How to set the ignition on a chainsaw

Factory Ignition System Design Features

The ignition system for a domestic or professional chainsaw initially consists of:

- magneto, or factory ignition coil;

- candles with a pre-installed cap;

- electrical high-voltage wiring, pre-connecting the spark plug to the coil;

- keys that instantly turn off the running power unit of the chainsaw.

In the device of a household gasoline tool, magneto is a kind of generator responsible for the continuous generation of alternating current with the subsequent transfer of energy to the built-in candle. The design of the magneto initially consists directly of a standard stationary winding of an inductive coil, as well as a permanently operating magnet pre-installed on the built-in flywheel.

Magneto, provided in the standard built-in ignition device for household and professional gasoline saws, are divided by equipment manufacturers into:

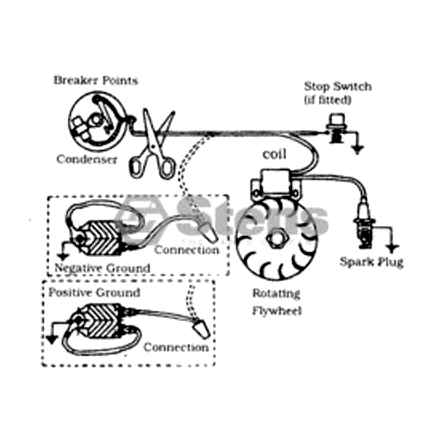

- contact. in the design of these nodes, the first output of the built-in factory high-voltage winding is connected to the spark plugs. In the basic design of the contact magneto, a capacitor is initially provided, which prevents overheating and gradual oxidation of the contacts of the standard breaker;

- non-contact. the principle of operation of units of this type is based on the operation of the built-in control coil of the factory, which, at the same time, plays the role of an element that regulates the supply of voltage. During the regular opening of the thyristor, the standard capacitor begins to actively discharge. As a result, a sufficiently high current is continuously generated in the turns of the high-voltage factory primary winding, which is inducted into the high-voltage voltage. It leads to instantaneous breakdown at the built-in spark plug located in the cylinder of the power unit. The electrical network of the non-contact magneto operates stably in the mode of continuously generated short-term pulses generated in time with each forward movement of the factory cylinder and the corresponding rotation of the engine crankshaft.

Manufacturers of chain garden equipment use different types of factory magneto in the configuration of chainsaws. The main difference between them lies only in the principle of action. At the same time, contact and non-contact magneto have approximately the same working efficiency.

How to determine the advance angle of the built-in ignition?

The design of the built-in ignition coil ensures coincidence between the factory optimal position of the moving piston and spark plug discharge. During the operation of 4-stroke power units, the spark must jump before the piston returns to the uppermost position. This is due to the fact that such engines take longer to burn fuel. In their factory device, the speed of operation of the internal combustion engine parts is equal to the speed of the planned ignition of the filled fuel. In this regard, the piston manages to pass a certain path from the moment of instantaneous breakthrough of the created spark to the place where the candle is located. until the period for which the burning gases are guaranteed to have time to create extremely high pressure indicators.

During the mass assembly of engines under standard factory conditions, manufacturers do not perform ignition adjustments. Instead, markings are left on the rotating elements that must be aligned during installation.

Chainsaw ignition

In order for a gasoline saw to start running stably at idle, the fuel located in the factory cylinder of its power unit must ignite. For this, a standard ignition system is provided in the basic configuration of any branded chain tool. The ability of the internal combustion engine to make the first cold start and steadily gain momentum when the operator presses the gas trigger largely depends on its serviceability. The ignition of a household saw is distinguished by a simple device and a constant operating principle. Having studied their features, it will be easier for the operator to carry out maintenance and self-repair of the unit.

How to check the ignition coil of a chainsaw?

There are several effective ways to check a factory ignition coil. The first one is visual. To do this, the operator must carefully remove the magneto from the saw structure, having previously disconnected all contacts connected to it. After that, you need to inspect the item.

Most often, its malfunctions consist in:

- damage to standard insulation, initially caused by gradual or sudden overheating, increased vibration, as well as voltage surges in the created electrical network. All this leads to a short circuit in the factory windings of the coil;

- violation of the integrity of standard high-voltage wires. this results in overload and breakage of electrical wires.

In any of these cases, you will need to immediately replace the electronic ignition of the gasoline chain saw.

The second way to check the coil is to test it with a multimeter.

- Connect the device to the positive and parallel negative factory contacts, having previously configured it in the mode of constant measurement of the generated resistance;

- After ringing the built-in coil, you need to look at the device. In household chainsaws from different manufacturers, the resistance values may differ from each other. Typically, the average is around 0.4–2 ohms. If zero resistance is displayed on the multimeter used, then an accidental short circuit has occurred in its standard winding. In few cases, the device can show infinity. then the operator will need to find an open circuit.

In each of these cases, the repair of the factory ignition coil is carried out only through a complete replacement of the part.

Each of the methods allows you to obtain information about the health and stability of the factory ignition system of a gasoline saw. In some models of garden power tools, manufacturers provide for the possibility of replacing only the defective coil. In other cases, the owners of chainsaws are required to replace the entire ignition system.

How to set the ignition on a chainsaw?

As in the case of the constant need for self-adjustment of the carburetor, a chainsaw used in a private economy or on a forest shaft must be amenable to timely adjustment of the built-in standard ignition. The essence of this procedure is to install the gap originally provided between the flywheel of the power unit and the standard ignition coil. The size of this gap may initially be different. it all depends on the purpose, as well as the design features of the saw. The average distance is considered to be not less than 0.2 and not more than 0.4 mm. In the event of a violation of the correct gap, the base ignition system will not be able to generate the spark required for timely instantaneous ignition of the filled fuel mixture in time.

In order to initially correctly adjust the appropriate clearance between the flywheel and the ignition coil on the chainsaw, its owner will need a special plate template. However, buying it for a one-time use is not always profitable. In some cases, the template can be replaced with a homemade one. To make it, the operator will need a plastic smooth bottle, from the side of which a thin strip must be cut. At the same time, there should be no embossing on a homemade template.

The operator can adjust the ignition on the chainsaw directly in the following order:

- First, you need to slightly loosen the plastic bolts designed to fix the standard ignition element;

- Further, the magnets provided on the flywheel will need to be brought to the factory coil;

- Then, a homemade or previously purchased template must be installed between the base high-voltage coil and the built-in engine flywheel. After that, the coil fixing bolts will need to be tightened in the opposite direction;

- Next, the operator must carefully remove the template.

- At the end, you will need to scroll the built-in flywheel. At the same time, you need to make sure that when rotating, the element does not touch the coil and other parts of the chainsaw.

How to set the ignition on a chainsaw?

Adjusting the gap between the flywheel and the ignition coil on the chainsaw is required when the tool does not start. Immediately before adjustment, you need to check the condition of the spark plug. To do this, you need to remove the wires from the head and carefully unscrew the part from the socket with a special key. If the candle is not wet, and small light spots of oil are visible on its ceramic walls, then you need to proceed to the next stage of the check.

To do this, you need to put a cap with standard wiring on the candle and pull the starter rope sharply several times. If, at the same time, the spark did not appear, then you should proceed to adjusting the gap between the flywheel and the magneto.

An infringement of the clearance between these parts of the chainsaw may cause careless handling of the tool. In standard form, the distance between the magneto and the flywheel should be no more than 0.2 mm. It is quite easy to check this value. To do this, you will need to place a special gasket between the elements. If it freely enters the space between the elements, then the gap is set correctly.

Many craftsmen claim that it is possible to correctly adjust the ignition on a chainsaw only using a template. However, not every tool owner can afford to purchase a disposable product at a fairly high price. Many gardeners use homemade stripe templates cut from a flat plastic juice container.

Further adjustment of the ignition of the chainsaw is performed in the following order:

- First you need to loosen the system fixing bolts;

- After that, a template should be inserted between the standard ignition coil and the built-in flywheel;

- At the end, the fixing adjustment bolts will need to be tightened.

The design and principle of operation of the ignition system for a household chainsaw

Every saw that runs on a gasoline engine must be equipped with an ignition system. The main function of this unit is to timely ignite the fuel inside the cylinder. To do this, the ignition system of the chainsaw creates an electrical discharge that breaks through the space between the electrodes of the standard spark plugs. The correctness and efficiency of its engine operation largely depends on the serviceability of this unit of the chainsaw. In this regard, special attention should be paid to checking this important part of the tool.

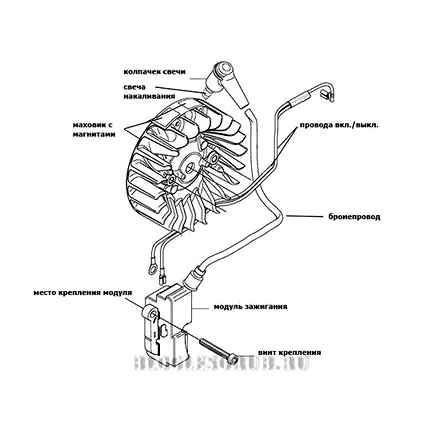

The electronic ignition of a household chainsaw, as standard, consists of a number of the following parts:

- magneto;

- spark plug;

- keys that turn off the motor;

- wiring connecting the elements to each other.

Magneto is a separate type of alternating current generator. When working, it creates electrical energy, and directs it to the spark plug of the chainsaw. The magneto device includes an inductor on which a stationary winding is wound. The element also includes a permanent magnet that is attached to the flywheel. When the chainsaw is operating, the flywheel rotates simultaneously with the engine crankshaft.

At the right time, a certain standard part of the device divides the existing contacts. This leads to a sharp increase in voltage and a spark flash between the electrodes of the factory spark plug.

This increases the risk of overheating of the contacts. To exclude this, as well as oxidation of the wiring, the electrical circuit of the standard ignition system is equipped with a capacitor.

The ignition circuit of a household chainsaw equipped with a contactless base magneto is based on the action of the control coil. It functions as a voltage flow regulator. The electronic unit of such an ignition system is supplemented with a capacitor, a diode and a thyristor. The latter is needed to pass a current with certain voltage parameters. During the opening of the thyristor, the capacitor begins to discharge, thereby creating a current inside the turns of the base primary winding.

After that, the current is converted into a high-voltage DC voltage, which creates a breakdown in the standard spark plug located in the cylinder. The standard electric chain of a chainsaw operates on the impulse principle simultaneously with the translational cyclic movements of the engine cylinder and the rotation of the crankshaft.

How to check the ignition coil of a chainsaw?

Often, the cause of the malfunction of the tool used is not only the wrong clearance between the existing standard flywheel and the standard coil, but also in the breakdown of the latter. In this case, you will need to carefully check the coil.

- inspect the condition of the coil body and make sure that there are no cracks or other defects on it;

- check the cleanliness of the coil elements and the electrical wiring connected to it;

- inspect the condition of the insulation of the wires;

- evaluate the reliability of fasteners;

- inspect the condition of the cap, which forms a spark;

- check the condition of the candle;

- check the operation of the candle switch;

- use a multimeter to check the voltage inside the node.

Check the coil in this order:

How To Gap An Ignition Coil On ( chainsaws/strimmers/mowers/etc ) quick tip!

- First you need to measure the resistance that the magneto creates. This method is used if the owner of the chainsaw knows the optimal parameters. When forming the required pulse, it will be necessary to separate the indicators formed by different semiconductor elements. In this case, a sign of a malfunction is the ringing of the circuit through the minus and the high-voltage wire. As a result, the measuring device shows an overestimated resistance or an open circuit;

- Next, you need to use a device that will make it possible to check the operation of the candle and the presence of a spark. It will need to be connected at the point where the circuit is broken between the spark plugs and the high-voltage wire. The disadvantage of this method is that the device required for testing is quite expensive.

Another way to check the coil does not require the use of expensive instruments. It is only used when the owner of the chainsaw no longer has options for diagnosing the ignition system. When checking from a candle, you will need to throw off the cap and insert a small nail into it. After that, the cap must be put on the candle so that the distance between the nail and the cylinder is about 6–7 cm. After that, the saw must be started and the spark must be inspected. If the coil is in good condition, the spark will be bright blue. Other shades of spark will indicate a malfunction of the magneto.

Coil repairs should be done in a clean, dry place. In this case, it is necessary to exclude the ingress of dust, oil or other liquids on the parts of the mechanisms. Otherwise, there will be a risk of short circuiting, which will lead to complex breakdown of the tool assembly.

Ignition timing

The mechanical device and the factory setting of the magneto ensure that the discharge time of the spark plug coincides with the optimal position of the moving piston. For four-stroke gasoline engines, spark breakthrough must occur even before the piston reaches top dead center. this is due to the fact that the process of complete ignition of the air-fuel mixture takes a certain time. The speed of movement of engine parts is comparable to the speed of fuel ignition, so the piston has time to travel a certain distance from the moment the spark breaks through to the moment the burning gases create extremely high pressure.

How to check ignition timing chainsaw

There is an ignition timing for each engine. It is equal to the rotation of the crank, expressed in degrees, from the moment of breakdown in the interelectrode space of the spark plug until the moment when the piston is at top dead center. This indicator depends on many parameters, including the design features of the engine and the properties of the fuel mixture.

In practice, during the mass production of an engine at the factory, individual adjustment of the ignition of each product is not made, but the corresponding marks are set on the rotating parts, which must be aligned during installation.

When is the ignition setting required? There are the main symptoms of a system crash:

- the engine will not start;

- the motor works, but with noticeable interruptions;

- there is a decrease in tool power.

In these cases, you should not rush to contact the service center. Try to adjust the ignition yourself first.

The device and principle of operation of the chainsaw ignition system

The standard ignition system for a carburetor engine consists of:

- magneto;

- spark plug;

- an electrical cable connecting them to each other;

- engine shutdown keys.

Magneto is a type of alternator that supplies electricity to spark plugs. It consists of a stationary winding of an inductor and a permanent magnet attached to a flywheel that rotates with the crankshaft of a gasoline engine. A moving magnetic field creates an electromotive force in a low-voltage winding, which is converted by a transformer into a voltage with a potential sufficient to generate a spark.

For contact magnets, the first terminal of the high-voltage winding is connected to the spark plug, and the second is connected to the ground through a mechanical switch. At a certain moment, a special structural element divides the contacts, which leads to a sharp increase in the voltage in the network and a spark slip in the interelectrode space of the candle.

To prevent overheating and oxidation of the breaker contacts, a capacitor is connected to the electrical circuit.

The ignition circuit of a chainsaw with a contactless magneto is based on the operation of a control coil, which plays the role of a voltage supply regulator. The electronic unit also includes a diode, a capacitor and a thyristor that transmits a current with a voltage of a certain magnitude. When it is opened, the capacitor is intensively discharged, forming a current in the turns of the primary winding, which is inducted into a high-voltage voltage, giving a breakdown on the spark plug installed in the cylinder. The electrical network operates in a pulsed mode in time with the rotation of the crankshaft and the translational movement of the cylinders.

The procedure for checking and adjusting the correct operation of the engine

The most vulnerable element of a carburetor engine is the spark plug. It also allows you to judge the probable causes of malfunction of individual units of a gasoline engine. The following procedure is recommended.

-

Dismantle the spark plug and inspect it. A dry candle with a slight brown tint of the electrodes can be considered serviceable.

When installing a new electrical module on the engine, the magneto gap must be adjusted. The optimal distance between the flywheel and the ignition coil is 0.2-0.4 mm for most chainsaws.

To be sure, it is recommended to carefully study the documentation for the purchased model and follow the manufacturer’s requirements.

With such a small gap, it will not be possible to use an available measuring tool for direct measurement. In practice, a Husqvarna saw uses a template in the form of a spacer cut from thin, flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when it is installed, and then pulled out.

In order not to have to resort to adjusting the ignition, operate the tool carefully, avoiding knocks. In particular, this applies to chainsaws with electronic chips in the ignition system, since they are very sensitive to mechanical damage.