How to saw the rafters at the right angle

The main connecting knots

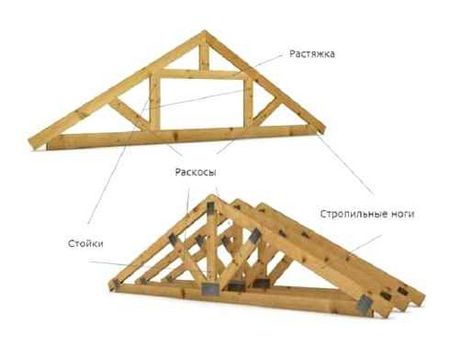

The main components of the rafter system are: the rafter truss. the connection of the rafter pair, stretching, as well as racks and struts; ridge node. the combination of two opposite rafters; a link of mauerlat and rafters supported by it; module, which includes purlin, strut and joist; connection rafter with pushpull and strut.

How to Measure and Cut Rafters

The most complex part of the roof frame is a truss, which is different in that it is collected on the ground, and then ferried to the roof, as the only way to successfully fit one piece of wood under another. Truss consists of at least three elements in addition to the main elements. the two opposite rafters and spar, includes additional fragments. struts and braces, reducing the pressure of the structure on the walls and is created using different types of nailing almost without the use of metal fasteners.

The ridge node also has several features. it is formed by joining two opposite rafters through special cuts or notches. To create a ridge knot there are many methods and it is fixed by means of metal battens, bolts or nails.

The rafters and the mauerlattice are joined by making a notch in each rafter which corresponds to the shape of the element that supports it. The rafters are fixed to the mauerlat, so that they do not shift sideways, and strengthening the connection between the rafters and the mauerlat is achieved by attaching metal corners, construction staples, nails or bolts.

Module of the purlin, rails and purlin form, hammering into places of their connections construction staples, steel dowels or overlays of strips of steel.Unit of beam, stud and purlin allows to divide the load between external and internal walls of the building. Sub-frameworks, rafters and rafters are assembled into one module by creating notches. To ensure their connection is not weak, construction staples are used.

Elements of the rafter frame

The rafter system consists of a large number of elements, whose main tasks to give the roof shape and the required slope, to evenly distribute the load from it on the bearing walls, to prevent foundation defects. The main elements of the construction are rafters. These are beams fixed at a certain angle in pairs. They are fixed to the maueralt on one side and form the ridge on the other.

Hanging elements

They have only one point of support: the mauerolat. Therefore, the hanging rafters are forced to take additional load. on the stretching. To strengthen such a structure, horizontal, compensating elements are added to it. transoms (contractions), pincers. The first can be several, at different heights. Hanging rafters are installed on buildings with small spans. up to 6 m.

Flattened, with support elements

Such rafters have two fixation points at the same time. They are attached to the ridge purlin and to the mauerlattice. These rafter systems can be used if the building has one or more load-bearing walls, which can hold the ridge (rafters). These supports are an opportunity to significantly reduce the load on the rafters.

Sagging systems are used for buildings of impressive area, with large spans (10-12 m). Their upper edges rest on the ridge beam, while the latter rest on either the load-bearing wall or the columns. In single-pitch structures, this role is assumed by the higher wall of the building.

Mauerlat

In most rafter systems, the legs are attached to the mauerlatum, which is fixed along the perimeter of the walls of the building. It is a necessity for buildings with walls made of concrete, bricks and other man-made blocks. Only few types of buildings can manage without mauerlat. These include:

- Houses where the walls are constructed of logs or timber. No additional fastening is required, because wood and wood are a perfect union.

- Buildings built with frame technology. Here, the support beams. the upper stringer. take on the role of the maueroute.

For walls built from any other material, this part of the roof system. an element of a must. They often become a solid bar (100h150 mm, 150h150 mm, 200h200 mm) in houses from the logs. logs. Primary tasks Mauerlata. softening pressure on the wall, the elimination of loads on the points of attachment, the even distribution of weight of the roof pie. Fix this element with anchor bolts, or metal studs embedded in the construction phase of the walls. Between the mauerlat and the walls of the house must lay a waterproofing layer that protects it from contact with other materials.

Designing the rafter system. a difficult stage, because it is necessary to correctly calculate the wind and snow load, as well as determine the type of material for the roof, the angle of slope, take into account the weight of all elements that make up the roof structure. Any error in the calculations may cause the construction of poor quality, unreliable rafter system. The worst possible consequence. the destruction of the roof.

Assembling a simple hip rafter system

The easiest way to build a hip roof is to buy a ready-made rafter system and its installation. But the construction of a hip rafter system with their own hands will give more pleasure and allow you to create a structure that matches the entire structure. To make sure of your own strength, you can practice on small buildings, for example, to erect a four-pitch roof over a gazebo or a summer kitchen.

The creation of a simple hip roof proceeds in several stages.

Creating a roof model and drafting.

The construction of any design stage is preceded by design. This helps to determine the shape of the structure and purchase the right amount of material. A simple hip roof does not require a complex drawing, it is enough to draw by hand an approximate diagram of the rafters of a hip roof.

To make the simplest design of a hip roof is enough to follow the steps described in the following instructions:

- The parameters of the building are determined, according to which the approximate drawing of the roof in profile and in full view is made. To drawings conformed to real parameters, you need to choose a scale, most often choose 1:25. This means that the actual size should be divided by 25.

- Choose the optimal height of the roof helps drawing the contour of the roof, and in several ways. At the most suitable figure measure the angle of inclination of slopes.

- Next, mark the installation points of the trusses in the figure, and each side should be divided into equal sections. The pitch of the rafters of a hip roof must be optimal so as not to increase the consumption of building material, but also not to strengthen the construction with additional counter-battens.

- The next step is to determine the length of the ridge. It should be remembered that this part of the structure should connect the whole number of trusses. Remove the same lengths from both sides of the long side.

- Based on the drawing, calculate the required amount of material.

The number of fasteners is determined by the number of rafters, taking into account all the node fasteners. For each rafter you need to buy two corners. Boards are best to buy with a small margin, so that there was an opportunity to eliminate accidental errors in construction. If the design is erected on a concrete or brick box, then you should take care of the purchase of timber, which will be built from the mauerlat for a hip roof.

Mounting the main part.

For the convenience of work, experienced builders recommend making auxiliary scaffolding.

Installation of the hip rafter system begins with the arrangement of the ridge:

- Immediately in the middle of the walls, which will adjoin the walls, nailed one board each. Between them pull a construction cord, which should run strictly along the central axis.

- At one end of the structure two rafters are attached, their intersection should pass under the cord. Mark a timber cut for the upper heel of the rafters, taking into consideration the ridge purlin of about 5 cm in thickness. Sawed down the necessary part of the element, so that the envelope roof has the desired shape.

- The remaining rafters are sawn according to the made blank. Remember that when erecting a hip roof with hanging rafters the length of the eaves is taken into account.

- Assemble the trusses of the two rafters and fasten them to one nail.

- Install a ridge beam through all the trusses and nail the rafters to it.

- At the bottom, the cantilevered rafters are attached to the mauerolat, and the hanging rafters of the hip roof. To the floor joists. In both cases, fastening is performed using metal angles.

- Previously nailed auxiliary boards can be removed, as there is no longer a need for them.

Construction of hip rafters.

The rafters of the hip section are fixed in a similar way to the straight rafters: the top is nailed, the bottom is screwed on. to the mower shaft or top timber by means of angle brackets.

- Position the first diagonal rafter and mark the place of the cut. The lower part of the element has to be placed in the corner of the roof.

- Sawing off the element to the planned mowing line and fixing it: the top. using nails, bottom. angles.

- The remaining diagonal rafters are installed in a similar manner.

- To fill the gable of a hip roof the flashings are measured and installed individually.

- After that proceed to the installation of main slopes.

After installing all the elements of the rafter system perform the following: with the wire twist every second rafter is tied to the log of the second row or to the wooden plugs, which were previously laid in the walls. In addition, a wire twist can be embedded in masonry or between the blocks in the construction of walls. It should be remembered that from the top to the location of the curling should be at least three rows of bricks or two rows of blocks.

The finished rafter system is closed by purlins. If the coating will be soft, the crate must be a solid board, plywood or OSB. Rigid roofing materials can be stacked on a crate of bars, nailed at a certain pitch.

Fixing the rafters to the maueralt: consider the knots

The reliability of the roof directly depends on how well it will be assembled all of its supporting system. And its main elements are the rafters. The whole system consists of rafters that support and spread additional elements, such as push-pull props, pry bars, side purlins, support struts and stretchers. The rafters are connected on the ridge beam above, and their lower edges are very often based on the mauerlat, attached to the lateral load-bearing walls of the building.

As the mauerlat is subjected to the heaviest load it is made of a strong bar. Its cross-section is determined by the massiveness of the entire rafter system, but in general the size ranges from 150 × 150 to 200 × 200 mm. This load-bearing element is designed for even distribution of load from the entire roof structure and roofing on the load-bearing walls of the building. Mounting the rafters to the mauerlatu carried out in various ways. They are chosen locally depending on the type of rafter system (which may be a layered or hanging), its complexity and massiveness, the magnitude of the total load, which will be subjected to the entire roof structure.

Varieties of rafter connections mauerlat

First of all there are sliding and rigid rafters to the maueroute.

Sliding fasteners consist of two separate elements, one of which has the ability to move relative to the other.

These fasteners can be different in design closed and removable.

- Closed fastening consists of an angle, which is attached by one side to the mauerolat, and on the other side has a special slotted eye. It is fitted with a metal hinge with holes for attaching to the rafter. Due to the free, not fixed vertical side of the angle, the fastener allows the rafter to move if necessary, without deforming the walls of the building.

- Open attachment is carried out on the same principle, the only difference is that the metal hinge is not inserted into the eyelet, and simply the upper part of the vertical flange of the angle is bent down after installation, thereby fixing the connection.

This can include metal corners of different sizes, LK fasteners, which will securely fix the rafter, which is installed with a bar, without damaging it with fasteners screws or nails.

- LK fasteners are produced in several dimensional variants, so they can be selected for any thickness of a beam or plank. The thickness of metal, from which these fasteners are made, is 2 mm, whatever the size of. Depending on the size, fasteners have different designations.

| LK-1L | 40 × 170 |

| LK-2P | 40 × 170 |

| LK-3L | 40 × 210 |

| LK-4P | 40 × 210 |

| LK-5L | 40 × 250 |

| LK-6P | 40 × 250 |

It should be noted that these mounts are not only suitable for fixing the rafters on the mauerlat, they are also used to fix the nodes “floor beams. mauerlat”.

The main advantage of this fastener is the maximum rigidity and reliability of the connection of wooden elements.

There are bends designed for fastening of rafters without fillets. They have higher flanges and more self-tapping screws. they are made of metal with thickness of 2; 2,5 or 3 mm.

Fixing of rafters to the maueralt with angles

| Reinforced Corner | 105 × 105 × 90 × 2 | Reinforced corner KP5 | 140 × 140 × 65 × 2,5 |

| Reinforced Corner | 130 × 130 × 100 × 2 | Reinforced angle KP6 | 105 × 172 × 90 × 3,0 |

| Reinforced corner | 105 × 105 × 90 × 2 | Reinforced corner KP7 | 145 × 145 × 90 × 2,5 |

| Reinforcing corner | 50 × 50 × 35 × 2 | Reinforced corner KP8 | 145 × 70 × 90 × 2,5 |

| Reinforced Corner | 70 × 70 × 55 × 2 | Reinforcing corner KPL1 | 90 × 90 × 65 × 2 |

| Reinforced corner | 90 × 90 × 40 × 2 | Reinforced corner KPL11 | 90 × 90 × 65 × 2 |

| Reinforced corner KP1 | 90 × 90 × 65 × 2,5 | Reinforced angle KPL2 | 105 × 105 × 90 × 2 |

| Reinforcement corner KP11 | 90 × 90 × 65 × 2,5 | Reinforced corner KPL21 | 105 × 105 × 90 × 2 |

| Reinforcing corner KP2 | 105 × 105 × 90 × 2,5 | Reinforced corner KPL3 | 90 × 50 × 55 × 2 |

| Reinforced corner KP21 | 105 × 105 × 90 × 2,5 | Reinforcement bracket KPL4 | 70 × 70 × 55 × 2 |

| Reinforcement corner KP3 | 90 × 50 × 55 × 2,5 | Reinforced corner KPL5 | 50 × 50 × 35 × 2 |

| Reinforcing corner KP4 | 70 × 70 × 55 × 2,5 | Reinforcing corner KPL6 | 60 × 60 × 45 × 2 |

Some of the bends mentioned in the table need to be mentioned in more detail as their description requires further specification:

КР 11 and КР21 are reinforced angles, often marked as К Р1 and КР2. These elements have an oval-shaped hole for anchoring, which reduces the risk of bolt collapse in case of shrinkage.

KP5 and KP6 are angles used for fastening elements that bear a heavy load. Corner to К Р6 also has an oval hole, and it is recommended for use in creating a rafter system on a new house, which will still give the shrinkage. These models are in demand when installing structures that have a large weight.

Corner to K M is made of peorized steel and is used to secure the rafters with a large cross section. Particularly suitable for wooden constructions. This corner fixes the elements of the structure very securely. and when using it it is not required to cut the rafters into the mauerolat is enough at the first saw a right angle.

KMRP angle is used for fastening details of rafters at right angles, including rafters with mauerolats. It also differs from the usual corners of his elongated hole, through which it is possible to shift during shrinkage without damaging the fixing bolt. It can be used in designs where you can not make a mortise one element to another.

KMRP angle brackets are made of 2 mm thick steel. Three different versions are available:

| a | b | c | |

| KMRP1 | 60 | 60 | 60 |

| KMRP2 | 80 | 80 | 80 |

| KMRP3 | 100 | 100 | 100 |

- Another option of attaching the rafters to the maueralt is to install them between two boards sawn at a certain angle and additionally in the lower part fixed by means of LK metal brackets or fixings.

This angle gives the rafters good stiffness and reliability. This method is well suited in cases where the rafters need to be fixed at the right angle, raising them above the horizontal plane of the mauerlattice, but fixing them to the vertical outer side.

- Method of attaching the rafters to the maueralt, made from a beam not too large cross-section. This is accomplished by reinforcing the bar with wooden underlays of the required thickness.

Board strips are attached to the maueralt with nails or self-tapping screws in the places where the rafters will be installed.

In this case, the rafters are made notches in the desired configuration and depth. The rafters are securely attached to the wall with a steel wire attached to the hammered-in steel crutch.

- In addition to the above methods of fixing, the rafters are nailed to the mauerlatum with staples. It should be noted that this method is quite common and has been used for a very long time. With proper fixing of these elements, the rafter system will last for many years.

The staples may be of different sizes, are hammered into the different places of the connection.

- Another anchoring element that is used as an auxiliary is a perforated tape TM. It is used to strengthen the fastening node if additional fixation is necessary.

In some cases, this element can be indispensable, so it also can not be excluded when installing the rafters on the mauerlat.

Further it is advisable to consider the structure of rafter systems. so it will be easier to understand which mounts are more suitable for them and why.

Features of rafter systems

The rafter system is selected according to the position of the loadbearing walls of the building. Each system has its own additional supporting or tightening elements.

Flattened rafters

System with sagging rafters is different in that it has one or more reference points, except for load-bearing walls. In this regard, the side walls take much of the load off.

Sagging rafters supported by a solid partition

Side posts and “headers”, which support the ridge and are fixed to the floor joists, are used as additional supporting elements. And the rafters themselves, in turn, simultaneously serve as pincers for the structure, and also relieve the load from the rafter system on the load-bearing walls.

Strung rafters are attached to the maueralt most often sliding connections that can shift during shrinkage or deformation of the walls, leaving the roof structure unharmed. This is especially important to consider in new buildings, since any recently completed building is bound to shrink under the influence of temperature fluctuations and ground movements.

Hanging rafters

Hanging rafters are called in connection with the fact that they have no other support than the two lateral load-bearing walls. It turns out that they kind of overhang the interior space of the building. In this case, the entire load of the roof frame structure falls on the mauerlat.

For fixing the hanging rafters to the mauerlattice uses rigid mounts with no degree of freedom of movement, as the framework has only two points of support.

Hanging rafters are struts, so they exert great pressure on the walls.

Hanging system with additional elements

To remove some of the load from the walls of the building additional elements such as push-pull props, “headstock” and pinched-rigel, which pull the system to the ridge beam and distribute the load on all walls evenly. Beams are installed parallel to the floor joists and tighten the rafters together. Without these additional details the construction may become unreliable.

Calculation of rafter installation

In order to make the rafter system reliable and durable, apart from the optimal way of connection it is necessary to choose the correct spacing of rafters. This parameter is selected according to the rafters dimensions (their cross-section and the length between the rests) and the roof structure.

In this table you can get information about the necessary parameters for the installation of a reliable truss system.

| 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | 6000 | |

| 600 | 40×150 | 40×175 | 50×150 | 50×150 | 50×175 | 50×200 | 50×200 |

| 900 | 50×150 | 50×175 | 50×200 | 75×175 | 75×175 | 75×200 | 75×200 |

| 1100 | 75×125 | 75×150 | 75×175 | 75×175 | 75×200 | 75×200 | 100×200 |

| 1400 | 75×150 | 75×175 | 75×200 | 75×200 | 75×200 | 100×200 | 100×200 |

| 1750 | 100×150 | 75×200 | 75×200 | 100×200 | 100×200 | 100×250 | 100×250 |

| 2150 | 100×150 | 100×175 | 100×200 | 100×200 | 100×250 | 100×250 | – |

A few rules for attaching rafters to the mauerlattice

To make the fasteners secure. It is necessary to follow a number of rules that are provided for this process:

- If metal fasteners are used for attachment, they must be fixed to the wooden connecting elements with the utmost care. quality self-tapping screws of the right length.

- If the rafters will be laid in the notches in the mauerault, the dimensions must be precisely aligned. This will ensure a tight, secure installation of the rafters in the prepared hinge, which should have a depth of ⅓ of the maueroute. However, it should be remembered that this rule will only be true if the mauerlat is made of a strong bar that has a cross-sectional dimension of at least 150 × 150 mm.

- In order not to weaken the mauerlat, most often hacks are performed in the rafters itself at the correct angle, and then additional node fixed corners. Saw cut in this case should not exceed ¼ of the thickness of the rafters. This attachment is rigid and can be applied in the hanging rafter system.

- When using bolts to fasten rafters to soffits, battens and other wooden elements, be sure to install a washer or metal plate on the bolt, to avoid flooding the nut into the wood and, therefore, weakening the structure.

- Mounting the rafters to the mauerlat only on the nails or screws is considered unreliable. so be sure to use corners or other metal fasteners of various configurations.

- When installing the rafters on the wooden walls, whether it is hanging or lean-to system, it is recommended to attach them to the mauerlatu sliding fasteners, especially if the roofing material has a fairly large weight.

Video: a few examples of fastening the rafters to the maueralt

The roof structure will be strong and will serve for a long time, without deforming under various external influences, if the calculations of all elements to produce correctly. Competently choose and properly install all fasteners.

General recommendations

The strength of the roof depends not only on how properly made notches. Consider the following tips:

- For the rafters, pick high-quality materials, because even if you make accurate cuts, the bar can not withstand the load. You can not save here, because it takes all the loads.

- Places of attachment with the maueralt should be free of wood defects, such as knots. Although they are stronger than wood, but around the curls are formed, which at the slightest load breaks.

- Do not hesitate to ask for help when setting up the roof, as it is a dangerous and responsible job.

Correctly executed node adjacency rafters and mauerlat guarantees a long service life of the construction.

What other elements are needed?

A double pitch roof is considered an uncomplicated construction, but to erect everything correctly, you should know all its components. The frame, in addition to the rafters themselves, includes other elements, namely:

- Mauerlat. This element of the system is located on the upper perimeter of the walls. It serves to evenly distribute the load from the gable roof. This is where the rafters rest. For the mauerlatte a timber with a cross-section of 15 by 15 centimeters is used.

- Purlin. This is the beam that supports the upper ends of the rafter pairs. As with the mauerlate, a wooden joist is used here.

- Hooking. an element used in hanging systems. Tie-in connects the lower ends of the rafters.

- The purlin is an optional extra. This is a wooden beam that serves as a base for the strut rests.

- Struts. They are used in the collapsed rafter system. Uprights support the ridge gutter.

Other elements can also be used. For example, to strengthen the entire structure are used struts, transoms, and so on. The mower rafters are also used, which are an extension of the rafters that make up the overhang of a gable roof.

Using rigid mounts

When installing the rafters on the joist by rigid mounting method, it is important to adhere to certain requirements and exclude bending, twisting, turning and shifting between the elements.

- secured with an angle with a filed bar for support;

- Making a notch in the rafters and fixing this connection with nails and staples.

Using the angle, with filing support bars the rafters are arranged on the mauerlat. The element itself must have a rigid load-bearing bracing by means of filing timber about 1 m long. It is also fixed on the sides with a metal corner to avoid shifting.

The second method is the most applicable at installation. In this version nailing is done from the side, at an angle, they are crossed inside the mauerlate, vertically the third nail must be driven. This results in a rather rigid node for the fasteners.

In both variants the connections are secured with another fixing of elements with the wall using wires or anchors.

If the slope of the roof is the same, the rafters are prepared using a template, that is, of the same size.

Marking and installation of the rafters

In the top view the square of the hip diagonally is cut by the diagonal rafter. In our example, the length of the diagonal calculated by the Pythagoras theorem is 1.414×2337 = 3305 mm.

The length of the hypotenuse of the rafter triangle under the truss is calculated from column 7 to 16.97 of the table of slopes. For a triangle with a base of 3.305 m, it would be 3305×1.082 = 3576 mm (3.576 m).

The height of the rafter triangle under the trimmer should be equal to the height of the triangles formed by the central walm and boundary walm rafters 3305×0,412 = 1362 mm.

Cross-sections of the bottom rafters

In attic roofs only the top of bottom rafters are levelled for purlins. In attics the inner part of the roof is lined, so the bottom of the rafters is also aligned with the bottom of the rafters.

Bevel rafter height

In this example, the rafters are made by mating two boards 50×300 mm with beveled bottom to the bottom plane of the rafters of the slope and hip.

Measure the length of the top vertical section of the rafter (289 mm). Use a 7×16.97 template to mark out the top trim line on the board of the butted rafter. Set aside a section of 289 mm on this mowing line. From the end of the piece, construct and measure perpendicular to the edge of the board (267 mm). This dimension aligns the height of the beveled rafter with the rowed rafters.

The same result is obtained mathematically. by multiplying the length of the vertical cut by the cosine of the angle of the bevel rafter 289×cos22,42° = 267 mm.

Support bevels

Set the circular saw to a reference angle rounded to 21° and cut the bevel along the top of the board. Measure the rafter height from the bottom edge of the resulting bevel to 267 mm, transfer it to the reverse side of the board. Strike a line along the board and cut a second bevel at a 21° angle parallel to the first. Create a diamond-shaped piece with opposite-parallel planes 267 mm high.

The top bevel of the rafters

The marking of the top slice of each half of the coupled rafter is made plywood template 7 to 16,97.

Mark the line of the vertical cut. This side will be on the inside when mating the boards into a rafter. Set the circular saw to a 45° angle and cut the board along the mowing line. Do the same with the second board. Pairing the boards here will result in a double-sided bevel that fits snugly into the corner of the hip.

The cutout (bird’s beak)

From the bottom of the vertical bevel cut, measure and mark 3.576 m. Using the template 7 to 16.97 from this point cross out the horizontal fishing line. Measure on it the thickness of the trim wall 150 mm plus a gap of 5-10 mm on the unevenness of the wall. Use the template to trace a vertical line. Mark the support cutout. Cut the board along the horizontal mowing line by setting the saw to 0°. Set the saw to 45° and make a vertical beveled cut by finishing sawing with the hand saw.

Assembling and installing the rafter

Nail down the two halves of the rafter and fit it. If everything is done correctly the top of the rafters will fit snugly into the corner of the hip convergence and the “beak” will match the corner of the outer walls.

Types of rafters and their application

The choice of rafter system. a responsible step that requires knowledge of the design of each type of roof. The rafters can be:

- Saddle rafters supported by ridge purlin and mauerolat. They are used in the construction of a single gable, simple gable roof, as well as one of the elements of the hipped and broken dormer roof.

- Sliding rafters are a type of strutted rafters used in wooden buildings with high shrinkage. They are distinguished by sliding fastening of the rafters to the maueralt, which allows to compensate for shrinkage of the walls without deforming the roof.

- Hanging rafters are a system of rafters connected by ledgers or purlins, typically used in the construction of a simple gable roof, as well as the upper rafters of the mansard roof. In the suspension rafter system ridge runner is absent, and in the upper part of the symmetrical rafters rest directly on each other.

- Tapered rafters, otherwise known as angle rafters or diagonal rafters. Used for a three- or four-pitch roof, as well as for roofs with complex geometry.