How to sharpen a chain saw in one minute

How to sharpen the chain of a chainsaw quickly and accurately without dismantling it

Chainsaw chain can be sharpened in a workshop (cost of service from 250 ) or with your own hands in the presence of special devices. But what to do when the tool is blunt at the logging site or in places where there are no workshops and special devices for sharpening? In this case you can use diamond tipped tips and get your chainsaw working again quickly and without too many problems yourself, knowing a few simple sharpening rules.

Using diamond tipped tips for sharpening saw chain links is not only appealing because of its simplicity and effectiveness. Chisels also provide a gentle sharpening process by removing a minimum thickness of metal from the cutting tooth compared to an emery or angle grinder. This allows for more resharpening, greatly extending the life of the chain until it is completely worn out.

If you keep sharpening with a dull chain you will need to use more physical strength for the tool, the cutting performance will suffer, the engine will overload, fuel consumption will increase and the life of the chain saw will come to an end very quickly. This is why sharpening the chain should not be delayed.

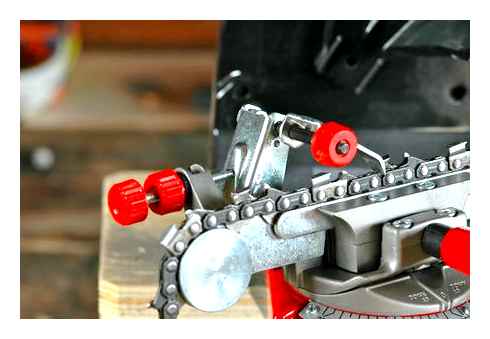

Sharpening teeth with diamond tipped attachments is possible while the saw chain is still on the guide bar, which not only shortens sharpening time at the cutting site but at the same time offers some comfort. But be sure to put the chain on the brake.

For convenience, first sharpen the left and then the right teeth, or vice versa. Place the burr between the cutting edge of the tooth and the depth guide at an angle of 25-30 degrees horizontally and perpendicular to the chain vertically.

When sharpening, the spike should be slightly elevated over the tooth and rotate in its direction. The good thing about this method is that it does not burn out the tooth stinger or weaken it like sharpening with an emery or angle grinder with their high RPM.

By the way, instead of an electric screwdriver you can use a drill or borer with a speed of up to 2000 rpm. But you must be very careful when doing this because the metal removal is intensive.

Since the height of the tooth decreases with each sharpening, it is necessary to sharpen the kerf after 2-3 sharpenings with a flat file or simply with a diamond tip.

What we need

The basic tool we will use is a circular file (not a tapered!). The sectional diameter of your file should match the rounding diameter of the saw chain’s cutting tooth. Files with a diameter of 4,8 mm are good for sharpening most domestic saws. Check this size with your saw and file accordingly.

It’s not uncommon for chain saw teeth to be sharpened by hand with a file. But I suggest to improve and speed up this process, so we need a screwdriver or a drill, preferably with adjustable speed.And the “highlight” of my sharpening technique. this is a small bearing. It can be anything. ball, roller, cylindrical, conical. The main thing is to hold it comfortably in your hand by its outer ring. Its purpose I will explain below.

Tool preparation

First remove the shank, that is the part of the file that fits into the handle. You can do it with an emery machine or with an angle grinder, whichever is more convenient. Then insert the file into the chuck of the drill or screwdriver and clamp it.

Then we make a sleeve from wood, plastic or any other material, which will be fit tightly on the free end of the file. The inner ring of our bearing should be firmly seated on the outer surface of the sleeve.

It is done in order to hold the tool with two hands during the work. one hand holds the drill grip, the second holds the bearing outer ring.

How do you know when a chainsaw chain is blunt?

You can get a blunt chain not only by the slower cutting performance but also by the vibration of the tool, which you can feel with your hands. Chain dullness can be caused by hard use. Sometimes the chain has to be sharpened several times in one working day. It is caused by the high volume of work, contact with the ground or with harder wood, e.g. knots.

Working with a dull chain can cause very serious problems, not only slow cutting and increased fuel consumption, but also the transmission of vibrations to the body that can destroy the bar and drive sprocket. That reduces the performance of the tool and causes serious wear on nearly every part of the chainsaw.

How to determine if a chainsaw chain needs sharpening

It is not a secret that the more often you use your chainsaw the faster your chain dulls. Some people have to sharpen several times a day (professional carpenters, sawmill workers), some people only need to sharpen once every six months.

- Inspect the sawdust: if all that’s left of your chainsaw is dust and sloppy scraps, it means it’s time to sharpen the saw. Sharp blades leave uniform shavings. Remember that a blunt chain can be life-threatening. It greatly increases the chances of kickback.

- You notice that your performance has decreased. Trees you worked with for half an hour now require twice as much time.

- Your chain has started to sag and this causes the chainsaw to stop intermittently during sawing, like a jammed cassette in a video receiver. This also leads to a reduction in quality and speed.

- Smoke is coming out while threading

How to properly sharpen a chain and what is the proper chain sharpening angle for a chainsaw chain

A sharp chain will cut perfectly and require very little power. Blunt blades tend to make an incision, but they don’t go nearly as deep. If you have to force your chainsaw to cut, it means that the blades are blunt and it’s time to grab a file.

- pair of gloves

- a set of tools for sharpening the saw (round and flat files, and a template for adjusting settings)

- vise

You can get this at any specialty hardware store. This is best done right away when you buy the chainsaw so you don’t have to waste time.

First thing to do: engage the chain brake and clamp the bar in the vise.

Place the guide between the rivets on the chain using the arrows on the guide. pointing to the nose of the bar.

Before you start sharpening, you need to clean the saw chain of all contaminants. You can do this with a brush brush and solvent to get rid of tar stains.

Mark one of the cogs with a marker pen. After 2 or 3 sharpening cycles, check. how the material comes off. If it is even, you are doing the job right. If it comes off in places, you need to check if you are using the right file. Take care not to hold the tool too high or too deep.

Position your round file in the hole. (Never use a regular pigtail file. This tool will ruin your chain blades.) Hold the handgrip in one hand and the base of the tool with the other. The angle of the chain should be 30-35 degrees horizontally toward the bar and 90 degrees vertically toward the sharpening bar. Now start sawing. Follow the angle of the top pick plate. The rollers on the guide will keep you from sinking too deep into the side panel of the cutter.

Move forward, that is, in the opposite direction from you. Run a file over the tooth of the blade several times. 2 or 3 should be enough to make the cutter glow in silver color. Remember to count the number of these movements and use the same number for all other links.

If the chainsaw pulls sideways while cutting, it could be because the blades are sharper on one side than the other. To avoid this and to always cut in a straight line, you should sharpen each tooth very carefully. The pressure and number of sharpening movements applied to each individual point must always be the same. Watch this carefully when you are sharpening.

If you see light spots on the cutting edge, the cutting tooth is not yet sharp. A tooth is considered well sharpened if these spots are completely absent.

While working, you have to push the chain through every 5 to 6 sharpened teeth. That’s what gloves are for. Release the chain brake and rotate the chain itself forward to sharpen more teeth. Repeat the same steps several times. It’s worth noting that while sharpening, you may find that you get a better feel for the interaction between the file and the chain with your bare hands.

When you are done sharpening one side, turn the chain saw over and sharpen the other teeth.

Use a depth gauge tool and file to adjust the height of the depth gauge on the chain. If the depth gauge is too high, the blades will not reach the wood.

You can tell the amount of wear from the marked pointer. The chain needs to be replaced if you have already reached this pointer.

One of the most important factors affecting the life of a carving headset is correct tensioning of the chain, so it must be checked at all times. The saw chain. even if it has been “pulled” at the factory. is stretching all the time, so you should periodically check the tension. With proper chain tension, the saw chain will wrap around the entire surface of the guide bar, and with the chain brake off, you can turn it.

You have to keep your chainsaw free of dirt and soil or it gets blunt very fast. You are also advised to sharpen your saw every time you fill the tank with fuel.

Blades can stay sharp for up to 10 times (or a little longer, depending on how you use the saw), then the chain needs to be replaced. If the cutters are blunt after several sharpening cycles, you should call in a professional. He can grind them to a uniform shape.

If you have used one chain for a few years and then decide to change it, the new chain will not fit smoothly and gently on the chainwheel and bar. This will cause the saw to wear down faster. Experts recommend to buy 2 extra chains at once and to alternate them from time to time. In this way, all components of the cutting set (chains, bar, gears) will fit together.

Take your chainsaw to a professional if you are not sure. The handyman uses a powerful sharpener, which resembles a miniature coping saw. It accurately grinds each tooth evenly: at the same angle and to the same depth.

How to sharpen a chainsaw chain

Sharpening a chainsaw chain is a procedure that gardeners and professional woodcutters regularly encounter. In this article, the master plumber will tell you how to restore the damaged teeth of the saw headset, and quickly return it to its previous working condition.

To understand how to properly sharpen a chain you need to understand the basic principles of chain construction and operation. You can’t just sharpen a chain by eye, you need to know the basic characteristics of the chain and its components.

A chainsaw chain consists of three types of links made of high-alloyed steel:

- Cutting. basic chain components. A distinction is made between right-hand and left-hand saw blades, which are arranged alternately, with their cutting edges above the plane of the bar. Tooth design includes cut depth limiter.

- Drive (shanks). serve to transmit torque from the gasoline motor to the chain through the drive sprocket. This feature extends sprocket life and makes the chain more stable on the bar.

- Connectors: connect chain shanks and cutters.

One of the main elements of the chain is the cutting tooth that plunges into the wood and removes shavings. The tooth depth limiter determines the thickness of the wood chip and limits the depth of penetration into the wood.

Recommended settings relative to the limiter are 0.025″ (0.65 mm) or 0.030″ (0.75 mm), depending on chain type.

The long life of any chainsaw depends on proper care and use, including that of the chainring. The good performance of the latter affects the performance of the unit and the performance parameters. Untimely sharpening can cause some problems with the saw itself. The most common ones are:

- Curved cuts;

- Heavy loads on the saw, resulting in increased wear and tear on the parts of the device, and hence a reduction in the life of the entire device;

- Increased fuel consumption.

If the saw produces fine, dusty chips and the saw plunges into the cut with great force, it means the target has blunted.

There are other signs of a dull chain:

- The speed of the tool has decreased;

- Uneven and sharp sawdust is produced;

- It is necessary to apply more force to cut the wood;

- The chain has been stretched or has become slack.

A chainsaw chain can quickly become blunt for the following reasons:

- If the saw is operated too often;

- When the operator presses hard on the saw while sawing;

- If the chain is made of poor quality metal, or if the steel has not been properly heat treated;

- If you frequently saw raw or resinous wood;

- When cutting hardwood trees such as: oak, birch, cherry, acacia, elm, ash and others;

- If the chain is blocked by sand or stones;

- If the chain is not properly sharpened or has insufficient tension when working.

The device of all chain saws is similar, so the algorithm of actions when removing the chain will be the same:

- First put on protective cotton gloves to avoid cuts from the cutting teeth.

- Remove the protective cover from the working part of the chainsaw and put it on its side on a flat surface.

- Unscrew the fastening nuts that hold the housing and the guide bar with a socket spanner of a suitable diameter and remove the upper housing cover.

- Now slide the guide bar all the way down to the sprocket, loosen the chain and remove the working parts from the fastening bolts.

- Disconnect chain from guide bar.

How to sharpen with an angle grinder

Now to the question of how to sharpen the chain with an angle grinder on a chainsaw. Quite a common option, but still has its own peculiarities.

In general, chain sharpening gasoline saw, carried out with his own hands using power tools in the form of angle grinder. not an easy task. The reason for this is that you have to be extremely accurate and precise. Do not use any limiters. Hence, this peculiarity.

First, the angle grinder must be secured with a workbench or table. It is desirable to have a reliable clamp. After securing, check that the power tool will not vibrate strongly. If there are vibrations, the construction will have to be reinforced even more.

Technology of sharpening involves the need to spend the teeth on the abrasive wheel installed on the angle grinder.

The danger of the method is that the shaft with a sharpening disc (wheel) rotates very quickly. The load is transmitted to the chain. Careless operation can result in injury to the craftsman. So be extremely careful.

The angle grinder used as a sharpening tool has several weight disadvantages at once:

- it is difficult to control the thickness of the removed layer, and everything depends on the accuracy of the master;

- When sharpening with an angle grinder, errors are much more frequent than with a file;

- if you are not careful, you could cut the connecting ears that hold the links in place.

In addition to fixing the angle grinder on the machine or table, you can use an alternative method. In this case, the chain is fixed, and already to it the angle grinder, held in the hands, is brought. But it usually reduces sharpening accuracy even more.

Now you know how you can sharpen a chain from a chainsaw with an angle grinder.

Use of the machine

Specialists agree that it is better to use a chain sharpening machine for chain saws. It can be used to achieve factory precision.

To learn how to properly sharpen the chain from your chainsaw on the machine, you need to follow these steps:

- the saw should be set in the special hole;

- loosen the clamping screw of the chain;

- set the sharpening level, referring to the table or to the condition of the bluntest tooth;

- Consistently work one tooth after another, changing the polarity on the machine;

- or to grind the teeth one by one (right then left) so as not to reverse the polarity;

- At the end of the procedure, treat the chainsaw with machine oil.

That’s it, the procedure is complete. Minimum time and maximum precision.

How to grind with an angle grinder

The method requires skill and ability to. Unlike a sharpening machine there are no limiters. Carefulness and safety rules are required of the master. it is better to use this method by experienced people. Angle grinder (angle grinder) is securely mounted on a table or other stable place.

It is better to make a special clamp for this. After fixation, check whether there is vibration, including the tool in test mode for a few minutes. If the conditions are satisfactory, you may start your work. Sharpening chains for chainsaws with an angle grinder with your own hands is carried out by bringing the link to the abrasive wheel.

In conclusion, we can say that no matter how the chain sharpening for a chainsaw with their own hands, the main thing is the accuracy and precision of the master. When machining by hand, corner errors and uneven grinding of the metal are possible, and when machining there is a risk of injury.

Additional recommendations on how to sharpen a chainsaw chain with your own hands

Strictly obey the safety instructions in the work. It is necessary to work in gloves made of coarse material, so as not to injure your hands, because the working surface of the teeth is very sharp.

If the grinding process requires the chain to be disassembled, do not apply excessive force to the threaded fasteners during reinstallation. To tighten the bar mount screws it is best to use an electric screwdriver calibrated to the limb.

Experts recommend a method of increasing the strength and wear resistance of chains, which is known as “stabilization of the internal structure of the metal. To do this, the new tire is warmed up in an oil bath for one and a half to two weeks at 55-65ºC. Operation confirms the effectiveness of this technology.

expert recommendations

There are helpful tips for getting your chainsaw sharpened quickly and efficiently. General tips:

- First you need to run the headset in at a low speed, this allows the lubricant to get on each bar element;

- the chain must be energized, looseness can lead to injuries, especially when using an electric machine;

- It is advisable to dress the headset after each continuous operation of the tool and to check the teeth carefully before sawing;

- Lubricate each element of the bar in a timely manner, which not only improves the process of working with wood, but also reduces the load on the rotor, the motor.

Depth of cut, condition of cutting edge and limiter should be checked after 3-4 sharpenings. It is recommended to consult the template for your particular model.

Sharpening the chain of a chainsaw is an essential part of working with this tool. How sharp the teeth are affects performance and safety when cutting. To sharpen the cutting edge of the bar you can use an electric or manual machine, at home it is easier to use a file. It is necessary to take into account the specifics of a particular model of headset, measure each element with a gauge.

How to choose a chain saw chain sharpening machine?

To choose a chain saw chain sharpening machine we need to know a few important features. These include:

- power. each power trimmer is equipped with a motor that receives power from the electric network. It is better to buy machines with higher power. These devices have a solid working life and are easier to bear considerable loads;

- Spindle speed of the standard spindle. this parameter determines the speed of recovery. In practice, the higher this characteristic, the faster will be sharpening. For infrequent but regular use, a machine with a spindle speed of about 3 thousand is suitable. rpm. For constant intensive use, it is better to choose machines in which the spindle is able to rotate at speeds ranging from 4800 to 7500 rpm;

- Diameter of the wheel for sharpening the headset. this parameter determines the range of use of the machine. Machine for sharpening chainsaw chains, in which the standard wheel has a diameter of up to 105 mm, can be used in the household. Also there are machines, which are equipped with a disc with a diameter of up to 400 mm. This equipment is mainly used in large machine-building plants;

- Additional options. among them stands out the ability to rotate the standard head for grinding. By turning the part in different directions and changing the sharpening angle, the saw’s owner is able to evenly sharpen the blunt teeth of the saw set.

Having studied all these characteristics, the owner of a chainsaw will be able to buy a suitable machine, which will make it possible to quickly restore the worn headset at home.