How to saw a chainsaw. Tilt

Technology of sawing logs on a chainsaw boards

The chainsaw is a technically complex and dangerous tool, for this reason, working with a saw, you need to comply with certain rules. Sowerant users are often related to working with a chainsaw with less attention and violate the rules, this leads to injury to the operator or a tool breakdown.

In this article, we will consider how to properly prepare a chainsaw for work, what are the rules and methods of rolling and sawing trees, we will talk about how to cut a chainsaw, separately dwell on safety precautions.

Chainsaw Mill Cutting Guide

Preparation for work

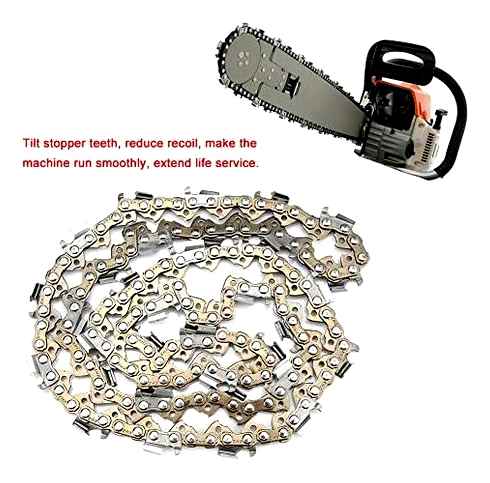

The first thing where work begins with a chainsaw is its assembly. The assembly scheme of various models is practically no different. A saw tire and circuit are installed on the saw, the chain is tending.

The chain can be considered properly stretched if it does not sag on the tire and easily scrolls through with his hands. If in order to crank the chain you have to make too much effort, then it is pulled and you should slightly loosen its tension.

Next, it is necessary to control the sharpening of the circuit, for this, the cutting edge of each working tooth is visually inspected. The edges should be even without dents and Zazubrin.

The next stage is the gas station refueling. The fuel mixture is prepared in a certain proportion, to find out which by reading the user’s guide supplied with a saw. Basically, the fuel mixture is diluted in a proportion of 1:50, that is, one liter of AI gasoline. 92 must add 20 grams of oil for two.stroke engines.

Important: When pouring fuel and oil for lubricating the chain into the tanks, you need to be extremely careful and not confuse. If you pour oil into a tank for the fuel mixture, then the chainsaw will not work. To restore performance, it will be necessary to rinse the fuel tank with gasoline, as well as clean the fuel highway and carburetor, which is quite difficult.

Circular saw. high performance and ease of work

Circular saw is the best option for performing work. It has excellent performance and allows you to cut a considerable number of blanks in a relatively short time, and with high quality. In addition, such a saw allows you to perform a longitudinal cut of the material, but you need to know how to cut the board along exactly.

One of the most important criteria when choosing a circular is the maximum cut depth. There are devices on the market that saw materials with a thickness of 30 to 130 mm. That is, you can choose a machine for cutting only thin boards, and for sawing bars.

It is also worth paying attention to the cutting tool itself. Disks with a large number of teeth will provide a neat high.quality cut, the speed of cutting will be low. But the wheels with a small number of teeth will provide high performance of work, but the quality of the cut will be worse.

Now about how to cut evenly a circular saw. One of the conditions of high.quality work is a reliable fixation of the workpiece. If the material is weak, then with the cut, the board can “go”, and the cut will be uneven.

If the circular saw is manual, then all the work should be done on a workbench equipped with stops and guides for blanks. Such a device can be made independently, taking as a basis any table.

Before the cutting, it is important to correctly establish the depth of the saw. Some hand saws have an adjustable side guide, with which you can perform a longitudinal sawing of the material. If there is no such device, then use the same workbench.

convenient in terms of work is a table circular, which is already equipped with everything necessary. guides, fixators. Often such equipment allows you to make a cut of workpieces at an angle.

In the process of sawing, it is important not to exceed the effort on the tool, otherwise the cut quality will be low, the increased load on the saw will lead to a rapid blunt of the cutting disk.

Do not forget about safety measures when using such equipment. Work should only be performed after checking the health of the saw and the correctness of fixing the workpiece. Also, do not neglect protective means. masks, glasses.

How the device for the dissolution of the thick board should look like

In order to simplify the dissolution of thick boards, it is necessary to assemble the simplest product from a laminated wood-bearing plate. To make the home master understand how it looks, let’s try to describe it. If you look at the end of the device, it will be similar to the English “h”, where the distance between the lower legs should be equal to the width of the limit of the circular saw. It is on it that the device will be fixed.

The length of this device can be different, but it is best if it is equal to the mill of the circular saw. Well, on the step.by.step manufacture of this device, we will not stop. It is too simple to spend the time of a respected reader on this time.

The device is attached to the limit of the circular saw

Tools for rolling trees

In order to blame the tree in a certain direction, professional rollers and not only use special tools. The most common of them are gross forks, wedges and shoulder blades. Special hydraulic or mechanical jacks can also be used.

Wedges can be made of wood directly at the site of the roll or purchased in specialized stores. Clines made of polymeric materials, the size of which is chosen depending on the diameter of the cutting wood, are widely used.

In order to have an idea of gross jacks, we recommend watching a video in which it is shown how with the help of this device the lumberjab cuts down and puts the pine tree in the direction it needs.

Grinding blades work on the principle of wedge, only have a lever, thanks to which the operator can increase the effort and help the tree fall in the right direction. The principle of operation of the gross spatula or it is also called the lever can be found out by watching the video below.

The position of the roller

In order not to get an injury when drilling a tree, a foller must always choose the right position. The location is considered correct, in which the foller can get away from the danger at any time. For this reason, before bringing down the trees, the operator must clean all the small shoots, for which you can stumble and fall. During the roll, the saw must be held with both hands and be in the area of the opposite from the one where it is planned to dump the tree.

It is allowed to be in the zone of falling wood only in order to cut out the wedge, which is done first.

Features of sawing

It is not difficult to cut the firewood of a chainsaw, especially if the goats are used, there is an assistant. Before touching the log by the chain, the engine must be dispersed as much as possible. If the space allows, then it is better to cut a tire section that is close to the engine as close as possible. Pressure should be controlled by the load load. In the process of work, place the chainsaw so that it is on the side, not ahead.

The cutting of the barrel lying on the ground is made in two approaches: they perform cuts half the thickness of the tree, turning it 180 degrees, and completely cut.

Puncture of the branches is made by the extreme section of the tire, especially this applies to branches on the fallen trees. This will exclude the likelihood of a cutting tool in the ground.

As for the roll of wood, here the scheme is this: from the side in which the barrel will fall, we make a quarter of thickness. over, it is done at an angle of 45 degrees. Then we go on the other side and just above the available cut, we produce the second. the main (for the entire thickness). The cutting process needs to be controlled in order to notice the fall of the tree in time, time to pull the saw from the cut and move aside.

Chainsaw Chain Repair

Use of the wedge

How to cut trees of a chainsaw, we have already examined, but there is another option for a roll. using a wedge. It is used only for cutting healthy, straight trees, the angle of inclination of the trunk of which is no more than one degree.

Do not use the wedge if the crown of the tree is uneven and it is impossible to calculate how much the mass of branches are larger on one of the sides. However, all these rules can be neglected, if the tree is small, has no more than three meters in height and no more than 20 cm in thickness.

To secure the saw, his assistant ties a rope to the barrel and holds it in a stretched state. If necessary, he must be ready to pull for it to direct the movement of the barrel in the right direction.

The first file should be made in the barrel from the side opposite to the direction of the alleged fall. The wedge is inserted into the backlings and drove it a little with an ax. On the other side of the barrel, they make a second. In this case, you should create an effort using a tied rope. it should be sufficient to include the barrel to the angle required for the fall.

Cut the tree of a chainsaw so that it falls in the right direction, another special tool will help. a gross blade. At the same time, the wedge itself, inserted into the cut, will play the role of insurance. The shoulder blade is located in the second cut located on the side of the fall. To adjust the trajectory of the barrel, it must be used as a lever, turning and rejecting it in different directions.

Valka with tuning

If the question arises of how to cut a large tree near a private house with a small territory, it is worth considering the option of tacking with tuning. This means that the sawn tree must be pre.mounted to a high support so that it does not fall after the cut, but hung on a rope. This method will allow you to carefully cut down the tree and not damage the objects surrounding it.

It is worth noting that the tuning of the same trunk (below the sawing place) is extremely undesirable, because the cut off a piece of wood after the saw will swing strongly to the sides. The cut fragment thus can inflict a tree for a tree or damage the property located nearby.

Work procedure during the roll of wood

The execution of the cuts occurs in several stages. The first (upper) cut is made on a quarter of the diameter of the barrel, at an angle of 45 °, you need to approach the tree from the fall. Then a cut is made from below. It is made horizontally to the level where both cuts will connect. After performing two filings, you should get an angle carved in the barrel, size 45 °. Do not cut the tree completely, otherwise it will not be possible to guess in which direction its trunk will fall.

Now the gross drinking is used. Before starting work, make sure that there are no people, pets and objects in the fall area that can be damaged. The gross cut is made on the side that is opposite to the alleged direction of the fall of the barrel, it should be located five centimeters from the lower file, parallel to it.

Performing the gross cut, leave the non.drink. 1/10 of the total diameter of the tree trunk. This is important, as it provides the right trajectory of its fall. If you do not do this cut, or make less than the specified size, the trajectory of the fall of the tree will become unpredictable.

Subure the saw in the barrel slowly. So that the tire does not jam in the barrel, insert the wedge into the main cut before the tree begins to fall. The wedge should be made of plastic or wood, a metal wedge can damage the chain. Engine revolutions during the operation of the saw. maximum.

Working, watch carefully where the trunk is moving. So you can take measures in a timely manner if you feel that the fall has gone in that direction.

The arrows indicate the cuts: 1- upper, 2 —Nizhny, 3- gross. The unfinished part of the tree is a hinge that prevents the fall in an undesirable direction

I drunk two options: in the first case, it was completed by a double right angle, it is more difficult to make it, but the tree is guaranteed to fall in the direction that you planned, in the second case, the most commonly encountered version of the file described above is performed

When the barrel starts to fall, quickly remove the saw from the cut, turn off the engine and leave the operation area. Perform all actions quickly, delay can be dangerous.

Advice. The tree is more convenient to cut in the direction of curvature, the greatest development of branches and branches, if the trunk is flattened. towards a smaller diameter.

That’s all, we examined how to properly bring down the trees with a chainsaw. subject to the above rules, you can blame the right tree without much effort. And most importantly here is to be attentive and concentrated. Before the first roll, you can practice on a small dry tree, if you have it on the site, or look for this in a nearby landing.

Ways to cut logs

Before cutting the workpiece, it is important to reflect on how to achieve a high.quality finished product with a minimum waste. The tree is unequal in quality, the lower region of the rod gives a more expensive timber.

When sawing from a log, you can get such varieties of timber:

- Broke. raw materials, the dimensions of which are more than ten centimeters. The most popular look is a four.dancing beam, in a section of a square. It is used as building materials in the manufacture of furniture headset;

- Board. raw materials, up to ten centimeters thick and width, which exceeds the thickness by 2 times. Boards are made from logs or bars and used in the construction and production of furniture.

Owning the theory of basics and practice, it is possible to make boards and bars yourself.

Advantages of sawing logs of a chainsaw

File and ax, like woodworking inventory, are now gradually gone the past, losing with a sufficiently powerful benzo- and electric pills.

A manual chain saw functions thanks to a two.stroke motor on gasoline, the main component is a sharpened chain.

- Excellent efficiency that greatly simplifies human labor;

- Mobility, it can easily be rearranged in other locations, put in a car, it does not work on an electric network;

- Can be used with an increased level of moisture and even during precipitation;

- The possibility of involving a variety of nozzles for the performance of many tasks;

- Ease of operation;

- Acceptable cost in comparison with special woodworking machines.

Therefore, not only experts with many years of experience prefer this product, but the owners of summer cottages are happy to operate a chainsaw to solve daily problems in the garden and construction.

Handmade technology

The choice of tool for removing plantings depends on the dimensions of the plant. If you need to remove a small tree or shrub, then it is safer to use an ax or a two.handed saw.

If the barrel has serious sizes without a motorized saw can not do.

- With the help of an ax, a slanting guide is performed on the side where the fall of the tree is supposed. It is necessary to set the desired trajectory and ensure the safety of workers. Its depth should be at least a quarter of the barrel.

- With the help of a saw, a horizontal cut is made from the same side until the connection with the brown and the formation of the wedge.

- The grinding cut is made on the opposite side. It should be placed in parallel to the first cut and above it by 5. 10 cm. It is forbidden to cut a tree completely! This can make the trajectory of falling unpredictable. You should leave at least 10 cm of the whole core of the barrel, which will allow you to control the angle.

- It is better to carry out a group of workers from two to three people using ropes. If in this way it does not work to tie the barrel, it is allowed to push it with your hands. You can resort to the lever method using a long stick that allows you to push the tree at a height of three to four meters above the gross cut.

Final work

After the end of the roll, the plant must be treated and taken to a separate place specially designed for this. To dispose of it entirely cannot. You need to saw off the branches, and cut the log into separate parts.

It is better to perform these works using a chainsaw. this will be faster and more efficient. Branches should be cut down from the bottom of the barrel in the direction upward.

- It is also necessary to divide the barrel into segments using a certain technology that will prevent the pinch of saws in wood.

- The essence of the technique is to saw the logs and the use of the wedge in the resulting cut, which relieves the tension between fragments of the tree.

- This will protect from the jamming of the tool between parts of the log and allow it to work without effort.

Why crookedly cuts off?

The disk saws that fishing line for the trimmer to which it is directed. In this case, the tool should be kept or pressed to the guide tight enough so that it does not go aside.

If, despite all the efforts, the drink turns out to be crooked, the reason is in a worthless disk. A plowed disk with bilateral blue spots may start wagging with the slightest heating. If the teeth on the one hand are normal, and on the other, they are knocked out or blunt, the saw can be taken in one direction, no matter how they try to hold it.

How to choose a quarter in the board with a circular?

For this, the desired depth of cut is set. To select a quarter with a size of 20×20, the disk should leave the platform by 20-22 mm (the increase in the irregularities of the board). To select a versatile quarter, for example, 15x 20, depth adjustment is set twice for each size, 15-16 mm and 20-22 mm.

In the future, the operation is performed in the same way as sawing a trimming board: at the right distance, a guide bar is installed on two rods, a cut is performed on a wide plane. Then the board is placed on the edge and the second cut is done.

Since the edge is narrow, difficulties may arise. on some models the guide bar may not be close to the platform. In this case, a beam is attached to the board (or bar) with clamps or self.tapping screws, which increases the width to the desired size.

If it is not possible to make a cut along the edge with the help of the guide, it can be done on a pencil marking. It is difficult to hold the circular on the edge of a narrow board (20-30 mm). In such cases, it is sometimes more convenient to either fasten a support beam, or place a blank between two bars (boards), along which the saw platform will move.