How to sharpen a chainsaw chain by hand

How to sharpen a chainsaw correctly

Timely and competent do-it-yourself sharpening of chains for a chainsaw will allow not only to extend the use of the device, but also to save effort and time for processing wood. Signs of a sharp chain are the formation of sawdust of the same size and regular geometric shape. To provide the desired level of sharpness of the teeth, any tool for sharpening chainsaws, for example, any sharpening tool, will do. These are a file, an angle grinder and a machine.

File

For sharpening and straightening saw chains, two types of files are used. The first is a round file with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of household tools, round files with a diameter of 4, 4.8 mm are used, due to the fact that they have a small tooth. For professional models, more powerful chains with a larger tooth are used, and accordingly files with a diameter of 5.2, 5.5 mm are needed.

In order to sharpen correctly, it is not enough to sharpen only the cutting edges of the tooth, you also need to adjust the cutting depth limiter. If this is not done, the chain will not cut into the material being cut to the required depth, which will noticeably reduce the speed of work and, just like in a situation with a blunt chain, can lead to overheating of the saw motor due to insufficient load on the motor. This work is done with a flat file.

How the Pro’s sharpen a chainsaw

First about the horror stories

If you cut with a blunt chainsaw, you will get three negative factors:

- Reduce the efficiency of your process. For example, instead of two cubes, cut one (at the same time);

- Expose the mechanism to intense wear, with the risk of destroying the drive sprocket and tire;

- Get increased fuel consumption;

There is also a fourth, perhaps not so significant factor. “torn” cut of the saw cut.

And of course, you will get tired more, you will (perhaps) be angry with yourself, like “why should I be a fool, do not sharpen in advance, now suffer”

Here is a test question for you (photo on the right). Guess what kind of shavings “came out” from under the sharp and dull chain? (the answer will be below).

Electric grinding machines

For straightening a large number of chains, as a rule, in service centers or in manufacturing plants, electric sharpening machines are used. Depending on the manufacturer, the design of the machines may differ, but they have the same principle of operation.

The saw chain is installed in a special guide, which is mounted on the basis of the turntable and has a special retainer to hold the sharpened tooth. The latch is able to move horizontally. An electric emery is installed at an adjustable angle to the sharpened tooth, which is turned on by the operator by pressing the start button. The immersion depth of the emery, as well as the angle at which the sharpening is performed, can be adjusted. The dive itself is performed by the operator. The chain is straightened with a special grinding wheel, which can be changed if necessary.

We work with a file

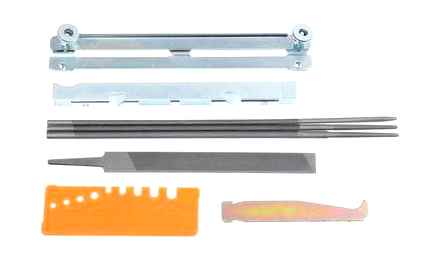

The best solution is simple gadgets for sharpening work. This set includes a round and flat file, special holders, a gauge template, a hook for removing chips, etc. Structurally, “adaptations” may differ, but the functionality has a common logic.

The diameter of a round file is directly related to the size of the chain:

- – Chains with ø 1.3. require a file of ø 4 mm (used much more often);

- – Chains with ø 1.6. require a file ø 5.2 mm;

- – To sharpen the depth gauge, use a flat file.

HOW TO SHARPEN A CHAINSAW CHAIN.

Sharpening process

- Having previously “turned on” the chain brake, firmly grip the tire of the chainsaw in a vice (a firmly clamped saw is the key to successful sharpening)

- Set the template so that the arrow points towards the nose of the tire. Be sure to mark (with chalk) the tooth from which you started sharpening, otherwise you can go along the second circle;

- Sharpen in the direction of the arrows. Remember, there is a special factory cut on each tooth in the chain. It indicates the maximum sharpening angle.

- In addition to the cutting tooth, there are stops on each link. They are sharpened as needed. This is necessary when, as a result of sharpening, the height of the tooth decreases, and problems arise in the operation of the chainsaw. As a rule, the limiter is sharpened after 2-3 sharpening of the teeth;

“If you don’t have the skills to sharpen, it’s better to start with inexpensive chains.”.

Recommendations:

- The file should not go beyond the upper part of the cutting edge by more than 1/5 of the working part of the file. The pressure is carried out with the same effort;

- The movement of the grinding tool is performed in one direction “away from you”, and the number of movements for each tooth must be equal;

- To sharpen a vertical plane, the position of the file must be at right angles;

- For sharpening the horizontal plane, file position, at an angle of 20-30 °

- If there are teeth of different heights, the reference is the smallest.

Advantages: Ability to “charge the saw” in the field. At the same time it’s cheap.

Topics. some expert advice:

“Announcement in the newspaper: I am changing the chainsaw for a prosthesis”.

I hope the information was moderately useful. If yes, then subscribe to the blog for updates and share the article with your friends All the best to you. Good luck!

Quote of wisdom: It’s not about the word, but the tone in which this word is pronounced (Belinsky).

The saw chain is a metal base with series-connected links that have teeth characterized by cutting properties. You can improve them if you sharpen the chainsaw chain at home, but you must follow the rules and use a tool specially designed for this. The latter can be homemade or factory made.

How to understand that the chain is dull

- Increased physical effort;

- Sagging (stretching) of the chain;

- Vibration and “braking” cutting passage;

- Inaccurate sawing and change in the type of sawdust (they become uneven with sharp “needle” edges, small and dusty). This is already the answer to the test.

“In the opinion of the experts, and in my opinion too: well-sharpened teeth are more important than engine power.”

Why dull? The reasons are generally known, but I will name the main ones:

- Intense or voluminous work;

- Accidental contact with stone, earth, hard knots, etc.;

- Mishandling (broad term).

Electric grinding machines

The most accurate and efficient way to repair a chain is to use specialized equipment. This is a machine for sharpening chainsaw chains with your own hands.

It costs a lot, but it completely eliminates the human factor, errors in manual sharpening. It is advisable to purchase it when the amount of work to be done is significant. However, there are budget models that are available to many owners of country houses, dachas.

It is necessary to set the angle of the chain and the abrasive wheel and the pitch of the links. Manufacturers offer several types of chain locking mechanisms. Refer to the user manual for specific model recommendations. Move the device to the edge slowly.

It is recommended not to make the passage for more than 2 seconds. If it is not possible to do the processing at once, the abrasive wheel is retracted and after a short period of time the tooth is sharpened again. Thus, it is possible to avoid overheating of the metal, while maintaining its performance. The product passport indicates which saw blade you need to use for the machine.

We sharpen the chainsaw chain with our own hands. All possible and available ways

“The lumberjack working with a blunt ax was advised:. Sharpen the ax.

He replied:. There is no time. It is necessary to cut down the forest. “

Today I decided to tell you about the tool, without which, it seems to me, today it is simply impossible. A good tool should work well, and this largely depends on its owner.

Cleaning the autumn garden, preparing firewood for winter, building a bathhouse, repairing a wooden fence will require not only time and desire, but also the readiness of the “cutting” tool. If it’s a chainsaw, then it must be properly sharpened.

Of course, there are paid specialists, and you, for example, have extra money But we know that such a procedure is performed periodically and therefore a natural question arises: how to sharpen a chainsaw chain at home? I’ll tell you about that. Go!

Correct sharpening of a chain for a chainsaw with your own hands. methods, necessary tools, secrets and nuances

Any instrument needs timely care. A chainsaw is one of the types of equipment that you need to pay special attention to. The device poses a certain danger, but if the chain is dull, then the risks increase significantly.

Sharpening is often necessary during intensive work. Therefore, it makes sense to learn how to restore its performance, since sharpening a chain for a chainsaw with your own hands is not a difficult operation, but having mastered it, labor productivity will increase, as well as work safety.

We work with a file

The best solution is simple gadgets for sharpening work. This set includes a round and flat file, special holders, a gauge template, a hook for removing chips, etc. Structurally, “adaptations” may differ, but the functionality has a common logic.

The diameter of a round file is directly related to the size of the chain:

- – Chains with ø 1.3. require a file of ø 4 mm (used much more often);

- – Chains with ø 1.6. require a file ø 5.2 mm;

- – To sharpen the depth gauge, use a flat file.

Sharpening process

- Having previously “turned on” the chain brake, firmly grip the tire of the chainsaw in a vice (a firmly clamped saw is the key to successful sharpening)

- Set the template so that the arrow points towards the nose of the tire. Be sure to mark (with chalk) the tooth from which you started sharpening, otherwise you can go along the second circle;

- Sharpen in the direction of the arrows. Remember, there is a special factory cut on each tooth in the chain. It indicates the maximum sharpening angle.

- In addition to the cutting tooth, there are stops on each link. They are sharpened as needed. This is necessary when, as a result of sharpening, the height of the tooth decreases, and problems arise in the operation of the chainsaw. As a rule, the limiter is sharpened after 2-3 sharpening of the teeth;

“If you don’t have the skills to sharpen, it’s better to start with inexpensive chains.”.

Recommendations:

- The file should not go beyond the upper part of the cutting edge by more than 1/5 of the working part of the file. The pressure is carried out with the same effort;

- The movement of the grinding tool is performed in one direction “away from you”, and the number of movements for each tooth must be equal;

- To sharpen a vertical plane, the position of the file must be at right angles;

- For sharpening the horizontal plane, file position, at an angle of 20-30 °

- If there are teeth of different heights, the reference is the smallest.

Advantages: Ability to “charge the saw” in the field. At the same time it’s cheap.

How to sharpen with an angle grinder

The method requires skill and skill. Unlike a sharpening machine, there are no stops here. The master is required to be accurate and comply with safety rules. It is better for experienced people to use the method. angle grinder (angle grinder) is previously securely attached to a table or other stable place.

Better to make a special clamp for this. After fixing, check if there is vibration, turning on the instrument in the test mode for a few minutes. If conditions are satisfactory, you can start work. Directly sharpening chains for chainsaws with your own hands with an angle grinder is carried out by supplying a link to the abrasive wheel.

In conclusion, we can say that no matter how sharpening the chain for a chainsaw is done with your own hands, the main thing is the accuracy and accuracy of the master. With manual processing, corner errors and uneven grinding of the metal are possible, and with machine processing, there are risks of injury.

Hand-operated machines

The design of such a machine is similar to a bow saw. Only where the saw blade is located is the round file. With such a machine, you can sharpen and straighten the teeth, adjusting the proportionality of the upper edges to the smallest (control) size. The mechanism allows you to accurately set the parameters. After adjusting to the “control” tooth, sharpening is carried out in two or three movements. And then the transition. to the next tooth.

When it is necessary to grind off the stopper, we change the round file to a flat file.

Advantages of the method: Allows you to sharpen teeth, including those that have lost their original shape, in a high-quality, convenient and without large physical costs.

Disadvantages: The price of the tool and the distance from the possible site of the saw operation.

“After finishing the“ sharpening procedures ”, blow out the chain with compressed air (from a compressor or pump) and put it briefly in clean engine oil. Of course, almost no one does such events, but for the chain, they will only benefit. “

What to choose for sharpening is up to you. This is due to how often you use your chainsaw. From the accuracy of handling it. From the quality of the purchased chain. And, of course, from the opportunity to spend a certain amount. It is impossible to compare the methods, because as the German proverb says. “apples should be compared with apples”.