How to saw a hole for the sink in the countertop

How to perform such work independently

For example, consider installing the sink in a countertop made of particle board. Type of installation. above the table surface. The entire work process can be broken down into the following steps:

The work should begin with the preparation of the necessary tools. Make sure that the sink comes with all the necessary fasteners. From the tools you will need:

- construction pencil;

- level, angle and tape measure;

- Drill and drill for woodwork;

- electric screwdriver;

- The jigsaw is electric;

- silicone and self-tapping screws.

You can begin the work. Make sure that you do not interfere with foreign objects. It is desirable that the countertop is not fixed to the bollard frame. If the table is already assembled, that’s okay. Carefully mark out the hole. Let’s look at how to do it under a rectangular sink:

- With a construction pencil we draw two mowing lines, perpendicular to each other. At the place of their intersection will be the drainage hole.

- Turn the sink over, place it on the countertop and outline its contour. Do not forget to take into account the level of the edge of the sink relative to the table doors.

- We measure the width of the sink rim and draw the inner contour. The cutting will be done along this scythe line.

- Once again double-check all the parameters and then start cutting.

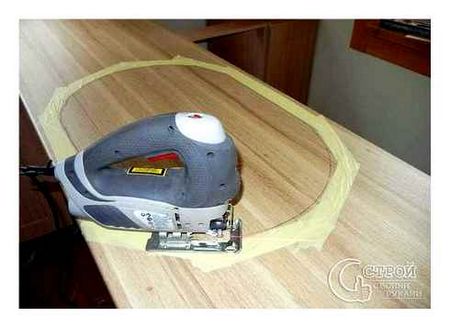

Use an electric jigsaw to cut the holes. To insert the saw, you should drill technological holes in the table top. Usually they are made with a drill in the corners of the contour. All drilling work is done on the front side of the countertop. This will give you the opportunity to work without any kind of chipping of the laminated areas of the table. Now you can take a jigsaw and cut a hole along the inner contour. After that you should preliminarily try on your sink to the obtained hole.

Pay attention! If there is a small backlash. you have cut correctly. If there is no backlash. trim the edges of the hole with a jigsaw.

Now the edges of the hole must be deburred. This is to ensure that the rough edges do not interfere with the execution of quality sealing joints. This work is done with sandpaper of fine grit. Seal after cleaning. There are two ways to do this:

The first method is good, but it should be done with great care, so as not to miss areas of the countertop. It is best if you do not spare the sealant and apply it with a decent reserve. The second way is more difficult. PVA glue must dry almost an hour. But it protects against moisture penetration.

Cut out We use the inner diameter of the template Trying on the sink Assembling the sink Insert the connections Apply sealant Install the mixer Filler can be used instead of sealant

Throw the template out of the package, let amateurs use it. Now you will learn how to mark the countertop specialists in their business. You have a few important things to consider:

Then we turn our basin and lay it on the countertop, taking into account the above-mentioned details. Be sure to invite the hostess, show her the limits of maneuvering and ask her to make the final choice.

Otherwise, if she will not like the location of the sink, you will have to buy a new countertop. When all the wishes of the female half are taken into account, tracing with a pencil or a thin marker, depending on the color of the countertop, the dimensions of the sink.

Within walking distance of you, a cabinet furniture calculation service is placed.

Cutting Sink Hole in Laminate Countertop | How to Cut Countertops with a Jigsaw

Inserting the sink

We need to get the jigsaw into this circle, to do this we choose from our arsenal a drill bit with the largest diameter possible. And make a hole, stepping inside the circle from the line, at least 16mm.Read on and you will understand why.

It is necessary to lead the line of marking not along the jigsaw blade, but along the inner edge of the jigsaw sole. The distance from the jigsaw to the edge of the inner sole of the jigsaw is equal to the distance from the edge of the sink to the sink lock. Т. е. This is the necessary rim on which the sink is held.

By the way, to not let the edge of the table top fall on your feet, you need to screw black self-tapping screws of any length into the kerf. At least three diagonal points. And then you won’t need a third hand and your feet will be in one piece.

Protection from moisture

Having previously checked the cutout for unobstructed entry of the sink and degreased with acetone. we apply silicone. Protecting your finger with a glove, carefully rub the silicone into the end face, not sparing it at the same time.Along the edge of a cut we make a silicone ring to prevent the penetration of moisture.

Within walking distance of you, there is a service for calculating cabinet furniture.

Choosing a place

Before sawing the countertop, you need to determine exactly where the sink will be installed. It should not protrude beyond the inner fishing line of the box, otherwise you will have to cut the sides. Position the structure so that you have easy access to it, while leaving room for accessories, detergents, and other things. Popular layout options:

Depending on the design features, the instructions on how to cut the sink in the countertop may differ in the number of procedures and their sequence. Nevertheless, in general, the algorithm of actions is approximately the same.

How to perform such work yourself

For example, consider the installation of the sink in the countertop, made of particle board. The type of installation. above the surface of the table. The entire work process can be broken down into the following steps:

Work should begin with the preparation of the necessary tools. Make sure that the sink comes with all the necessary fasteners. Of the tools you will need:

- A construction pencil;

- level, angle and tape measure;

- Drill and drill bit for wood work;

- Electric screwdriver;

- Jigsaw electric;

- silicone and self-tapping screws.

You can begin to work. Make sure that you are not disturbed by foreign objects. It is desirable that the tabletop was not fixed to the table frame. If the table is already assembled. no problem, you can saw the hole out anyway. Mark the contour carefully. Consider how this is done for a rectangular sink:

- Using a construction pencil, draw two scythe lines perpendicular to each other. At the place of their intersection there will be a drainage hole.

- Turn the sink over, put it on the table top and mark its contour. Do not forget to consider the level of the edge of the sink relative to the table doors.

- We measure the width of the sink rim and draw the inner contour. The cutting will be done with this scythe line.

- Check all the parameters once more, and then start cutting.

The hole must be cut out with an electric jigsaw. To insert the saw, you should drill technological holes in the countertop. Usually you drill them on the corners of the contour. All drilling work is performed on the front side of the countertop. This will allow you to do the job without any kind of chipping of the laminated areas of the table. Now you can take a jigsaw and cut a hole on the inner contour. After that you should preliminarily try on your sink to the obtained hole.

Now it is necessary to deburr the edges of the hole. This is to ensure that the rough edges do not interfere with quality sealing of the joints. This work is done with fine grit sandpaper. After scraping, seal sealing. Two methods can be used for this:

The first method is good, but it should be done with great care so as not to miss areas of the countertop. It is best if you won’t feel sorry for the sealant and apply it with a good reserve. The second way is more difficult. PVA glue must dry for almost an hour. But it protects from moisture penetration.

Use the inner diameter of the template

You can use filler instead of sealant

Several ways of insetting

Let’s consider in more detail how to cut the countertop under the sink. The main task to be solved correctly when installing the sink is to observe the geometry of the mounting hole in the countertop. At the initial stage, we should decide which method of installation we will use.

Pay attention! The main thing is to consider the design features of the sink.

The upper edges of the sink are below the surface of the countertop. Externally, this method looks strict and quite attractive, it is used for expensive sets. When performing it, certain requirements should be observed:

- it is necessary to have special tools, sink of certain shapes;

- trimmed edges of the countertop should necessarily be treated with a water-repellent composition.

Inserting the sink at the same level as the countertop. It is important to properly perform the preliminary preparation of the surface:

- The areas that will be in contact with the sink are prepared with special tools, making an indentation equal to the thickness of the sides of your sink,

- This work is rather complicated, the hole for the sink must be made with great care.

The sink is installed slightly above the countertop level. The method is the easiest and does not require much effort. You can install the sink in this way yourself, having a minimum set of tools.

Installation of recessed sinks

If the option of overhead sink is not suitable for you, this is quite normal. Yes, it is easier to install them, but from the position of tightness and appearance, their mortise counterparts are significantly superior.

Fundamentally complex action during mortise need not be carried out. The most important step is considered to be the cutting out of the holes.

Installation is performed according to the following instructions:

- The optimal place for installation is determined on the worktop;

- Marking is made according to the sink shape;

- To mark it, you should turn the sink over and outline it;

- For sinks with complicated shapes the manufacturer provides a template for a cutout;

- At least 7 cm from the edge of the tabletop you cut a hole with the jigsaw;

- From the scythe line marking should be indented about 18 mm to leave room under the support for the sides;

- the hole is machined;

- Apply a layer of sealant around the perimeter;

- The sink is pressed with the help of clamps, which are usually included in the kit;

- remnants of sealant are removed;

- connections are made.

READ Which side to saw the countertop with the jigsaw

Here everything looks a little bit more complicated. In addition to the jigsaw, you will need an electric drill to make the starting hole under the saw of the jigsaw.

How to install a round sink into a countertop, the correct cutout for a sink.How to cut the sink into the worktop

If you have a sufficiently thin countertop. Make sure that it can support the weight of the sink under the load of water and dishes.

How to install a sink yourself

Everybody can install a sink by himself. It is very easy to do, if you prepare in advance and study the instructions. Installation begins with the preparation of the plan and marking. Then comes the work of cutting out the main hole and the installation of the structure. During the work, it is important to observe safety precautions, since the work will be carried out with sharp tools.

How to install the sink in the countertop: a simple algorithm

In this article, we will look at one very serious operation, which greatly affects the quality of the kitchen set.

We’ll talk about cutting in the sink. We will look at the whole process from beginning to end with all its nuances.

Before inserting the sink, you need to determine in which part of the countertop it should be located.

To do this, the countertop must be placed on the bottom modules of the kitchen, and the box in which the sink should be placed, from the inside, outline with a pencil (on the countertop) to determine the internal space for it.

After that, the countertop must be placed with the bottom up, and mark the place for cutting a hole. This is done as follows:

First, the location of the sink itself is determined (it must not go beyond the inner border of the box, otherwise, for its embedding, you will need to cut not only the countertop, but also the sides of the box

- Then, with a tape measure is necessary to measure the distance from edge to an ear, in which fasteners are fastened

-

After that, in case the sink is round, find the center of the drawn circle. It is found as follows: on a circle, in any place, put a point to which the straight piece or ruler is attached. To this line it is necessary to attach another detail (or angle piece) with a right angle. A fishing line is drawn near the center. Then the second point is taken and the same is done. The intersection point of the two lines will be the center of the drawn circle (yes, sometimes the knowledge of geometry can be very useful)

-

Through the center of the circle is carried out mowing line (type, diameters). They are needed in order to measure the distance measured by us from the edge of the sink to its lug for fasteners.

- Having made 8-10 such “notches” through them, with the help of the same sink we spend curves (in parts) which form inside the circle drawn by us one more circle with radius less than radius of the basic circle on distance from edge of a sink to its ear. This will be the circle that needs to be cut out with a jigsaw.

- Insert the jigsaw file into this drill, and cut the hole. Don’t forget, when the hole is almost cut, to support the cut part of the countertop, as it may break off, breaking the plastic off the front.

When the hole is done, its inner part should be covered with silicone, as this place is the most problematic place in the kitchen. It should be as much as possible protected from a moisture hit inside a countertop as in this case, the countertop can simply “break” from moisture. and it is full replacement.

So, after the hole is filled with silicone, we begin to prepare the sink for the mortise.

To do this, you need to stick on its inner surface adhesive tape, which always comes with the kit (plus fasteners and plus, plastic tubes for drainage).

Pay attention before you buy the sink: Sticky tape (which should be glued inside), should not be glued to it. It should come with. Almost all of the sinks in which the adhesive tape was pre-applied, it was adhered incorrectly.

And correctly it should be glued so that there is a small distance between it and the edge of the sink (it turns out as a groove), where the silicone is poured.

It turns out at the same time, two barriers: the adhesive tape and silicone.

So, when all this is done, and the silicone poured, the sink is inserted into the hole cut out in the countertop (from bottom to top). If the countertop is placed, for example, on two chairs, one of them, you can immediately put under the sink, thus fixing it.

I would like to point out that this is one of the most frustrating things about installing a kitchen set.

The fasteners by which it is attached to the tabletop are usually bad (meaning poorly designed). There are almost always problems with it (for this, you should always have a spare of this fastener for installation).

There are situations when it simply does not fix the countertop, and slides down to the sink (which is what happened on the installation, photos from which are posted in this article as an example).

No matter how we bent the tendrils of the fastener itself, it stubbornly slipped off the tabletop (and, of course, did not fix it).

The easiest way out of this situation is as shown in the pictures: you need to insert a piece of particle board or something else between the sink and the fastener itself. Thus, the fastener is fixed, and, twisting, pulling the sink.

But, we mustn’t forget one detail: exercise with installation, if possible not very long, because the silicone, which was poured inside the sink, when it pressed against the countertop, partly “came out”. It should not have time to cure, because in this case, when removing it, you can remove some of the silicone under the sink.

When it is tightened to the countertop, you need to make sure that there are no gaps between it and the countertop. If you have them, it means that it is tightened badly.

At the end of the embedding, you need to wipe the silicone that came out from under the sink and the sink itself.

Preparation and dimensioning

To make a correct cut under the sink, it is necessary to carry out preparatory work, although the process itself is not particularly difficult. You need to prepare all the tools you might need.

Among them can be a hacksaw, an electric jigsaw, a drill, a small saw, a tape measure, a pencil or a marker.

After all the tools are ready, you can start work immediately. In order to properly cut through the countertop, you must first mark the place for the sink.

This can be done in several ways:

- Using a special template, thanks to which all the dimensions are transferred to the countertop. These products quite often come with the sink as a set.

- Self-made template will allow you to perform embedding without the factory markings. To do this, you need to turn the sink and put it on a piece of cardboard, and then trace the contour. Now cut the workpiece so that each side is around 3 cm smaller than the required size.

- It is possible not to use a template, but simply to turn the sink over and place it on the place of installation. Now you need to trace the product and saw the tabletop according to the measurements. Only in this case, too, you must indent a few centimeters inside the contour.

After making the marks, you can now begin the drilling out of the hole. In order for it to turn out flat, you need to be as accurate and careful as possible.

Regarding the material of the worktop, the cutting tool must be chosen according to the workpiece material. Of course, it’s best to use an electric jigsaw for this. With it, you can get the job done quickly and without too much work.

How to cut a hole for the sink in the countertop yourself

The furniture industry offers a wide range of products to choose from, including kitchen sets. Their variety is impressive and you can choose any one, based on preferences and financial capabilities. But in most cases, the sink is sold separately and installed by the purchaser himself. Therefore, it is necessary to know certain rules and tricks for carrying out such a procedure, as well as have a certain set of tools.