assemble the mowing head. Be sure to insert the spring and washer (if applicable) before final assembly of the accessory. Place the spool in the body and thread the ends of the cord through the holes or eyelets.

- Put on the cover and lock it latches.

- Screw the adapter back onto the gearbox shaft, also securing it with a screwdriver. You will need to twist the trimmer coil to the left (against the arrows).

Major coil faults

Trimmer users and lawn mowers often face a problem with a semi-automatic mowing head. Coil malfunctions can be as follows:

- The line does NOT extend automatically;

- The cord spontaneously comes out of the reel.

DIY trimmer coil repair

A petrol or electric trimmer is the only true solution for mowing grass in hard-to-reach places that a wheeled lawnmower does NOT. Trimmers use metal knives or special fishing line as a cutting tool, which is tucked into the trimmer coil. But, unfortunately, the trimmer heads become unusable over time during operation. Some malfunctions can be eliminated by hand, and with some you will need a complete replacement of the mowing head.

Trimmer coil device

Trimmer mowing heads come in a variety of designs, both simple and complex. The picture below shows an exploded view of the Husqvarna (Husqvarna) Semi-Automatic Trimmer Head.

This type of head is present on most lawn mowers and trimmers such as Stihl (Stihl), Patriot (Patriot), Champion (Champion), Bosch (Bosch), Huter (Huter) and others. The device of the mowing head is quite simple. It includes the following details:

- Mowing head base;

- Button for semi-automatic cord feeding;

- Spool (spool) into which the line is tucked;

- Spring;

- Eyelets. through them the line comes out;

- Trimmer head cover;

- Line (cord).

There are also simpler trim heads, shown in the following photo.

All these equipment do not allow changing the length of the line in a semi-automatic mode (after pressing a button). If the cord breaks, you have to stop the mower and change it manually.

The cord lengthens spontaneously

There are times when the trimmer user notices a very fast line flow. However, he never hit the ground with a button to lengthen the line. The reason that the line spontaneously lengthens, cutting into a special knife on the casing of the device, may be the absence of a spring in the mowing head. Often novice users of mowers, trying to load the line into the reel, forget to install the pressure spring in the head, or completely lose it when opening the lid, and in the future, they do not even suspect of its existence.

Is it possible to make a trimmer coil with your own hands

- Take a piece of plywood or PCB and draw a circle about 14 cm in diameter on it.

- Cut the disc with a jigsaw or metal saw.

- Drill a hole in the center of the disc that matches the diameter of the gearbox shaft. Do not forget to put a washer on it before installing the disc on the shaft.

- Small corners can be screwed along the edges of the disc or 1-2 holes can be made on opposite sides. They will serve for filling the fishing line in them.

- To fix the line, you can screw several screws into the plywood.

This homemade mowing attachment is attached to the shaft with a nut. Tighten or unscrew the nut without fixing the shaft. To replace the cord, it will be enough to loosen the screws, insert a piece of fishing line of the required length and press it again.

Also, the mowing attachment for attaching the fishing line to it can be made of metal sheet. How to do this can be understood from the following.

How to install and remove the string trimmer head?

A few simple steps are required to install the nylon line trimmer impact head (for cutting grass).

- Unscrew the shaft stud locking nut (clockwise),

- Remove the cup and clamping plate held by the nut.

- Lock the shaft with the hex key (included).

- Thread (counterclockwise) the nylon line trimmer head onto the shaft pin.

- Remove blocking hex wrench.

The removed nut and clamping washer must be kept in a safe place, as these parts are not used if the impact head with line is installed on the Lawn (garden) trimmer. However, these parts are needed to fasten cutters intended for cutting bushes.

The sequence of installation. removal of the impact head with nylon line for cutting grass in household areas on a string trimmer

Accordingly, the removal of the working impact head of the trimmer with nylon line for lawn grass removal is performed in the reverse order.

The described operation of installing and removing the impact head of the trimmer with nylon line, in fact, requires consideration of another maintenance operation, due to which the line is replaced in the Lawn (garden) Mirrors.

Lawn Trimmer (Garden). Maintenance

Regardless of the type of drive of the automated scythe, the cutting part of such a device is usually represented by the common design of the trimmer head. In general, the equipment can contain the following units and blocks as part of the structure:

- Main unit (petrol or electric drive),

- Operator handle,

- Trimmer head,

- Head with nylon cutting line (diameter 2.5mm),

- Stock nylon line (usually 2.5. 3 meters),

- Steel cutter brushcutter 3 teeth and 8 teeth.

Additionally, a set for a lawn trimmer (garden), as a rule, includes working accessories. It also includes the necessary tools, as well as other components, the use of which requires operation and maintenance operations:

- Safety belt,

- Gloves,

- Protective face shield,

- Anti-noise headphones,

- Set of working tools,

- Spare spark plugs,

- Oil mixing container.

When using a string trimmer for lawn or other, the engine will need to be refueled periodically. In addition, in the process of doing household work. trimming grass and bushes, it may be necessary to change the working head of the hedge trimmer. Or replacing the line with a trimmer in the striking head.

Assembling the head for a trimmer for a brush cutter Lawn

Machines for treating lawns and other areas, along with impact heads, are supplied with hedgecutters, which are actually circular metal saws. Usually Brushcutters with 3, 8 or more cutting teeth are used.

To install a brush cutter for work, you will again need to remove the head of the scythe. Then the required tool with 3, 8 or more teeth is selected from the set. Brush cutter discs are usually protected by a plastic guard in the blade area. The cover must be removed, after which the brush cutter disk is installed in place.

The sequence of installation of the brush cutter: 1. installation of the saw on the axle; 2. leveling club; 3. circular cutter clamping cup; 4. lock nut; 5. clamping hex key

The installation does not require any special work. It is enough to put on the selected dust, an equalizing washer and an annular cup, and then screw and tighten the lock nut.

Tightening the nut requires securing the drive shaft (discussed above) and using a hex wrench (included), which is also used to replace the motor plug. Generally, the nut is tightened counterclockwise (on most models).

How to change nylon line for a trimmer?

To fill the impact head of the lawn trimmer with nylon line for cutting grass, the impact head must first be removed from the drive shaft and disassembled.

The disassembly process is simple. There are visible grooves on the head body, actually indicating the lugs. In THESE places of the lid body, create a slight pressure while pulling the lid.

The operation to disassemble the module case, where the nylon line is inserted, which acts as a cutting tool of the trimmer in the mode of cutting grass lawns

To insert new nylon line into the trimmer, you will need approximately 3 meters of material in each groove (6 meters in total) of the dedicated plastic spool. The coil is preliminarily removed from the spindle together with the spring and washer. Remains of previously loaded nylon line from the spool must be removed.

Next, take a previously purchased nylon line (diameter 2.5 mm), unwind 6 meters of product, cut off the measured piece. Fold the resulting trimmer line in half. The end of the nylon line forms a kind of loop at the half fold.

Lawn trimmer (garden): how to remove the head replace the line install the brush cutter

The tool for household purposes, which the Lawn (garden) trimmer is, is marked in practice by its active use. Technically, this type of machine is considered a very familiar device. Traditionally, trimmers Brush cutters and string mowers are based on a standard combustion engine system. True, electric models are increasingly appearing on the market. However, consider the first option in terms of maintenance.

Winding nylon line onto the spool of the head

In the next step of the operation, the coil of the lawn trimmer head should be wrapped around the palm of the left hand, holding it in the position shown in the picture below. With the other hand, a loop of nylon line is thrown over the protrusion of the central edge, dividing the winding area of the reel into two sectors.

Laying nylon line in the trimmer, more precisely in the sectors of the reel. Loop version of material stop before winding. Some lawn (garden) trimmers have other options for the stop (attachment)

Wind both halves of nylon line evenly and firmly counterclockwise (or in the direction of the arrow marked on the spool body). Stretching. it is necessary to wind the slings without twisting one slings on the other. Winding ends when the remaining ends of the nylon line are approximately 150 mm long.

Then insert the spool back into the spindle and thread the remaining 150mm ends of the nylon line into the spindle grooves specifically provided for THESE purposes. Next, the spindle part of the assembly is pressed against the palm of the left hand and on the opposite side of the coil, the washer and the spring previously removed are installed in place.

Assembly process. installation of the wound coil: 1. release of the remaining 150 mm ends of the nylon line into the special grooves of the spindle; 2. installation of previously removed elements on the coil

This completes the replacement of the fishing line in the trimmers, The assembled module is installed on the drive part, as discussed above in the text. Meanwhile, many models of lawn (garden) trimmers are also supplied with brush cutters, the use of which also requires installation procedures.

How to properly fuel the trimmer motor?

The automated garden scythe promises good durability when used correctly, including refueling. A gasoline engine of such a device is not allowed to operate on pure gasoline. Before refueling, you need to prepare a working mixture of fuel. namely, mix unleaded gasoline with engine oil.

The working fuel tank included in the kit, as a rule, has marks on the body for the correct mixture: 1. level of unleaded gasoline; 2. engine oil levels depending on the ratio

Mixing unleaded gasoline with engine oil is required in the correct ratio. Therefore, many manufacturers of string and other gasoline trimmers mark the working containers.

The user will only have to fill the mixing tank with fresh unleaded gasoline in accordance with the fuel marker line. Then machine oil is added until the fuel mixture reaches the 40: 1 ratio mark (optimal for two-stroke engines).